Preparation method of modified perfluorosulfonic acid proton exchange membrane for fuel battery

A proton exchange membrane, perfluorosulfonic acid technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of complex operation process, high production cost, complex production process, etc., and achieve uncomplicated preparation process and environmental pollution. Small, great performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

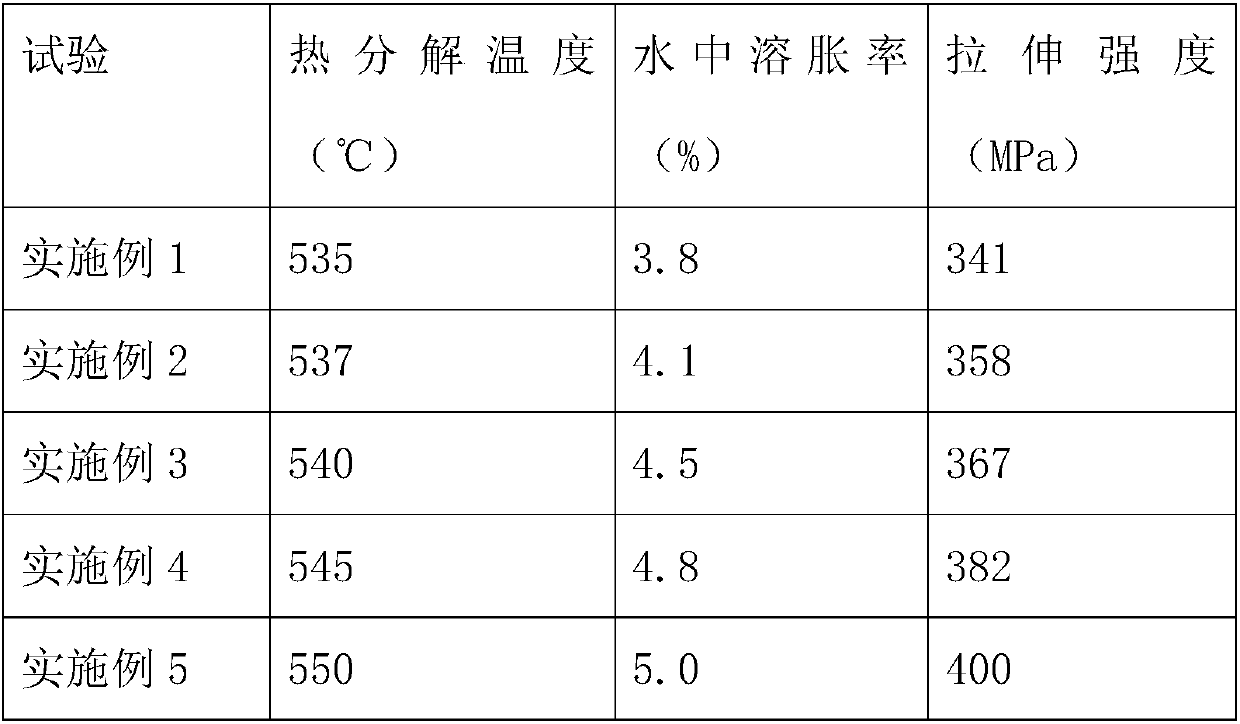

Examples

Embodiment 1

[0021] S1: 40 parts of lignin, 25 parts of diethyl ether and 70 parts of distilled water were mixed, and stirred at a temperature of 90°C at a rate of 200r / min for 1h;

[0022] S2: Lower the temperature of the solution obtained in step S1 to 40°C, then introduce chlorine gas at 2ml / min, and continue the reaction for 10 minutes; then add 20 parts of p-toluenesulfonic acid, raise the temperature to 60°C, and stir at a rate of 200r / min Reaction for 30min, the product was obtained after distillation;

[0023] S3: Add the distillation product obtained in step S2 into the casting solution of the perfluorosulfonic acid proton exchange membrane, wherein the distillation product accounts for 30%; ultrasonically treat at a temperature of 50° C. to make it uniform, and obtain a mixed solution;

[0024] S4: casting the mixed solution obtained in step S3 into a mold, and placing it in an oven at 120° C., and then vacuuming and maintaining it for 8 hours to obtain a composite proton exchang...

Embodiment 2

[0027] S1: Mix 60 parts of lignin, 30 parts of diethyl ether and 80 parts of distilled water, and stir and react at a rate of 150 r / min for 3 hours at a temperature of 110°C;

[0028] S2: Lower the temperature of the solution obtained in step S1 to 50°C, then pass in chlorine gas at 2ml / min, and continue the reaction for 20 minutes; then add 10 parts of p-toluenesulfonic acid, raise the temperature to 80°C, and stir at a rate of 300r / min Reaction for 50min, the product was obtained after distillation;

[0029] S3: adding the distillation product obtained in step S2 into the casting solution of the perfluorosulfonic acid proton exchange membrane, wherein the distillation product accounts for 60%; ultrasonic treatment at a temperature of 60° C. to make it uniform to obtain a mixed solution;

[0030] S4: casting the mixed solution obtained in step S3 into a mold, and placing it in an oven at 140° C., and then vacuuming and maintaining it for 20 hours to obtain a composite proton ...

Embodiment 3

[0033] S1: Mix 45 parts of lignin, 28 parts of diethyl ether and 75 parts of distilled water, and stir and react at a temperature of 95°C at a speed of 165r / min for 1.5h;

[0034] S2: Lower the temperature of the solution obtained in step S1 to 45°C, then introduce chlorine gas at 2ml / min, and continue the reaction for 12 minutes; then add 15 parts of p-toluenesulfonic acid, raise the temperature to 65°C, and stir at a rate of 250r / min Reaction 35min, obtain product after distillation;

[0035] S3: Add the distillation product obtained in step S2 into the casting solution of the perfluorosulfonic acid proton exchange membrane, wherein the distillation product accounts for 40%; ultrasonically treat at a temperature of 55° C. to make it uniform, and obtain a mixed solution;

[0036] S4: casting the mixed solution obtained in step S3 into a mold, and placing it in an oven at 125° C., and then vacuuming and keeping it for 10 hours to obtain a composite proton exchange membrane;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com