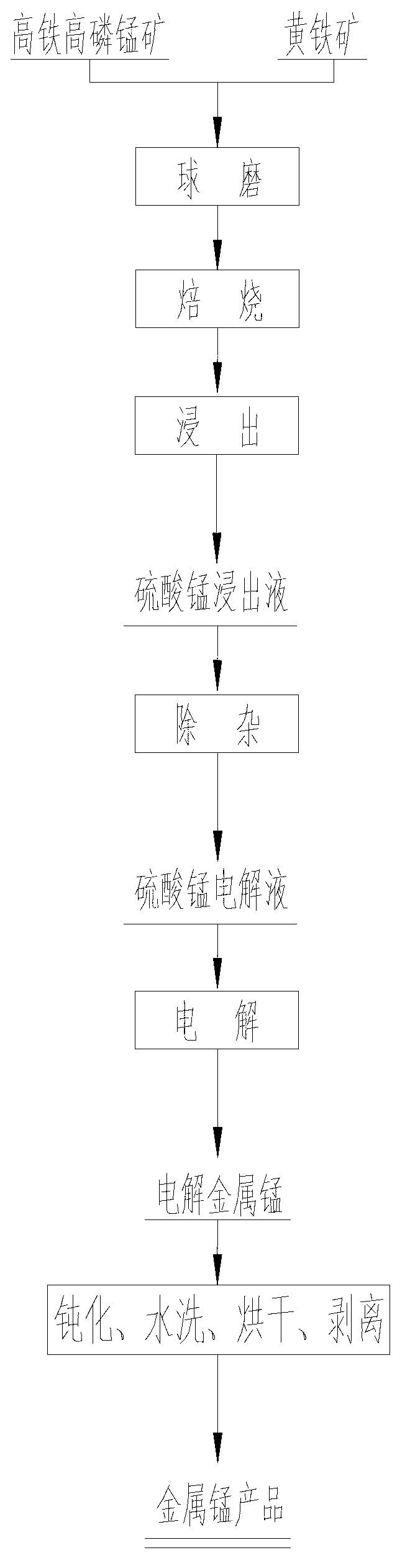

Method for preparing electrolytic manganese metal by using high-iron and high-phosphor manganese ores

A technology for high iron and high phosphorus manganese ore and electrolytic manganese metal, which is applied in the directions of photography, instruments, photography auxiliary technology, etc., can solve the problems of ore increasing the burden of solution purification, pollution of soil and groundwater resources, and ineffective utilization of manganese ore. , to reduce the edge effect, improve the extraction rate, and prevent impurities from entering the solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

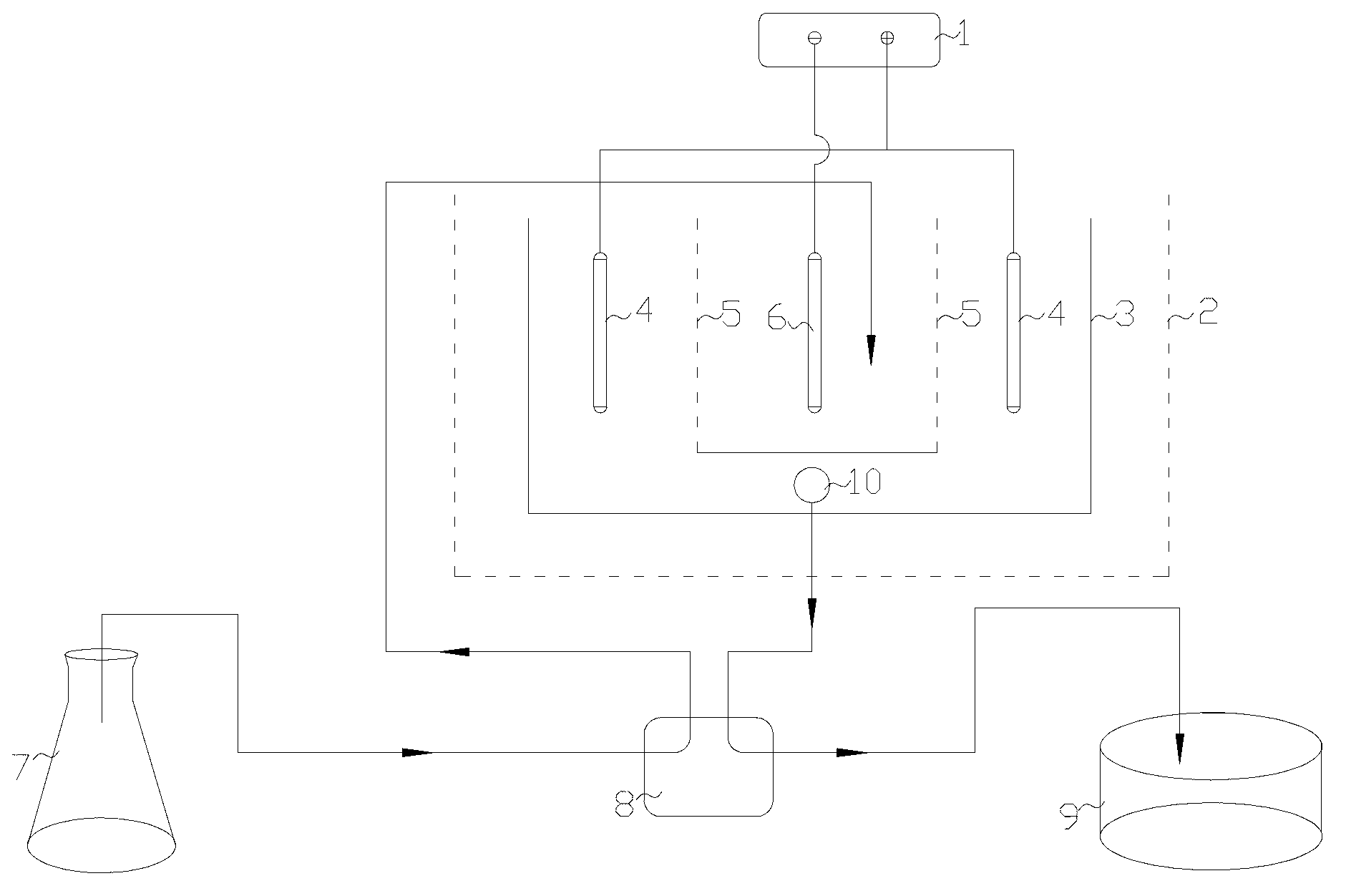

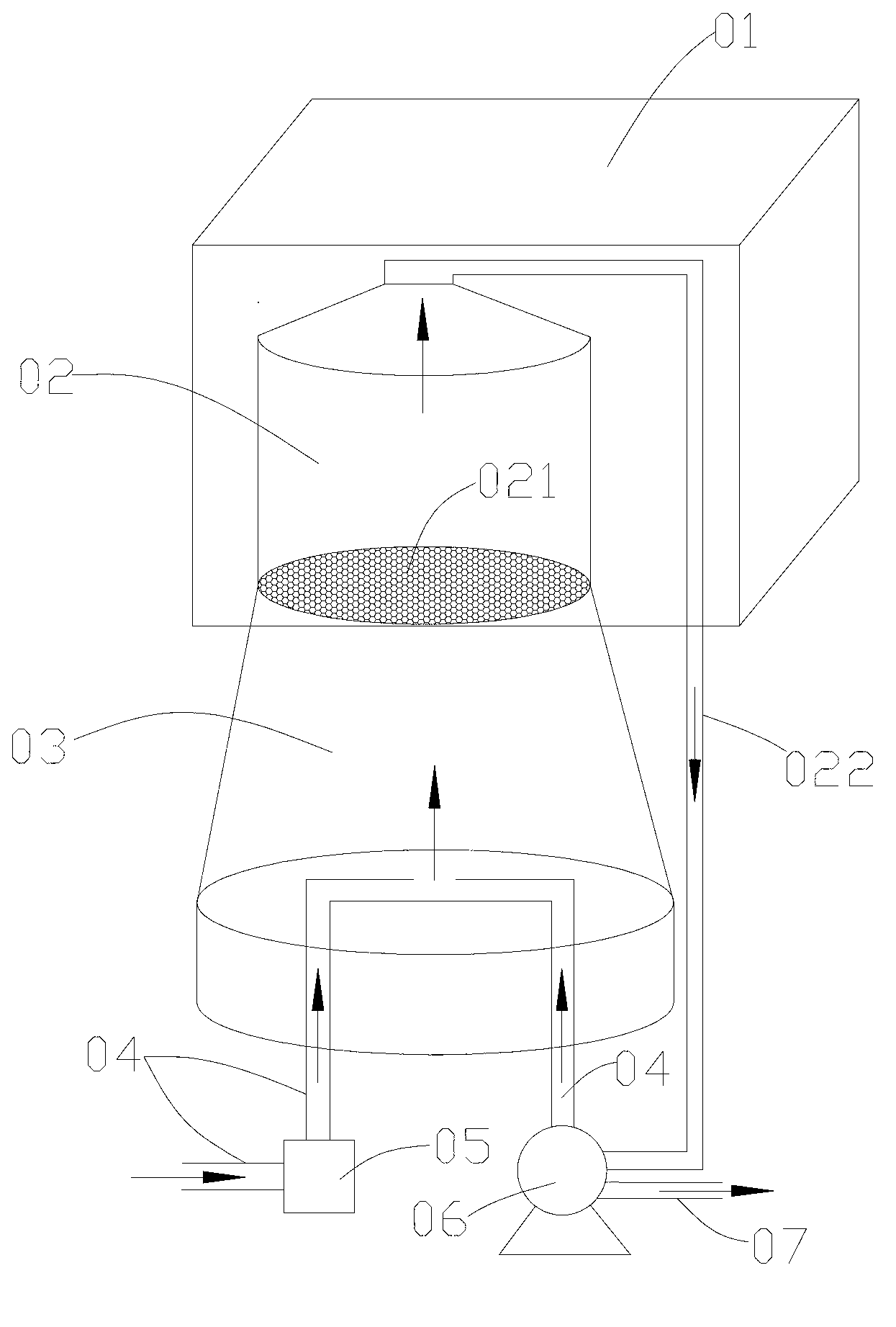

[0034]Put the high-iron high-phosphorus manganese ore and pyrite into the ball mill respectively. The speed of the ball mill is 350r / min, and the ball milling time is 2 hours. Because the ground ore powder is mixed and roasted in a self-made furnace with false bottom ventilation , so if the particle size of the ground ore powder is too large, the contact area of the two ores will be reduced and cannot be fully mixed. If the particle size of the ground ore powder is too small, it will be taken away by the air flow and the roasting cannot be completed. The obtained mineral powder has a particle size of 150 mesh. The high-iron, high-phosphorus manganese ore powder and pyrite powder were mixed at a molar ratio of 1:1.5, and roasted at a constant temperature using a self-made blast furnace with a false bottom as the roasting equipment. The roasting temperature was 560°C and the roasting time was 3 hours. Add the roasted clinker into clear water to leaching the ore in a mass ratio...

Embodiment 2

[0037] Put the high-iron high-phosphorus manganese ore and pyrite into a ball mill respectively, the rotating speed of the ball mill is 350r / min, the ball milling time is 2 hours, and sieve to obtain mineral powder with a particle size of 200 mesh. The high-iron, high-phosphorus manganese ore powder and pyrite powder were mixed at a molar ratio of 1:1.8, and roasted at a constant temperature using a self-made blast furnace with a false bottom as the roasting equipment. The roasting temperature was 600°C and the roasting time was 3.5 hours. Add the roasted clinker to clean water to leaching the ore in a mass ratio of 1:6, and keep stirring. After 3.5 hours of leaching, the leach solution was analyzed for all elements. The leach solution was manganese sulfate leach solution containing impurities, and the leaching rate of manganese was 89.3%. Then, the manganese sulfate leach solution was pretreated, and 9 g of barium sulfide was added per liter of leach solution, and continued to...

Embodiment 3

[0039] Put the high-iron high-phosphorus manganese ore and pyrite into a ball mill respectively, the rotating speed of the ball mill is 350r / min, the ball milling time is 2 hours, and sieve to obtain mineral powder with a particle size of 250 mesh. The high-iron, high-phosphorus manganese ore powder and pyrite powder were mixed at a molar ratio of 1:2.5, and roasted at a constant temperature using a self-made blast furnace with a false bottom as the roasting equipment. The roasting temperature was 620°C and the roasting time was 4 hours. Add the roasted clinker into clear water to leaching the ore in a mass ratio of 1:7, and keep stirring. After 4 hours of leaching, the leach solution was analyzed for all elements. The leach solution was manganese sulfate leach solution containing impurities, and the leaching rate of manganese was 87.7%. Then, the manganese sulfate leach solution was pretreated, and 10 g of barium sulfide was added per liter of leach solution, and continued to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com