Heat-resisting lithium battery diaphragm and preparation method thereof

A technology for lithium battery separators and battery separators, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of complex manufacturing process, high cost, and low pressure resistance, and achieve simple manufacturing process and low cost , the effect of high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

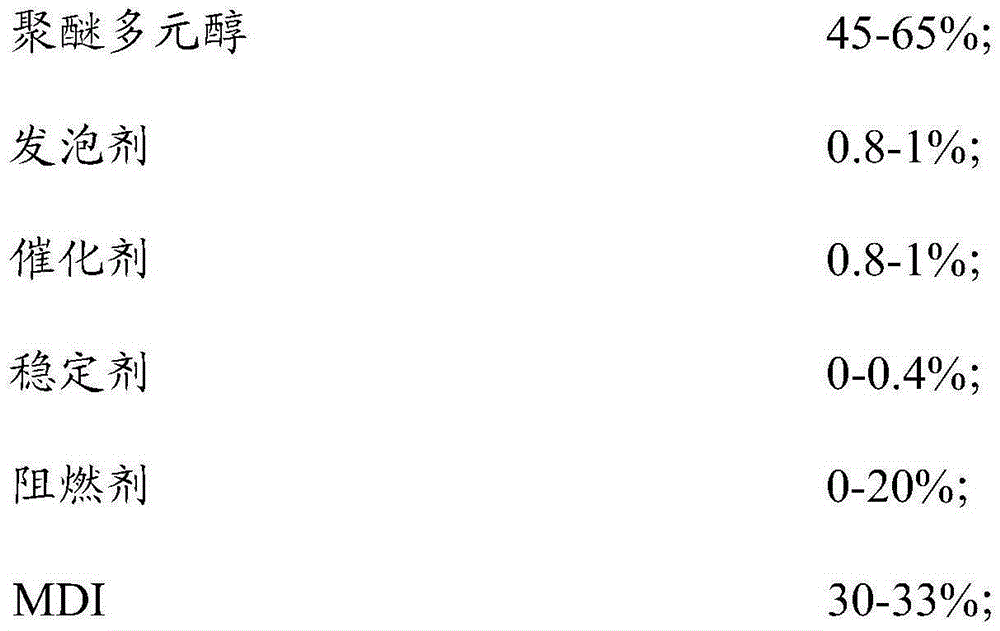

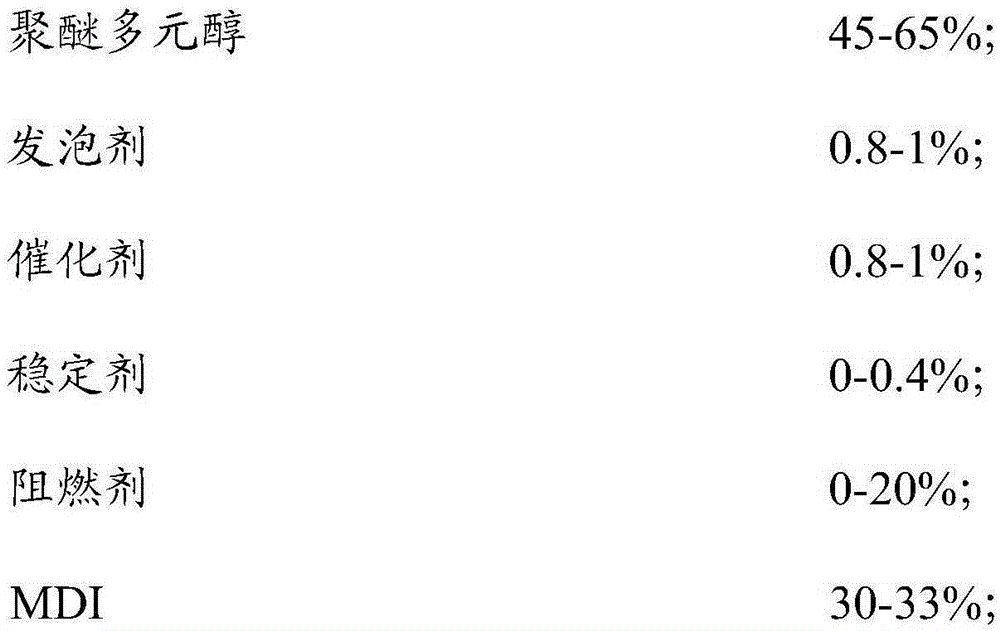

Method used

Image

Examples

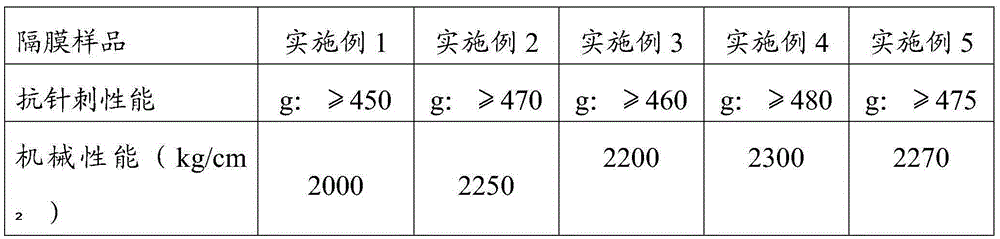

Embodiment 1

[0035] Weigh 65% of component A polyether polyol (the following are weight ratios), 1% of foaming agent, and 1% of catalyst, pour it into the mixer, stir evenly, and then weigh 33% of B component MDI. Put the weighed A component material and B component material into the A material tank and B material tank of the polyurethane foam machine respectively, and after being stirred by the polyurethane foam machine, pour it into a rectangular or square mold for foaming and molding. Among them, the polyurethane foam machine A material pump speed is 400-500 rpm, B material pump speed is 300-400 rpm; stirring speed is 1700-2100 rpm; injection material is 100-3000 g / s; mold temperature is 40-50 degrees ; Foaming time 8-10 minutes.

[0036] Place the foamed block product on a special foam cutting machine, cut into slices according to the thickness requirements, and then stamp the sheet according to the size and specification requirements. Its thickness is 5μm, the porosity is 70%, the ai...

Embodiment 2

[0038] Weigh 62% of component A polyether polyol (the following are weight ratios), 0.8% of blowing agent, 1% of catalyst, and 0.2% of stabilizer, pour it into the mixer, stir evenly, and then weigh 30% of B component MDI it is good. Put the weighed A component material and B component material into the A material tank and B material tank of the polyurethane foam machine respectively, and after being stirred by the polyurethane foam machine, pour it into a rectangular or square mold for foaming and molding. Among them, the polyurethane foam machine A material pump speed is 400-500 rpm, B material pump speed is 300-400 rpm; stirring speed is 1700-2100 rpm; injection material is 100-3000 g / s; mold temperature is 40-50 degrees ; Foaming time 8-10 minutes.

[0039] Place the foamed block product on a special foam cutting machine, cut into slices according to the thickness requirements, and then stamp the sheet according to the size and specification requirements. Its thickness i...

Embodiment 3

[0041] Weigh 56% of A component polyether polyol (the following are weight ratios), 0.8% of foaming agent, 0.8% of catalyst, 0.4% of stabilizer, and 10% of flame retardant and pour it into the mixer, stir evenly, and then B component MDI32% weighed well. Put the weighed A component material and B component material into the A material tank and B material tank of the polyurethane foam machine respectively, and after being stirred by the polyurethane foam machine, pour it into a rectangular or square mold for foaming and molding. Among them, the polyurethane foam machine A material pump speed is 400-500 rpm, B material pump speed is 300-400 rpm; stirring speed is 1700-2100 rpm; injection material is 100-3000 g / s; mold temperature is 40-50 degrees ; Foaming time 8-10 minutes.

[0042] Place the foamed block product on a special foam cutting machine, cut into slices according to the thickness requirements, and then stamp the sheet according to the size and specification requireme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com