Patents

Literature

250results about How to "Improve low temperature discharge performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

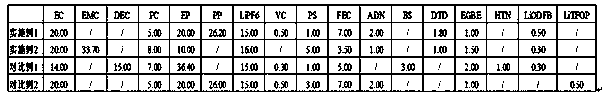

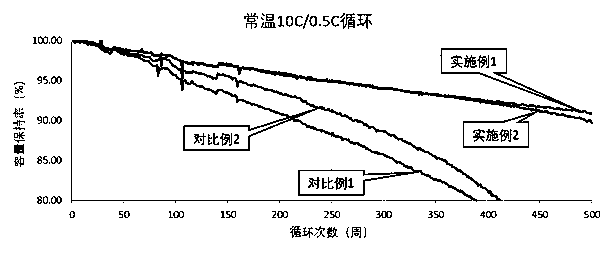

Electrolyte additive and application thereof in lithium ion battery

ActiveCN104766995AImprove cycle lifeImprove featuresLi-accumulatorsOrganic electrolytesHigh temperature storageSulfur

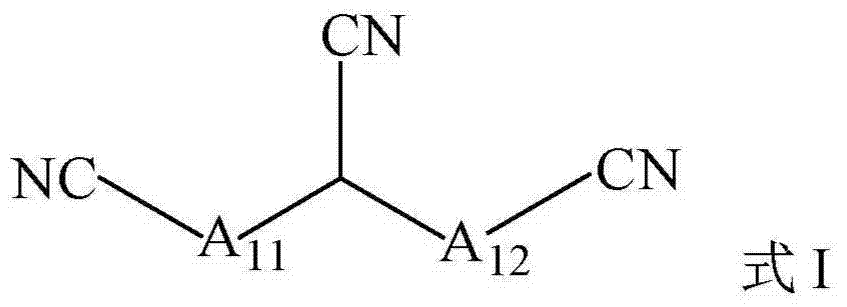

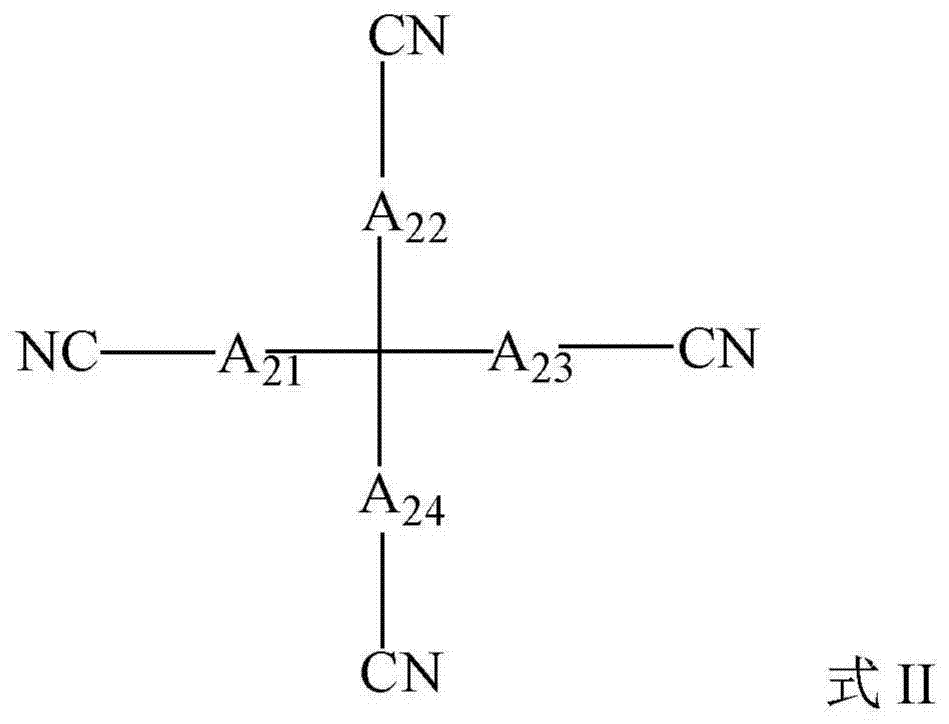

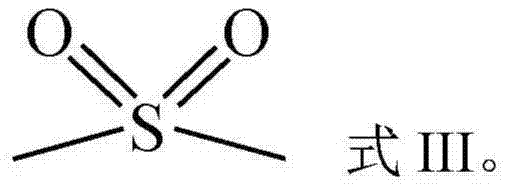

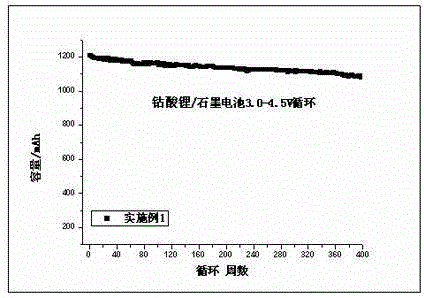

The invention discloses an electrolyte additive and an application thereof in a lithium ion battery. The electrolyte additive comprises a polynitrile-based compound and a compound comprising a sulfur bond and an oxygen bond. When the electrolyte additive is applied to the lithium ion battery, good cycle life, good low-temperature discharging property and good high-temperature storage property of the lithium ion battery under the high voltage still can be maintained.

Owner:CONTEMPORARY AMPEREX TECH CO

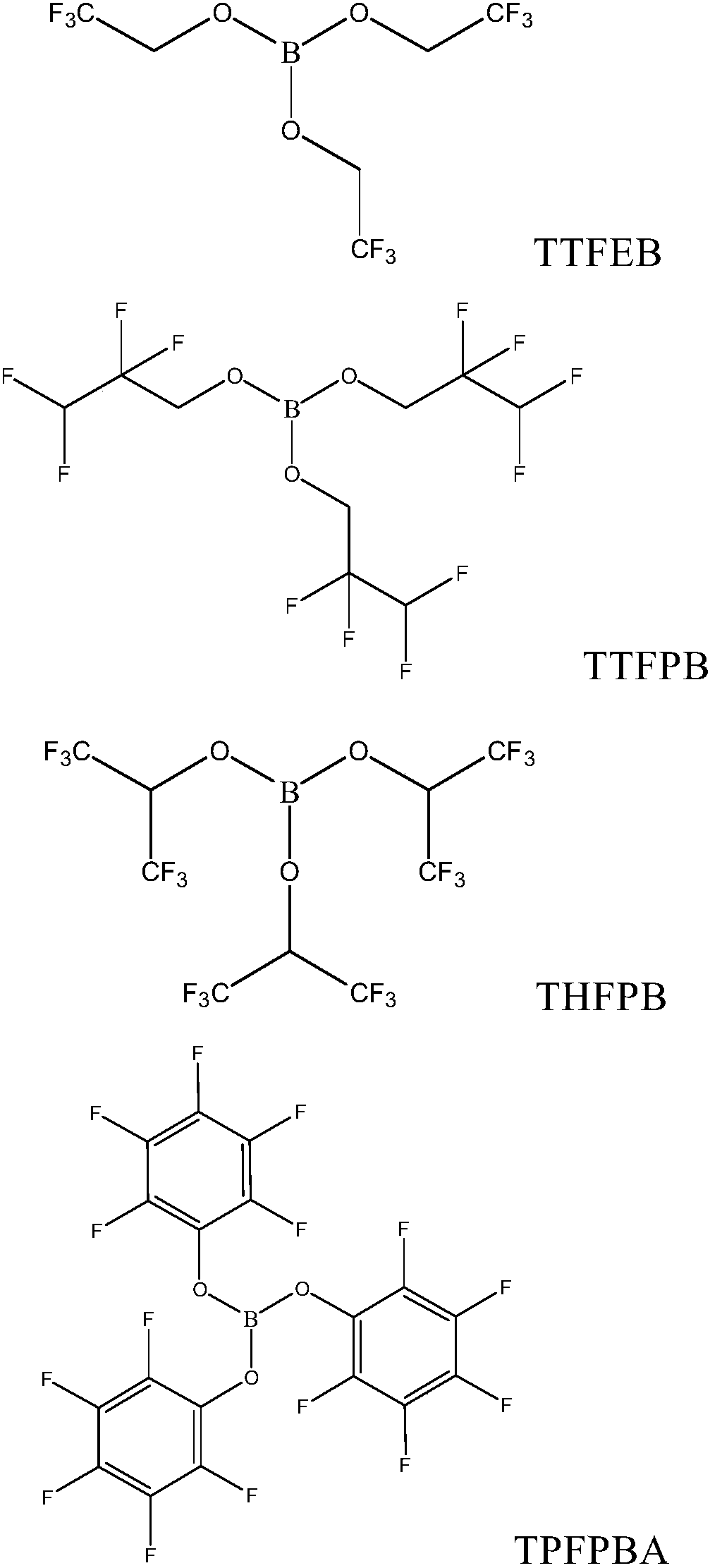

High-voltage lithium-ion battery electrolyte

InactiveCN104466250AImprove electrochemical reactivityPromote circulationSecondary cellsOrganic electrolytesElectrolytic agentPhysical chemistry

The invention relates to the technical field of lithium-ion battery electrolytes, in particular to a high-voltage lithium-ion battery electrolyte. The high-voltage lithium-ion battery electrolyte comprises non-aqueous solvent, lithium salt and an additive. The additive comprises the mixture of phosphonitrile, annular sulphate and hydrogen fluoroether. The high-voltage lithium-ion battery electrolyte can form a film on the surface of an electrode through the synergistic effect of the phosphonitrile, the annular sulphate and the hydrogen fluoroether, oxygenolysis of the electrolyte is restrained, and the cycle performance of 4.5 V and 5.0 V high-voltage lithium-ion batteries is obviously improved.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

Electrolyte and lithium ion battery

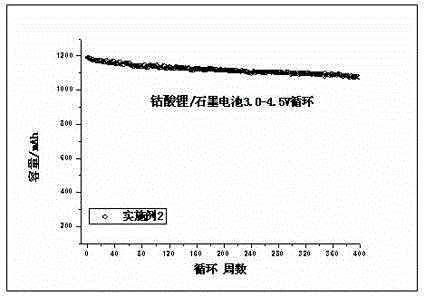

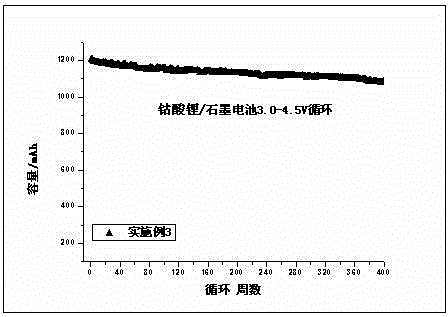

ActiveCN107394269AEasy to storeImprove cycle performanceSecondary cellsLithium sulphateOrganic solvent

The invention provides an electrolyte and a lithium ion battery. The electrolyte comprises a lithium salt, an organic solvent and an additive, wherein the additive comprises a first additive, and the first additive comprises alkyl lithium sulfate and fluoro-ether. By the electrolyte, the storage performance, the cycle property, the rate performance and the low-temperature discharge performance of the lithium ion battery under high temperature and high voltage can be improved, meanwhile, the safety performance of the lithium ion battery is improved, and the service lifetime of the lithium ion battery is prolonged.

Owner:NINGDE AMPEREX TECH

Cathode diachylon used for power-type lead-acid storage battery and manufacture method thereof

InactiveCN102088088AStrong maneuverabilityHigh viscosityLead-acid accumulator electrodesIonActivated carbon

The invention discloses cathode diachylon used for a power-type lead-acid storage battery, comprising the following components: 100kg of lead powder, 0.10-0.12kg of short fiber, 0.40-0.60kg of humic acid, 0.12-0.30kg of sodium lignin sulfonate, 1.00-2.00kg of acetylene black, 1.00-1.50kg of conduction graphite, 2.00-3.00kg of activated carbon, 0.60-1.00kg of barium sulphate, 15000-22000g of deionized water and 7200-6000ml of sulfuric acid with the concentration of 1.30-1.40g / cm<3>(25 DEG C). The cathode diachylon has the beneficial effect that the power-type battery produced by the cathode diachylon has the advantages of high specific energy and good large current discharging capability, the low-temperature volume and cycle life are obviously improved.

Owner:SHANDONG SACRED SUN POWER SOURCES

Lead plaster for low temperature resistant lead storage battery for electric scooter and preparation method of lead plaster

ActiveCN103779557AInhibition of \"shrinkage\"Inhibit \"passivation\"Cell electrodesFiberElectrical battery

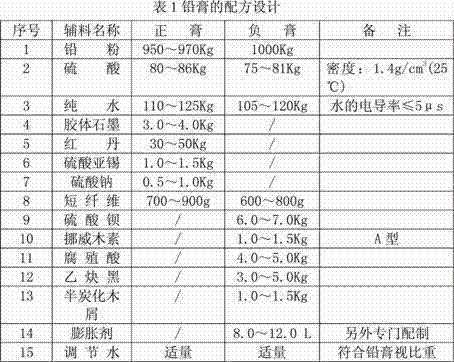

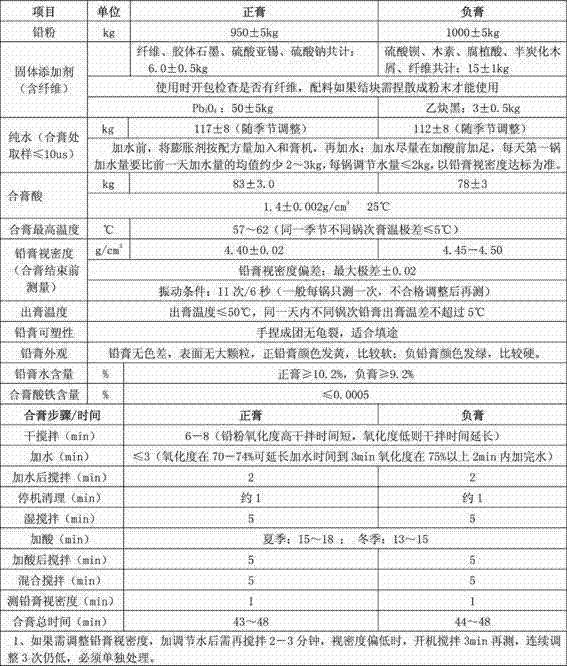

The invention relates to a lead plaster for a low temperature resistant lead storage battery for an electric scooter and a preparation method of the lead plaster. The lead plaster comprises an anode lead plaster and a cathode lead plaster, wherein the anode lead plaster comprises the following components in parts by weight: 950-970 parts of lead powder, 80-86 parts of 1.3-1.4g / cm<3> sulfuric acid, 110-125 parts of pure water, 3.0-4.0 parts of colloidal graphite, 30-50 parts of red lead, 1.0-1.5 parts of tin sulfate, 0.5-1.0 part of sodium sulfate and 0.7-0.9 part of short fiber; the cathode lead plaster comprises the following components in parts by weight: 1000 parts of lead powder, 75-81 parts of 1.3-1.4g / cm<3> sulfuric acid, 105-120 parts of pure water, 0.6-0.8 part of short fiber, 6.0-7.0 parts of barium sulfate, 1.0-1.5 parts of Norway lignin, 4.0-5.0 parts of humic acid, 3.0-5.0 parts of acetylene black and 1.0-1.5 parts of semi-carbonized saw dust. According to the lead plaster and the preparation method thereof, the acceptance performance when the battery is charged at low temperature is improved and the discharge capacity is increased; the lead plaster disclosed by the invention is applicable to low-temperature environment and is especially suitable for northeast and northwest regions in China.

Owner:河北超威电源有限公司

Negative plate of battery, preparation method thereof and battery comprising negative plate

InactiveCN102683708AHold off high current performanceImprove high current performanceFinal product manufactureLead-acid accumulator electrodesFiberCapacitance

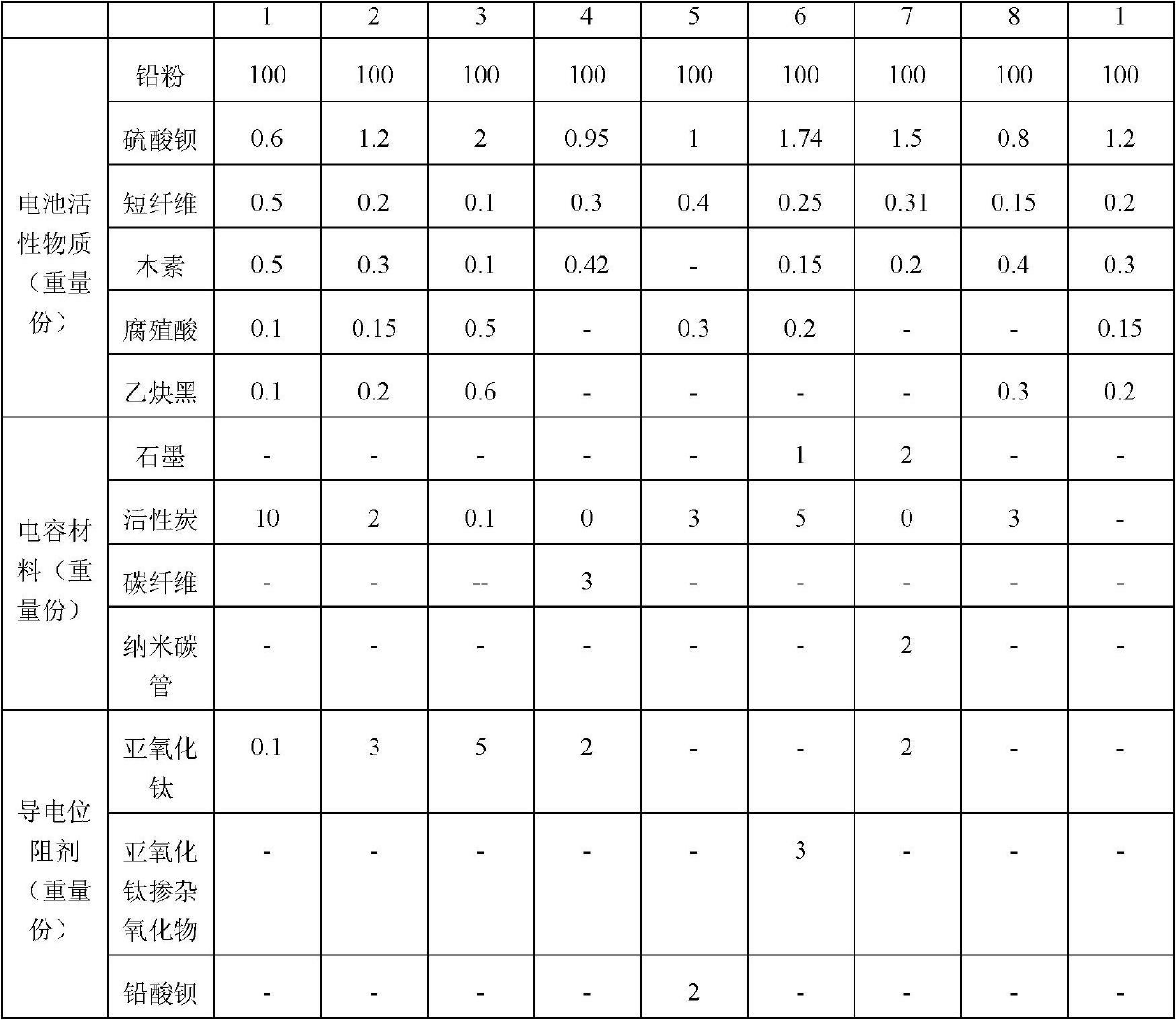

The invention discloses a negative plate of a battery, a preparation method thereof and the battery comprising the negative plate. The negative plate is composed of a plate grid and a negative pole material coated on the plate grid, and the negative pole material comprises a battery active material, a capacitor material as well as a conductive steric hindrance agent; the battery active material comprises 100 parts by weight of lead powder, 0.6-2.0 parts by weight of barium sulfate and 0.1-0.5 part by weight of short fiber, and the capacitor material comprises 0.1-10 parts by weight of active carbon; and the additive amount of the electric conduction steric hindrance agent is 0.1-5.0 in parts by weight, and the conductive steric hindrance agent comprises Magneli mutual sulfoxide titanium oxide and / or plumbous acid barium. The raw material of the negative plate of the battery provided by the invention can be used for postponing a negative board sulphate phenomenon through combining the three parts, the cold-starting property is markedly improved, and the heavy-current charge-discharge property is optimized.

Owner:湖南维邦新能源有限公司

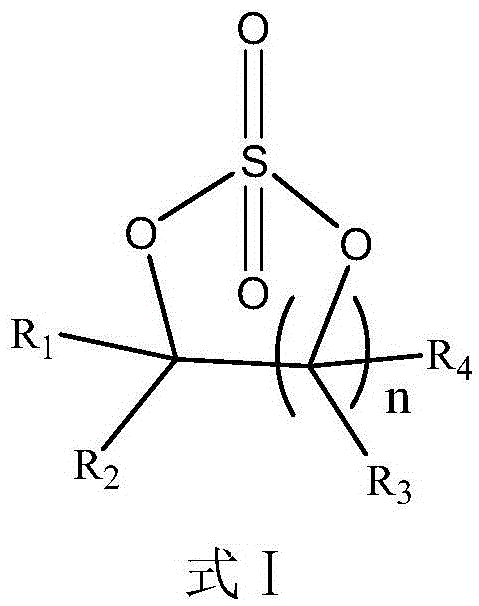

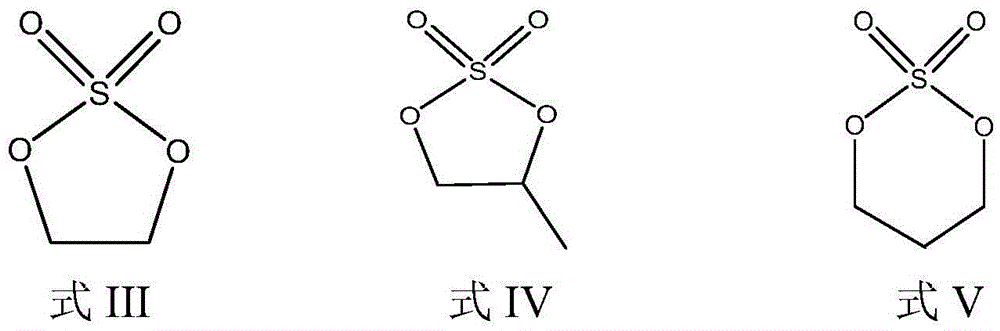

Additive for battery electrolyte, lithium ion battery electrolyte and lithium ion battery

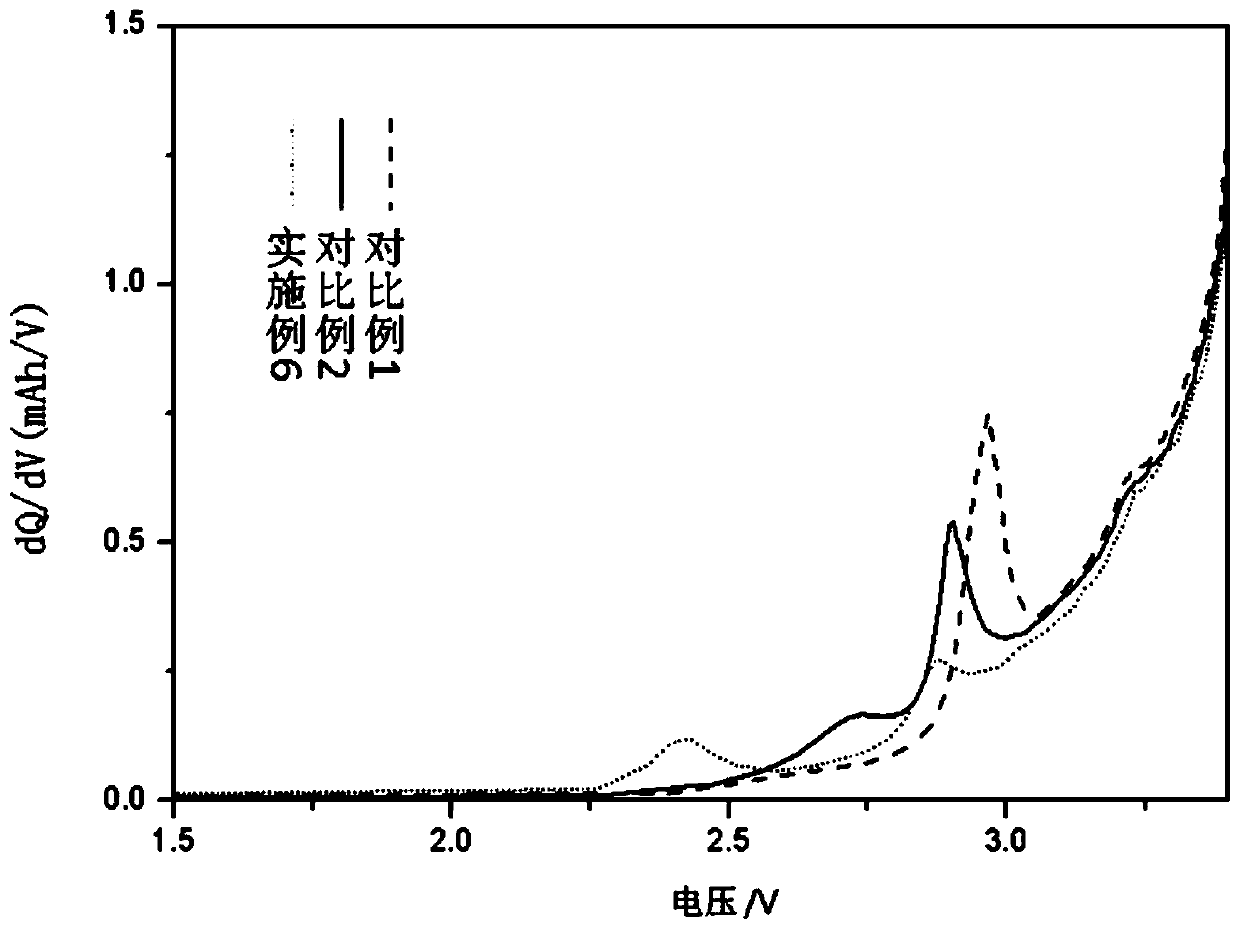

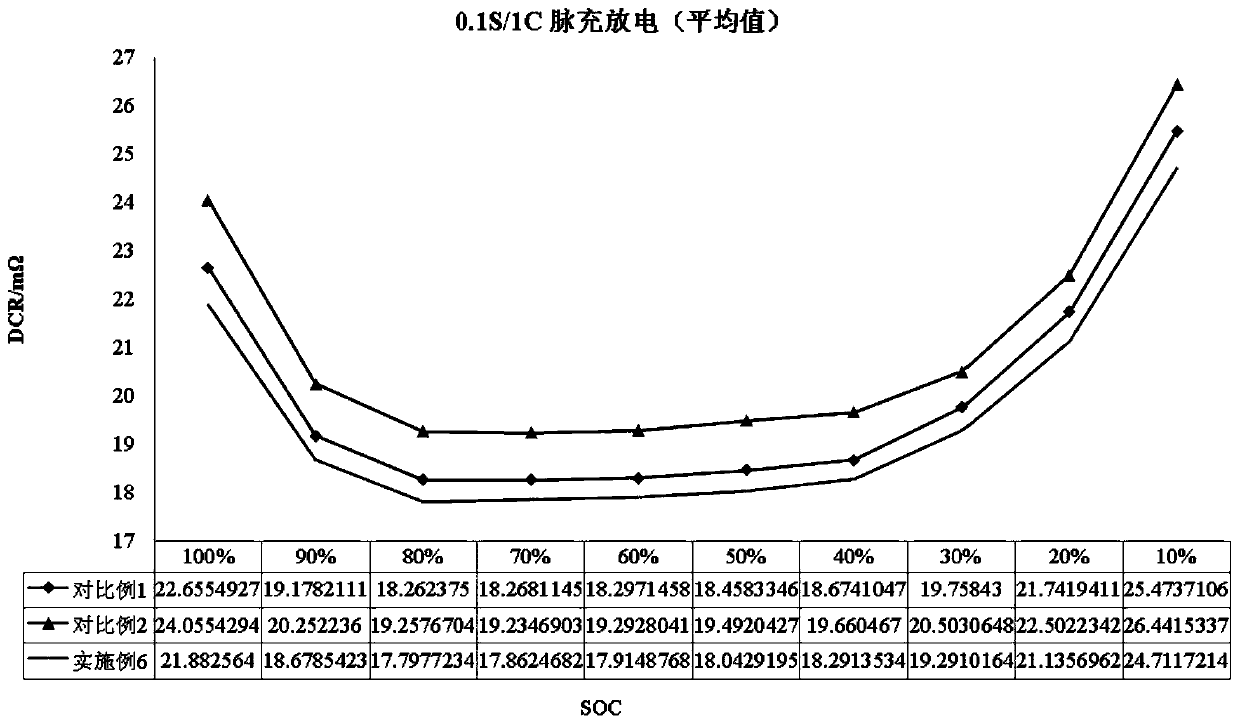

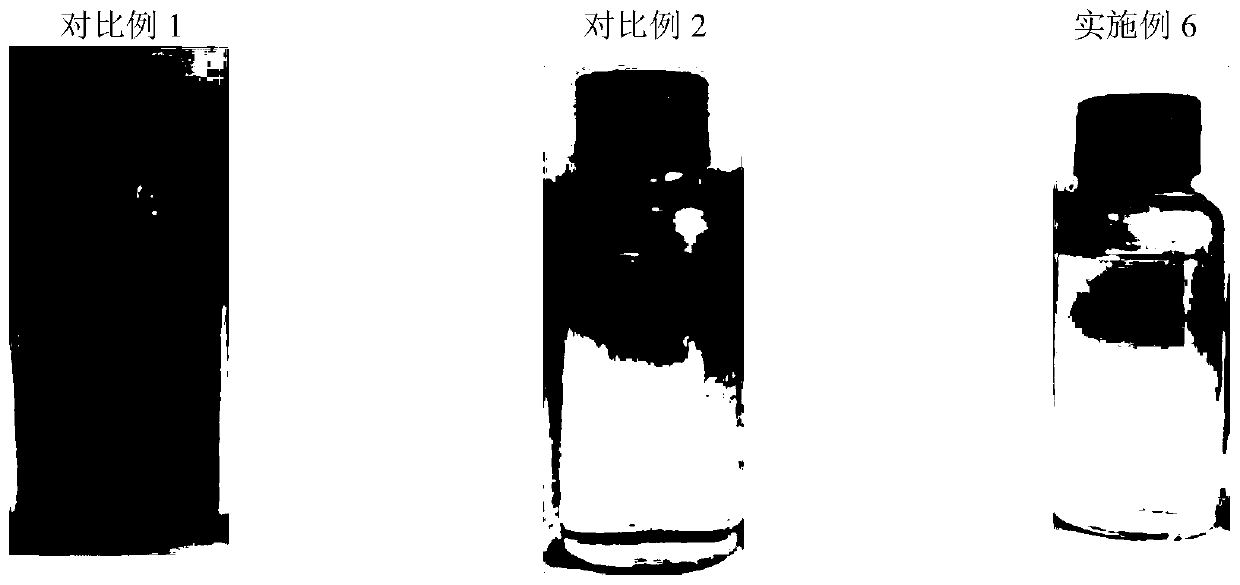

ActiveCN110931863AImprove output performanceInhibit side effectsCell electrodesSecondary cellsElectrolytic agentInterface impedance

The invention provides an additive for a battery electrolyte. The additive at least comprises one of compounds shown in structural formulas (1)-(7). According to the additive for the battery electrolyte, a low-impedance protective film can be formed on the surface of an electrode, side reactions of the electrode and the electrolyte are inhibited, the interface impedance is reduced, the high-low temperature performance is considered, and the overall output performance of a lithium ion battery is improved.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

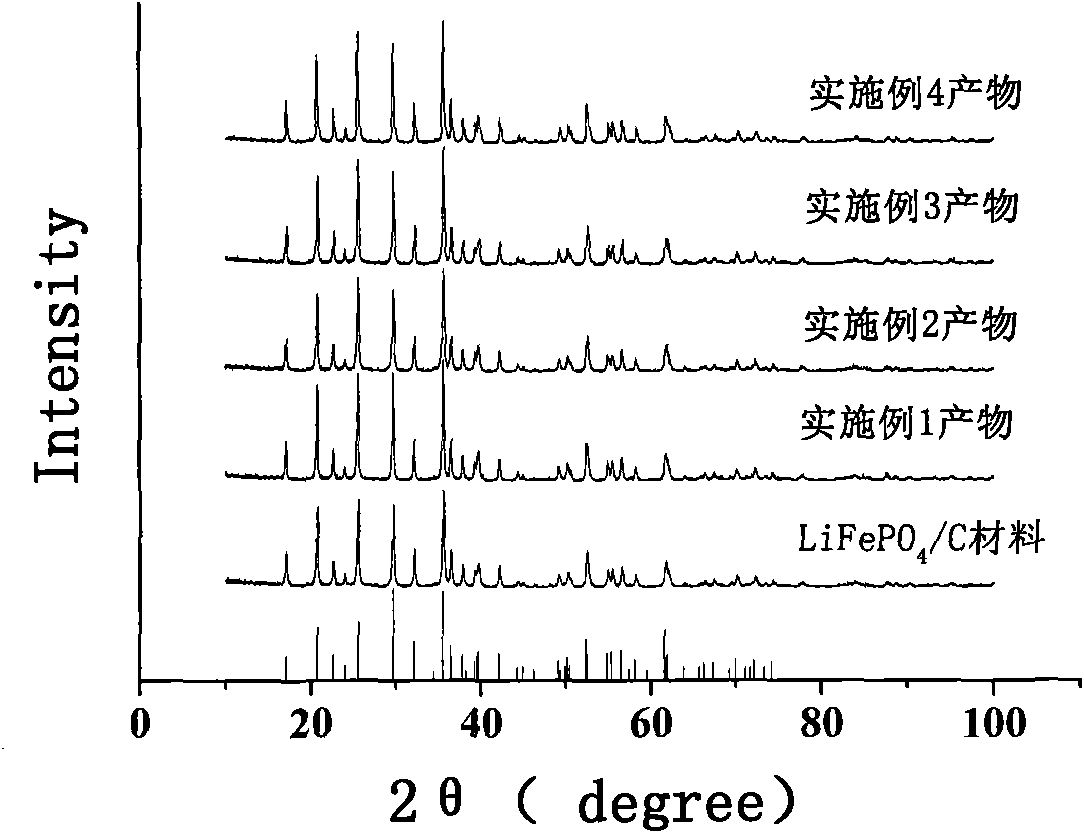

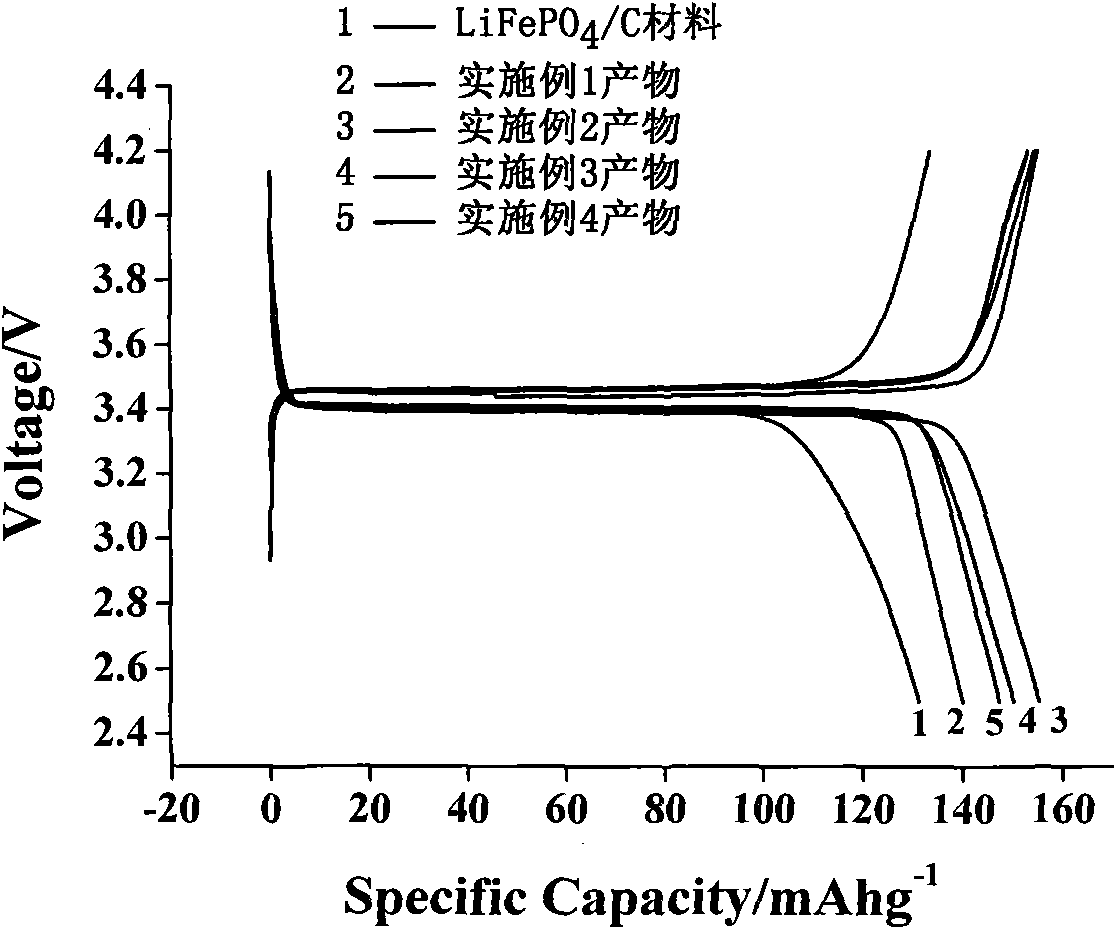

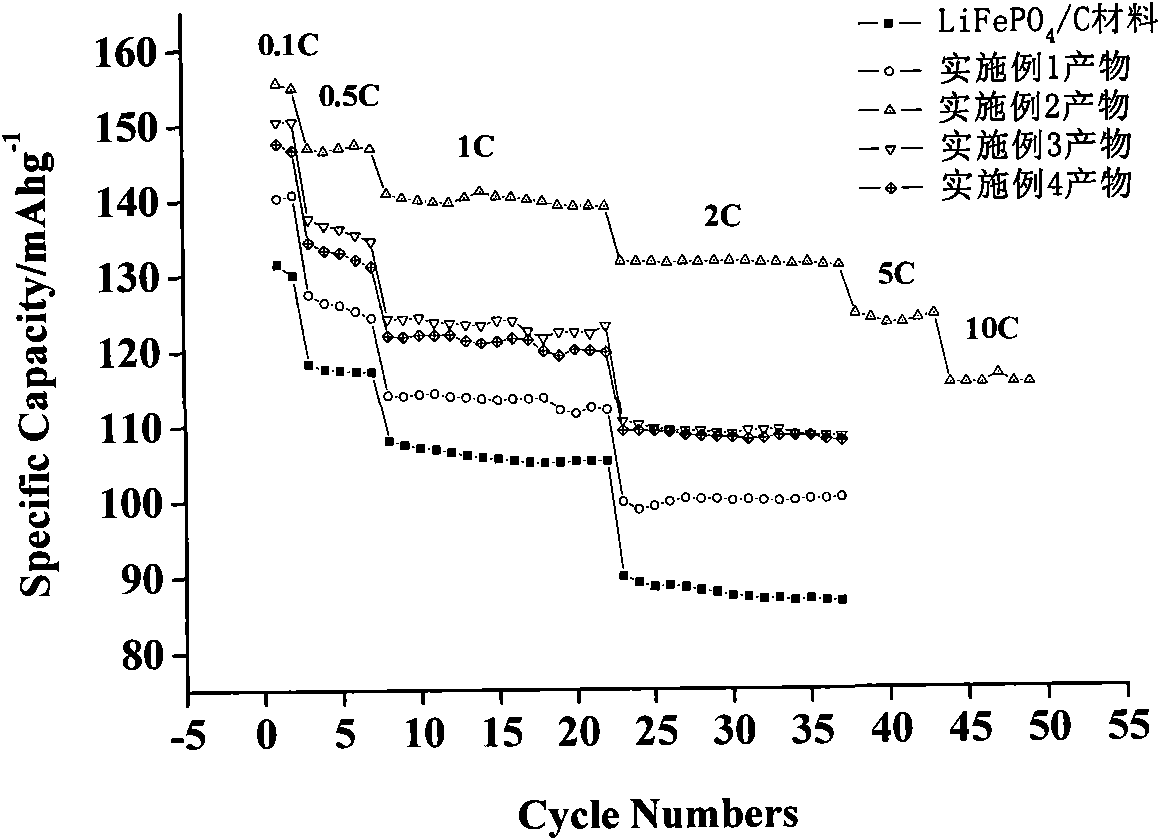

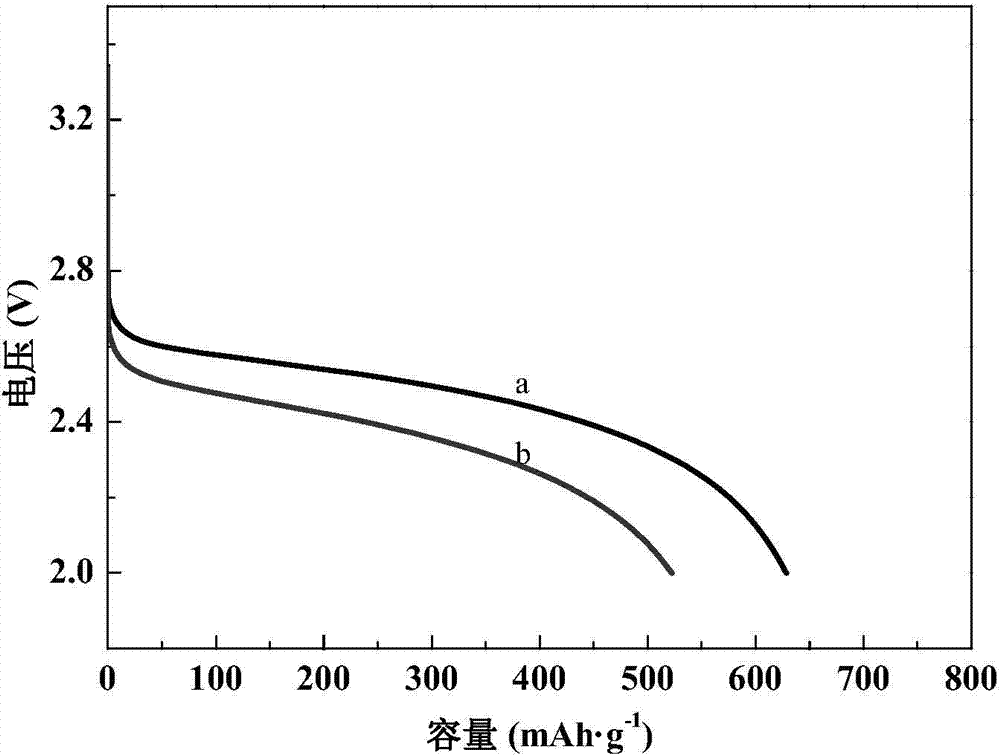

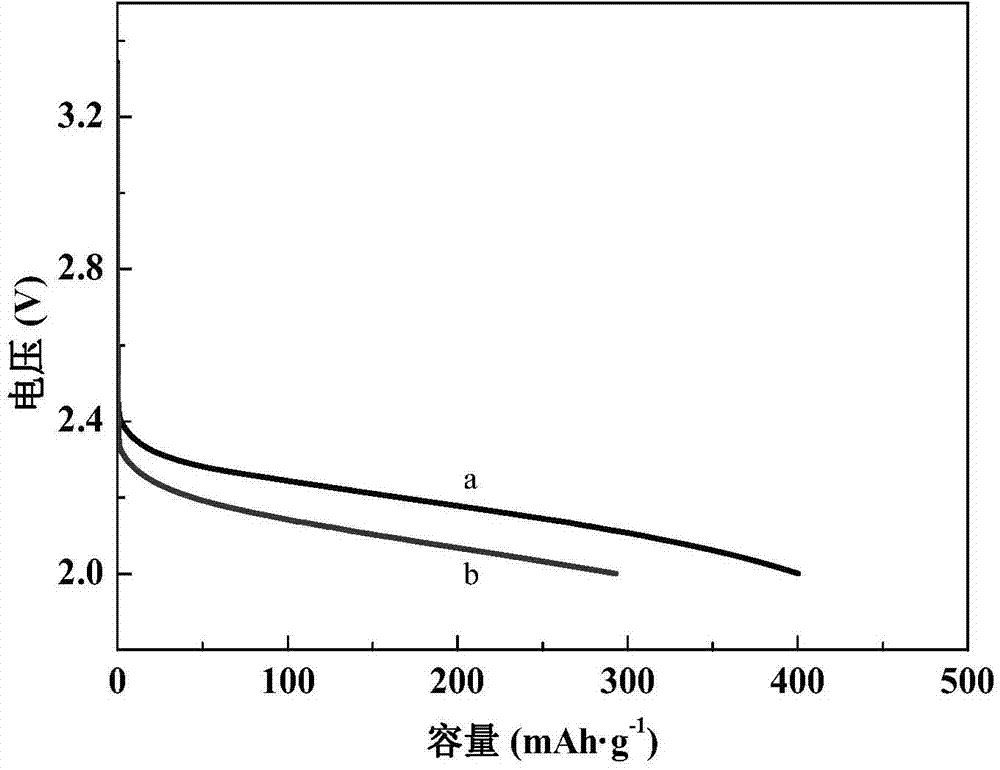

Preparation method of micro-nano lithium ferric phosphate (LiFePO4) positive electrode material of lithium-ion battery

The invention discloses a preparation method of a micro-nano lithium ferric phosphate (LiFePO4) positive electrode material of a lithium-ion battery and belongs to the technical field of preparation of an energy source material. The method comprises the following steps of: uniformly mixing a nano-sized precursor material, a lithium source, a carbon source and a proper amount of adhesive; obtaining a spherical LiFePO4 precursor material with micron-sized secondary particles by a dry mixing granulation process; and drying and performing high-temperature thermal treatment to obtain a spherical micro-nano LiFePO4 material, wherein the spherical micro-nano LiFePO4 material has the characteristics of high tap density, good processing performance, large specific surface area and porous property;and the battery which is assembled by the material is characterized by low temperature, good high-multiplying-power charging and discharging performance and high specific capacity. LiFePO4 powder which is prepared by the method consists of secondary micron spherical particles which are obtained by assembling primary nano particles, wherein the particle size of the primary particles is about 30 to100 nm; the mean particle size of the secondary particles is 1 to 20 mu m; the tap density can be equal to 1.2 to 1.5 g / cm<2>; discharging specific capacities of 0.1 C and 5 C at room temperature canbe equal to 145 to 152 milliampere hour per gram (mAh / g) and 120 to 130 mAh / g respectively; and the retention rate of the discharging specific capacity of 0.5 C at the temperature of 20 DEG C below zero is equal to 70 percent.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

Electrolyte and lithium ion battery comprising the same

ActiveCN105098242AImprove high temperature cycle performanceImproved magnification performanceFinal product manufactureSecondary cellsOrganic solventSulphate Ion

The application relates to an electrolyte and a lithium ion battery comprising the electrolyte. The electrolyte comprises a lithium salt, an organic solvent and additives. The additives comprise difluoro lithium phosphate and a cyclic sulphate ester compound. The electrolyte provided by the application is applied to the lithium ion battery. Specifically, after the electrolyte is applied to the lithium ion battery whose pole piece has heavy coating weight at the single-sided active substance layer, not only high-temperature cycle performance of the lithium ion battery is improved, but also the rate capability and the low-temperature discharging performance of the lithium ion battery is improved.

Owner:NINGDE AMPEREX TECH

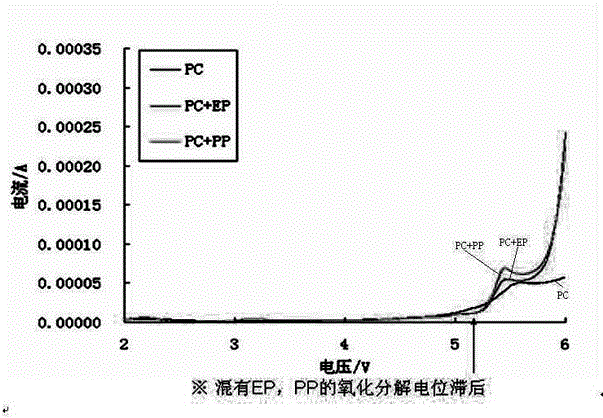

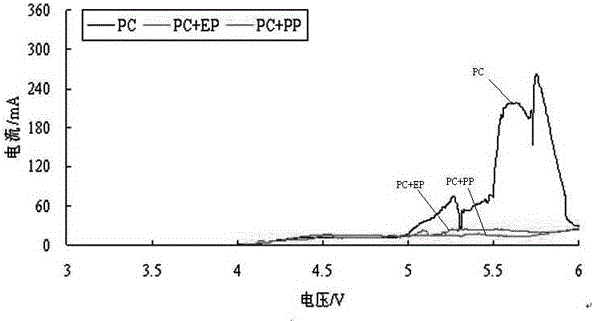

PC (Propylene Carbonate)-based high-voltage electrolyte and lithium ion battery

InactiveCN106159330APromote circulationAvoid co-insertionSecondary cellsHigh temperature storageElectrical battery

The invention provides PC (Propylene Carbonate)-based high-voltage electrolyte. The PC-based high-voltage electrolyte comprises a non-aqueous solvent, and a lithium salt and an additive which are dissolved into the non-aqueous solvent; the non-aqueous solvent comprises propylene carbonate (PC) and linear carboxylate; the mass percent content of the propylene carbonate (PC) in the electrolyte is 15%-50%; the additive comprises fluoroethylene carbonate, ethylene sulfate and a dinitrile compound. A solvent system and the additive are optimally combined and used to generate a cooperative effect and are used for a lithium ion battery, so that good cycle life, low-temperature discharging properties and high-temperature storage properties of the battery can still be kept under high voltage.

Owner:GUANGZHOU TINCI MATERIALS TECH

Isolating membrane and lithium ion secondary battery

ActiveCN103956448AIncrease liquid absorptionImprove ionic conductivityCell seperators/membranes/diaphragms/spacersLi-accumulatorsLithiumHigh absorption

The invention provides an isolating membrane and a lithium ion secondary battery. The isolating membrane comprises a microporous membrane with micropores and a coating arranged on the surface of the microporous membrane, wherein the coating comprises polymer particles and binder particles, the polymer particles are of empty shell structures, each empty shell structure comprises a shell and a cavity formed inside the shell, nanopores communicated with the cavity are distributed on the outer surface of the shell, and the diameters of the polymer particles are more than the bore diameter of the micropore of the microporous membrane; the diameters of the binder particles are more than the bore diameter of the micropore of the microporous membrane; the lithium ion secondary battery comprises a positive electrode piece, a negative electrode piece, the isolating membrane interlaid between the positive electrode piece and the negative electrode piece, and electrolyte. The isolating membrane has high absorption amount, high ionic electrical conductivity and low heat shrinkage, and the lithium ion secondary battery has good-normal temperature cycle performance, low-temperature discharge performance, rate capability and safety performance.

Owner:DONGGUAN AMPEREX TECH

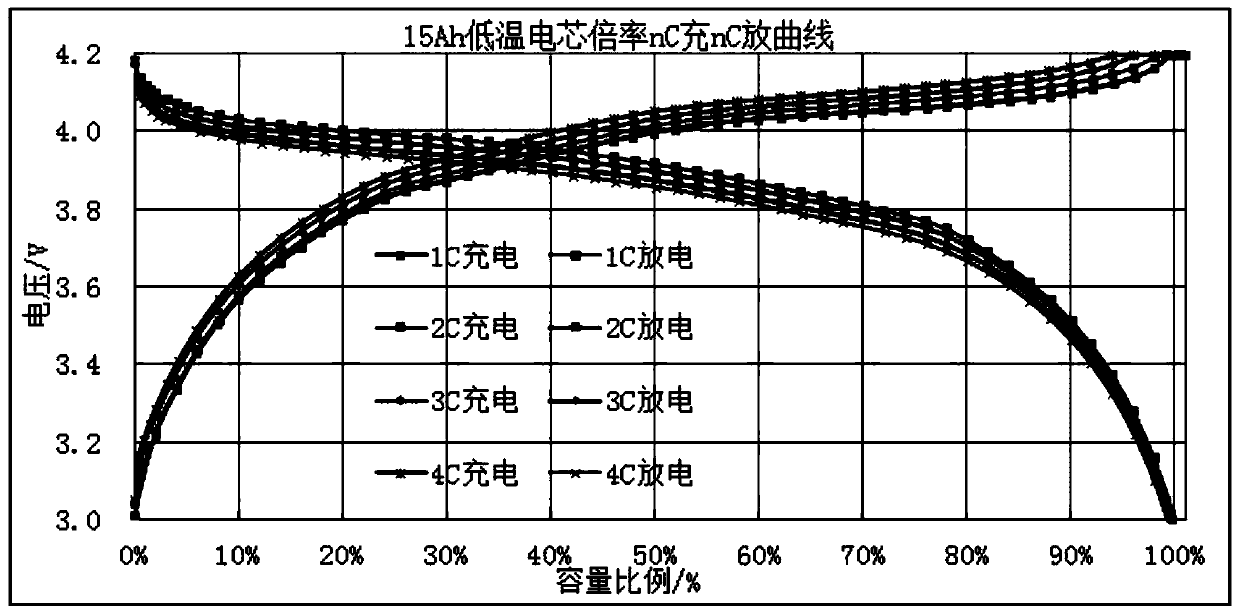

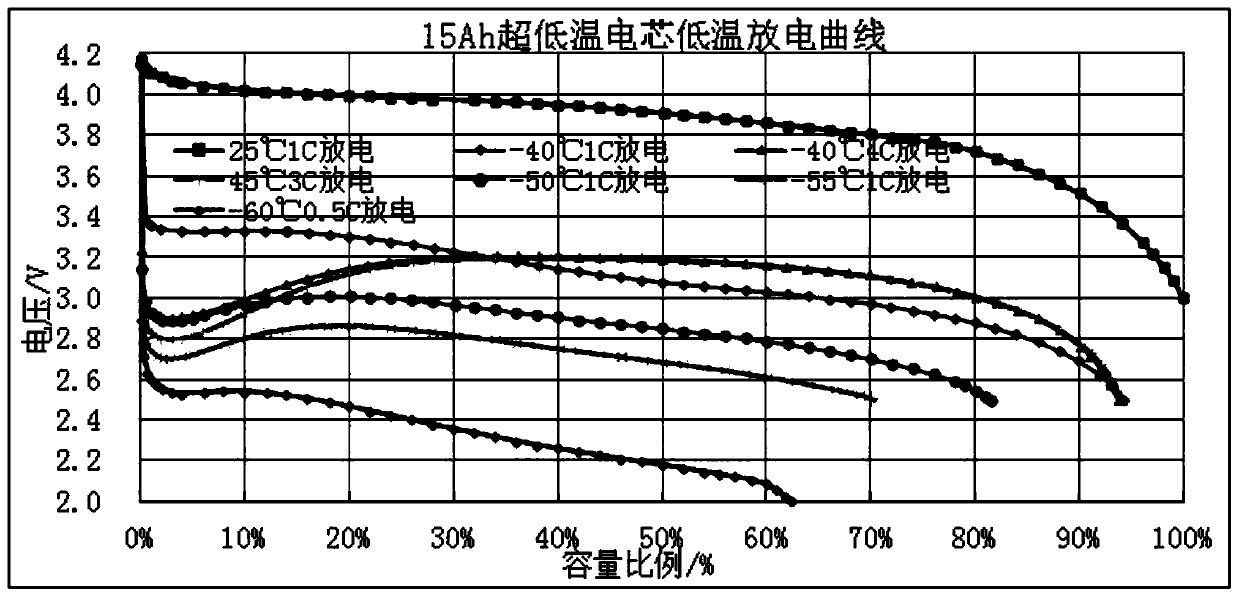

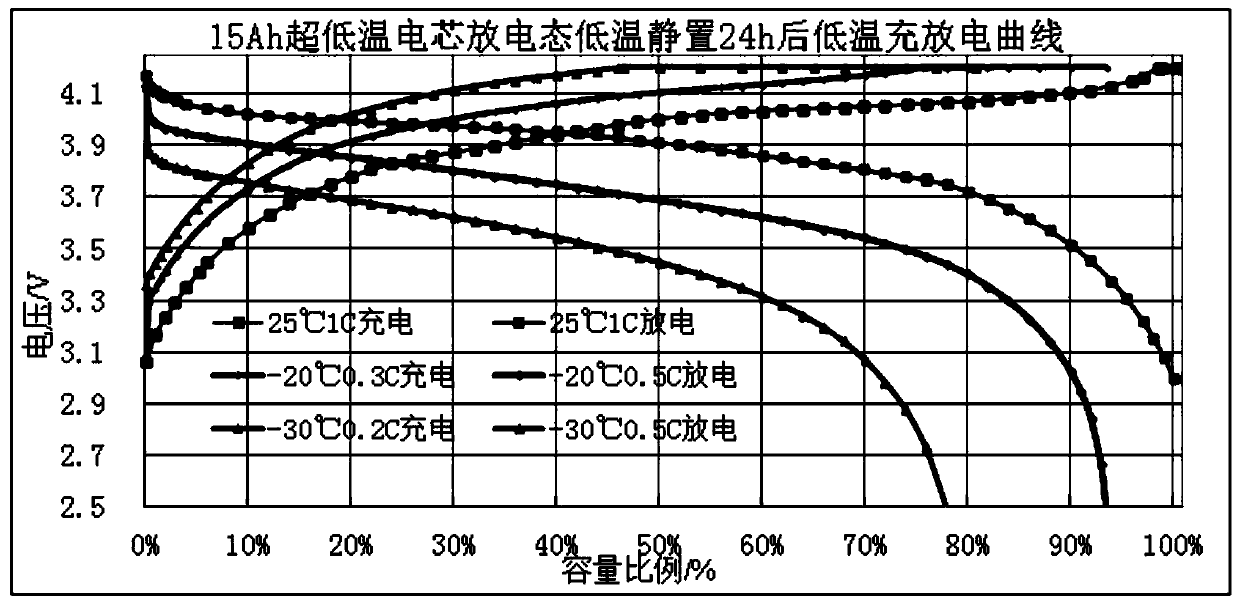

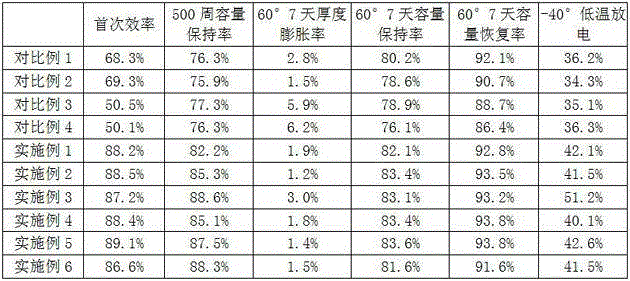

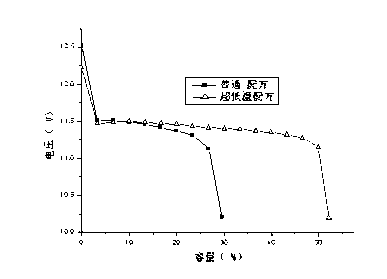

Ultralow temperature and high-rate lithium ion battery and preparation method thereof

ActiveCN109786724AImprove low temperature discharge performanceImprove low temperature charging performanceElectrode manufacturing processesFinal product manufactureWater basedHigh rate

The invention discloses an ultralow temperature and high-rate lithium ion battery and a preparation method thereof. The lithium ion battery comprises a positive plate, a negative plate, an isolation membrane and electrolyte; the positive plate is prepared from the components in mass percent: 92.5-94.0% of lithium manganate, 3.5-4.0% of composite conductive agent, and 2.5-3.5% of water-based binder; the negative plate is prepared from the components in mass percent:93.0-94.0% of graphite, 3.0-3.5% of composite conductive agent and 3.0-3.5% of water-based binder. The composite conductive agent in each of the positive plate and the negative plate is prepared from acetylene black, carbon nano-tube and graphene. For improving the conductivity of the electrode plate, reducing the polarization and improving the electric conductivity of the electrolyte at low temperature, the rate performance, the low-temperature charging / discharging performance and the safety performance of the lithium battery are effectively improved by optimizing the material collation and matching and like angles. The ultralow temperature and high-rate lithium ion battery disclosed by the invention breaks through the low-temperature application limitation of the existing lithium ion technology, greatly improves the electric chemistry performance of the lithium ion battery under the ultra-low temperature condition,and provides the guarantee for the application in the alpine region and military project.

Owner:贵州省铜仁华迪斯新能源有限公司

Lithium cell utilizing foamed nickel material as current-collecting body and producing method thereof

InactiveCN1707831AImprove electron conduction pathwaysImproved ability to work with heavy loadsElectrode carriers/collectorsNickel electrodeHeavy load

The present invention is lithium cell with foamed nickel material as current collector and its making process. This kind of lithium cell is obtained through the process including ultrasonic wave treatment, coating, and rolling or negative pressure adsorption to fill active matter, copper powder, PTFE emulsion, distilled water and alcohol into foamed nickel electrode. The lithium cell making process includes main steps of compounding material, filling, drying, pressurizing, etc. The present invention has obviously lowered electrochemical polarization of lithium cell, improved electron conducting path of electrode, improved heavy load work capacity, low temperature performance, lagging characteristic, etc of cell, and raised safety performance.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

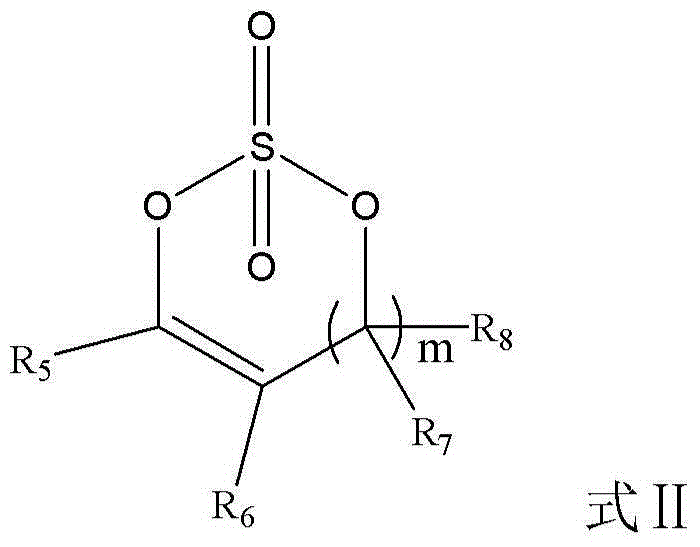

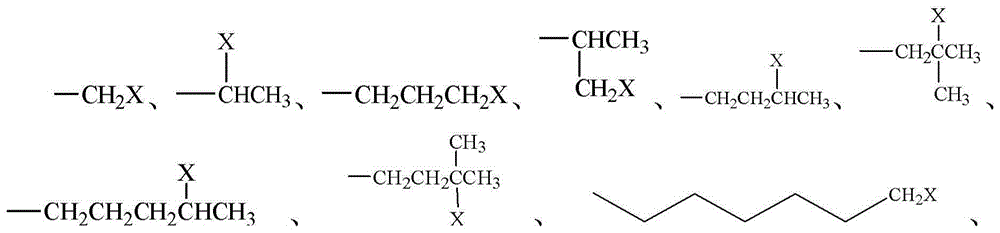

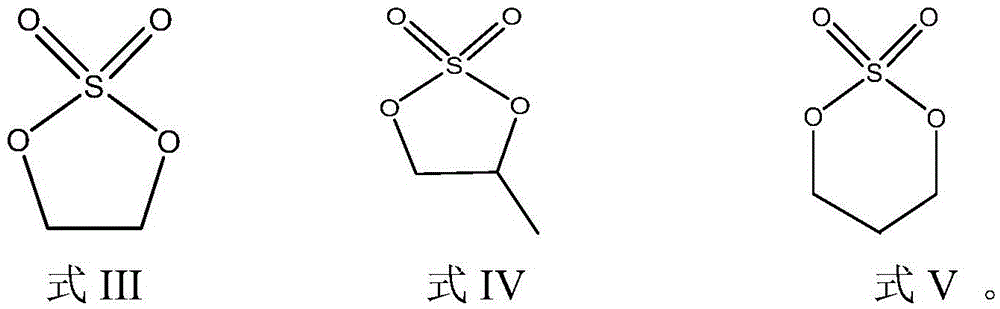

Electrolyte employing propylene carbonate as main solvent and lithium-ion battery

InactiveCN105186034AImprove cycle performanceImprove low temperature discharge performanceSecondary cellsElectrolytesElectrolytic agentElectrical battery

The invention discloses an electrolyte employing propylene carbonate as a main solvent and a lithium-ion battery. The electrolyte is prepared from a lithium salt, an organic solvent and an additive, wherein the organic solvent comprises the propylene carbonate and other non-aqueous solvents; the propylene carbonate is 10%-60% of total mass of the electrolyte; the additive comprises a conventional film-forming additive and a novel functional additive AB or AXB; the content of the conventional film-forming additive in the electrolyte is 0.1%-10%; and the molar concentration of the functional additive is 0.001mol / L to 0.1mol / L, preferably 0.03mol / L to 0.06mol / L. According to the functional additive of the electrolyte, an electrolyte system can be prompted to form stable interfacial films on the surfaces of a cathode and an anode; a propylene carbonate solvent is effectively restrained from being embedded into a graphite layer along with lithium ions; and the initial efficiency, the cycle performance and the low-temperature discharge property of the battery are effectively improved.

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

Electrolyte and secondary lithium battery

ActiveCN108123172AGood high temperature cycle performanceImprove high temperature storage performanceLi-accumulatorsOrganic electrolytesHigh temperature storageDifluorophosphate

The invention provides an electrolyte and a secondary lithium battery. The electrolyte comprises a lithium salt, an organic solvent and additives. The additives include fluoroborate and lithium difluorophosphate. When the electrolyte is applied to the secondary lithium battery, the secondary lithium battery simultaneously has excellent high-temperature cycle performance, high-temperature storage performance, low-temperature discharge performance and large-rate charge performance, and the low-temperature lithium precipitation of the secondary lithium battery is also significantly suppressed.

Owner:CONTEMPORARY AMPEREX TECH CO

Non-aqueous electrolyte and lithium ion battery containing same

ActiveCN105633466AImprove high temperature cycle performanceImprove low temperature discharge performanceSecondary cells servicing/maintenanceOrganic electrolytesOrganic solventSulphate Ion

The invention relates to a non-aqueous electrolyte and a lithium ion battery containing the same. The electrolyte comprises a lithium salt, an organic solvent and additives, wherein the additives comprise cyclic annular sulphate compound and a sodium salt. When the electrolyte provided by the invention is applied to the lithium ion battery, the high-temperature cycling performance of the lithium ion battery is improved; and meanwhile, the rate capability and the low-temperature discharging performance of the lithium ion battery are greatly improved, and lithium separating out in the low-temperature charging process is lowered.

Owner:NINGDE AMPEREX TECH

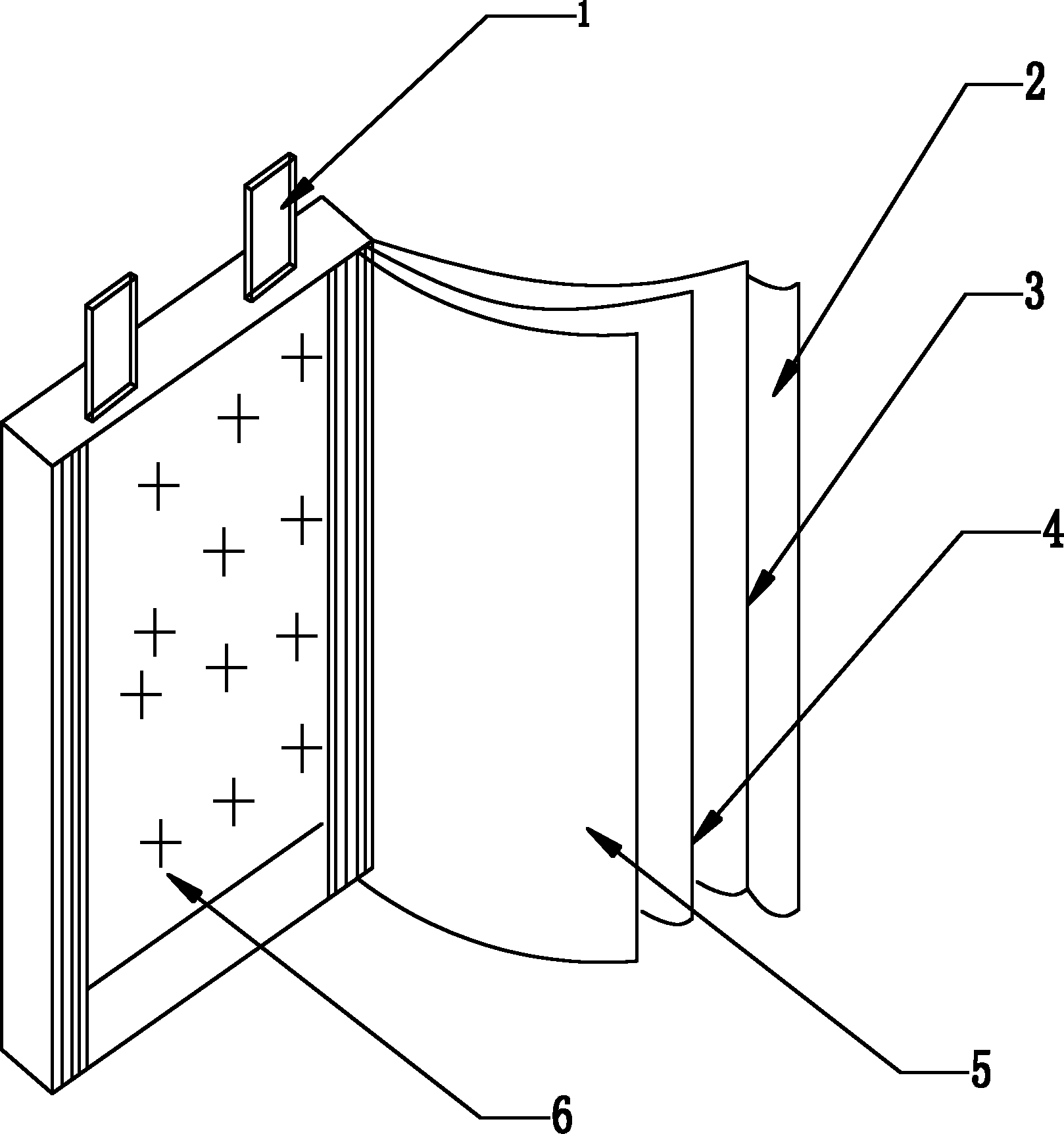

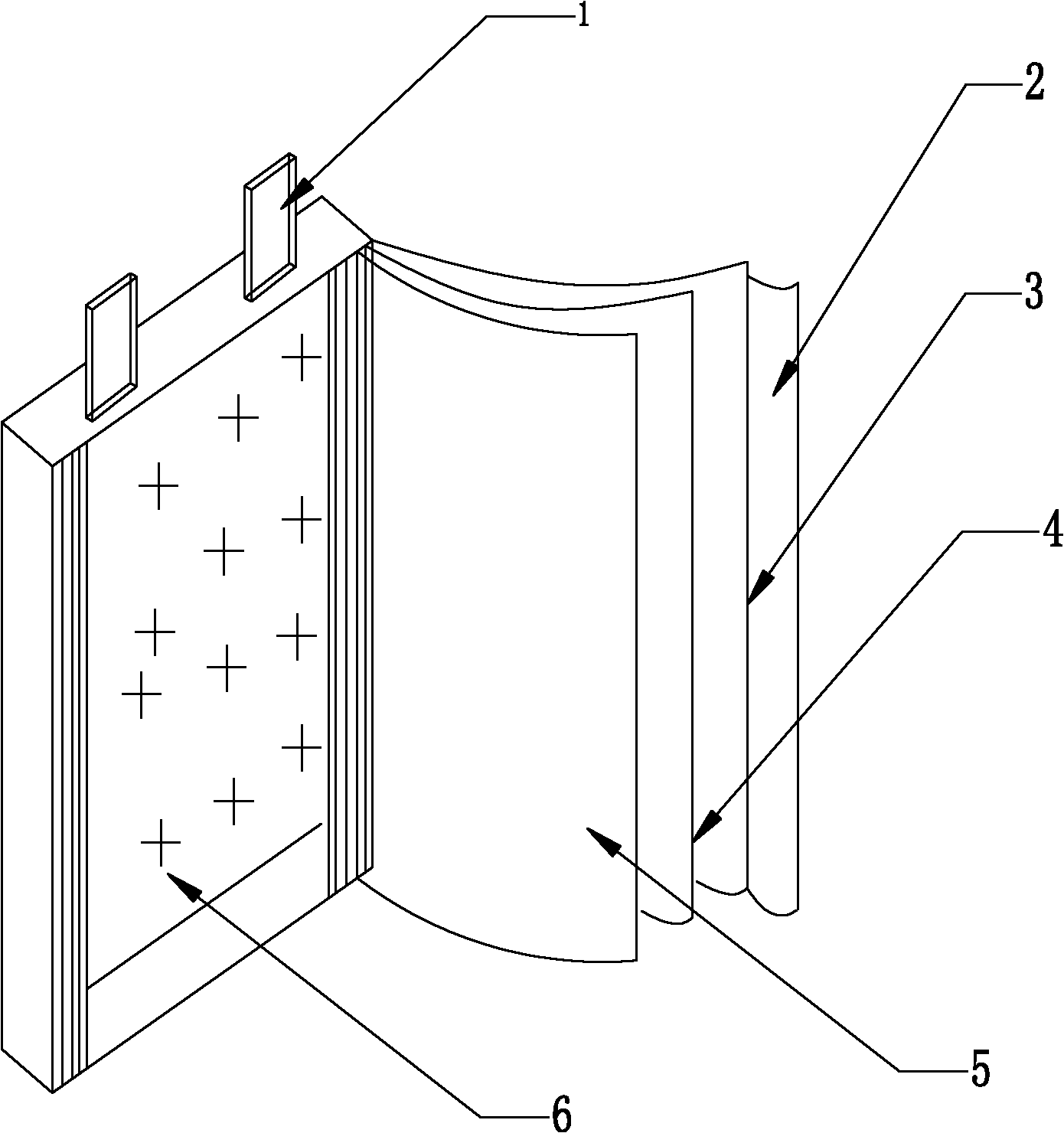

Polymer lithium ion low-temperature battery

InactiveCN102013517AImprove performanceIncrease specific energyCell electrodesSecondary cellsFiberCarbon fibers

The invention discloses a polymer lithium ion low-temperature battery. The compaction thickness of an anode plate (3) is between 53 and 82mu m, an anode active material is one or more of lithium manganate, lithium nickel cobalt manganate and lithium cobaltate, an adhesive is polyvinylidene fluoride, a conductive agent is one or more of flake graphite, acetylene with the specific surface area of 1,500+ / -200m<2> / g, vapor grown carbon fibers (VGCF) and carbon nano-fibers (CNF), and the weight percentage ratio of the anode active material to the adhesive to the flake graphite to the acetylene to the VGCF is 85-96:1-5:1-3:1-4:1-3; and the compaction thickness of a cathode plate (5) is between 56 and 62mu m, a cathode active material is one or two of artificial graphite and mesocarbon microbeads, an adhesive is one or more of the polyvinylidene fluoride, styrene butadiene rubber (SBR) and carboxymethylcellulose (CMC), a conductive agent is one or more of conductive carbon black, the VGCF and the CNF, and the weight percentage ratio of the cathode active material to the SBR to the CMC to the carbon black to the VGCF is 85-96:1-5:1-3:1-4:1-3. The polymer lithium ion low-temperature battery has high low-temperature discharge performance, discharge rate, specific energy and safety, and stable product performance.

Owner:HUNAN TIANHENG NEW ENERGY

Valve-controlled type lead-acid storage battery

ActiveCN103280582AFacilitate penetrationImprove low temperature discharge performanceCell electrodesFinal product manufactureFiberEngineering

The invention discloses a valve-controlled type lead-acid storage battery. Lead plaster in a positive plate of the valve-controlled type lead-acid storage battery comprises the following active substances in percentage by weight: 68%-81% of lead powder, 3%-12% of red lead, 0.05%-0.15% of short fiber, 7%-11% of deionized water, 5%-10% of sulphuric acid with the density of 1.4g / mL and 0.2%-1% of additive; and the lead plaster in a negative plate of the valve-controlled type lead-acid storage battery comprises the following active substances in percentage by weight: 68%-82% of lead powder, 0.1%-0.3% of short fiber, 6%-15% of deionized water, 5%-15% of sulphuric acid with the density of 1.4g / mL, 0.1%-0.5% of acetylene black, 0.1%-1% of humic acid, 0.1%-1% of lignin and 0.5%-0.8% of barium sulfate. The valve-controlled type lead-acid storage battery produced according to the formulas of a positive electrode and a negative electrode has the advantages that the low-temperature discharge performance is substantially improved, and the discharge capacity at -40 DEG C reaches above 50% of the normal capacity.

Owner:武汉长光电源有限公司

Method for synthesizing ferric phosphate material

The invention relates to a method for synthesizing a ferric phosphate material, belonging to the technical field of lithium ion cathode materials. The method for synthesizing the ferric phosphate material comprises the following steps of: (1) manufacturing a hollow spherical template: stirring oil with carbon hydrogen bonds and a water-soluble surfactant free of metal ions for 0.1-10 h in a water solution to form an emulsion, wherein the weight ratio of the oil to the surfactant is 1:(1-9), and the total weight of the oil and the surfactant accounts for 0.1-5% of the solution; (2) precipitating ferric phosphate: adjusting the pH value of an acid solution containing phosphates and ferric salts by using the emulsion to form ferric phosphate precipitate, wherein the precipitate is adhered to an emulsion microsphere to form a structure of which the exterior is ferric phosphate and the kernel is the emulsion microsphere; and (3) processing the ferric phosphate microsphere: filtering and drying the ferric phosphate microsphere, calcining the ferric phosphate microsphere at high temperature to form a hollow / shell structure microsphere ferric phosphate material. The method provided by the invention has the advantages of simple process, operation convenience, stable ferric phosphate microsphere, large rate discharge capacity and low temperature capacity and the like.

Owner:天津恒普科技发展有限公司

Synthesis method of high-purity fluorine-doped lithium iron phosphate anode material

InactiveCN101867041ALow priceThe synthesis process is simpleCell electrodesLithium iron phosphateSynthesis methods

The invention relates to a synthesis method of high-purity fluorine-doped lithium iron phosphate anode material, which belongs to the field of the electro-chemistry energy storage material. The invention relates to an F-doped in-situ wrapped LiFePO4 material, i.e. LiFe(PO4)1-x / 3Fx / C material. Analytical reagent LiOH.H2O, FeC2O4.2H2O, NH4H2PO4 is mixed with fluoride, carbon source is added into the mixture, and the mixture is spherically ground and dried to obtain a precursor. The precursor which is obtained in the previous step is roasted in two steps, and the precursor is firstly pre-heated and then is further roasted to obtain the product. The method has the advantages of low cost of raw materials, simple synthesis process, easy realization, high purity of product, high yield and the like; and has high magnification discharging performance and low-temperature discharging performance, and greatly improves the magnification performance, platform voltage and low-temperature performance of the LiFePO4 battery.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Novel electrolyte of lithium-ion battery and preparation method thereof

The invention discloses novel electrolyte of a lithium-ion battery and the preparation method thereof. When the negative pole piece of the lithium-ion battery is in a high voltage state, the electrolyte comprises the following raw material components by weigh percentage: 75 to 85 percent of organic solvent, 10 to 15 percent of lithium salt and 5 to 10 percent of additive, wherein the additive comprises an organic compound, which can form a good SEI (Solid Electrolyte Interface) film in the battery; and the amount of the added organic compound is 0.1 to 3 percent of the total weight. The preparation method comprises the following steps: a, providing a glove box filled with argon, of which the concentration of H2O is less than 100 ppm; b, weighing the organic solvent, the lithium salt and the additive according to corresponding weight; and c, adding the organic solvent, the lithium salt and the additive into the glove box sequentially, and then stirring sufficiently and uniformly to obtain the electrolyte of the lithium-ion battery. According to the invention, after the organic compound is added, the infiltration effect of the electrolyte to high voltage real negative pole material is improved, and in addition, a good SEI film can be formed by the electrolyte to improve the stability of the electrolyte.

Owner:DONGUAN KAIXIN BATTERY MATERIAL

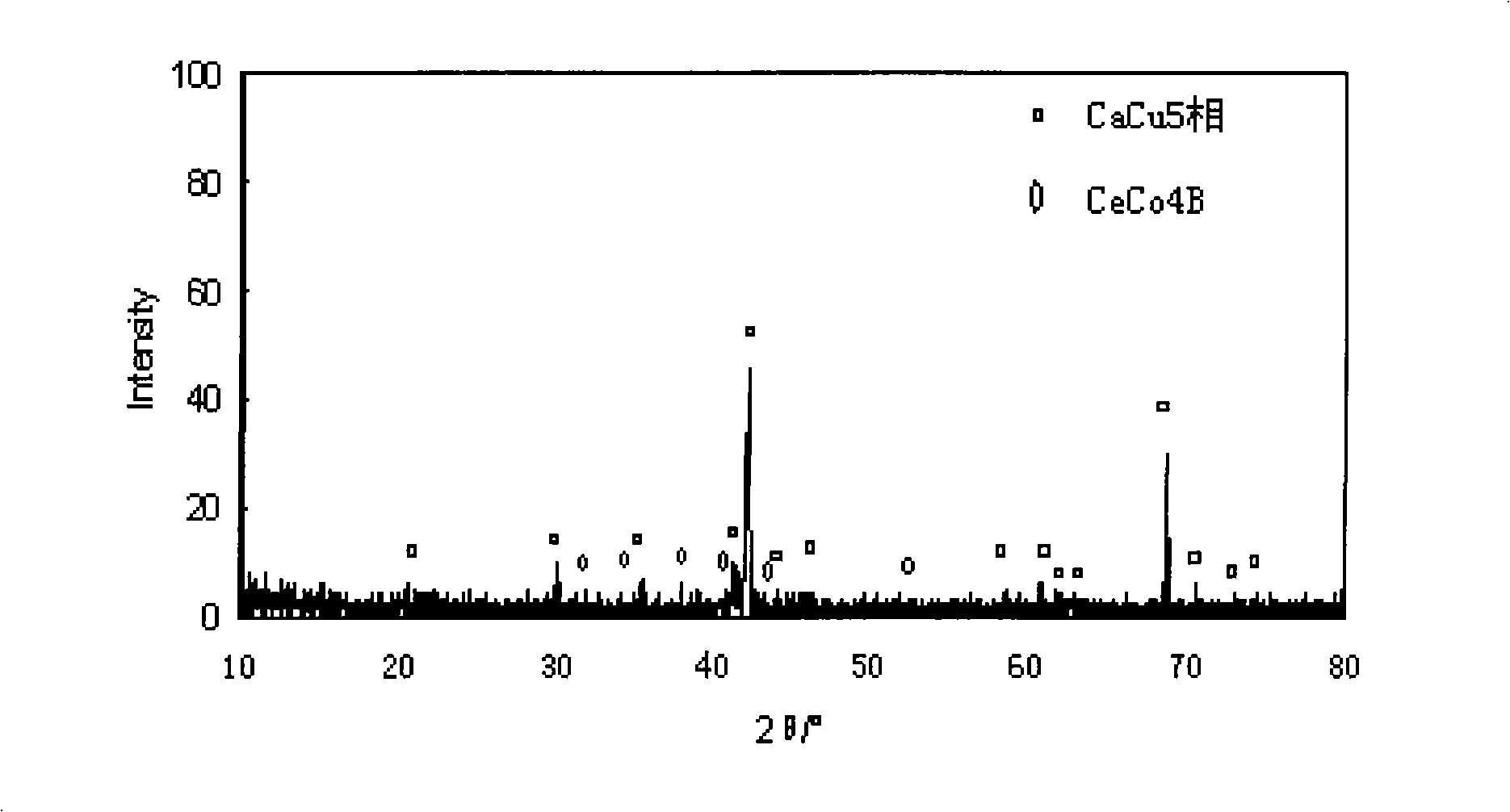

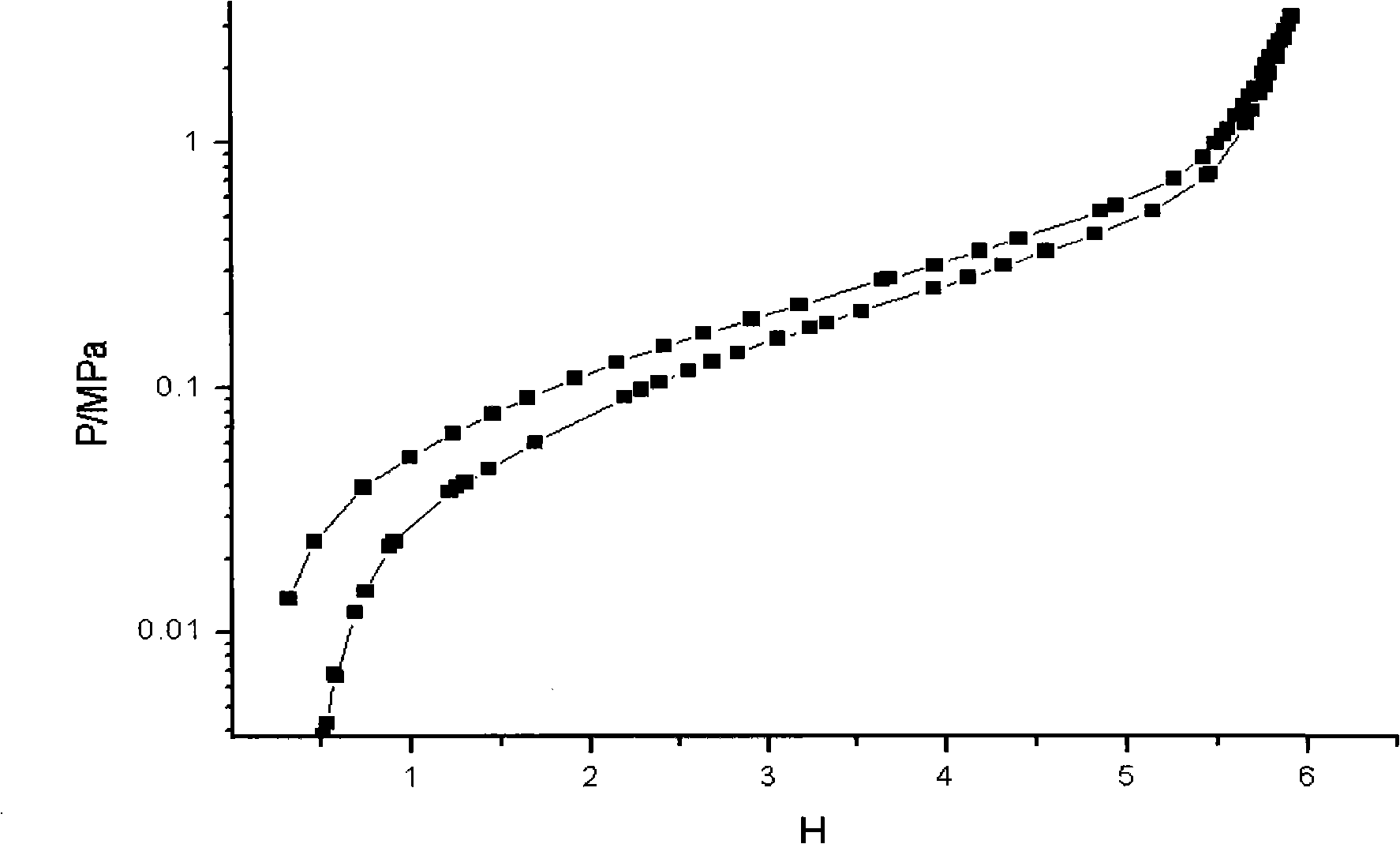

Hydrogen storage alloy for low temperature Ni-MH power cell

InactiveCN101320801AImprove high-current discharge performanceImprove low temperature discharge performanceCell electrodesNickel accumulatorsPower batteryNickel–hydrogen battery

A hydrogen-storing alloy for low temperature nickel-hydrogen power battery is disclosed, having the constituent atom rates as below: La1-x-y-zCexPryNdzNuaCobMncAldBe, wherein x=0.45-0.60, y=0.05-0.07, z=0.15-0.21, a=3.50-3.80, b=0.40-0.65, c=0.25-0.45, d=0.10-0.35, and e=0.05-0.15. The hydrogen-storing alloy can generate the second phase of CeCo4 B-type with high catalysis activeness so as to improve high-current discharge performance and low temperature discharge performance of the hydrogen-storing alloy, therefore the invention can not only be used for the low temperature nickel-hydrogen battery used on condition of -40 DEG C, but still possess excellent high-current discharge performance on condition of -2 DEG C.

Owner:GUANGDONG INST OF RARE METALS

Graphene ultralow-temperature power lithium battery

ActiveCN105390695AImprove conductivityChange smoothing structureMaterial nanotechnologyCell electrodesLithium iron phosphateNanoparticle

The invention discloses a graphene ultralow-temperature power lithium battery. The power lithium battery comprises a battery case, a negative electrode insulation sheet, a battery cell, a positive electrode insulation sheet and a cap. The battery cell comprises a positive electrode plate, a negative electrode plate and a diaphragm. The positive electrode plate comprises a positive electrode current collector, and positive electrode material coatings arranged on two side surfaces of the positive electrode current collector respectively; each positive electrode material coating is prepared by coating the surface of the positive electrode current collector with a positive electrode material mixture; and the positive electrode material mixture contains a nanoparticle positive electrode material, a positive electrode binder, a positive electrode mixed conductive agent and a positive electrode solvent, wherein the nanoparticle positive electrode material is a lithium iron phosphate nanoparticle, and the positive electrode mixed conductive agent contains, by weight, 97-99 parts of a positive electrode conductive agent base material, 0.2-0.4 parts of graphene, 0.2-0.4 parts of SP and 0.2-0.4 parts of KS-6.

Owner:王立军

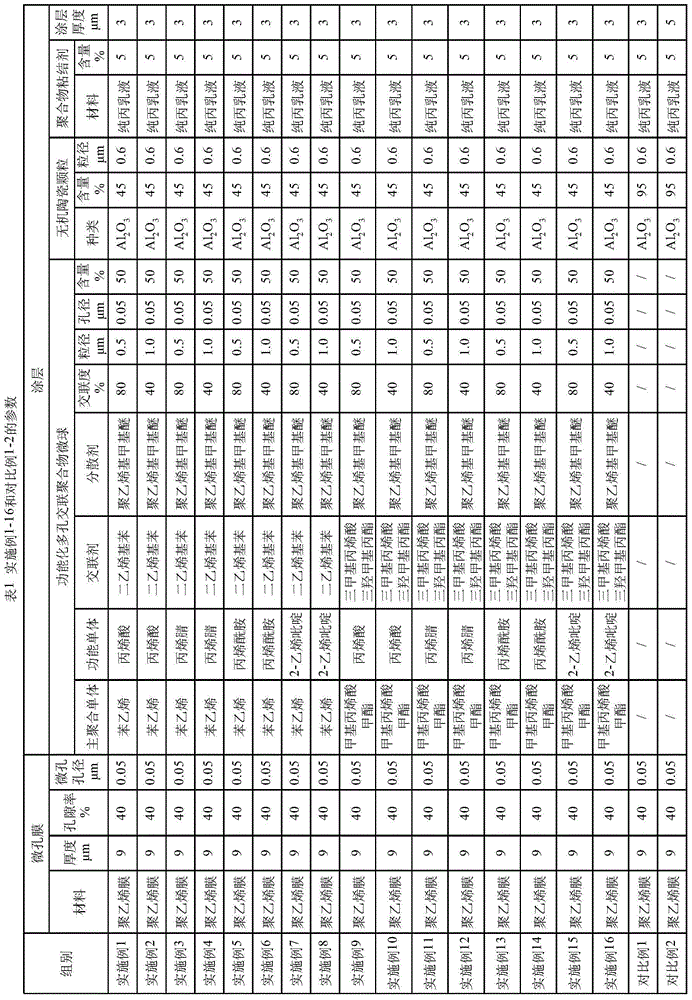

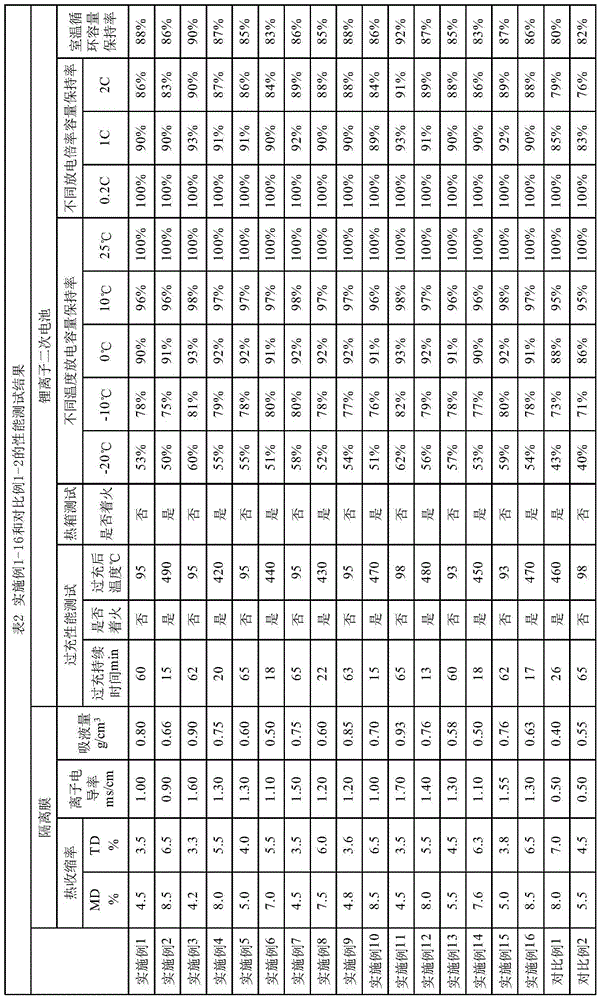

Isolation membrane and lithium ion secondary battery

ActiveCN106328865AImprove ionic conductivityIncrease liquid absorptionSecondary cellsCell component detailsCross-linkLithium

The invention provides an isolation membrane and a lithium ion secondary battery. The isolation membrane comprises a microporous membrane with micropores, and a coating layer which is coated on the surface of the microporous membrane, wherein the coating layer comprises functionalized porous cross-linked polymer microspheres, inorganic ceramic particles and a polymer binder; the functionalized porous cross-linked polymer microspheres comprise functionalized cross-linked polymer; the functionalized cross-linked polymer comprises functionalized groups; and the functionalized groups are selected from one or more of carboxyl, hydroxyl, cyano, acylamino, and amino. The lithium ion secondary battery comprises the isolation membrane. The isolation membrane provided by the invention has relatively high liquid absorption amount, relatively high ionic conductivity and relatively low thermal shrinkage. The lithium ion secondary battery provided by the invention has relatively high safety performance, low-temperature discharge performance, rate capability, and room-temperature cycle performance.

Owner:CONTEMPORARY AMPEREX TECH CO

Lithium secondary battery electrolyte solution and lithium secondary battery containing lithium secondary battery electrolyte solution

ActiveCN108539270AImprove normal temperature cycle performanceImprove high temperature storage performanceSecondary cells servicing/maintenanceHigh temperature storageOrganic solvent

The invention relates to a lithium secondary battery electrolyte solution and a lithium secondary battery containing the lithium secondary battery electrolyte solution. The lithium secondary battery electrolyte solution is prepared from organic solvent, conductive lithium salt, a double (triflyl) amine replaced by a phenyl group or a pyridyl group and an additive. According to the electrolyte solution, by adding the double (triflyl) amine replaced by the phenyl group or the pyridyl group and triallyl isocyanurate and 2-propinyl methyl carbonate in a combined mode, the normal temperature cycleperformance, the high temperature storage performance and the low temperature discharging performance of the electrolyte solution can be improved.

Owner:GUANGZHOU TINCI MATERIALS TECH

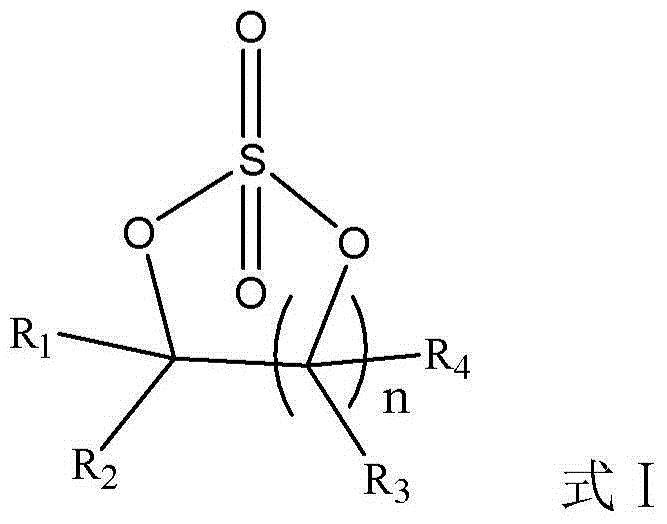

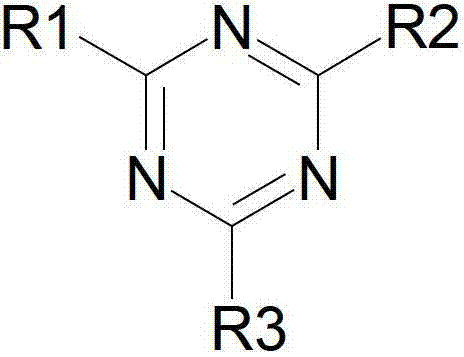

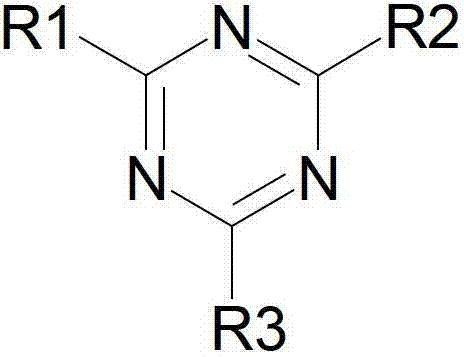

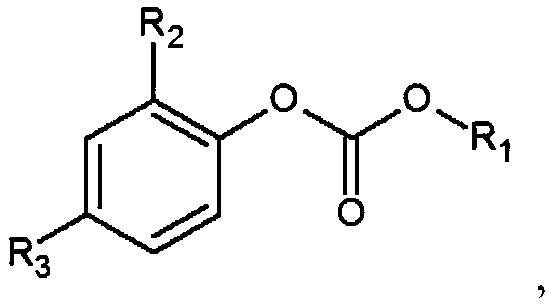

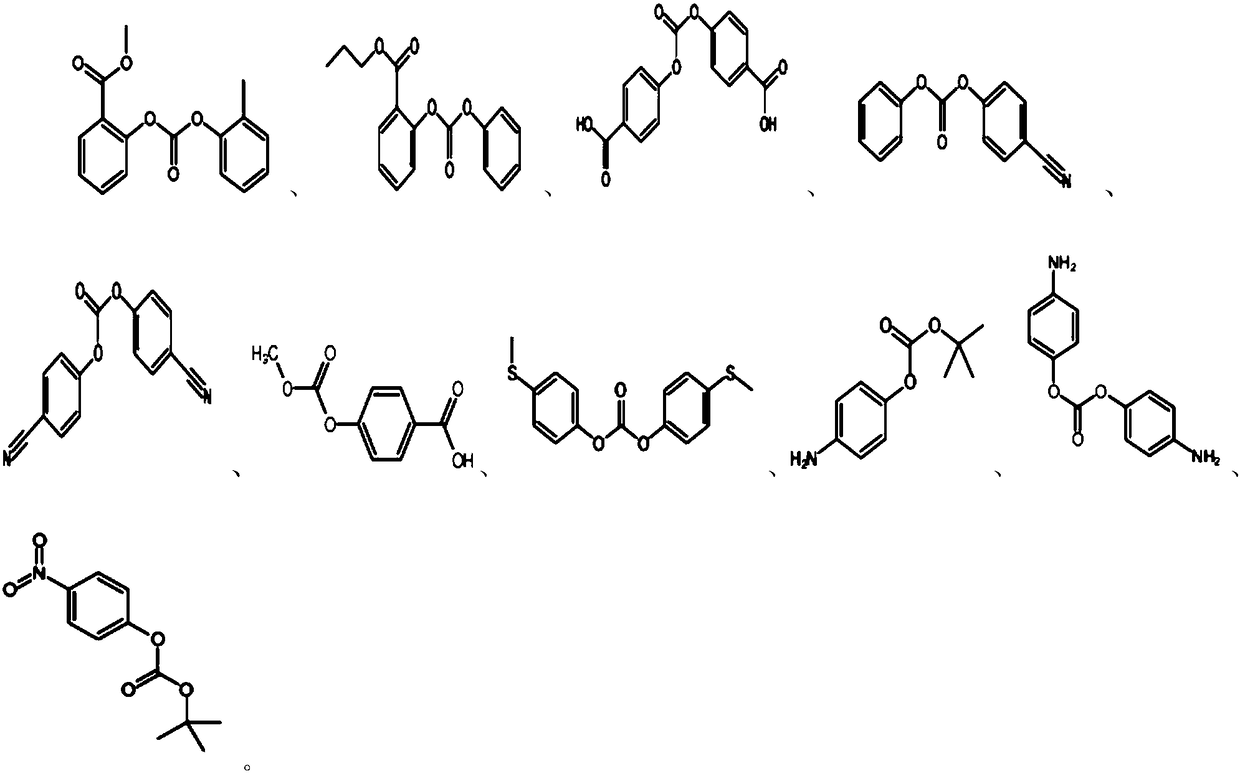

Non-aqueous electrolyte and lithium ion battery

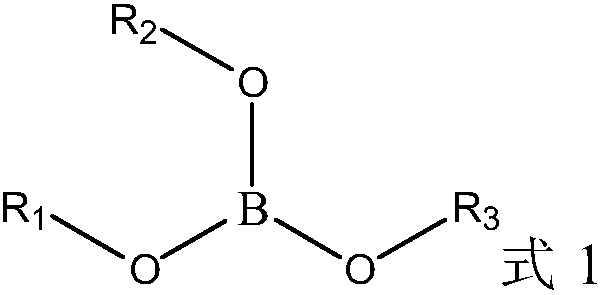

ActiveCN109390628AImprove high temperature storage performanceImprove low temperature discharge performanceSecondary cells servicing/maintenanceOrganic electrolytesLithium electrodeNon aqueous electrolytes

The invention relates to a non-aqueous electrolyte, comprising a lithium salt, an organic solvent and additives, wherein the additives comprise an additive A. The additive A is one or more selected from the group consisting of substances as shown in a general structural formula which is described in the specification. In the above formula, R1 is one selected from the group consisting of alkyl groups, and substituted or unsubstituted phenyl groups, wherein the substitution is partial substitution or complete substitution, and a substituent is one or more selected from the group consisting of analkyl group, a carboxyl group, a cyano group, an alkylthio group, and an amino group; and R2 and R3 are independently selected from the group consisting of hydrogen, an ester group, a carboxyl group,a cyano group, an alkylthio group, an amino group, and a nitro group, and at least one of R2 and R3 is not hydrogen. According to research results of the invention, the additive A having a structurerepresented by the general structural formula can improve the high-temperature storage performance, low-temperature discharge performance and safety performance of a battery.

Owner:宁德国泰华荣新材料有限公司

Positive electrode lead plaster of lead acid storage battery and preparation method

InactiveCN109509883AImprove low temperature discharge performanceExtended service lifeCell electrodesFiberGraphite

The invention belongs to the technical field of lead acid storage batteries, and particularly relates to positive electrode lead plaster of a lead acid storage battery. The positive electrode lead plaster of the lead acid storage battery is prepared from the following components in parts by weight: 1000 parts of lead powder, 110 to 120 parts of diluted sulfuric acid, 2.2 to 3.2 parts of graphite,1.2 to 2.2 parts of tetrabasic lead sulfate, 0.6 to 1.2 parts of short fiber, and 135 to 155 parts of water. Compared with the traditional positive electrode lead plaster of the lead acid storage battery, the positive electrode lead plaster of the lead acid storage battery has the advantages that the low-temperature discharge property of the storage battery is improved, the utilization rate of active substances is improved, the curing and formation time of a pole plate is shortened, the service life of the battery is prolonged, the emission of acid mist is reduced, and the environment is protected.

Owner:山东久力新能源集团有限公司

Low-temperature cycle iron phosphate lithium-ion power battery and preparation method thereof

ActiveCN107768667AHigh specific surface areaImprove conductivityFinal product manufactureCell electrodesPower batteryLithium iron phosphate

The invention relates to the technical field of lithium batteries, inp articular to a low-temperature cycle iron phosphate lithium-ion power battery and a preparation method of the low-temperature cycle iron phosphate lithium-ion power battery. The low-temperature cycle iron phosphate lithium-ion power battery comprises a positive electrode, a negative electrode and an electrolyte, the positive electrode comprises lithium iron phosphate, the average particle size distribution D50 of the volume of the lithium iron phosphate is 0.5-2 [mu]m, the tap density of the lithium iron phosphate is 0.8-1.5 g / cm<3>, the specific surface area of the lithium iron phosphate is 6-12 m<2> / g, the negative electrode comprises a green coke pulverized super-high temperature graphitized material, the particle size distribution D50 of the green coke pulverized super-high temperature graphitized material is 2-10 [mu]m, the tap density of the green coke pulverized super-high temperature graphitized material is1.2-2 g / cm<3>, and the specific surface area of the green coke pulverized super-high temperature graphitized material is 0.5-1.5 m<2> / g. The positive electrode and the negative electrode are modified,so that the low-temperature cycle performance of the lithium battery is improved.

Owner:江苏海四达电源有限公司

Electrolyte of high-voltage fast-charging lithium ion battery and lithium ion battery

InactiveCN111193071ALow viscosityImprove wettabilityFinal product manufactureSecondary cells servicing/maintenanceElectrolytic agentLithium-ion battery

The invention discloses an electrolyte of a high-voltage fast-charging lithium ion battery and the lithium battery. The electrolyte comprises a non-aqueous organic solvent, an electrolyte salt and anadditive, and the mass percentages of the non-aqueous organic solvent, the electrolyte salt and the additive in the electrolyte are 65%-90%, 10%-20% and 0-15% respectively. The electrolyte can improvethe normal-temperature quick charge cycle performance, the high-temperature storage performance and the low-temperature discharge performance of the high-voltage battery at the same time. The lithiumion battery prepared by adopting the electrolyte has lower surface density, is beneficial to reducing the impedance of the lithium ion battery, is smoother in lithium ion migration, can effectively improve the rate charge-discharge performance, and obviously improves the low-temperature discharge performance at the same time; the electrolyte of the high-voltage fast-charging lithium ion battery has the relatively high charging cut-off voltage, the capacity of the lithium ion battery can be improved by about 15%, and energy density reduction caused by surface density reduction is made up; andcompared with a conventional battery, the lithium ion battery has wider tabs, so that the ohmic impedance of the lithium ion battery is effectively reduced to facilitate electron transmission.

Owner:CHONGQING VDL ELECTRONICS

Lithium-ion battery electrolyte

ActiveCN104124469AWide temperature windowLow freezing pointSecondary cellsHigh temperature storageLithium-ion battery

The invention discloses a lithium-ion battery electrolyte relating to a lithium ion battery. The lithium-ion battery electrolyte comprises an organic solvent, a lithium salt and an additive, wherein the organic solvent comprises propylene carbonate, chain carboxylic ester and chain carbonic ester, wherein the content of propylene carbonate is 24-58 percent, the content of chain carboxylic ester is 9-58 percent, the content of chain carbonic ester is 0-26 percent, the content of the lithium salt is 9-16 percent, and the content of the additive is 2-10 percent; and the additive is selected from vinylene carbonate, fluoroethylene carbonate, vinyl vinylene carbonate, glycol sulfite, vinyl glycol sulfite, propylene sulfite, dimethyl sulfate or trimethylene sulfate. Propylene carbonate is used for completely replacing ethylene carbonate, and is low in melting point and high in boiling point, thus a temperature window of the electrolyte can be enlarged; and chain carboxylic ester is low in melting point and low in viscosity, thus the solidifying point and the viscosity of the electrode can be reduced, and the conductivity of the electrode is increased. PC (Poly Carbonate) co-block is inhibited by using the additive in the electrolyte, thus the film-forming property for the surface of a negative electrode can be improved, and the high-temperature storage property is improved.

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com