Isolating membrane and lithium ion secondary battery

A technology of isolation membrane and microporous membrane, which is applied in the direction of secondary batteries, lithium batteries, batteries, etc., can solve the problem of not being able to stop lithium-ion secondary batteries, not satisfying the long cycle life of lithium-ion secondary batteries, and the performance of electrolyte retention Increase and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

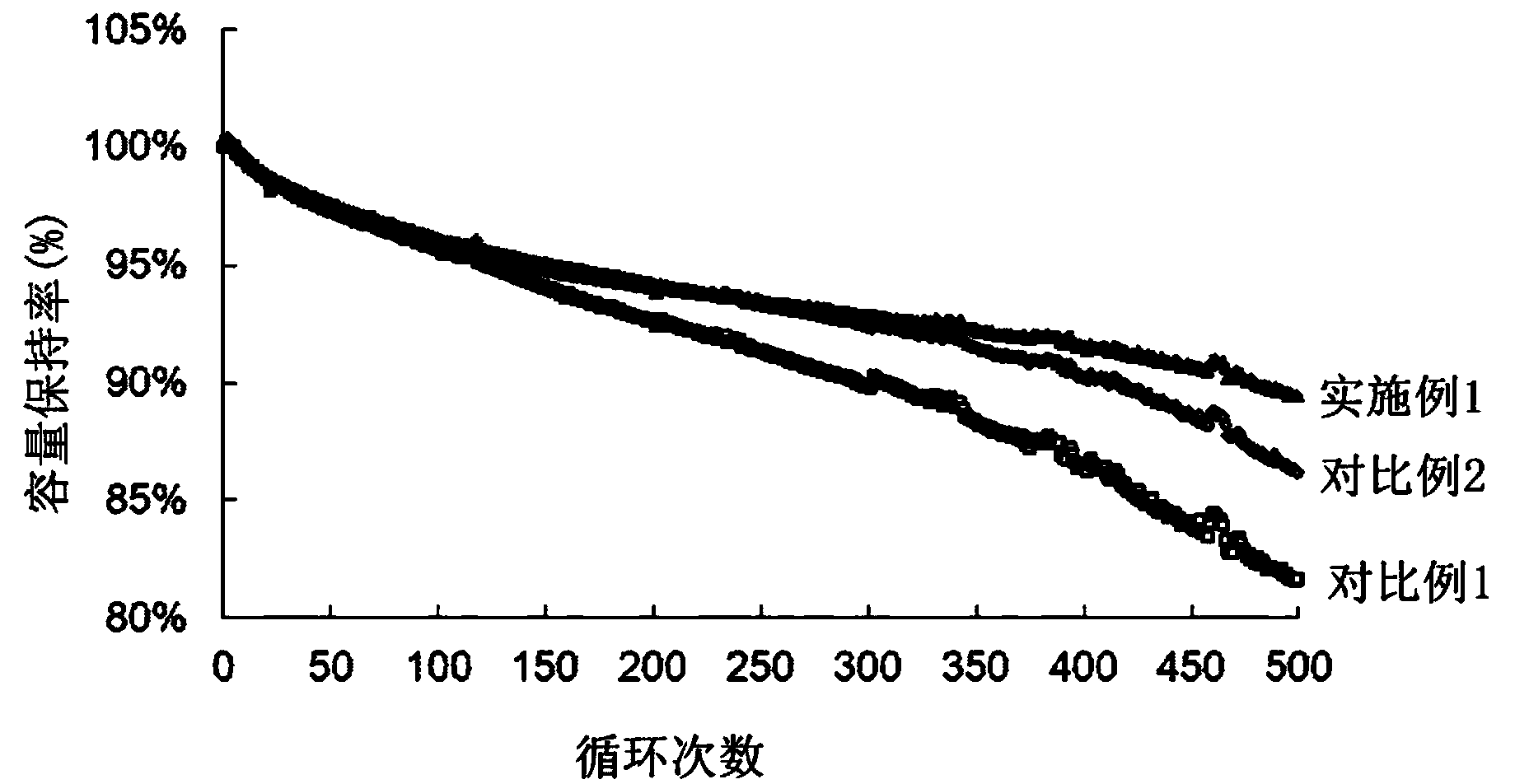

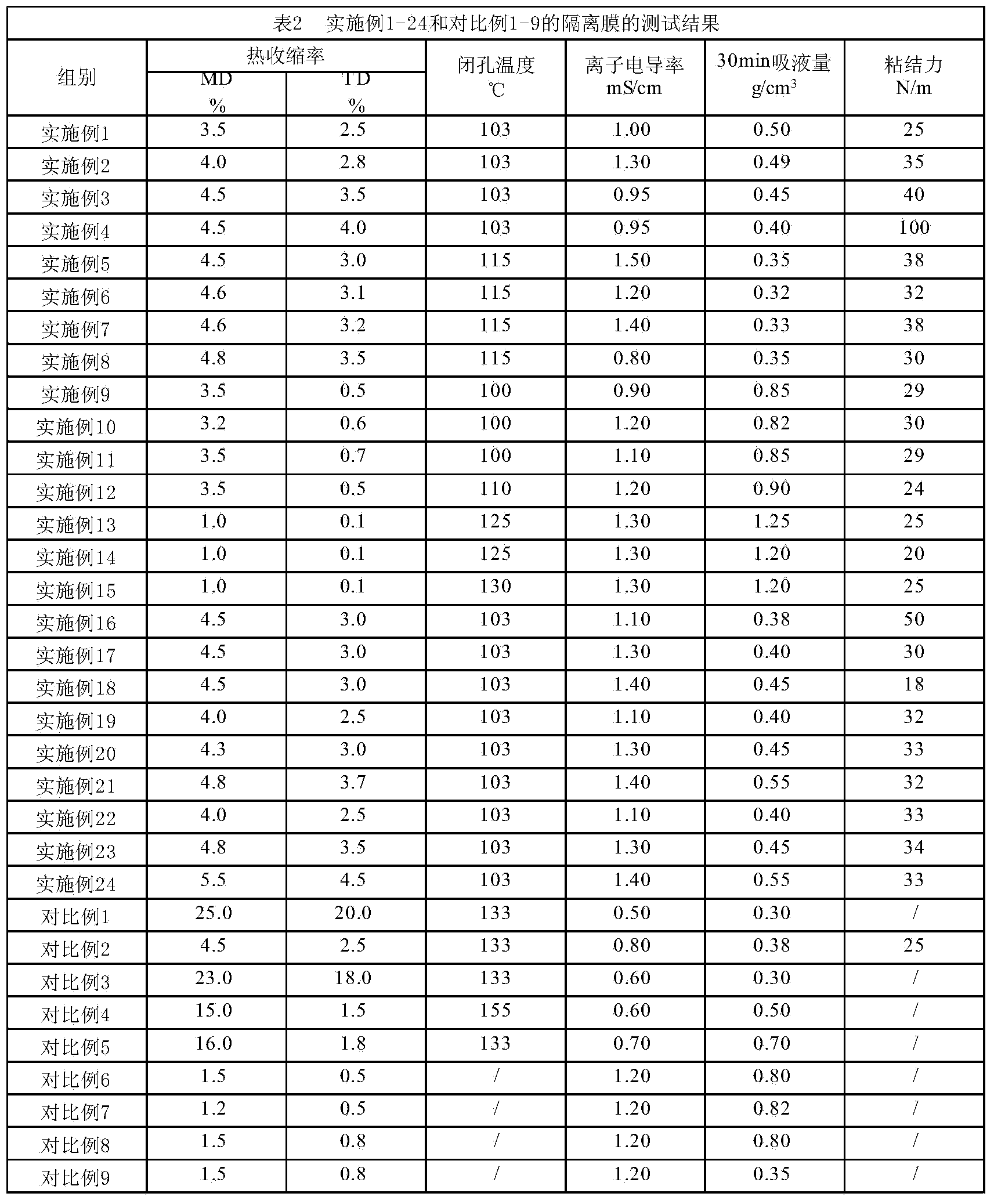

Examples

preparation example Construction

[0036]The method for preparing a separator according to the second aspect of the present invention is used to prepare the separator described in the first aspect of the present invention, comprising the steps of: adding polymer particles and binder particles to a solvent, stirring evenly to form a coating Slurry: coating the coating slurry on at least one surface of the microporous membrane, and drying to obtain the isolation membrane.

[0037] The preparation method of the isolation film according to the second aspect of the present invention is simple and easy to realize industrial production.

[0038] In the method for preparing a separator according to the second aspect of the present invention, the solvent may be deionized water. Using deionized water as a solvent is not only safe and environmentally friendly, but also can reduce production costs.

[0039] In the preparation method of the separator according to the second aspect of the present invention, the coating meth...

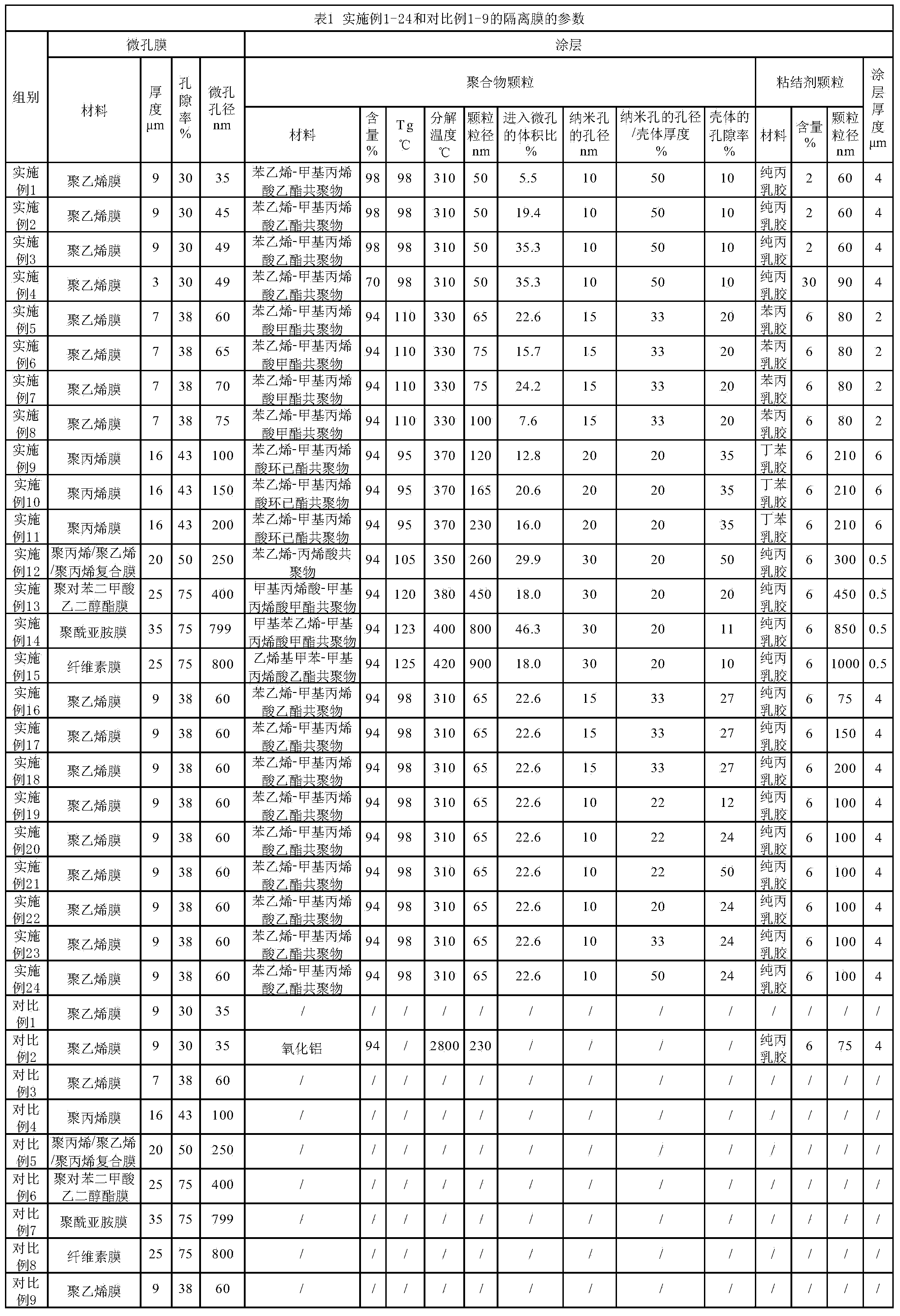

Embodiment 1

[0044] 1. Preparation of Isolation Membrane

[0045] (1) The polymer particle styrene-ethyl methacrylate copolymer with a particle size of 50nm, a glass transition temperature of 98°C and a decomposition temperature of 310°C and a binder particle of pure acrylic acid with a particle size of 60nm The latex is added to the solvent deionized water at a mass ratio of 98:2, and stirred evenly to make a coating slurry, wherein the diameter of the nanopore of the polymer particle is 10nm, the porosity of the shell is 10%, and the diameter of the nanopore is the same as The ratio of shell thickness is 50%;

[0046] (2) Coating the coating slurry on one of the surfaces of a microporous polyethylene film with a thickness of 9 μm, a micropore diameter of 35 nm, and a porosity of 30% by gravure printing, and drying to obtain a separator , where the volume ratio of polymer particles into the microporous membrane is 5.5%, and the thickness of the coating is 4 μm.

[0047] 2. Preparation o...

Embodiment 2

[0054] 1. Preparation of Isolation Membrane

[0055] (1) The polymer particle styrene-ethyl methacrylate copolymer with a particle size of 50nm, a glass transition temperature of 98°C and a decomposition temperature of 310°C and a binder particle of pure acrylic acid with a particle size of 60nm The latex is added to the solvent deionized water at a mass ratio of 98:2, and stirred evenly to make a coating slurry, wherein the diameter of the nanopore of the polymer particle is 10nm, the porosity of the shell is 10%, and the diameter of the nanopore is the same as The ratio of shell thickness is 50%;

[0056] (2) Coating the coating slurry on one of the surfaces of a microporous polyethylene film with a thickness of 9 μm, a micropore diameter of 45 nm, and a porosity of 30% by gravure printing, and drying to obtain a separator , where the volume ratio of polymer particles into the microporous membrane is 19.4%, and the thickness of the coating is 4 μm.

[0057] 2. Preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com