Process for preparing self-humidifying composite proton exchange film for fuel cell

A proton exchange membrane and fuel cell technology, which is used in fuel cell parts, fuel cells, solid electrolyte fuel cells, etc., can solve the problems of ineffective self-humidification operation and limited penetration, and achieve improved flexibility and The effect of compactness, ease of operation, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

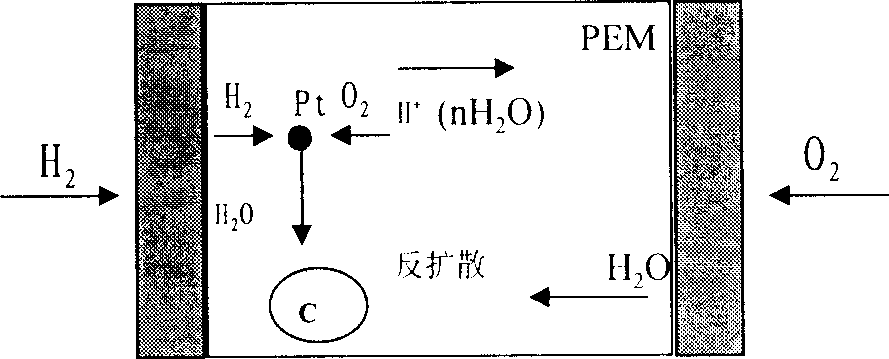

Problems solved by technology

Method used

Image

Examples

Embodiment 1

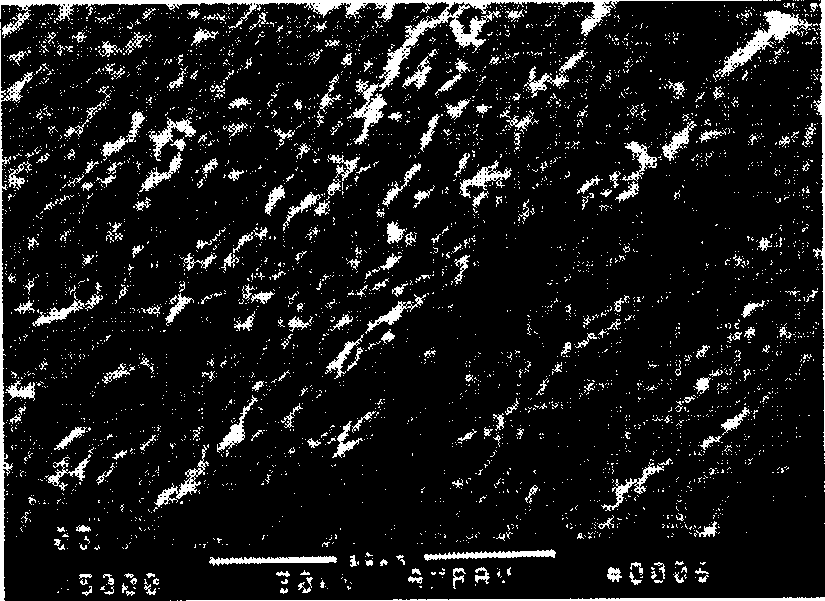

[0043] A mixed solvent of low-boiling organic alcohols (methanol, isopropanol, propanol) and water was used to heat and dissolve the corners of Nafion film (EW=1100) in a closed reaction kettle to prepare a 5% perfluorosulfonic acid solution. Weigh 17g Nafion solution, then press 0.06mgPt / cm 2 Add a certain amount of 20% Pt / C catalyst in a small beaker, add 2g of DMSO dropwise, and vibrate in ultrasonic for 20 minutes to make the catalyst disperse evenly. Cut out a piece of 10×11cm 2 A polytetrafluoroethylene (PTFE) porous membrane with a thickness of 15 μm, the SEM scanning electron micrograph of the porous membrane is shown in the attached figure 2 ; Soak in ethanol solution to remove organic matter on the surface. Then spread the PTFE porous membrane on a flat glass, and add the Nafion solution prepared above adding the Pt / C catalyst dropwise. Put it on a 50°C hot stage, and after one hour, the temperature was raised to 75°C, and after one hour, the temperature was rais...

Embodiment 2

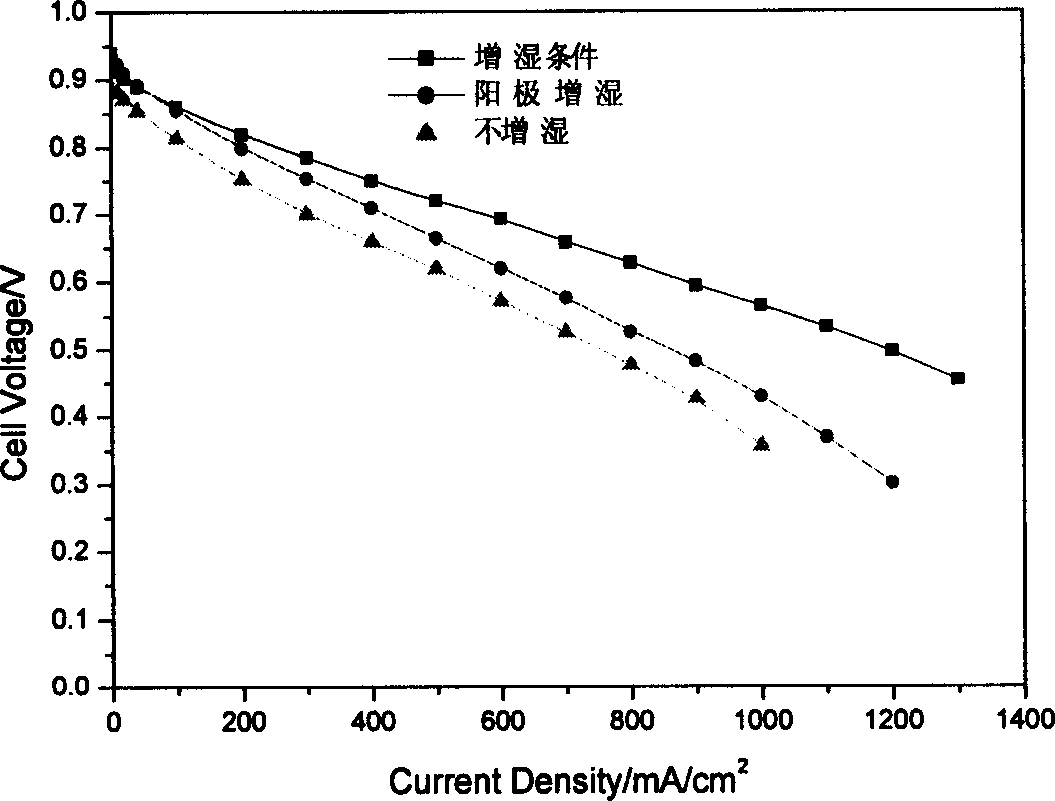

[0052] The three-in-one perfluorosulfonic acid composite membrane and membrane electrode were prepared by the method of Example 1, except that the thickness of the porous PTFE membrane used was 5 μm. 0.06mg Pt / cm in Nafion solution 2 The amount of Pt / C catalyst was added to make a self-humidifying composite membrane with a thickness of 35 μm. The membrane-electrode three-in-one is prepared by hot pressing the membrane. The assembled PEMFC was tested for battery performance on a single-cell evaluation device. The polarization curve of the test battery under humidified and non-humidified conditions is shown in the appendix Figure 6 .

[0053] The effect that the present invention has:

[0054] 1. The invention can realize stable operation under the condition of no external humidification, can simplify or cancel the pure water humidification system, can reduce the complexity of the system, improve the energy efficiency of the battery, and reduce the cost of the battery, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com