Method of lowering permeability of proton exchange film methy alcohol contg fluorine sulfonic acid

A technology of proton exchange membrane and fluorine-containing sulfonic acid, which is applied in electrodes of primary batteries, parts of fuel cells, electrical components, etc., can solve the problems of large amount of palladium, reduced methanol permeation, and decreased electrical conductivity, etc. Low, high conductivity, high alcohol resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Nafion Alcohol-restraining Treatment of 117 Membrane

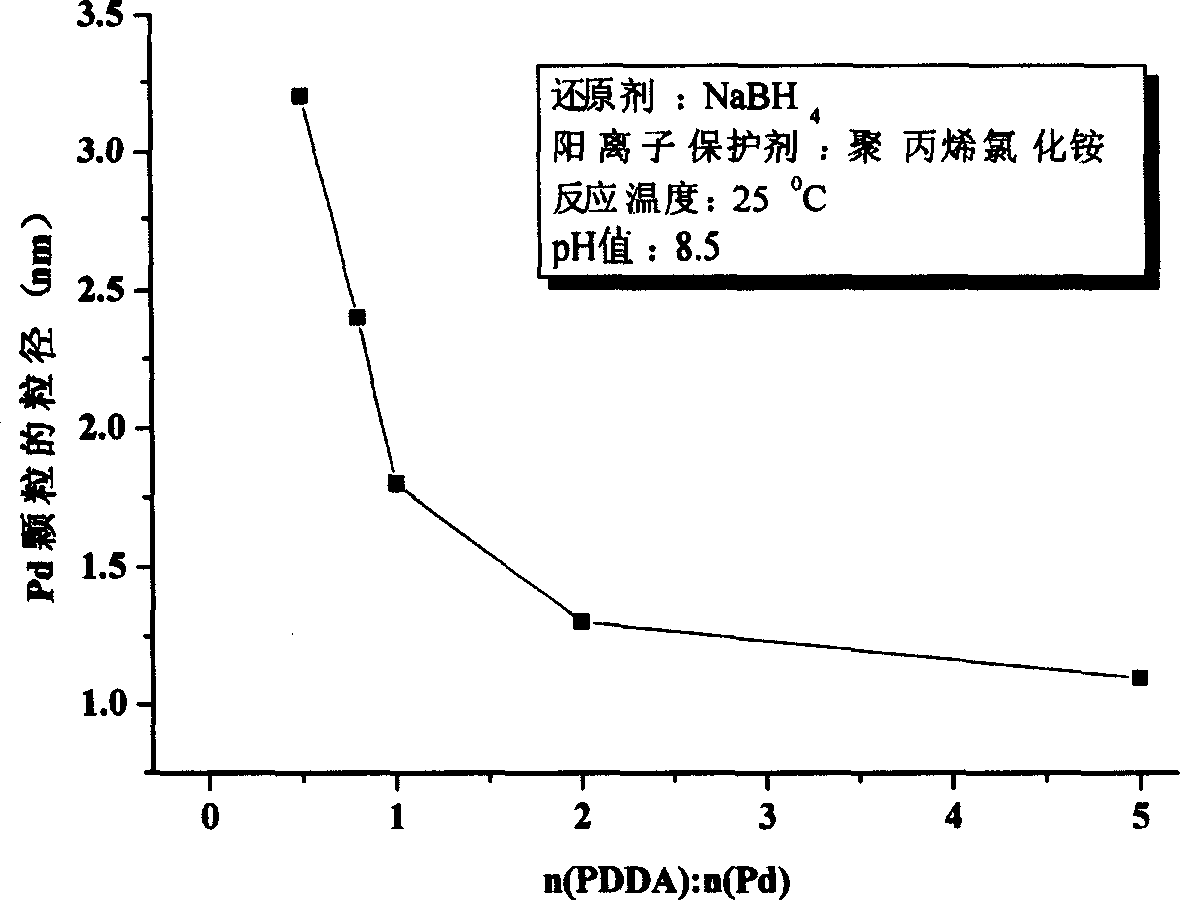

[0026] 1. Select a cationic polymer with a molecular chain length of 1 to 4 nm, and polydimethyldiallyl ammonium chloride (PDDA) with an average molecular weight of Mw to 2000, as a cationic polymer for modifying nano-Pd.

[0027] 2. Take 10mL of PDDA solution with a concentration of 0.005mol / L and dilute it to 79mL with deionized water with a conductivity > 18MΩ, and add PdCl with a concentration of 0.05mol / L in turn 2 Solution 1mL, isopropanol 60mL mixed evenly, adjust the pH value of the mixed solution to 8.5, N 2 Under the protection of the water bath, the temperature was raised to 75° C. and reacted for 10 minutes to obtain cationized nano-Pd particles with a particle size of ~2 nm.

[0028] 3, 4 tablets of Nafion 117 film sequentially in 5wt% H 2 o 2 , deionized water, 1mol / L H 2 SO 4 , soak in deionized water for 30 minutes, put into the cationized nano-Pd dispersion prepared in step 2 a...

Embodiment 2

[0037] Example 2: Dow Alcohol barrier treatment of membrane

[0038] 1. The copolymer of acrylamide-dimethyl diallyl ammonium chloride with average molecular weight Mw~1000 is selected as the cationic polymer for modifying nanometer Pd.

[0039] 2. Take 80mL of acrylamide-dimethyldiallylammonium chloride copolymer solution with a concentration of 0.001mol / L, and mix it with 1mL of PdCl with a concentration of 0.05mol / L 2 Mix well, adjust the pH value of the mixed solution to 8, N 2 Add dropwise NaBH with a concentration of 1mol / L at a rate of 1mL / min under protection 4 Solution 0.2mL (more than 3 times the dose, can also be equal dose), to obtain cationized nano-Pd particles, the particle size of ~ 1.6nm.

[0040] 3, 4 pieces of Dow membrane sequentially in 5 wt% H 2 o 2 , deionized water, 1mol / L H 2 SO 4 , soak in deionized water for 30 minutes, put into the cationized nano-Pd dispersion prepared in step 2 and soak to self-assemble Pd particles electrostatically, ...

Embodiment 3

[0048] Embodiment 3: the alcohol barrier treatment of polyvinylidene fluoride grafted polystyrene sulfonic acid resin film

[0049] The process of forming a film of polyvinylidene fluoride grafted polystyrene sulfonic acid resin prepared by the method described in CN1330425A, with a film thickness of 85um. The processing steps are:

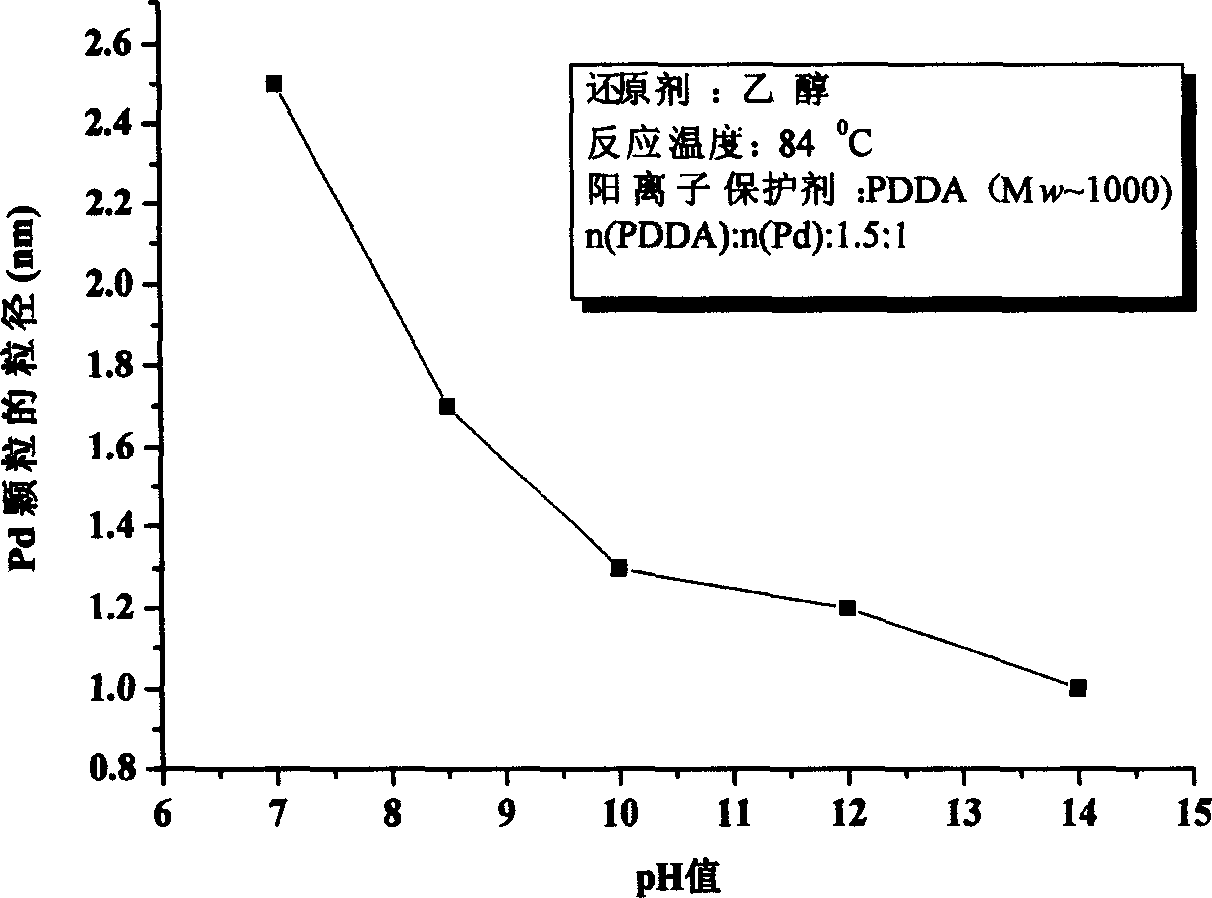

[0050] 1. Select polyallyl ammonium chloride with average molecular weight Mw~1000 as the cationic polymer for modifying nano Pd.

[0051] 2. Take 10 mL of tetramethylammonium chloride solution with a concentration of 0.005 mol / L and dilute it to 79 mL with deionized water with a conductivity > 18 MΩ, and add PdCl with a concentration of 0.05 mol / L in sequence 2 Solution 1mL, absolute ethanol 60mL mix well, adjust the pH value of the mixed solution to 12, N 2 Under the protection of the water bath, the temperature was raised to 84° C. and reacted for 10 minutes to obtain cationized nano-Pd particles with a particle size of ~1.3 nm.

[0052] 3. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com