Solvent-free composite PET/PE (Polyethylene Terephthalate/Polyethylene) film and preparation process thereof

A preparation process and solvent-free technology, applied in the field of solvent-free composite PET/PE film and its preparation process, can solve the problems of many harmful waste gas, poor bonding effect, environmental pollution, etc., and achieve high transparency, good bonding effect, thin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

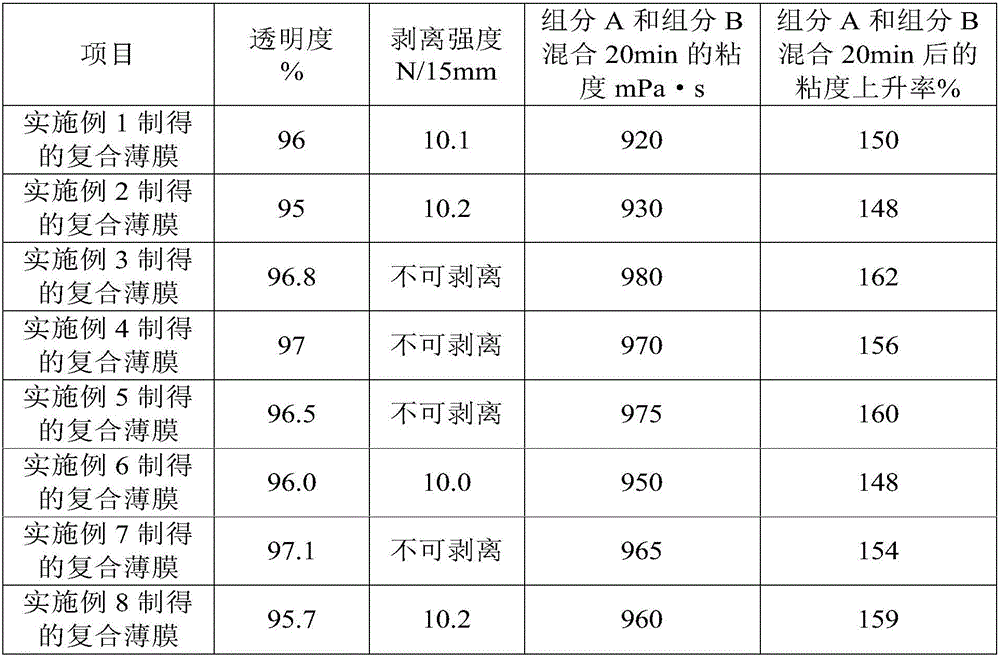

Examples

Embodiment 1

[0029] A solvent-free composite PET / PE film, comprising an outer layer, an adhesive layer and a base layer; wherein, one side of the adhesive layer is bonded to the outer layer, and the other side is bonded to the base layer; the outer layer is made of PET resin; The base layer is prepared from PE resin; the adhesive layer is prepared from a solvent-free adhesive; the solvent-free adhesive is composed of component A and component B; component A includes the following components: modified cashew nut shell oil 30 parts of permanent phenolic resin, 25 parts of ethylene-vinyl acetate copolymer, and 1 part of oxetane; component B includes the following components: diethylenetriamine, isophoronediamine.

[0030] Among them, the thickness of the outer layer is 1.8 μm; the thickness of the base layer is 1.2 μm; the content of vinyl acetate in ethylene-vinyl acetate copolymer is 60%; the mass ratio of diethylene triamine and isophorone diamine is 1:1 ; The preparation method of compone...

Embodiment 2

[0032] A solvent-free composite PET / PE film, comprising an outer layer, an adhesive layer and a base layer; wherein, one side of the adhesive layer is bonded to the outer layer, and the other side is bonded to the base layer; the outer layer is made of PET resin; The base layer is prepared from PE resin; the adhesive layer is prepared from a solvent-free adhesive; the solvent-free adhesive is composed of component A and component B; component A includes the following components: modified cashew nut shell oil 45 parts of permanent phenolic resin, 40 parts of ethylene-vinyl acetate copolymer, and 3 parts of oxetane; component B includes the following components: vinyltriamine.

[0033] Wherein, the thickness of the outer layer is 5 μm; the thickness of the base layer is 4 μm; the content of vinyl acetate in the ethylene-vinyl acetate copolymer is 80%; the preparation method of component A is: modifying the cashew nut shell oil of the mass parts Resin and ethylene-vinyl acetate c...

Embodiment 3

[0035] A solvent-free composite PET / PE film, comprising an outer layer, an adhesive layer and a base layer; wherein, one side of the adhesive layer is bonded to the outer layer, and the other side is bonded to the base layer; the outer layer is made of PET resin; The base layer is prepared from PE resin; the adhesive layer is prepared from a solvent-free adhesive; the solvent-free adhesive is composed of component A and component B; component A includes the following components: modified cashew nut shell oil 38 parts of permanent phenolic resin, 32 parts of ethylene-vinyl acetate copolymer, 2 parts of oxetane; component B includes the following components: diethylaminopropylamine.

[0036] Wherein, the thickness of the outer layer is 3.5 μm; the thickness of the base layer is 2.1 μm; the content of vinyl acetate in the ethylene-vinyl acetate copolymer is 70%; the preparation method of component A is: changing the cashew nut shell liquid phenolic resin and ethylene-vinyl acetat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com