Nanometer porous and super-hydrophobic skeleton strong solid acid material and preparing method thereof

A nanoporous, solid strong acid technology, applied in the fields of material chemistry and physical chemistry, can solve the problems of enhanced hydrophilicity of the skeleton, poor skeleton stability and hydrophobicity, poor hydrophilicity and stability, etc., and achieve excellent swelling performance, excellent Effect of improving catalytic performance and degree of crosslinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

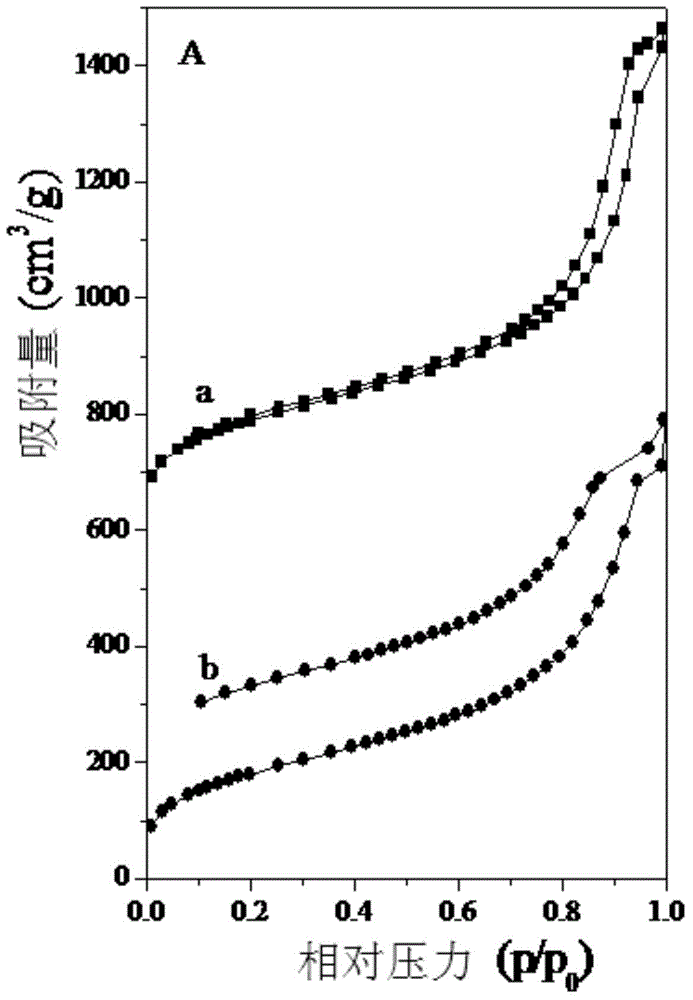

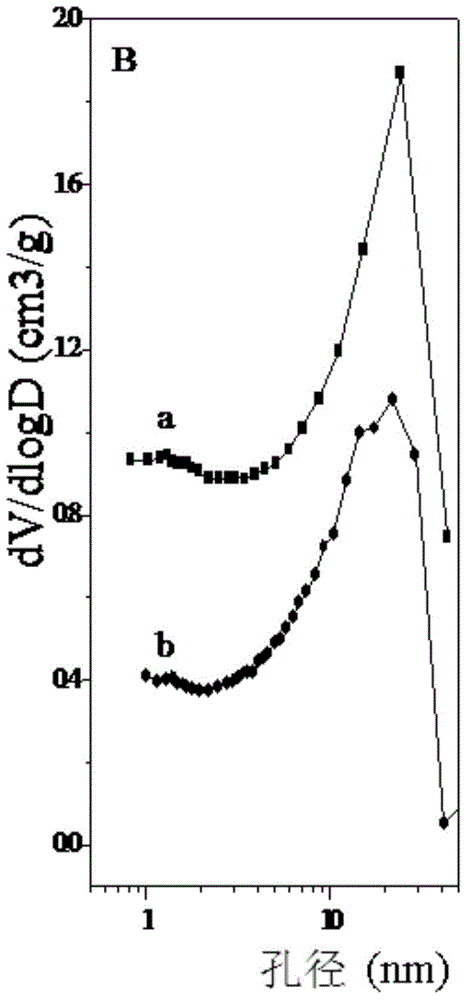

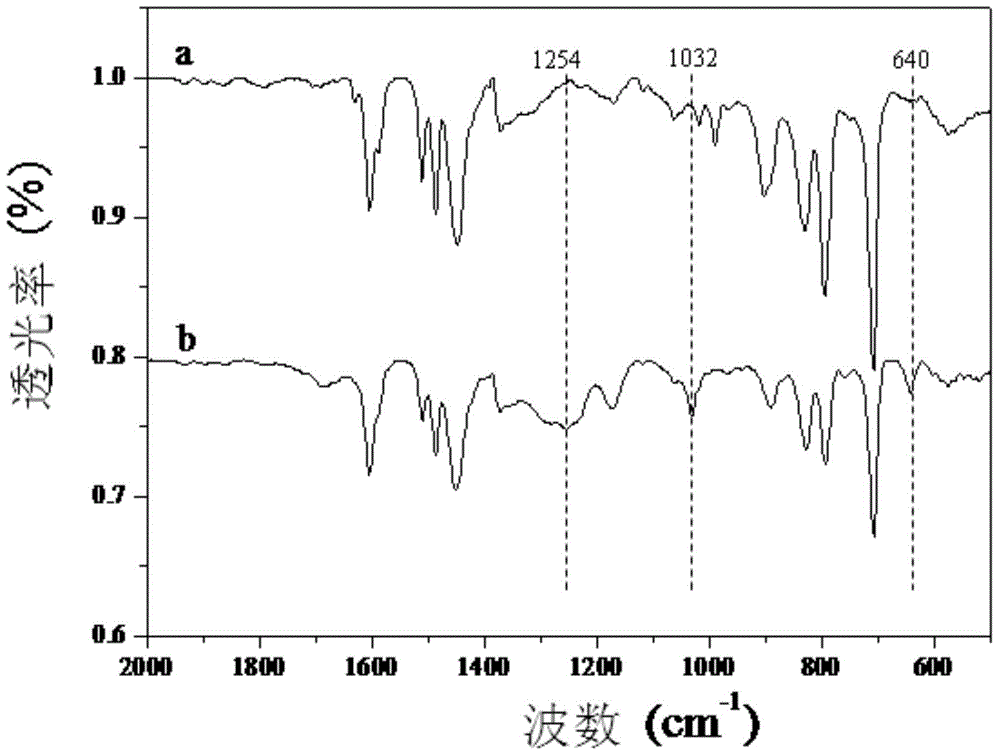

[0022] Example 1: A mesoporous polydivinylbenzene material was synthesized with a mixed solvent composed of tetrahydrofuran and water.

[0023] Add 2g of DVB (divinylbenzene) monomer into a mixed solvent containing 0.05g of benzoyl peroxide initiator, 23mL of tetrahydrofuran and 2mL of water, stir for 3 hours at normal temperature and pressure, and take it out after 1 day of solvent heat treatment at 80°C. Open the cover and evaporate the solvent at room temperature to obtain a polydivinylbenzene material with a high specific surface area and rich mesoporous structure.

Embodiment 2

[0024] Example 2: Synthesis of mesoporous polydivinylbenzene material using tetrahydrofuran as a solvent.

[0025] Add 2g of DVB monomer to a solvent containing 0.05g of benzoyl peroxide and 25mL of tetrahydrofuran, stir for 1 hour at normal temperature and pressure, then take it out after 12 hours of solvent heat treatment at 100°C, open the cover, and evaporate the solvent at room temperature to obtain high Specific surface area, polydivinylbenzene material with rich mesoporous structure. The resulting material has a specific surface area of 550 m 2 / g, the pore size is 3.7 nm.

Embodiment 3

[0026] Example 3: Synthesis of mesoporous polydivinylbenzene materials using toluene as a solvent.

[0027] Add 2g of DVB monomer to a solvent containing 0.05g of benzoyl peroxide and 7mL of toluene, stir at room temperature and pressure for 1 hour, then take it out after 48 hours of solvent heat treatment at 140°C, open the cover, and evaporate the solvent at room temperature to obtain high Specific surface area, polydivinylbenzene material with rich mesoporous structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com