Polymer lithium ion low-temperature battery

A low-temperature battery, lithium-ion technology, applied in battery electrodes, secondary batteries, battery pack components, etc., can solve the problems of inability to meet high current, poor low-temperature discharge performance, short discharge time, etc., and achieve high specific energy and low temperature. The effect of good discharge performance and large discharge rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

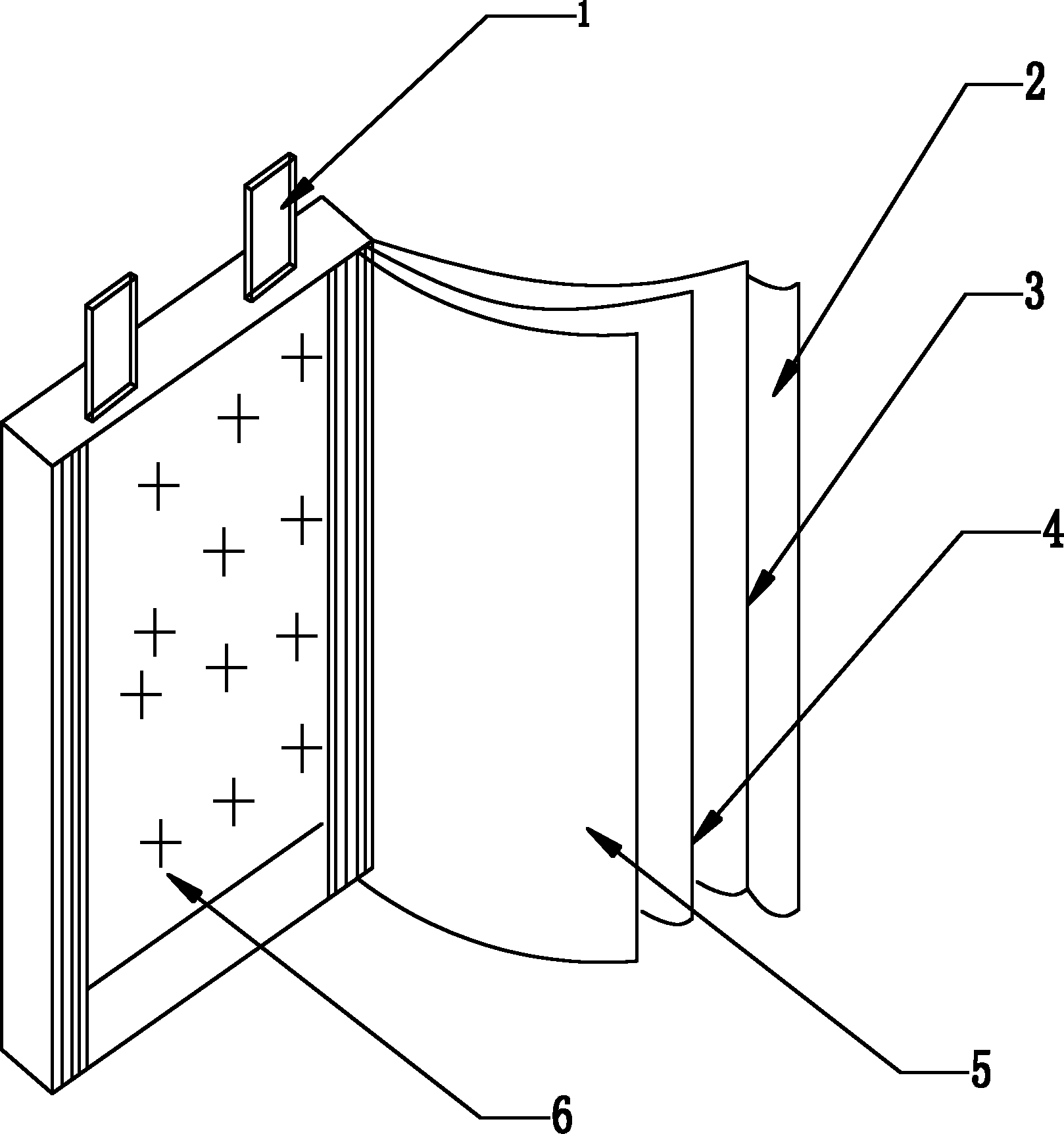

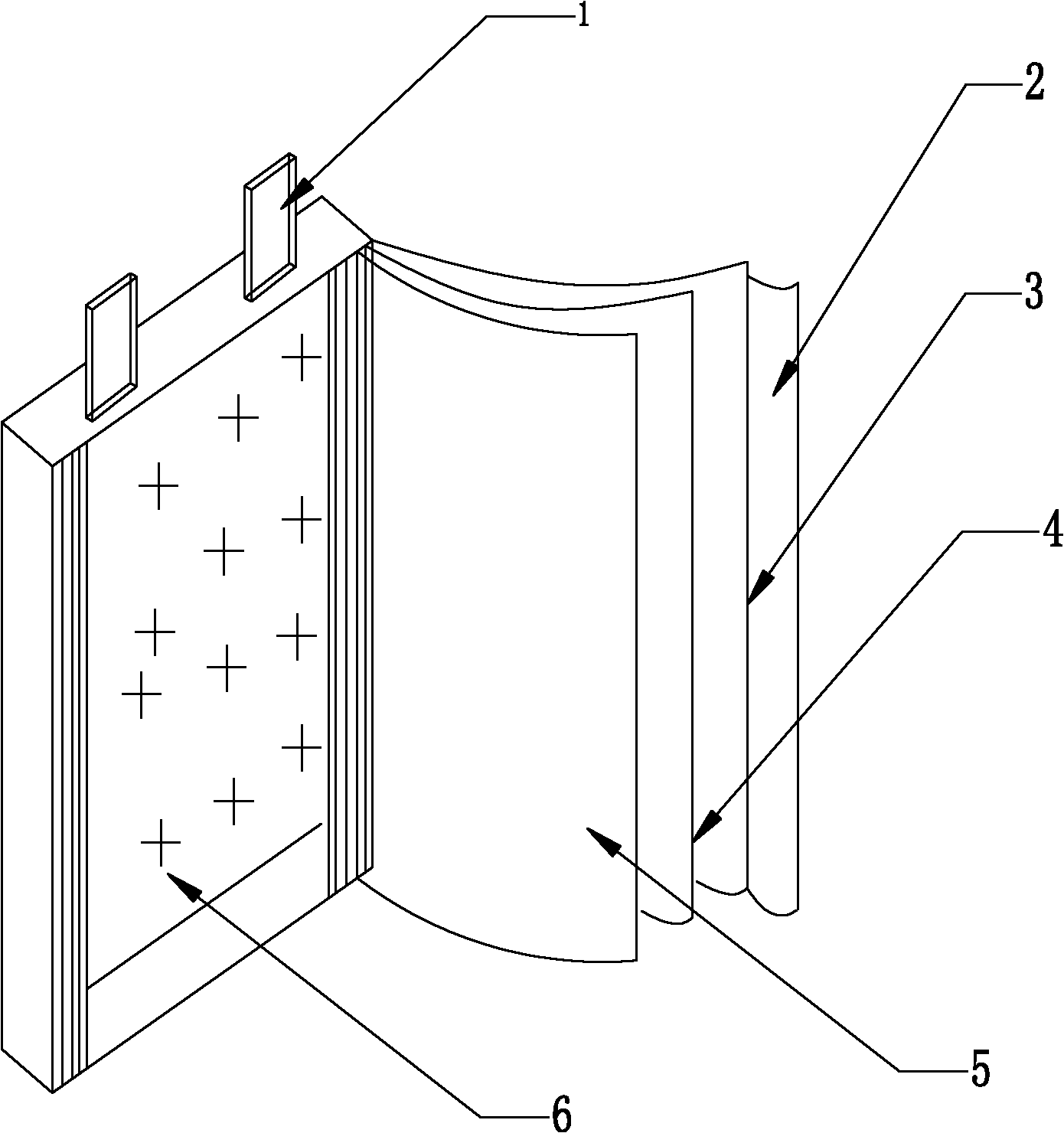

[0013] see figure 1 , The polymer lithium-ion low-temperature battery of the present invention is composed of a positive electrode sheet 3, a negative electrode sheet 5, a separator 4, an electrolyte solution 6, an aluminum-plastic film 2, and a tab 1.

[0014] Positive electrode sheet 3: the compacted thickness of the positive electrode sheet is (82±2) μm, the positive electrode active material is lithium manganate, the binder is polyvinylidene fluoride; the conductive agent is phosphor flake graphite, acetylene and VGCF; the positive electrode active material: viscose The weight percentage of adhesive: flake graphite: acetylene: VGCF is 93:2.0:1.0:2:2. After introducing VGCF, CNF and carbon black with high specific surface area, it can effectively improve the liquid absorption capacity of the electrode, directly increase the number of conductive ions and reduce the transmission distance of ions between active material particles, increase ionic conductivity and low temperatur...

Embodiment 2

[0022] The polymer lithium-ion low-temperature battery of the present invention is composed of a positive electrode sheet 3 , a negative electrode sheet 5 , a diaphragm 4 , an electrolyte 6 , an aluminum-plastic film 2 , and a tab 1 .

[0023] Positive electrode sheet 3: the compacted thickness of the positive electrode sheet is (82±2) μm, the positive electrode active material is lithium manganate, the binder is polyvinylidene fluoride; the conductive agent is phosphor flake graphite, acetylene and VGCF; the positive electrode active material: viscose The weight percentage of adhesive: flake graphite: acetylene: VGCF is 93:2.0:1.0:2:2. After introducing VGCF, CNF and carbon black with high specific surface area, it can effectively improve the liquid absorption capacity of the electrode, directly increase the number of conductive ions and reduce the transmission distance of ions between active material particles, increase ionic conductivity and low temperature Electrical condu...

Embodiment 3

[0031] The polymer lithium-ion low-temperature battery of the present invention is composed of a positive electrode sheet 3 , a negative electrode sheet 5 , a diaphragm 4 , an electrolyte 6 , an aluminum-plastic film 2 , and a tab 1 .

[0032] Positive electrode sheet 3: the compacted thickness of the positive electrode sheet is (53±2) μm, the positive electrode active material is lithium cobaltate, the binder is polyvinylidene fluoride; the conductive agent is phosphor flake graphite, acetylene and VGCF; the positive electrode active material: viscose The weight percentage of adhesive: flake graphite: acetylene: VGCF is 93.5: 1.5: 1.0: 1.8: 2.2. After introducing VGCF, CNF and carbon black with high specific surface area, it can effectively improve the liquid absorption capacity of the electrode, directly increase the number of conductive ions and reduce the transmission distance of ions between active material particles, increase ionic conductivity and low temperature Electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com