Method for preparing methanol-resisting high-conductivity proton exchange membrane

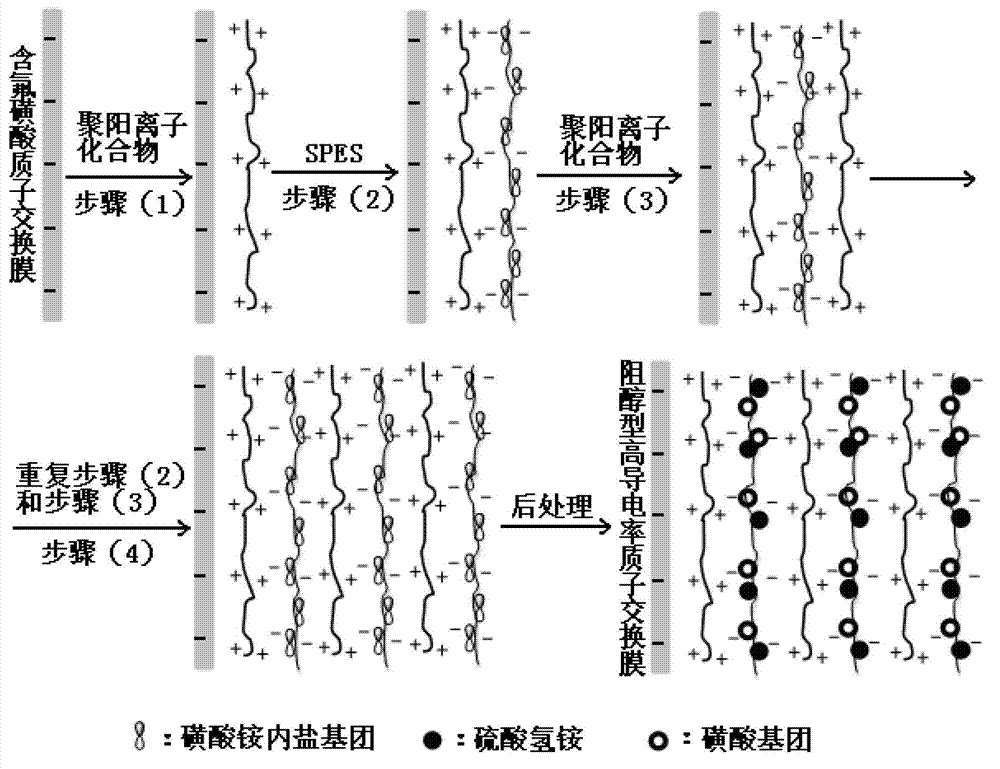

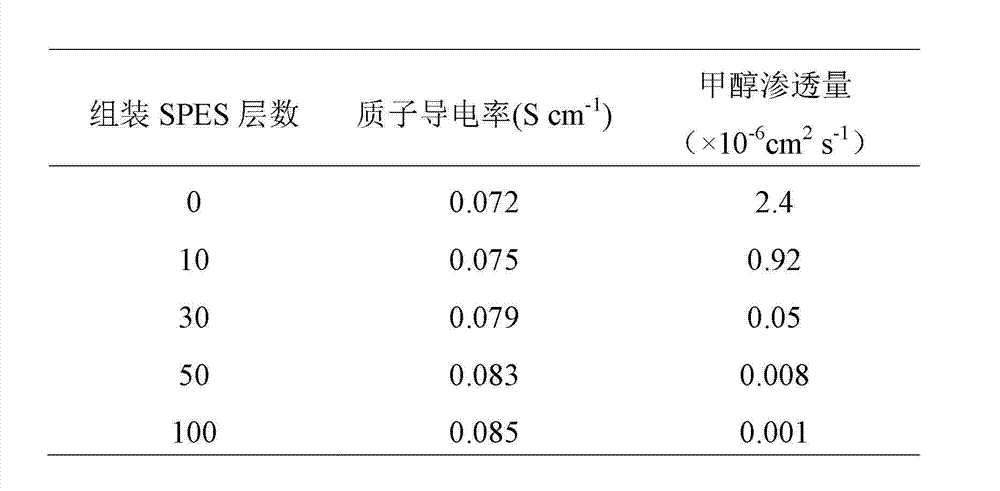

A technology of proton exchange membrane and high conductivity, which is applied in the direction of chemical instruments and methods, circuits, electrical components, etc. It can solve the problems of decreased proton conductivity and high methanol permeability, so as to improve proton conductivity, promote transmission and maintain protons The effect of conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Nafion ? Preparation of Alcohol-resisting Film by Layer-by-Layer Assembly of 117 Film

[0035] Nafion ? 117 membranes were sequentially soaked in 5 wt% H 2 o 2 , deionized water, and 1 mol / L dilute sulfuric acid solution, soak for 30 minutes each, take out, blow dry with nitrogen, and set aside;

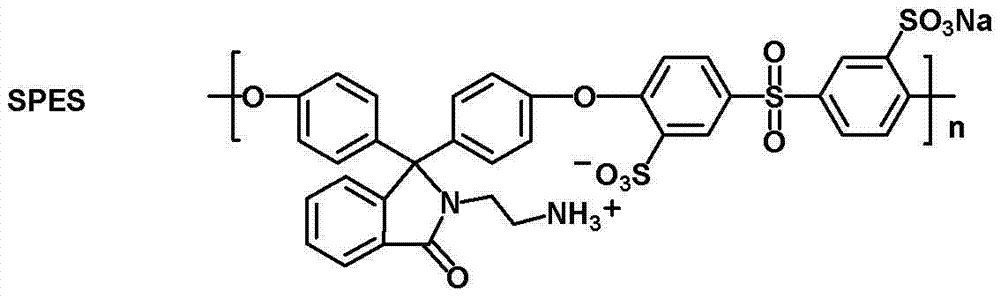

[0036] Put 5 pieces of Nafion with the size of 5cm×5cm after the above treatment ? Immerse the 117 membrane in an aqueous solution of polydiallyldimethylammonium chloride (PDDA) with a concentration of 7wt% by mass, take it out after soaking for 25 minutes at 30°C, and rinse off the Nafion with deionized water. ? 117 PDDA physically adsorbed on the surface of the film, blown dry with nitrogen, and then Nafion ? The 117 membrane was immersed in a polyelectrolyte SPES aqueous solution with a concentration of 0.1wt% by mass percentage, soaked at 20°C for 30 minutes, then took it out, and rinsed off the Nafion with deionized water. ? 117 The polyelectrolyte SPES wi...

Embodiment 2

[0041] Example 2 Flemion ? Layer-by-layer assembly of films and preparation of alcohol barrier films

[0042] Will Flemion ? The membranes were sequentially soaked in 5 wt% H 2 o 2 , deionized water, and 1 mol / L dilute sulfuric acid solution, soak for 30 minutes each, take out, blow dry with nitrogen, and set aside;

[0043] Take 5 pieces of 5cm×5cm Flemion after the above treatment ? The membrane was immersed in an aqueous solution of polyethyleneimine (LPEI) with a concentration of 0.9wt% by weight, soaked at 50°C for 10 minutes, then taken out, and rinsed with deionized water to remove the Flemion ? LPEI physically adsorbed on the surface of the membrane, blown dry with nitrogen, and then Flemion ? The membrane was immersed in a 2wt% polyelectrolyte SPES aqueous solution containing asymmetric charges, soaked at 50°C for 25 minutes, then took it out, and rinsed the Flemion with deionized water. ? Polyelectrolyte SPES containing asymmetric charges physically adsorbed on...

Embodiment 3

[0048] Example 3 Dow ? Layer-by-layer assembly of films and preparation of alcohol barrier films

[0049] Dow ? The membranes were sequentially soaked in 5 wt% H 2 o 2 , deionized water, and 1 mol / L dilute sulfuric acid solution, soak for 30 minutes each, take out, blow dry with nitrogen, and set aside;

[0050] Put 5 pieces of 5cm×5cm Dow after the above treatment ? The membrane was immersed in a poly(allylamine hydrochloride) (PAH) aqueous solution with a mass percentage concentration of 5wt%, and was soaked at 40°C for 20 minutes before being taken out, and the Dow was rinsed with deionized water. ? PAH physically adsorbed on the surface of the membrane, blown dry with nitrogen, and then Dow ? The membrane was immersed in an aqueous solution of polyelectrolyte SPES with a concentration of 1 wt% containing asymmetric charges, soaked at 25°C for 10 minutes, then took it out, and rinsed off the Dow with deionized water. ? Polyelectrolyte SPES containing asymmetric charge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com