Preparation method of high-performance proton exchange membrane

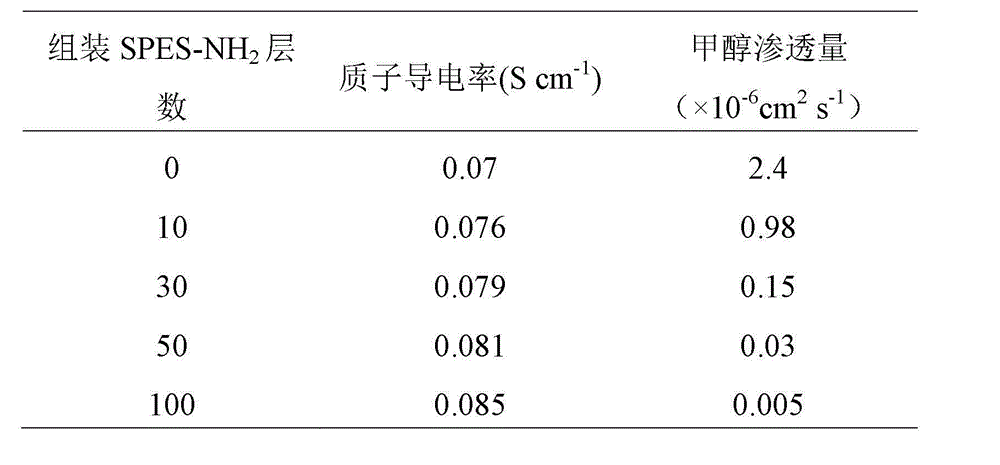

A proton exchange membrane, high-performance technology, used in fuel cell parts, fuel cells, electrical components, etc., can solve the problems of high methanol permeability and decreased proton conductivity of fluorine-containing sulfonic acid-based proton exchange membranes. The effect of maintaining proton conductivity, improving proton conductivity, and promoting transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

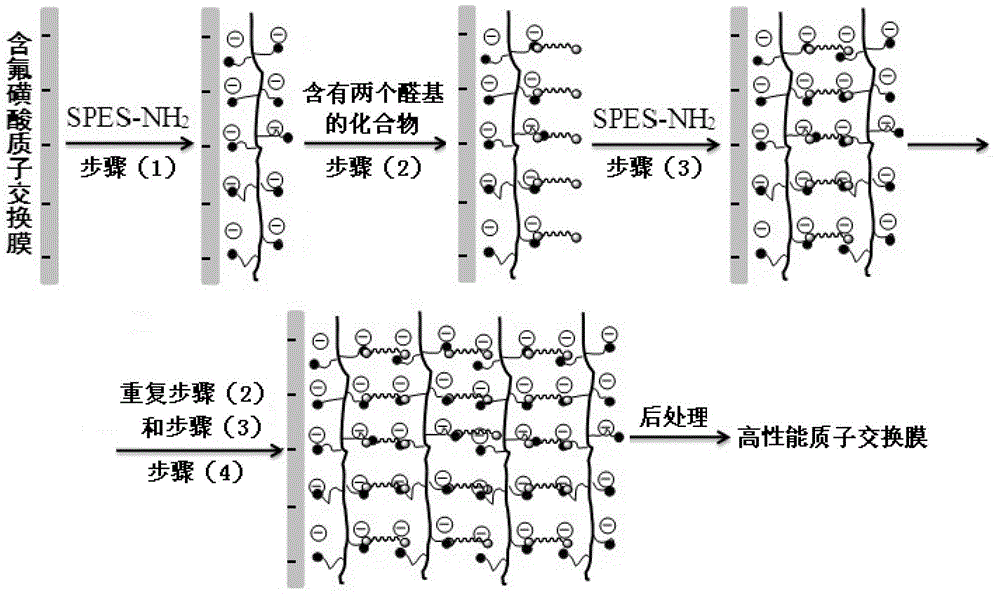

[0025] In the preparation method of a kind of high-performance proton exchange membrane of the present invention, adopt the fluorine-containing sulfonic acid type proton exchange membrane that size is 5 centimeters * 5 centimeters as the substrate, the fluorine-containing sulfonic acid type proton exchange membrane is that the proton conduction group is Sulfonate, the polymer backbone in the membrane is partially fluorine-containing or fully fluorine-containing proton exchange membrane, such as DuPont's series of membranes, Asahi Chemical’s series film, Asahi Glass Co. Series membranes, Dow Chemical's Membranes, Ballard's BAM membranes and other fluorine-containing sulfonic acid-type proton exchange membranes that meet this feature.

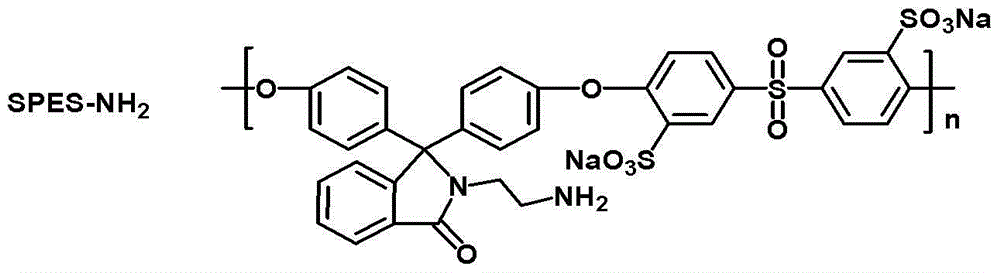

[0026] In the preparation method of a kind of high-performance proton exchange membrane of the present invention, said sulfonated polyelectrolyte SPES-NH containing amino group 2 The structure of the is as follows:

[0027]

[0028] Am...

Embodiment 1117

[0033] Example 1 Preparation of Alcohol-resisting Film by Layer-by-Layer Assembly of 117 Film

[0034] Will 117 membranes were sequentially soaked in 5 wt% H 2 o 2 , deionized water, and 1 mol / L dilute sulfuric acid solution, soak for 30 minutes each, take out, blow dry with nitrogen, and set aside;

[0035] Take 5 pieces of 5cm×5cm size of the above-mentioned processed The 117 membrane is immersed in the sulfonated polyelectrolyte SPES-NH containing amine groups with a concentration of 2 wt%. 2 In the aqueous solution, soak at 50°C for 25 minutes, take it out, and rinse it with deionized water Sulfonated Polyelectrolyte SPES-NH Containing Amino Groups Physically Adsorbed on 117 Membrane Surface 2 , blown dry with nitrogen, and then Immerse the 117 membrane in an aqueous solution of glutaraldehyde with a mass percentage concentration of 0.9wt%, soak it at 50°C for 10 minutes, take it out, and rinse it with deionized water Glutaraldehyde physically adsorbed on the...

Embodiment 2

[0040] Example 2 Layer-by-layer assembly of films and preparation of alcohol barrier films

[0041] Will The membranes were sequentially soaked in 5 wt% H 2 o 2 , deionized water, and 1 mol / L dilute sulfuric acid solution, soak for 30 minutes each, take out, blow dry with nitrogen, and set aside;

[0042] Take 5 pieces of 5cm×5cm size of the above-mentioned processed The membrane is immersed in the sulfonated polyelectrolyte SPES-NH containing amine groups with a concentration of 1 wt%. 2 In the aqueous solution, soak for 10 minutes at 25°C, take it out, and rinse it off with deionized water Sulfonated Polyelectrolyte SPES-NH Containing Amino Groups Physically Adsorbed on Membrane Surface 2 , blown dry with nitrogen, and then The membrane was immersed in a glutaraldehyde aqueous solution with a mass percentage concentration of 5wt%, soaked at 40°C for 20 minutes, took it out, and rinsed it with deionized water. The glutaraldehyde physically adsorbed on the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com