Patents

Literature

85results about How to "Excellent ion permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

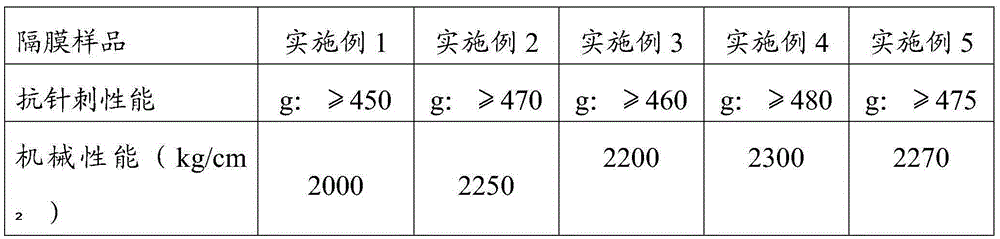

Non-woven ceramic membrane with excellent closed-pore performance for lithium ion battery and technology

ActiveCN103199209AReduce the temperatureSlow down the degree of electrochemical reactionCell component detailsCeramic coatingPore diameter

The invention provides a non-woven ceramic membrane with excellent closed-pore performance for a lithium ion battery. The non-woven ceramic membrane comprises a non-woven base material and coatings with the closed-pore performance. The non-woven ceramic membrane is characterized in that the coatings with the closed-pore performance are uniformly coated on the two surfaces of the non-woven base material, the thickness of the non-woven ceramic membrane for the lithium ion battery is 30-50mu m, the porosity of the non-woven ceramic membrane is 40-60%, the average pore diameter of the non-woven ceramic membrane is 0.1-0.5mu m, the closed-pore temperature of the non-woven ceramic membrane is 120-130 DEG C, and the membrane rupture temperature of the non-woven ceramic membrane is 300-500 DEG C. The invention also provides a preparation technology of the non-woven ceramic membrane with the excellent closed-pore performance for the lithium ion battery. The non-woven ceramic membrane has the advantage that the disintegration or explosion of the battery is not easy cause; the adhesive power between the ceramic coating and the base material is increased, and no powder falls off the surface of the membrane under the conditions of bending, rubbing and the like; the consistency of the membrane thickness is substantially improved; and the non-woven ceramic membrane has good high temperature resistance performance, high ion penetrability, low resistance and stable electrochemical property.

Owner:CHINA HAISUM ENG

Separator for non-aqueous secondary battery, method for producing the same, and non-aqueous secondary battery

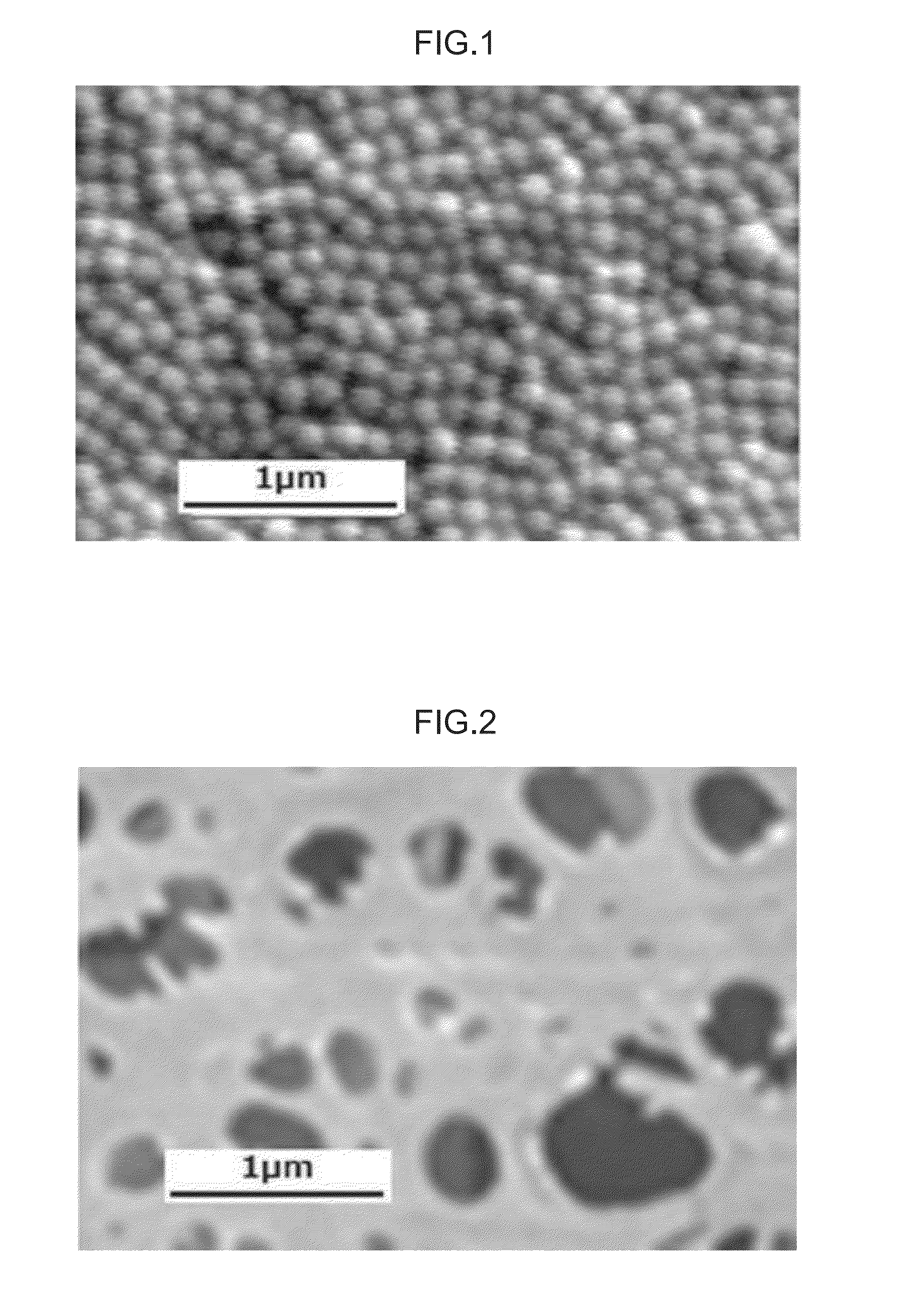

ActiveUS20140363726A1Excellent adhesion to electrodesFavorable handling propertyFinal product manufactureLi-accumulatorsPorous substratePolyvinylidene difluoride

The present invention provides a separator for a non-aqueous secondary battery including a porous substrate and an adhesive layer that is formed on at least one side of the porous substrate and is an aggregate layer of particles that contain a polyvinylidene fluoride resin and have an average particle diameter of from 0.01 μm to 1 μm, in which a content of the particles per one adhesive layer is from 0.1 g / m2 to 6.0 g / m2.

Owner:TEIJIN LTD

Separator for nonaqueous secondary battery

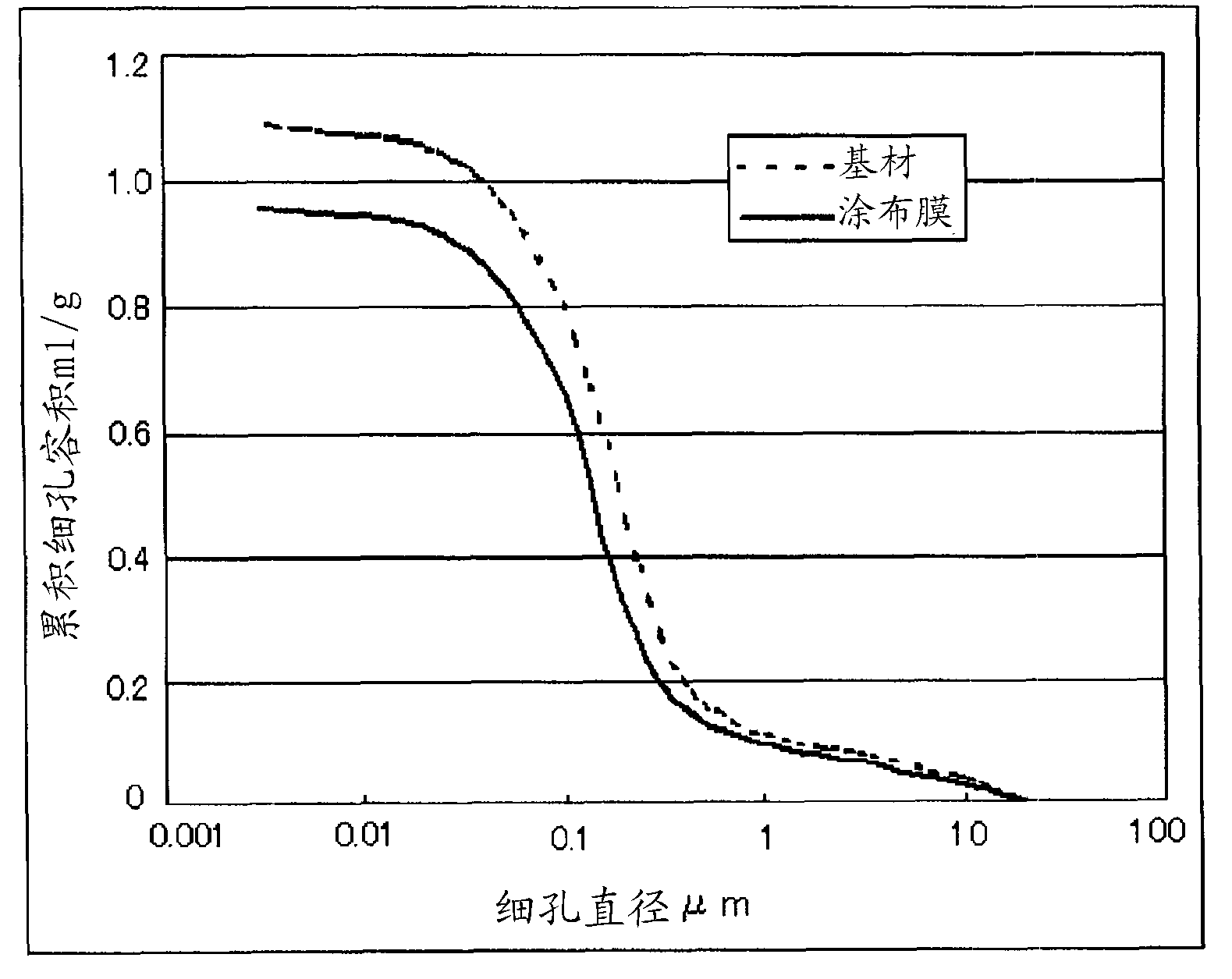

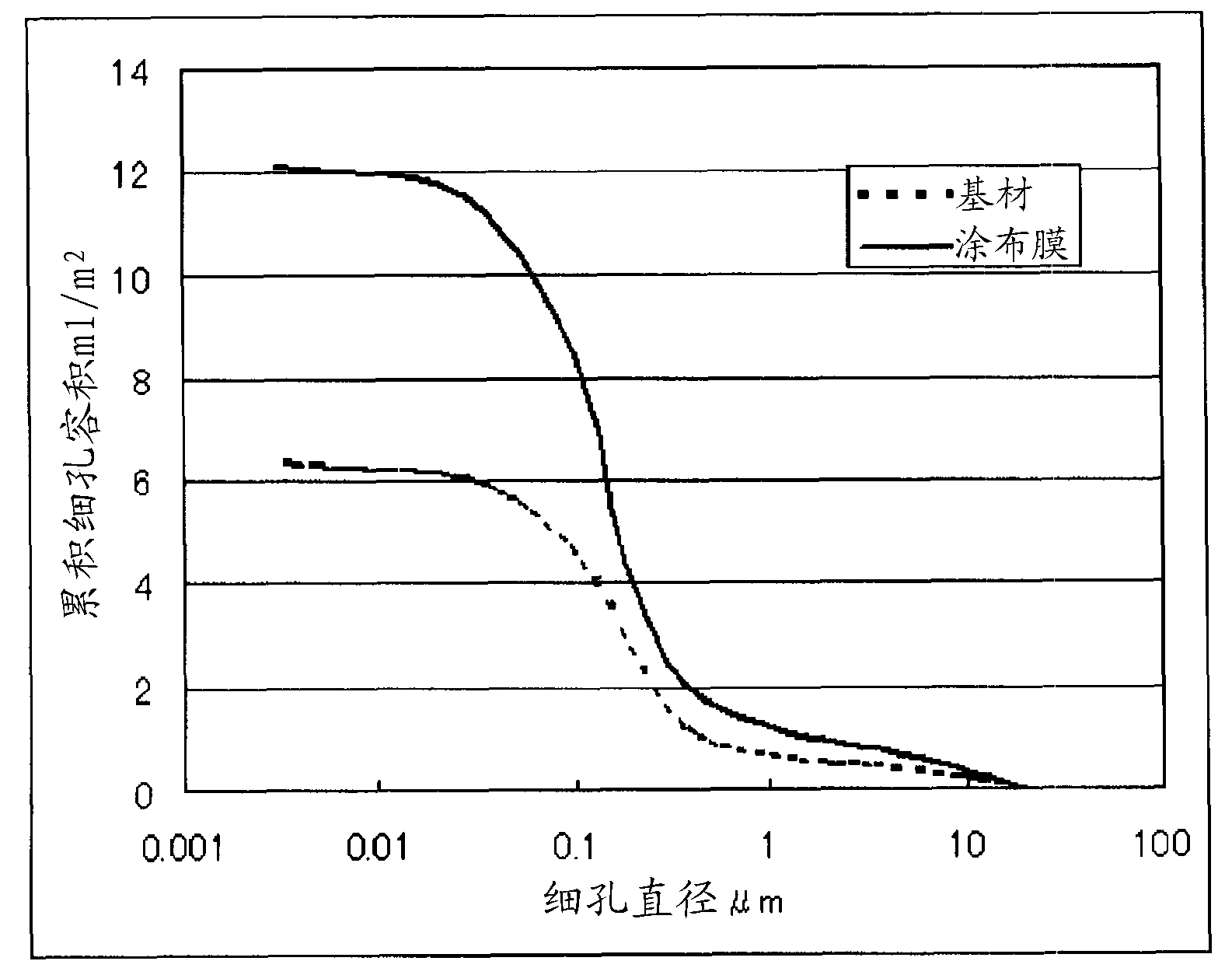

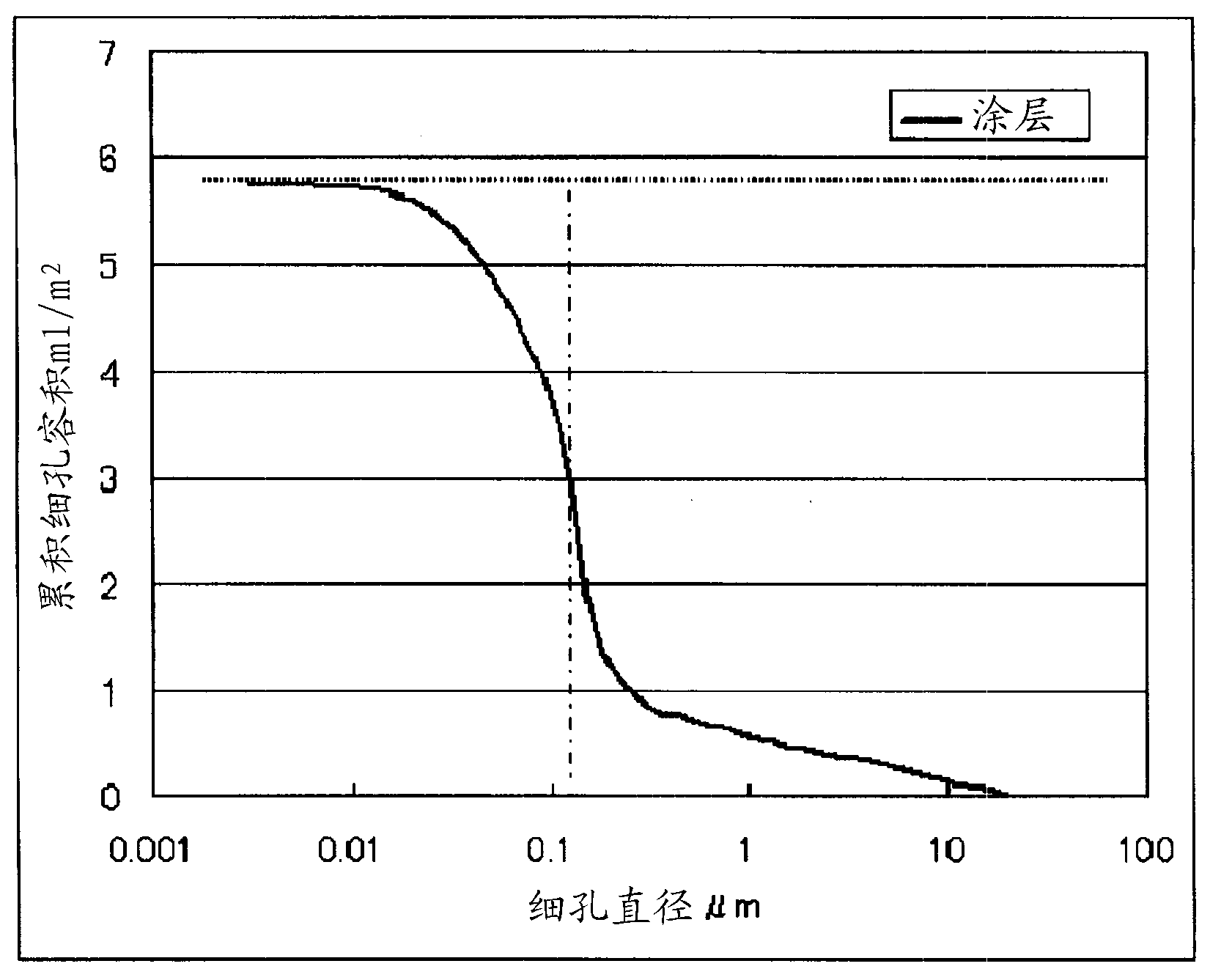

ActiveCN102160211AWith off featureImprove heat resistanceSecondary cellsCell component detailsElectrical resistance and conductancePolyolefin

The invention aims to provide a separator for nonaqueous secondary batteries, which has both excellent heat resistance and ion permeability in addition to shutdown characteristics. The first embodiment of the separator is a separator for nonaqueous secondary batteries which is composed of a porous composite membrane wherein a heat-resistant porous layer containing a heat-resistant resin is formed on at least one side of a base which is composed of a polyolefin microporous membrane, said separator being characterized in that the membrane resistance (A) of the base, the Gurley value (B) of the base, the membrane resistance (C) of the porous composite membrane and the Gurley value (D) of the porous composite membrane satisfy a specific relation. The second embodiment of the separator is characterized in that the heat-resistant porous layer has an average pore diameter as determined by a mercury intrusion method of 0.1-0.2 [mu]m. The third embodiment of the separator is characterized in that heat-resistant resin fibrils have an average fibril diameter of 10-80 nm and the pores in the heat-resistant porous layer have an average pore diameter of 50-250 nm.

Owner:TEIJIN LTD

Microporous polymer isolating film for Li-ion battery and method for producing the same

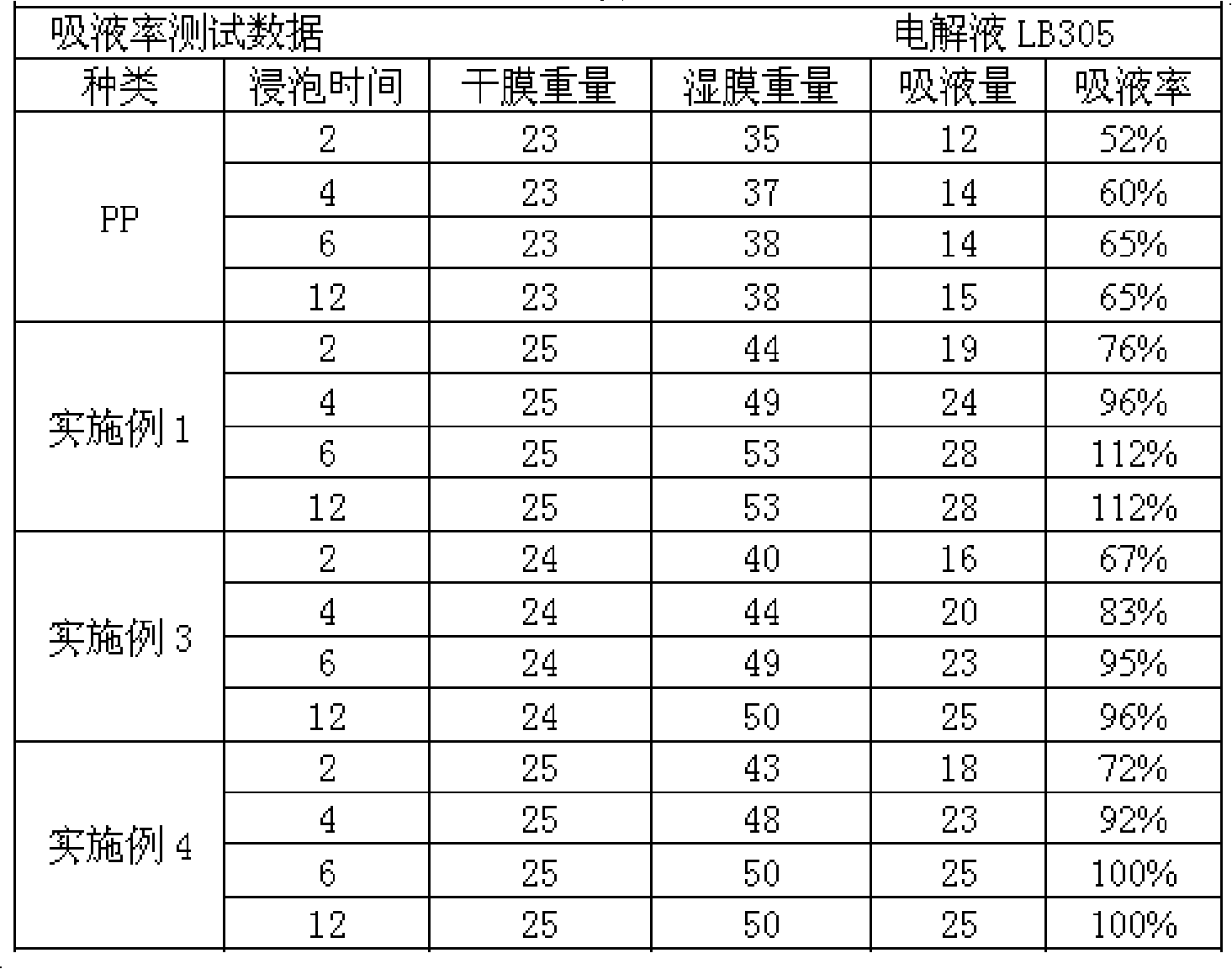

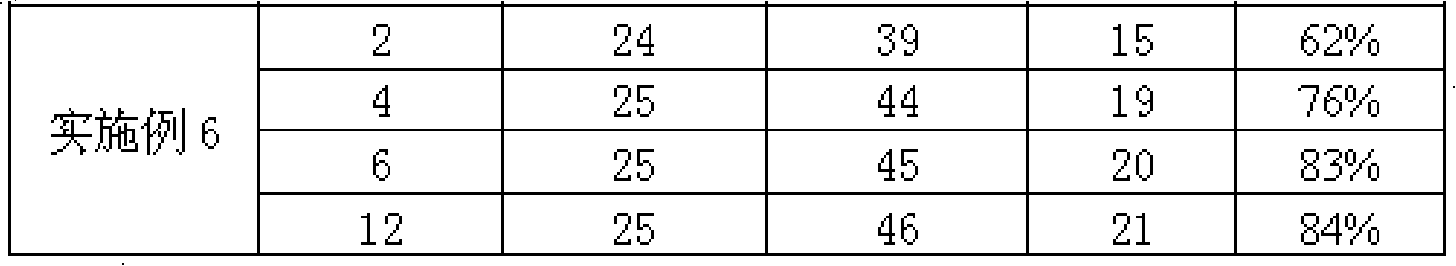

ActiveCN101212036AIncrease surface areaHigh porositySolid electrolytesFinal product manufactureHydrophilic monomerPolymer science

The invention relates to a diaphragm used for power maintaining device as a lithium ion secondary battery and a preparation method thereof, which belongs to a field of manufacturing battery and capacitor. The diaphragm of the invention takes water as reaction medium; polymers colloid and emulsion are obtained through polymerization reaction generated by polyvinyl alcohol, hydrophobic monomer and hydrophilic monomer with an initiator in water solution; by adopting tape-casting and coating process, the polymers colloid and emulsion are coated on a plastic baseband; the diaphragm is obtained through stripping after drying. The diaphragm has good liquid absorbability, high liquid absorption rate and retention, low resistivity, good mechanical strength and good thermal stability (little thermal shrinkage and little size distortion) as well as electrochemical stability; and the prepared lithium ion battery is characterized by good cycle stability and long service life.

Owner:CHENGDU ZHONGKE LAIFANG POWER SCI & TECH CO LTD

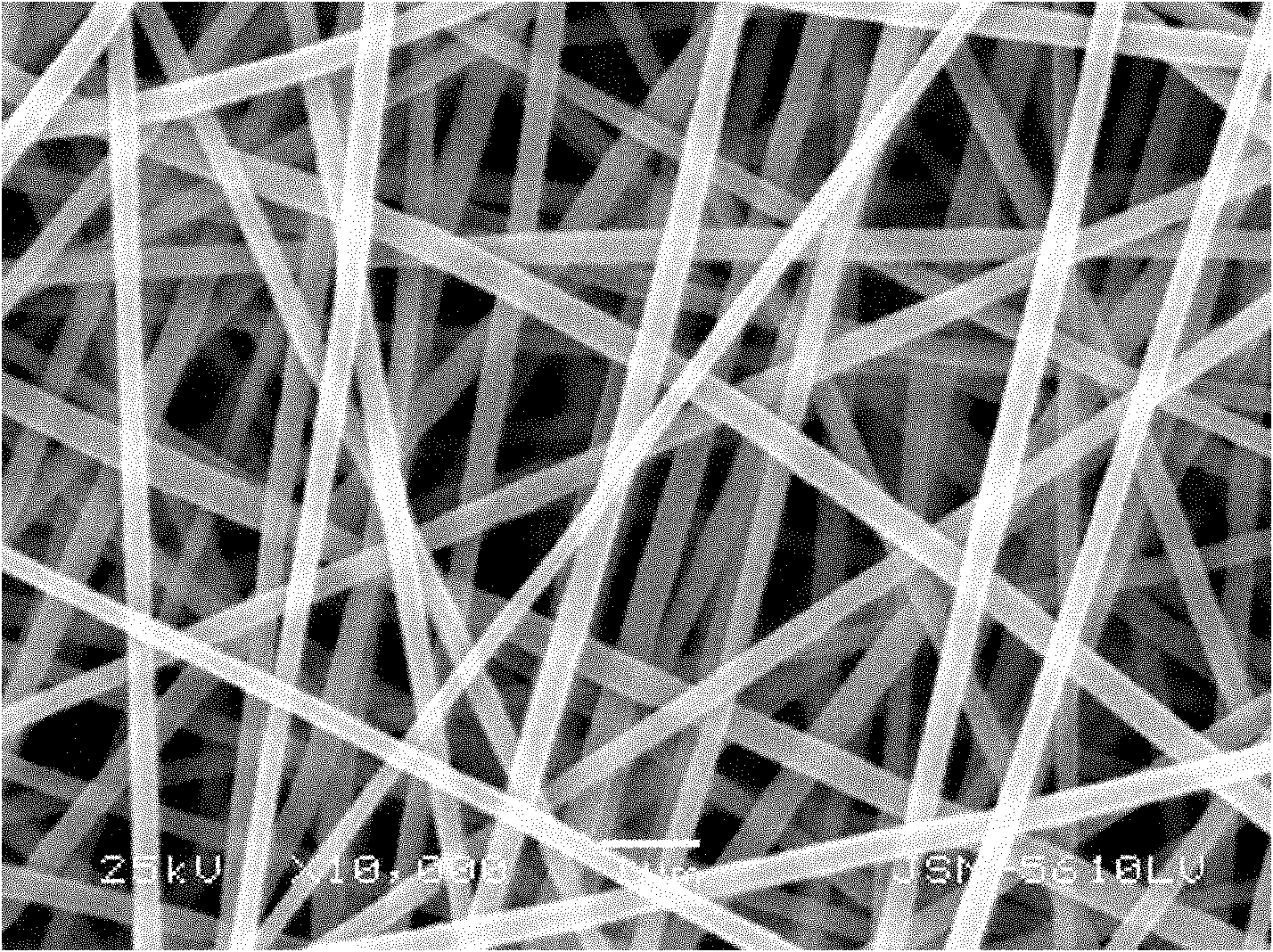

Reinforced nanofiber porous membrane and preparation method thereof

InactiveCN102140762AHigh porosityImprove wettabilityFibre typesCell component detailsFiberPolymer science

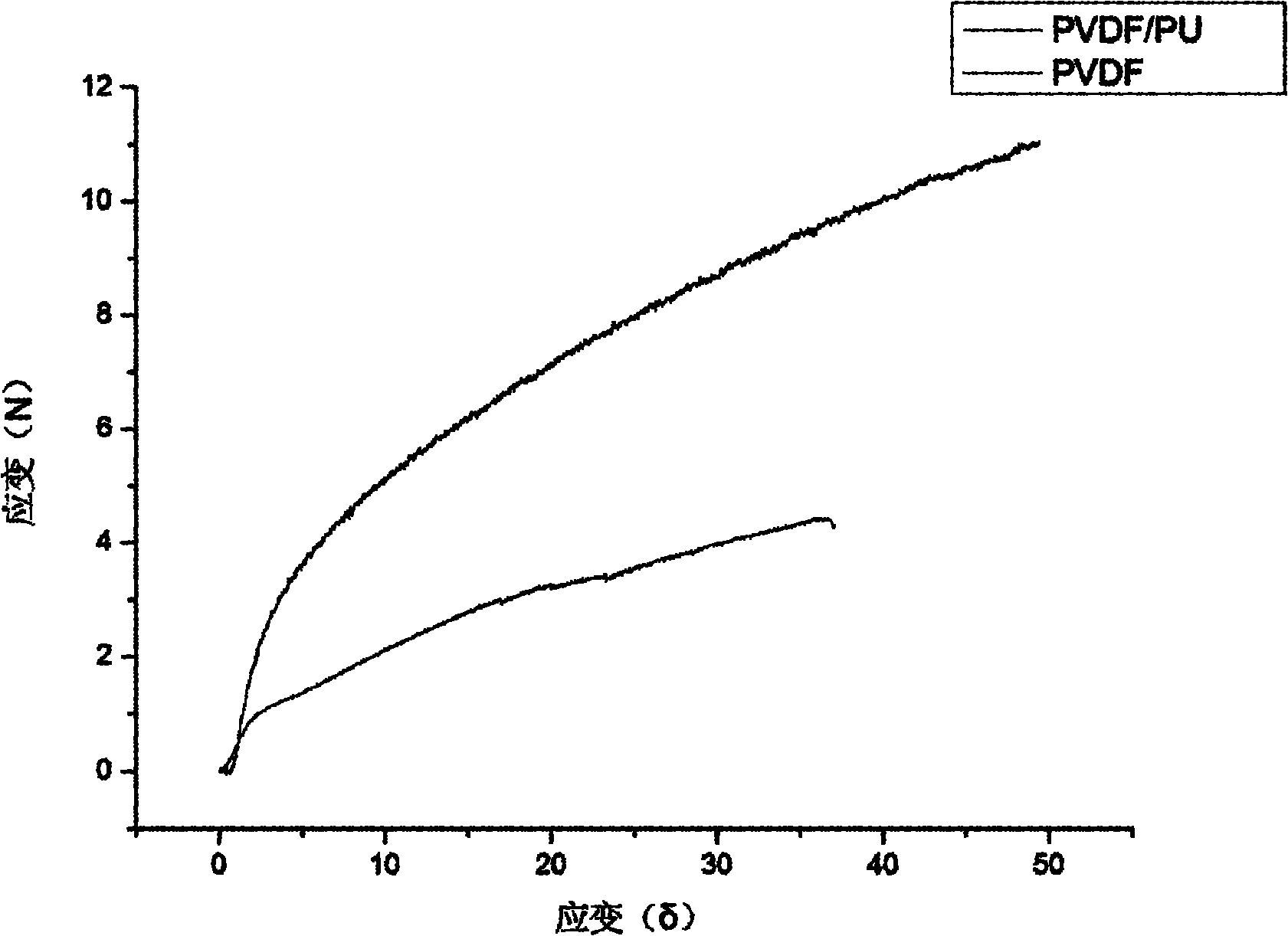

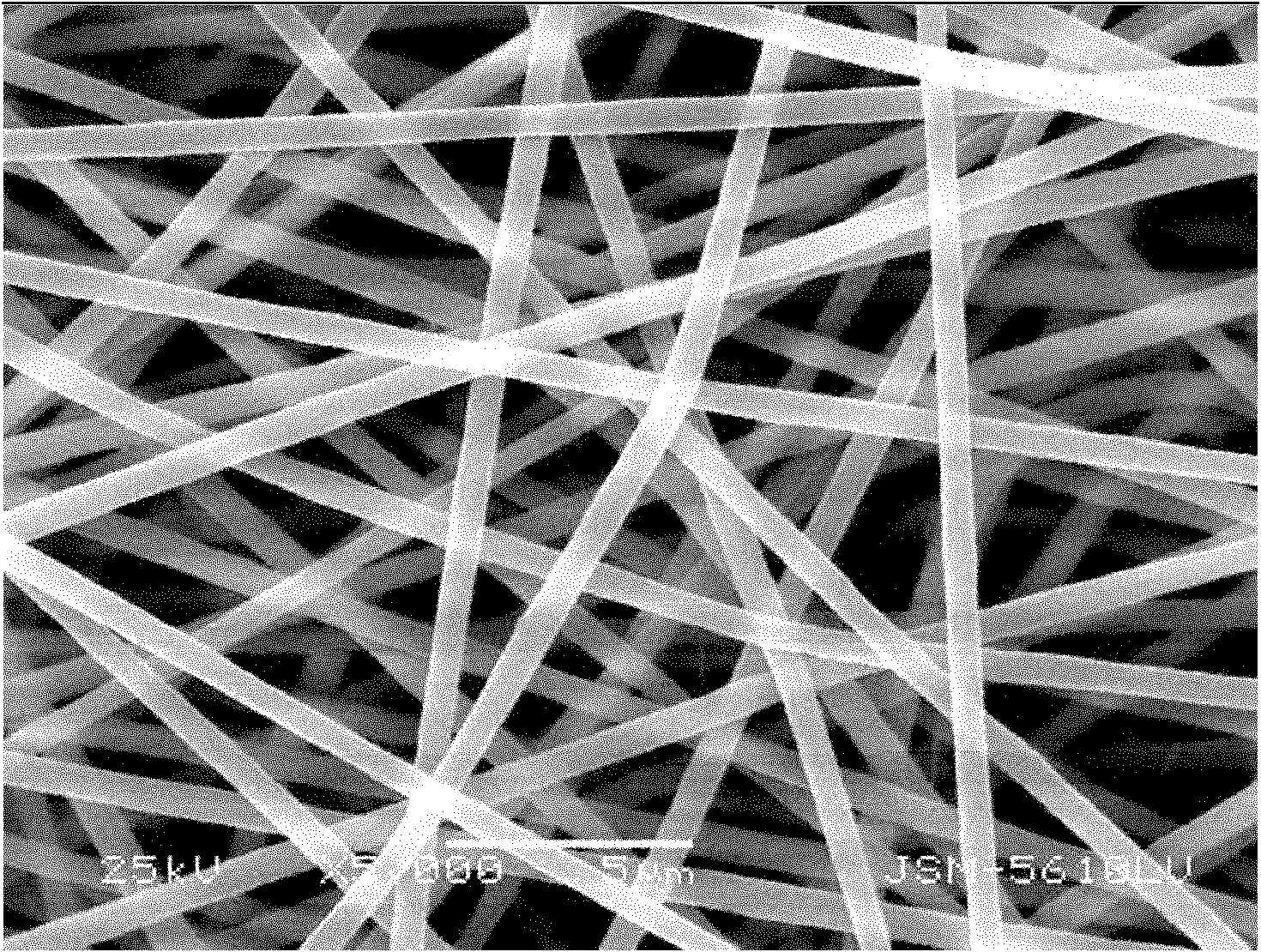

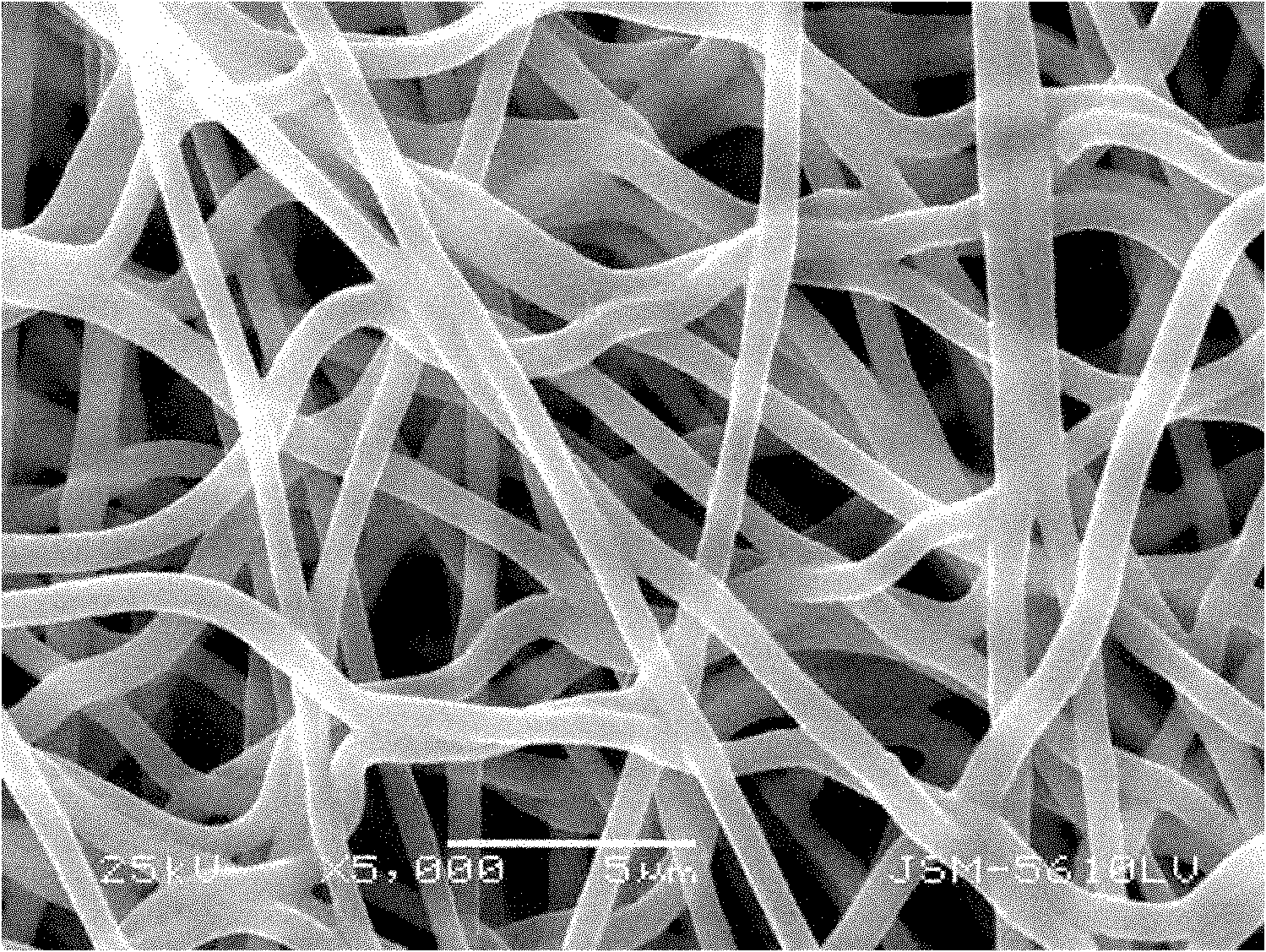

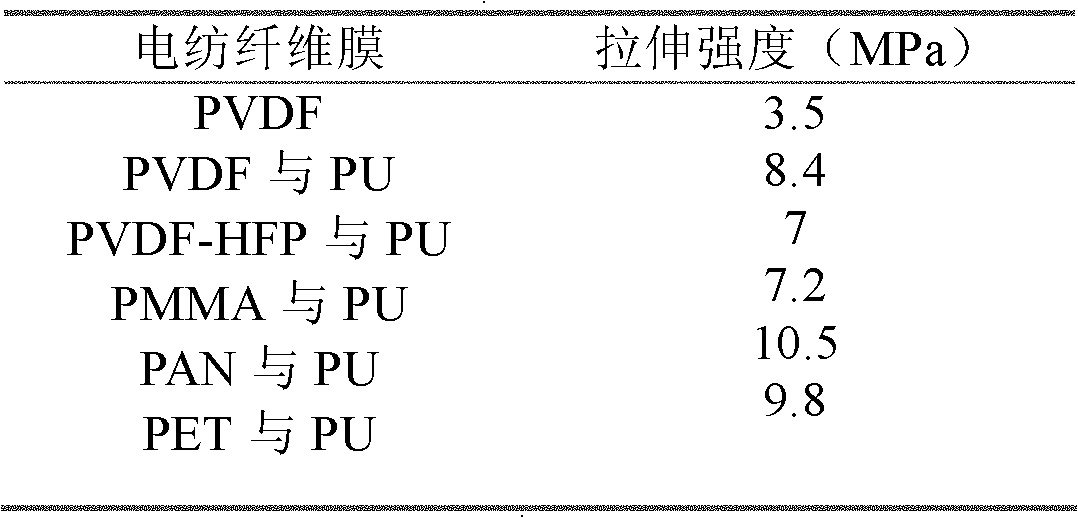

The invention relates to a reinforced nanofiber porous membrane and a preparation method thereof. The porous membrane is a two-component lithium ion battery diaphragm formed by compounding polymer resin with polyurethane, and has a semi-interpenetrating network structure, the porosity of 60 to 80 percent, and mechanical property which is 3 to 4 times higher than that of a polymer resin single-component porous membrane. The preparation method comprises the following steps of: preparing a polymer resin non-woven membrane by high-voltage electrostatic spinning, impregnating the non-woven membrane in solution of wet curing reaction polyurethane prepolymer with a high-reactivity isocyanate group, reacting -NCO in the polyurethane prepolymer with a -OH bond of water in air at room temperature to obtain the polyurethane through crosslinking and autopolymerization, so that nanofibers in the non-woven membrane are bonded to form a polymer resin and polyurethane two-component composite membrane, and the mechanical strength of the fiber membrane is greatly improved. The method is easy to operate, and the prepared non-woven membrane keeps the advantages of high porosity of a membrane prepared by an electrostatic spinning technology, and heat stability of the polymer resin, and has high ion permeability and affinity of electrolyte.

Owner:WUHAN UNIV OF TECH

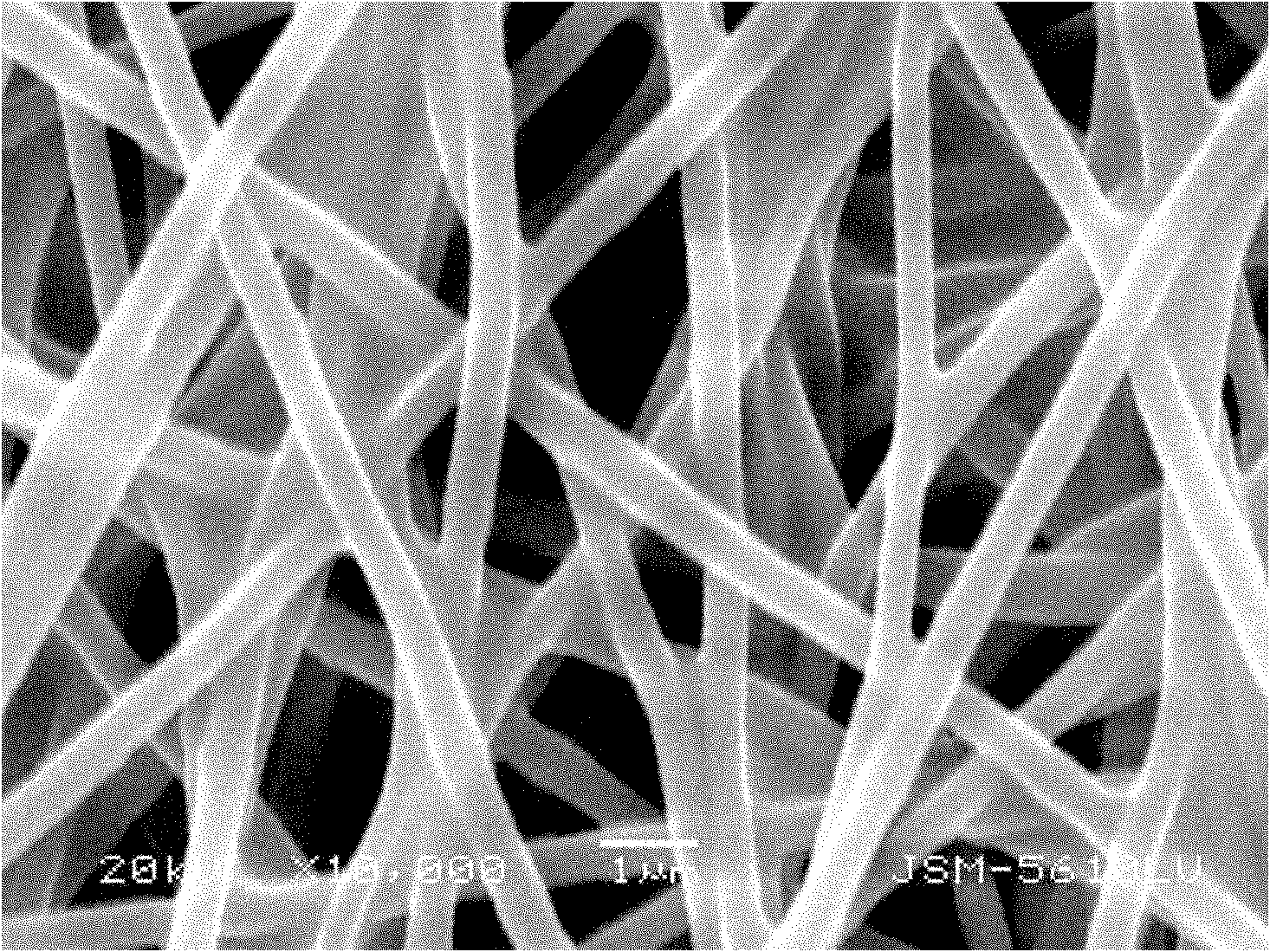

Enhanced bi-component nanofiber porous membrane and preparation method thereof

InactiveCN102140734AHigh porosityImprove wettabilityFilament/thread formingCell component detailsPolymer scienceVoid ratio

The invention relates to an enhanced bi-component nanofiber porous membrane and a preparation method thereof. The porous membrane is a lithium ion battery membrane with two components of polymer resin and polyurethane. The membrane is in a semi-interpenetrating network structure which has a void ratio of 60-80%, and the mechanical property is 2-3 times higher than a single-component porous membrane of polymer resin. The preparation method comprises the steps of: dissolving a polymer resin and polyurethane prepolymer bi-component composition in a solvent, and preparing a nonwoven membrane through an electrospinning technology; and putting the nonwoven membrane at room temperature to make -NCO in the polyurethane prepolymer react with the -OH bond of water in the air to produce polyurethanethrough crosslinking and autopolymerization. In the invention, the nanofiber in the nonwoven membrane binds to form the polymer resin and polyurethane bi-component compound membrane, and the mechanical strength of the fibrous membrane is improved greatly. The method is easy, and the prepared nonwoven membrane maintains the advantages of high void ratio, and good thermal stability of polymer resinof the membrane prepared by using the electrospinning technology, and the membrane has good ion permeability and electrolyte affinity.

Owner:WUHAN UNIV OF TECH

High-energy density lithium ion battery formation method

ActiveCN104157920AReduce first capacity lossImprove first-time efficiencySecondary cells charging/dischargingElectrolyte accumulators manufactureBattery chargeHigh energy

A high-energy density lithium ion battery formation method includes the following steps: S1, after battery filling, the filling hole is sealed with sealing cotton, and standing lasts for 16-48h; S2, a battery is charged to 3.7 to 4.0V by a multiplying power of 0.01 to 0.02C; S3, the battery is charged to 4.0-4.35V by a multiplying power of 0.03 to 0.05C; S4, the battery is charged to 4.35 to 4.5V by a multiplying power of 0.1 to 0.2C, and then the battery is charged for 1 to 3h at a constant voltage of 4.35 to 4.5V; S5, the battery is subjected to high temperature aging and then is subjected to exhaust-gas disposal, and then secondary filling is performed according to the weight change of the battery to supplement electrolyte lost during formation and aging; S6, the battery is sealed. The high-energy density lithium ion battery formation method improves the first efficiency, safety performance and cycle performance of a rich lithium anode-carbon cathode system battery, avoids the flatulence problem during formation, and reduces the internal resistance of the battery.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Method for preparing porous film by adopting high molecular weight polyolefin and product and application thereof

ActiveCN102153776AHigh mechanical strengthHigh temperature puncture strengthCell component detailsPolymer sciencePolyolefin

The invention discloses a method for preparing a porous film by adopting high molecular weight polyolefin. The method comprises the following steps of: (1) performing soaking treatment on the high molecular weight polyolefin; (2) blending the soaked high molecular weight polyolefin and materials such as thermoplastic resin, auxiliary agent and the like to prepare blended master batch; (3) preparing the obtained blended master batch into a film material; and (4) extracting the film material to obtain the porous film. The porous film has the characteristics of high mechanical strength, high porosity, uniform aperture size, high ion permeability, excellent dielectric property and the like, can be used as a lithium ion battery diaphragm, and has better safety; and the method has simple process and easily controlled conditions, is suitable for mechanized large-scale production, and has low cost and high efficiency.

Owner:LIAOYUAN HONGTU LI ION BATTERY DIAPHRAGM TECH

Preparation method of array magnetic reduced graphene oxide-carbon nanofiber

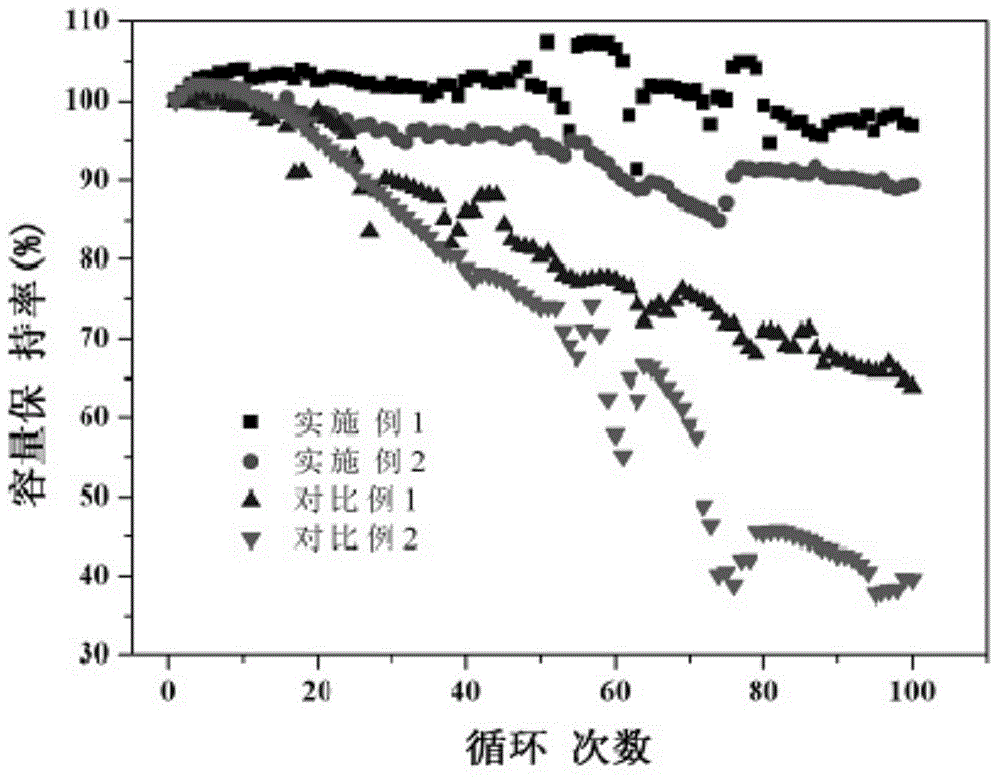

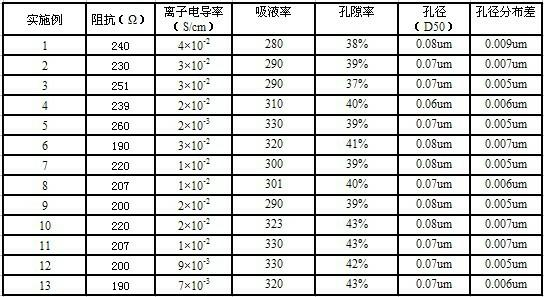

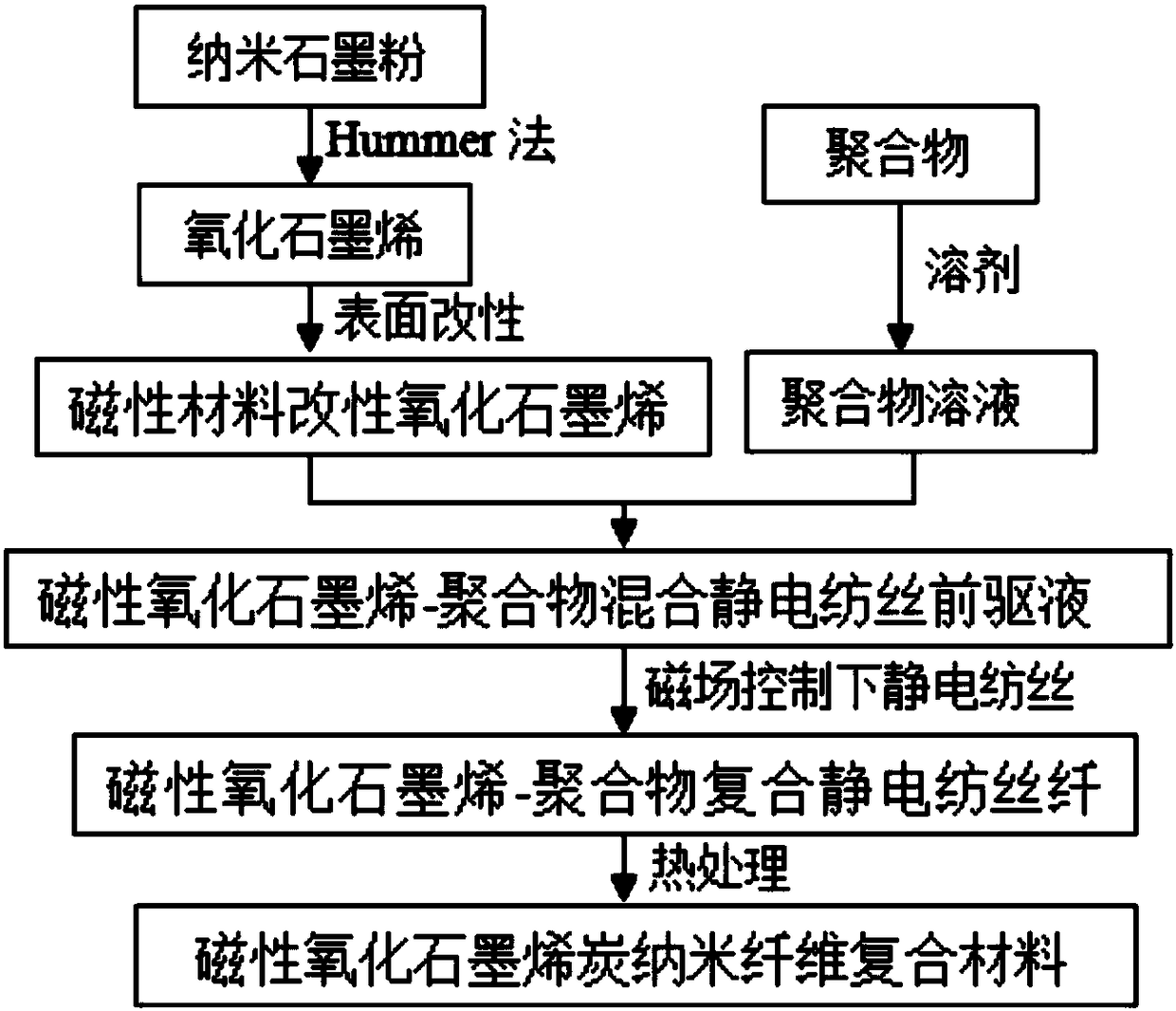

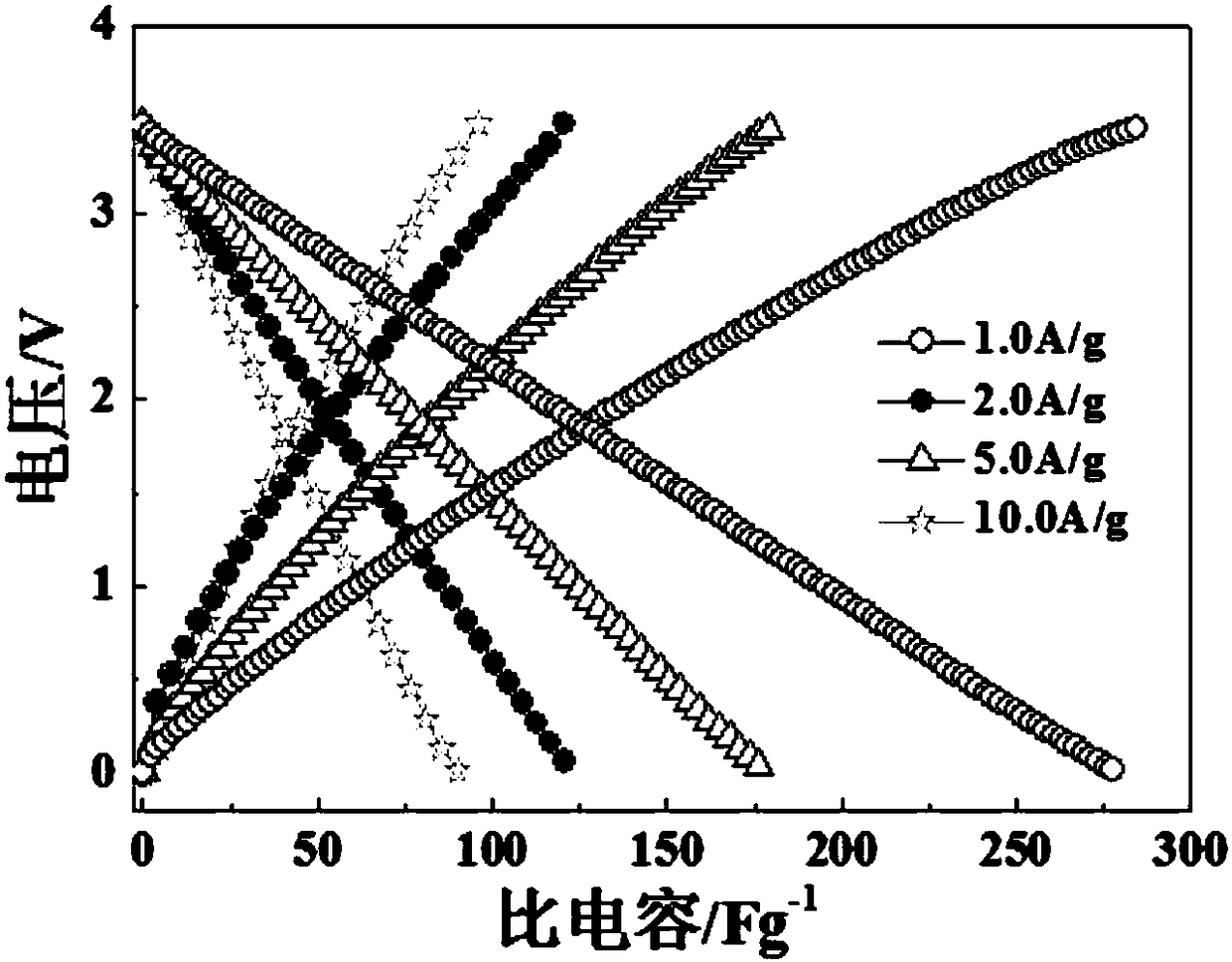

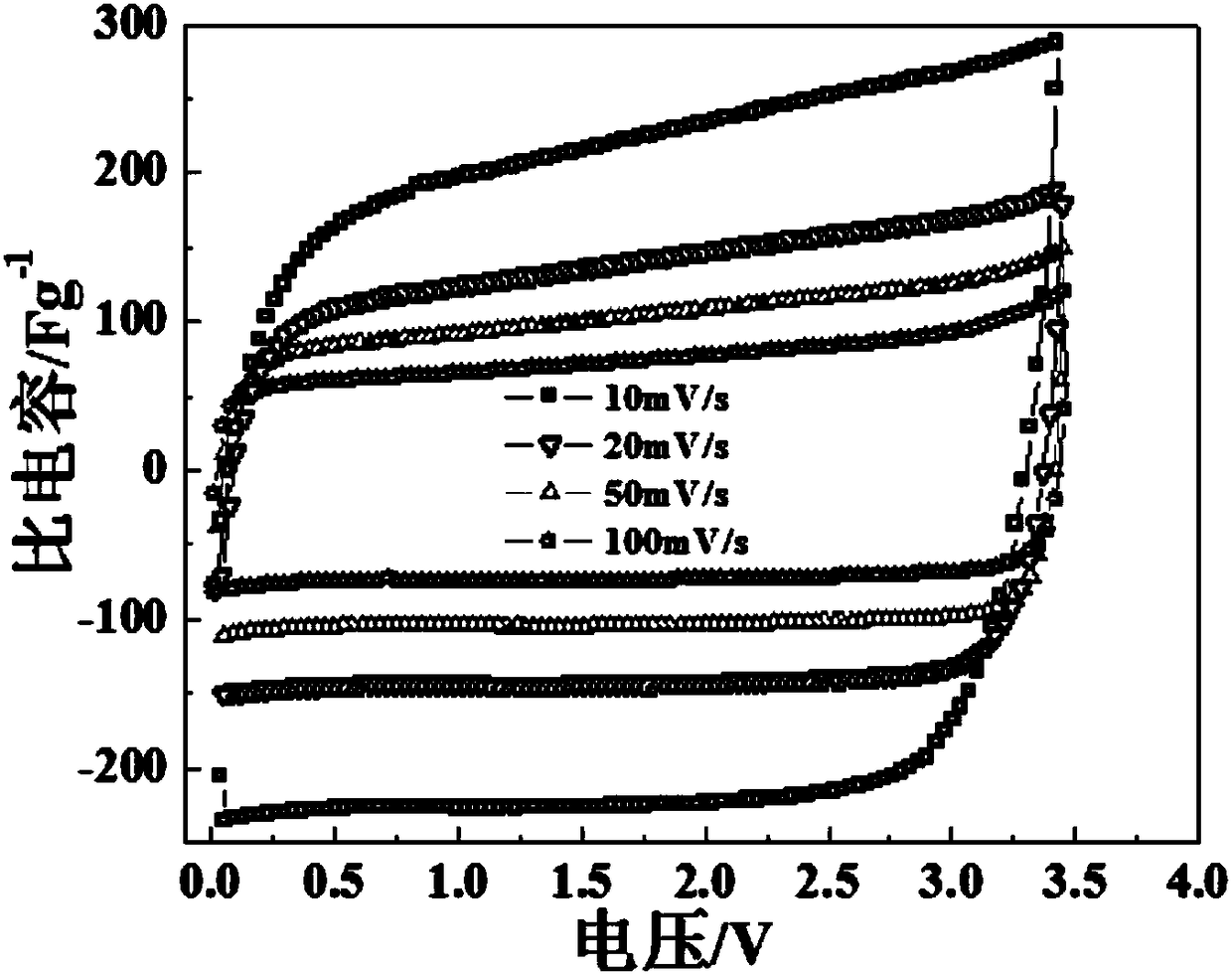

ActiveCN108315834AEasy to manufactureIncrease load capacityHybrid capacitor electrodesCell electrodesCapacitanceCharge discharge

The invention discloses a preparation method of array magnetic reduced graphene oxide-carbon nanofiber. The method comprises the following steps: taking flake graphite as a raw material, and preparinggraphene oxide with a Hummer method, so as to obtain the graphene oxide; preparing the graphene oxide and magnetic material precursor into magnetic material modified graphene oxide with a hydrothermal / solvothermal method, preparing the magnetic material modified graphene oxide, polymer and a solvent into a magnetic graphene oxide-polymer mixed electrostatic spinning precursor solution, preparingmagnetic graphene oxide-polymer compounded electrostatic spinning fiber, and performing heat treatment, so as to obtain a magnetic graphene oxide carbon nanofiber composite material. The method has the advantages that an RGO surface loaded nano metal oxide particle has a pseudocapacitor characteristic, can improve the charge energy storage density of the composite material, and is suitable for high-capacity power supercapacitors, with the specific capacitance being 240.3CP / F*g<-1>-254.1CP / F*g<-1> and the charge discharge efficiency being 99.1% to 99.6%.

Owner:锦州凯美能源有限公司

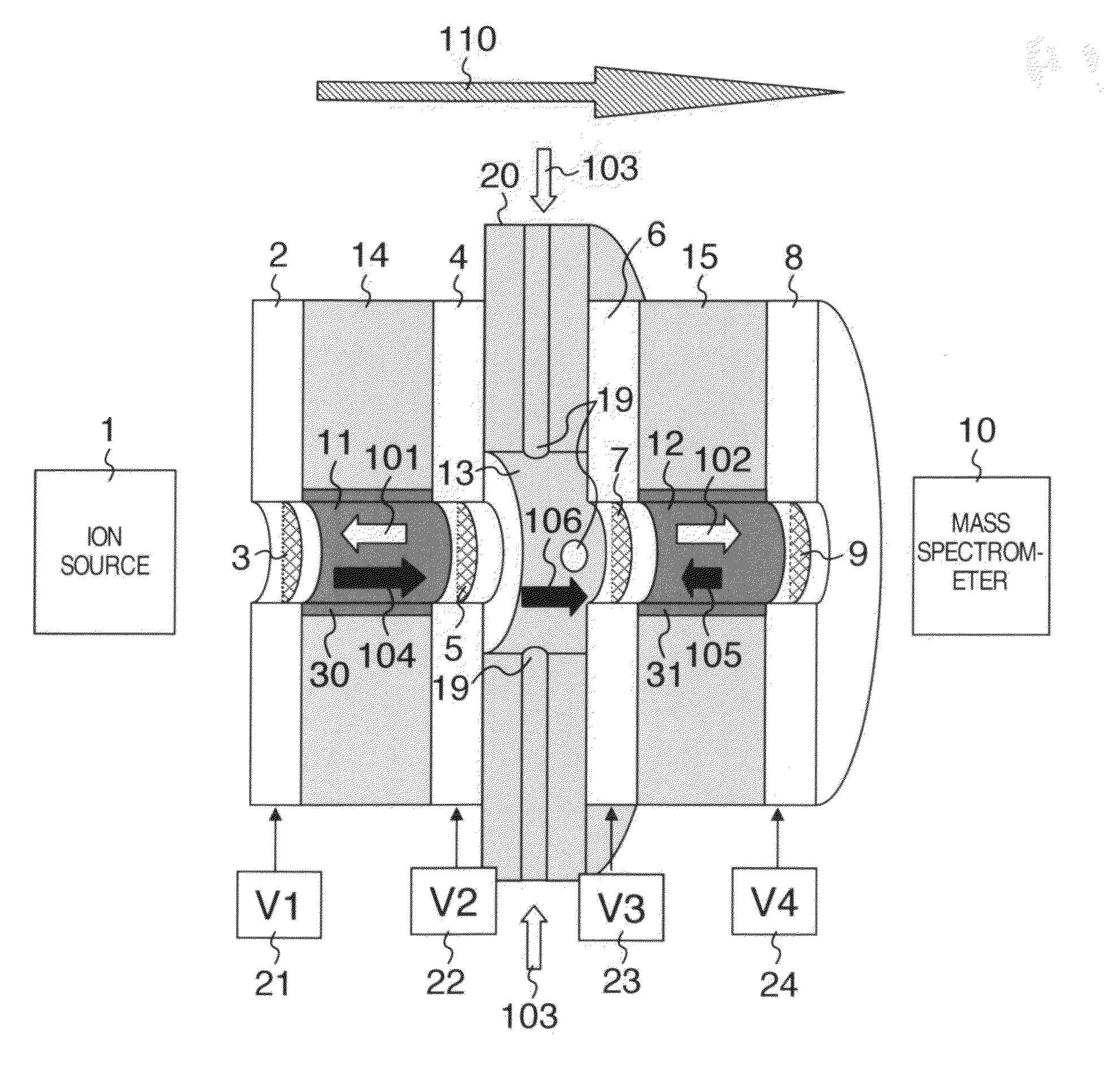

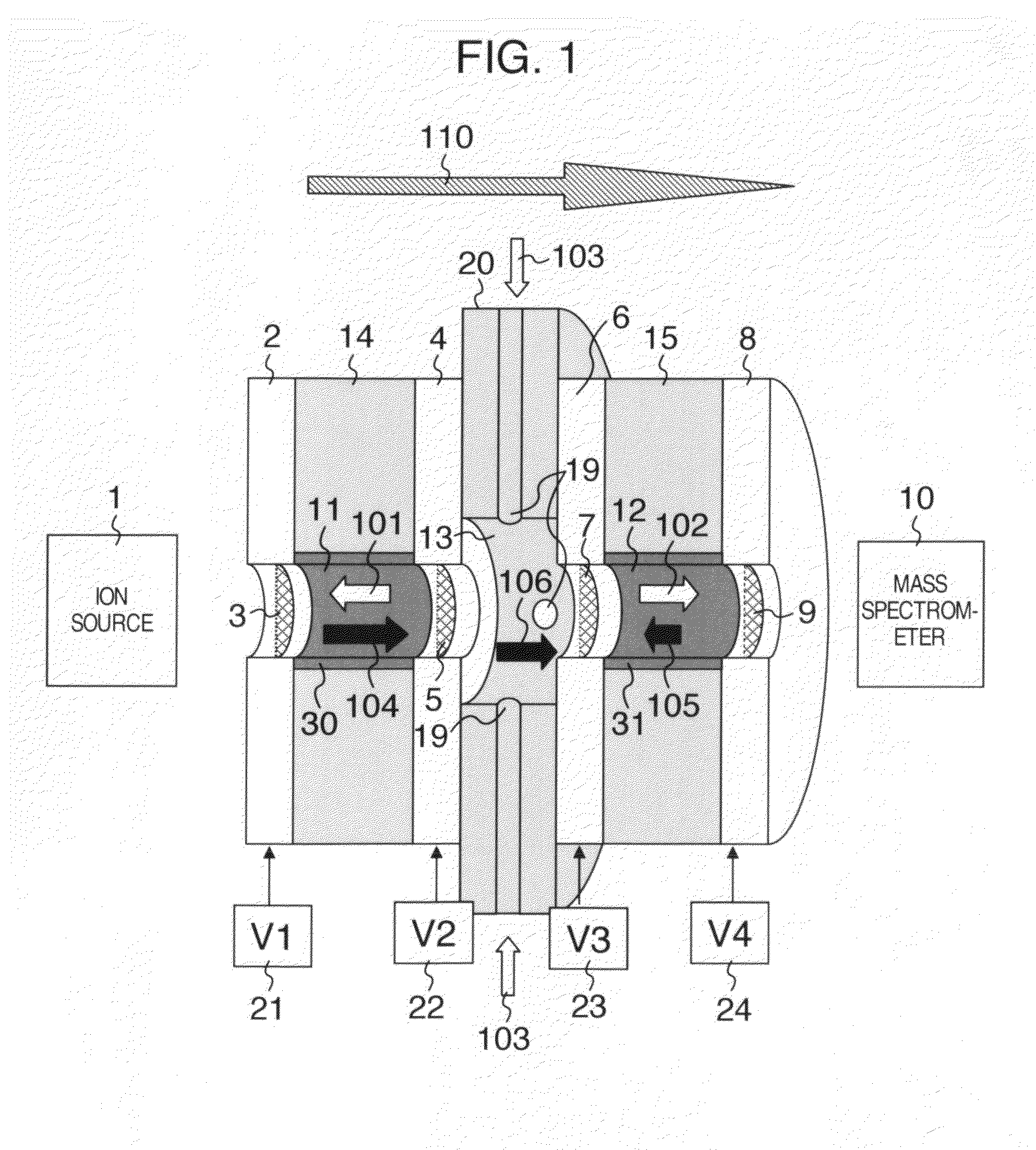

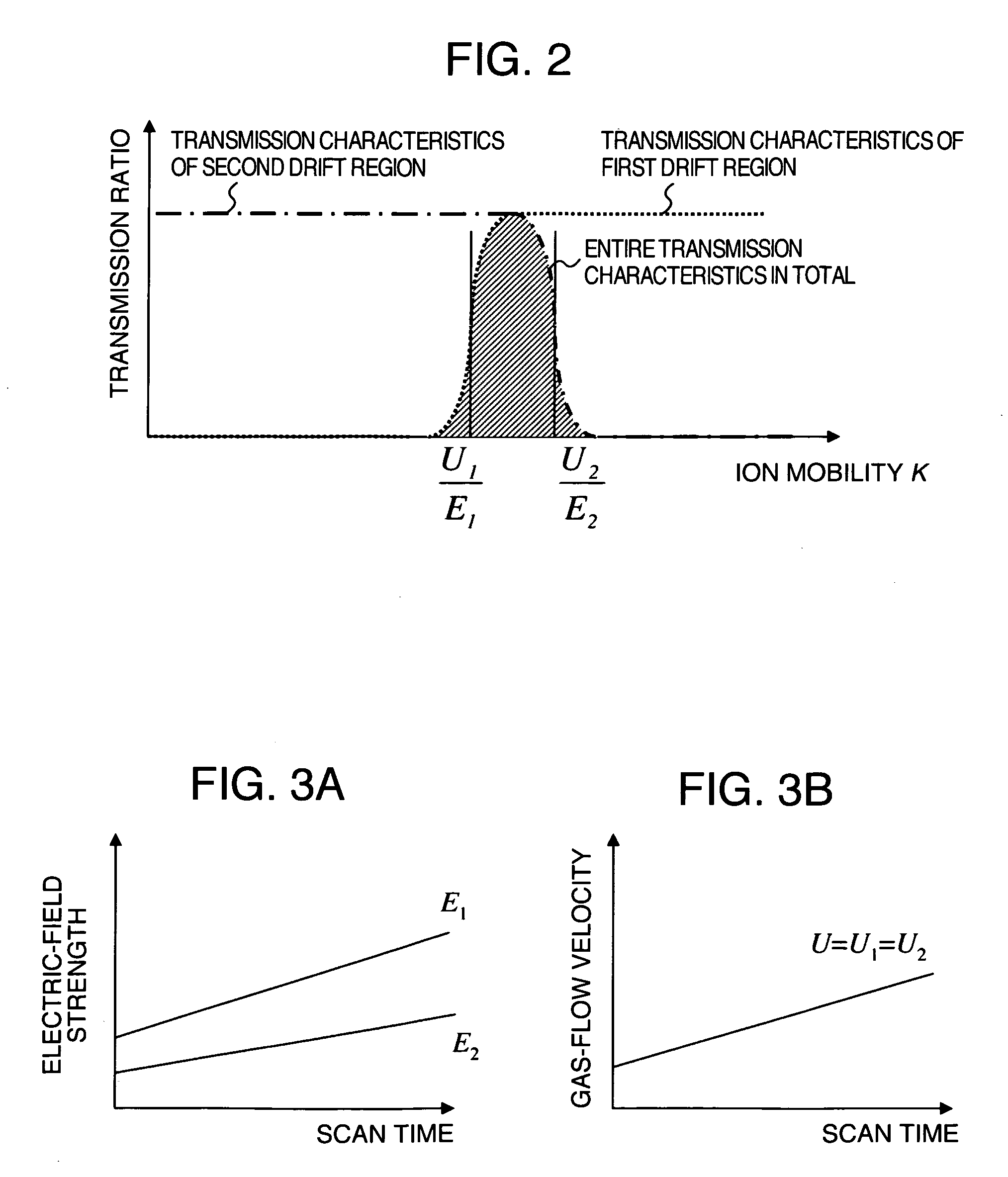

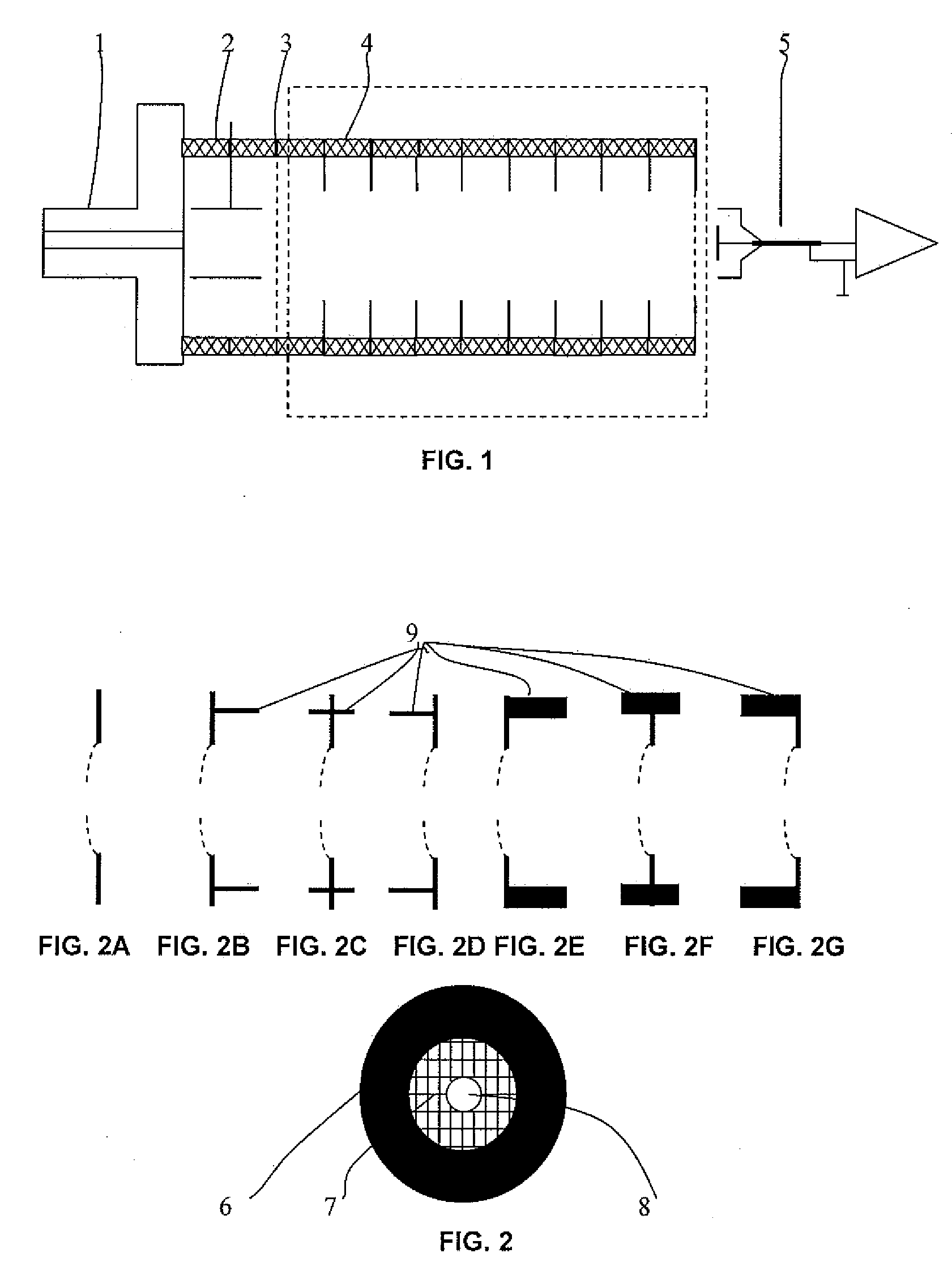

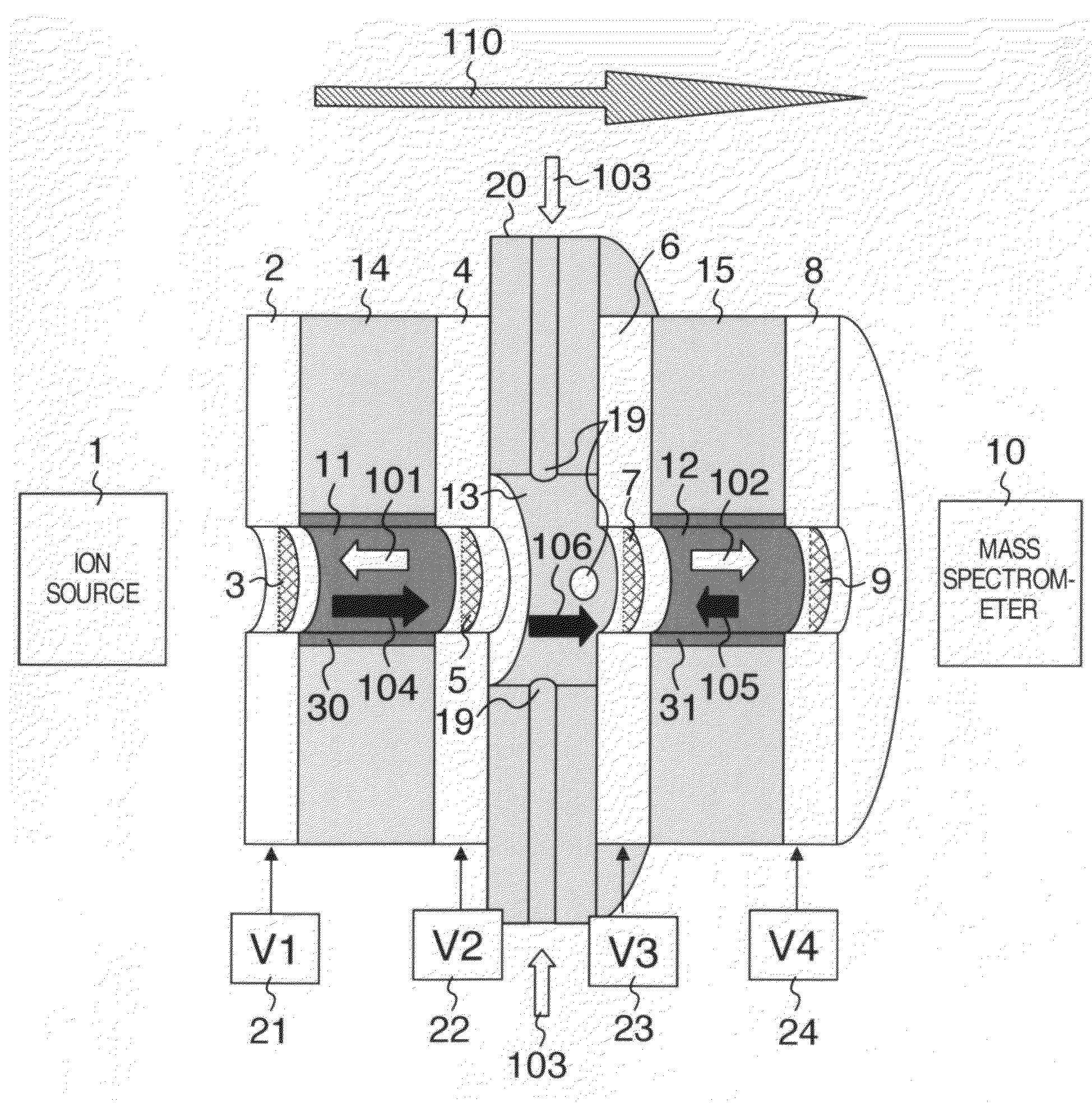

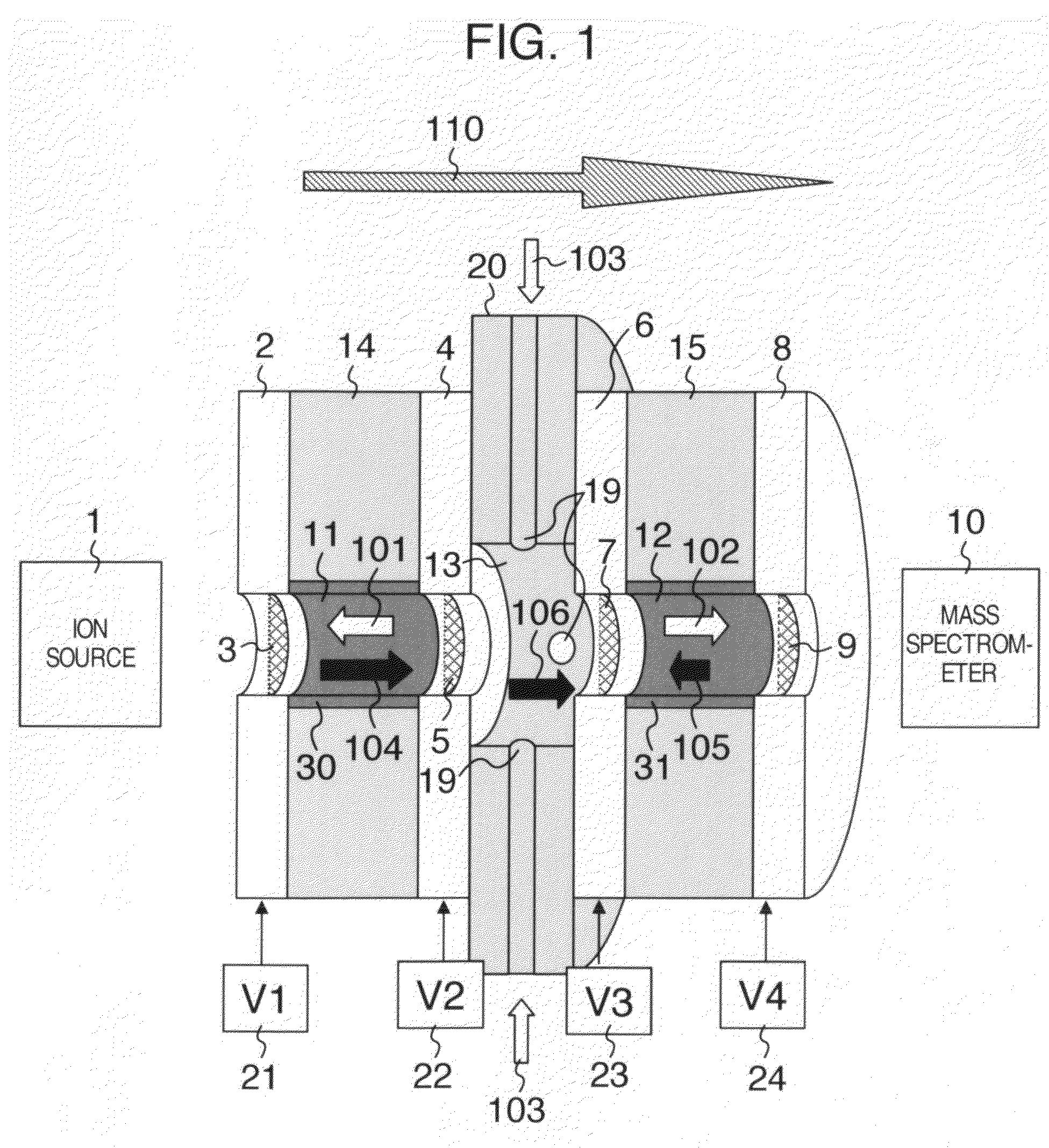

Ion mobility spectrometer and ion-mobility-spectrometry/mass-spectrometry hybrid spectrometer

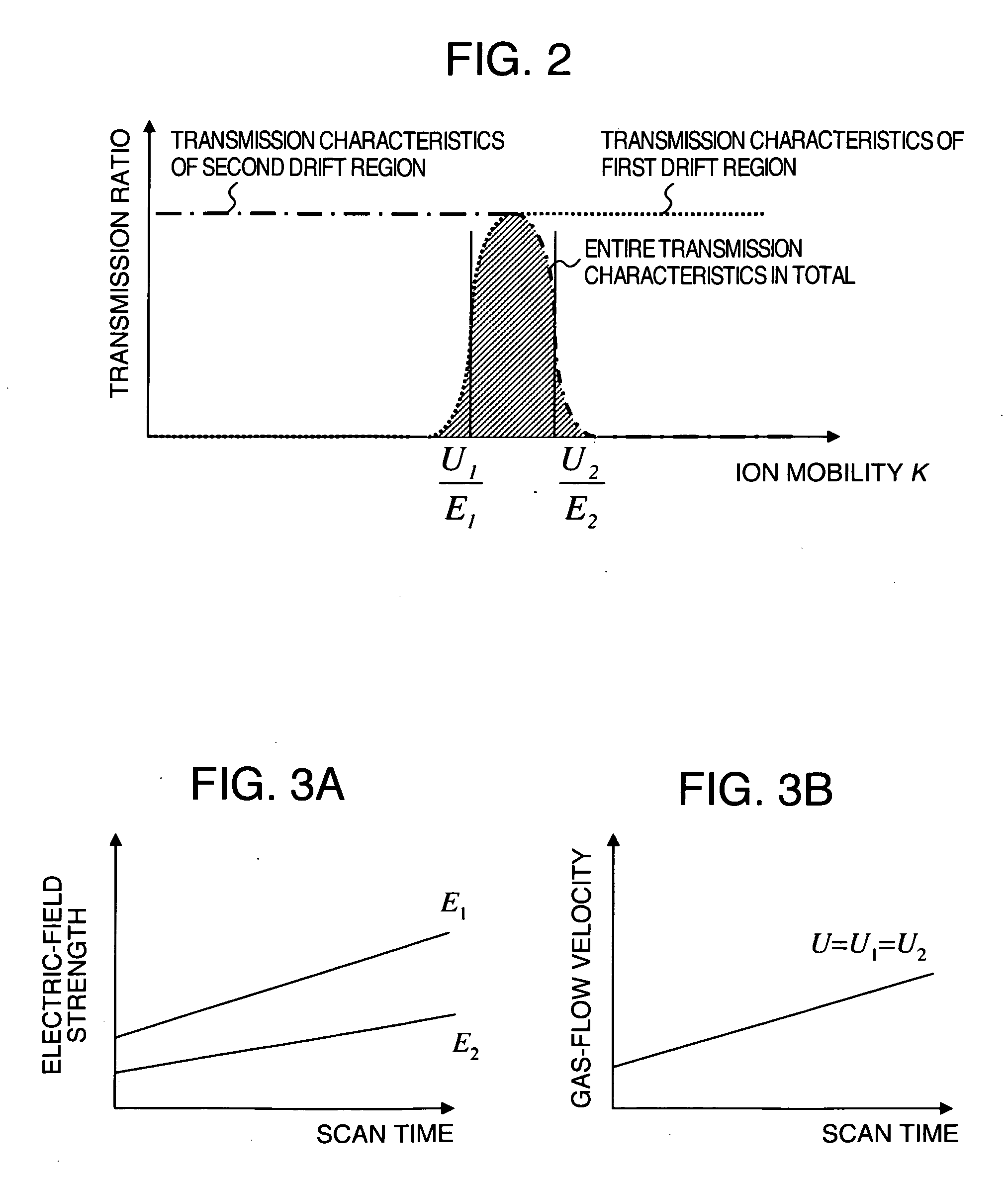

InactiveUS7718960B2Low costExcellent ion permeabilityTime-of-flight spectrometersMaterial analysis by electric/magnetic meansMass Spectrometry-Mass SpectrometryIon-mobility spectrometry

A low-cost and high-ion-transmission-ratio ion-mobility spectrometry filter, including an ion source, a first drift region in which a gas flow direction and a DC electric-field direction are opposite to each other, a second drift region in which a gas flow direction is provided, the gas flow direction being different from the gas flow direction in the first drift region, and being opposite to a DC electric-field application direction in the second drift region, an intermediate region having an electric field for causing ions to travel between the first drift region and the second drift region, and a detector for detecting ions which have passed through the first drift region and the second drift region.

Owner:HITACHI LTD

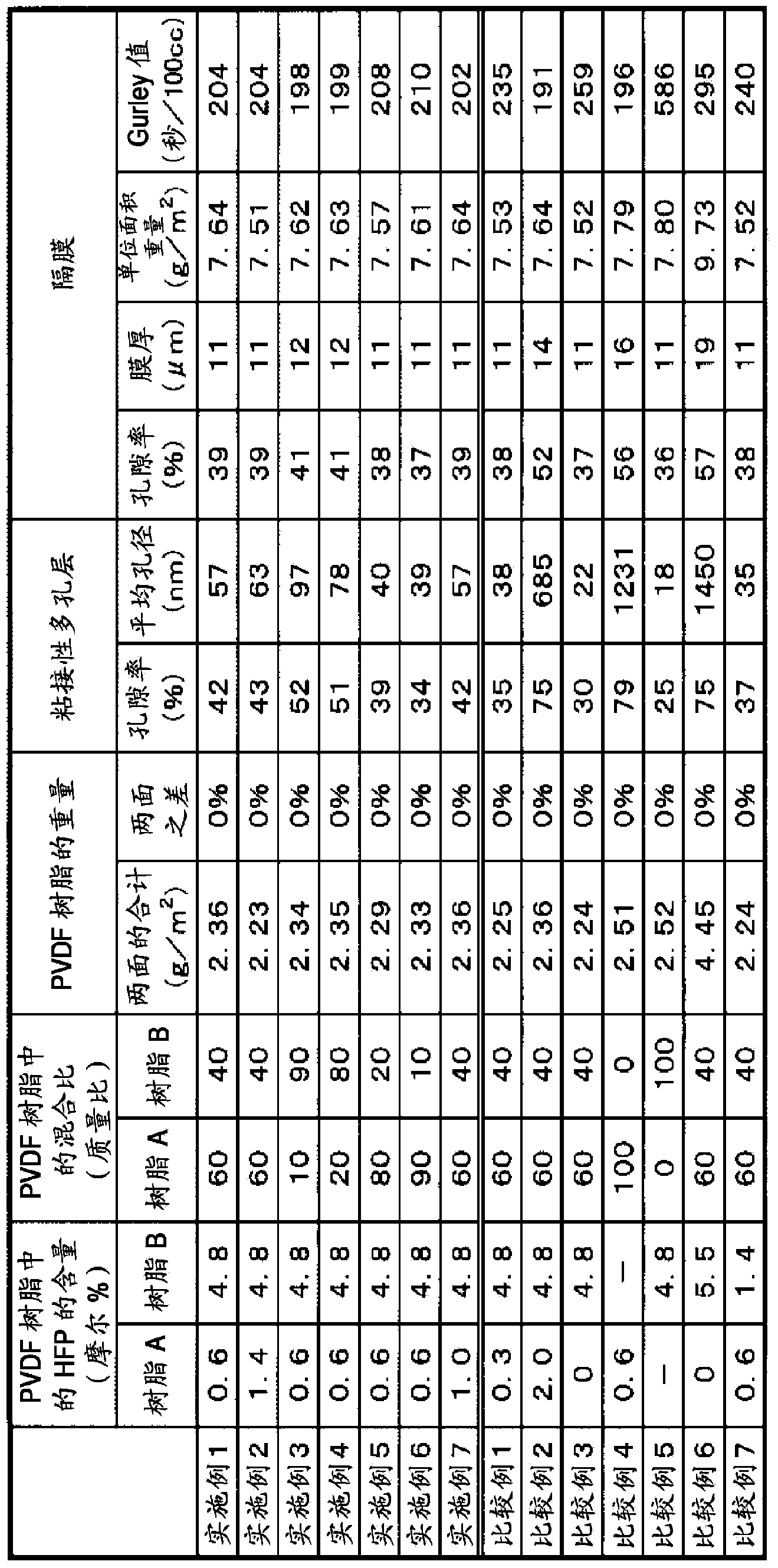

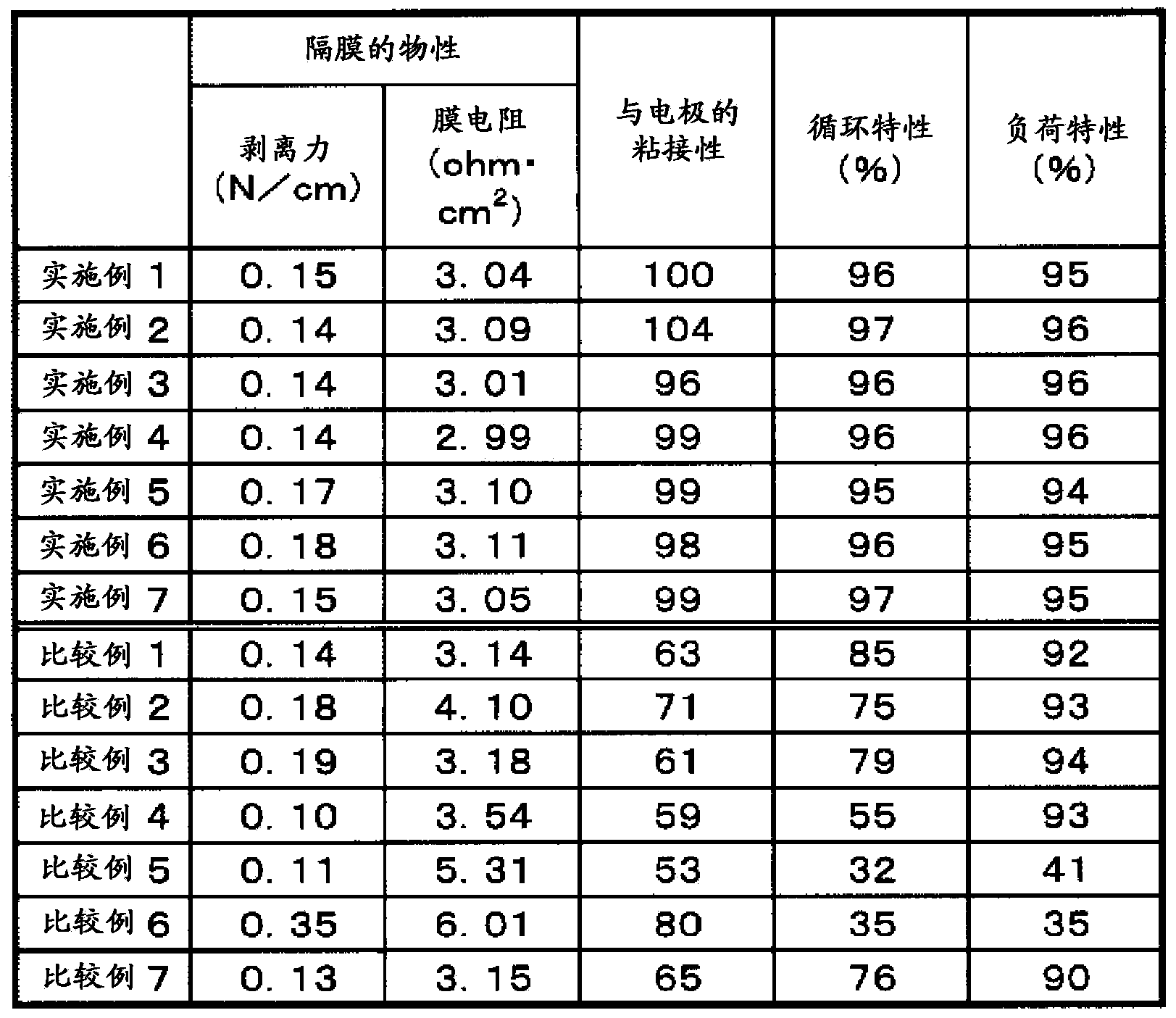

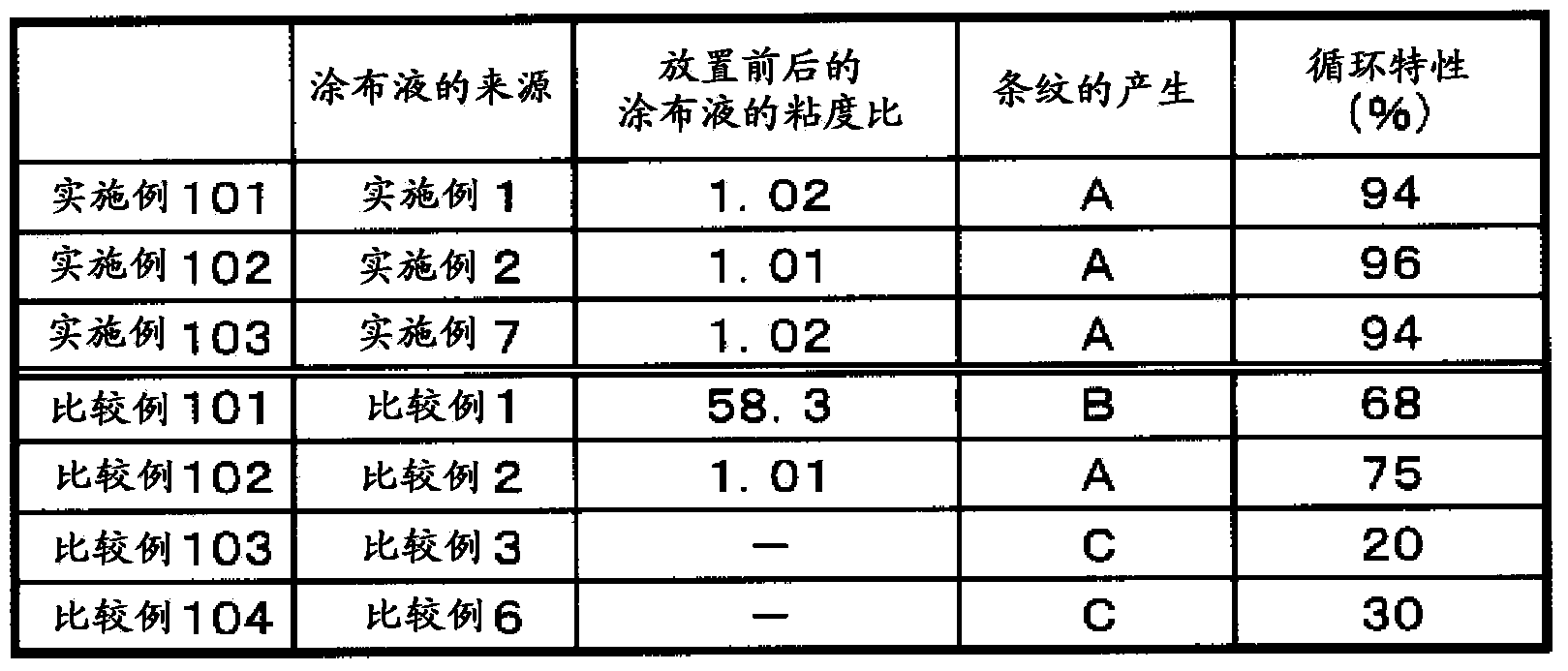

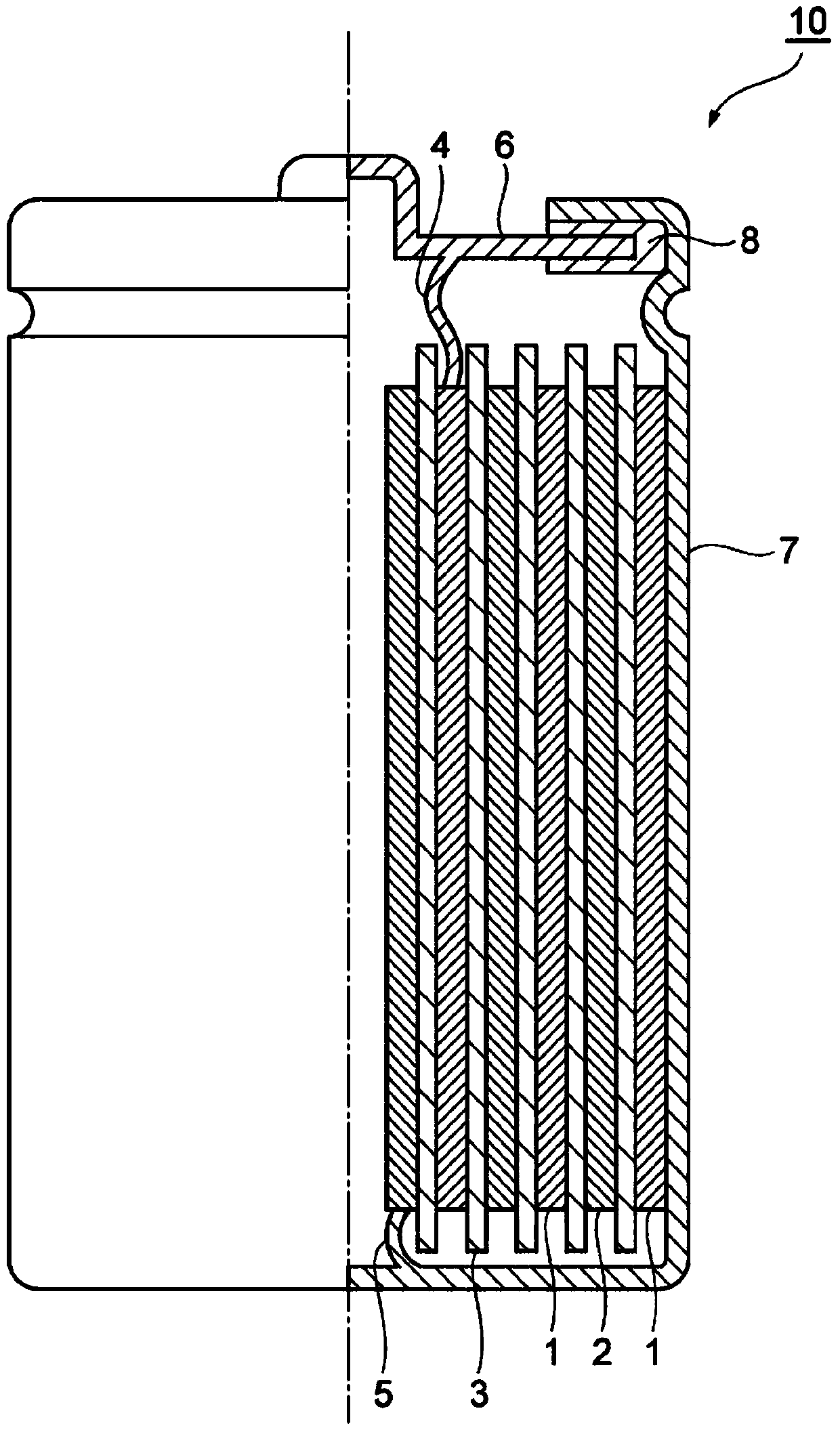

Separator for a non-aqueous secondary battery and non-aqueous secondary battery

ActiveUS20140255754A1Excellent ion permeabilityUniform porous structureJackets/cases materialsLi-accumulatorsPolyvinylidene fluorideStructural unit

The present invention provides a separator for a non-aqueous secondary battery including a porous substrate, and an adhesive porous layer that is formed at one or both sides of the porous substrate, contains (1) polyvinylidene fluoride resin A and (2) polyvinylidene fluoride resin B described below, and has a porosity of from 30% to 60% and an average pore size of from 20 nm to 100 nm:(1) polyvinylidene fluoride resin A is selected from the group consisting of vinylidene fluoride homopolymers and DVF copolymers containing structural units derived from vinylidene fluoride (VDF) and structural units derived from hexafluoropropylene (HFP), a total content of structural unit derived from HFP in each of the VDF copolymers being 1.5 mol % or less of a total content of structural unit in each of the VDF copolymers; and(2) polyvinylidene fluoride resin B selected from the group consisting of VDF copolymers containing a structural unit derived from VDF and a structural unit derived from hexafluoropropylene, a total content of structural unit derived from HFP in each of the VDF copolymers being greater than 1.5 mol % of a total content of structural unit in each of the VDF copolymers

Owner:TEIJIN LTD

Lithium ion battery diaphragm and its production method

InactiveCN1514501AHigh crystallization conversion rateLow priceCell component detailsPorosityElectrical battery

Characters of the invention are that crystal-nucleating agent of amide family compound is added into polyolefine resin. The procedure of the method includes following steps. (1) Under computer full control, hoisting system adds polyolefine resin containing 0.001-3% crystal-nucleating agent to extruder. In temperature 130-280 deg.C, the material is melted and extruded out. Then, primal flat film is rolled and obtained by using cooling roller to treat the material at temperature 40-110 deg.C. (2) The said primal flat film is fed into vertical and horizontal biaxial stretcher for stretch formability. Finally, heat customization is carried out. The selected crystal-nucleating agent possesses high crystal transformation ratio, and abundant source. Battery diaphragm provides features of high porosity, shapely hole shape, good intensity in both directions, and low cost. The invention can be applied to lithium cell, secondary cell or other type batteries after hydrophilic treatment.

Owner:XINXIANG ZHONGKE SCI&TECH

Nonaqueous secondary battery separator and non-aqueous secondary battery

ActiveCN103891002AImprove permeabilityGood adhesionJackets/cases materialsLi-accumulatorsPorous substrateHexafluoropropylene

The invention provides a nonaqueous secondary battery separator which has a porous substrate, and, provided on one or both surfaces of the porous substrate, an adhesive porous layer which contains a polyvinylidene fluoride resin (A) and a polyvinylidene fluoride resin (B) described below. Polyvinylidene fluoride resin (A): the polyvinylidene fluoride resin contains vinylidene fluoride-derived structural units and hexafluoropropylene-derived structural units, wherein the ratio of hexafluoropropylene-derived structural units to all structural units is 0.5-1.5 mol%. Polyvinylidene fluoride resin (B): the polyvinylidene fluoride resin contains vinylidene fluoride-derived structural units and hexafluoropropylene-derived structural units, wherein the ratio of hexafluoropropylene-derived structural units to all structural units is greater than 1.5 mol%.

Owner:TEIJIN LTD

Separator for electrochemical element and fabrication method for same

InactiveCN104272503AImprove heat resistanceGood flexibilityHybrid capacitor separatorsElectrolytic capacitorsFiberPhysical chemistry

Owner:RESONAC CORPORATION +1

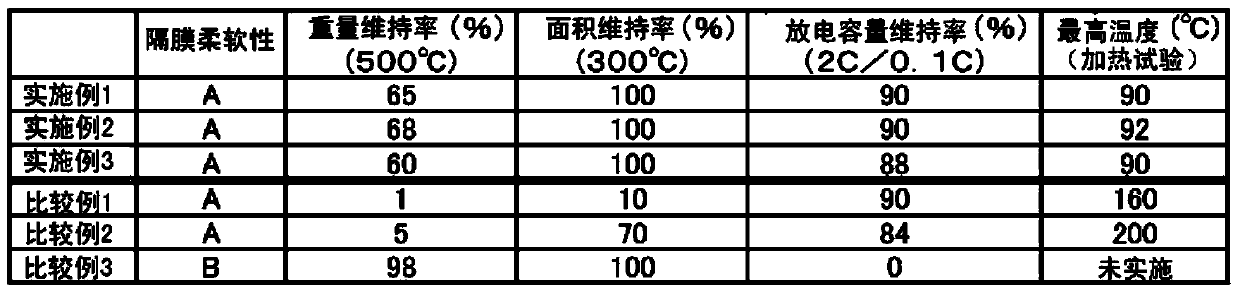

Heat-resisting lithium battery diaphragm and preparation method thereof

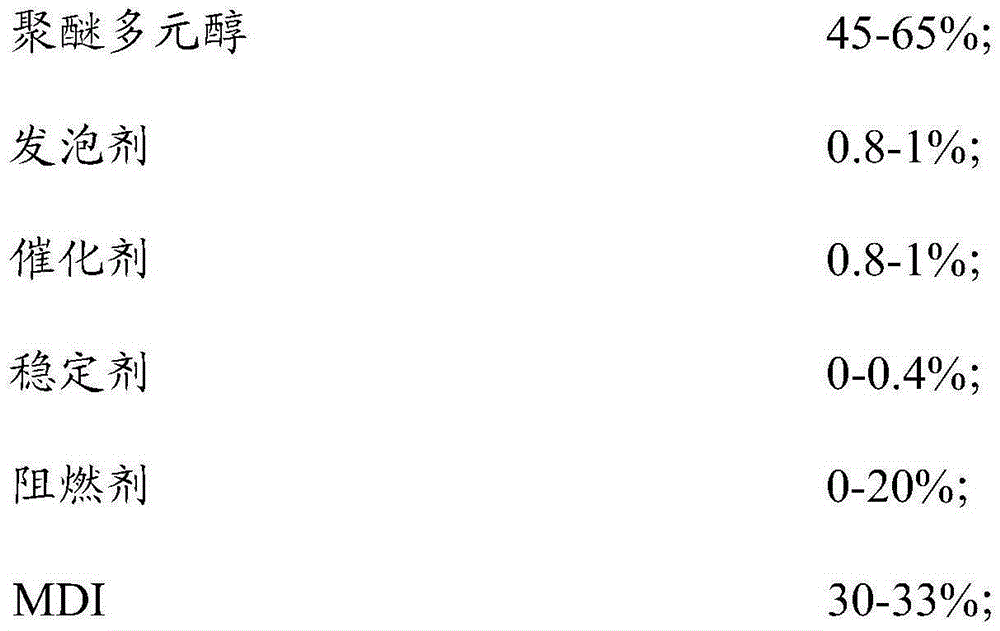

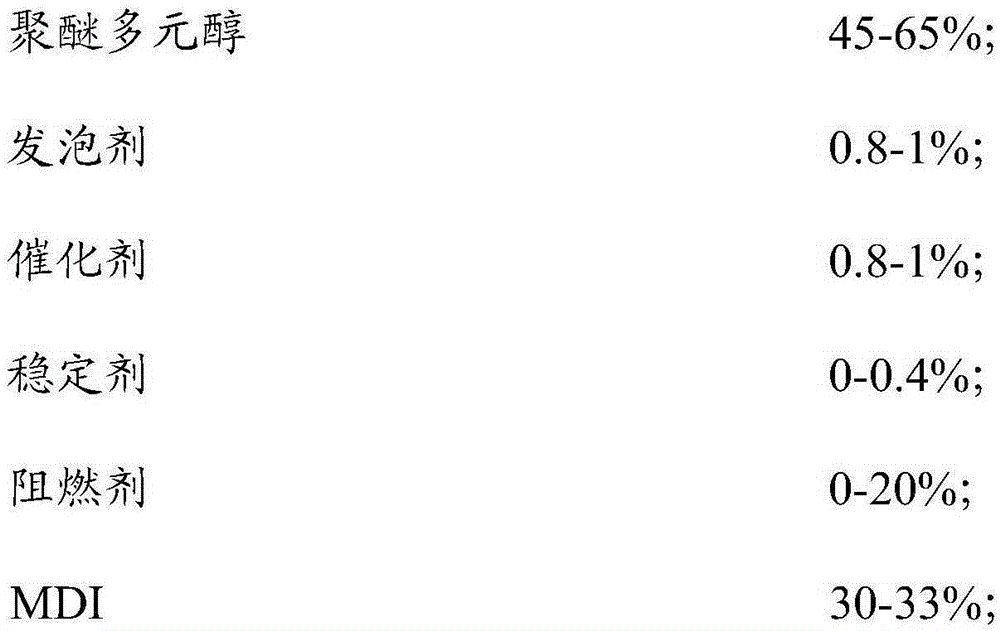

The invention provides a heat-resisting lithium battery diaphragm and a preparation method thereof. The method comprises the following steps: (a) weighing a component A, which comprises the following materials: polyether polyol, a foaming agent, a catalyst, a stabilizer and a fire retardant in weight ratio, pouring the materials into stirring equipment and mixing the materials evenly; (b) weighing a component B MDI in the weight ratio, respectively feeding the weighed materials of the component A and the material of the component B into a material jar A and a material jar B of a polyurethane foaming machine, stirring the materials in the polyurethane foaming machine, filling the materials into a rectangular or square mold, and carrying out foaming molding; and (c) putting a pelletized product which is molded in a foaming manner on a special foam horizontal cutting machine, cutting the pelletized product into slices according to the thickness requirement, and carrying out punch forming on the slices according to the size specification requirements, wherein the thicknesses of the slices are 5-41 microns; the porosity is 70%-75%; and the air permeability is 15-30 sec / 100cc. The heat-resisting lithium battery diaphragm has the advantages of high porosity, low thickness, high absorption amount, high ion permeability, low resistance, good compressive property, stable electrochemical properties, simplicity in manufacturing process, low cost, high quality and the like.

Owner:浙江清优材料科技有限公司

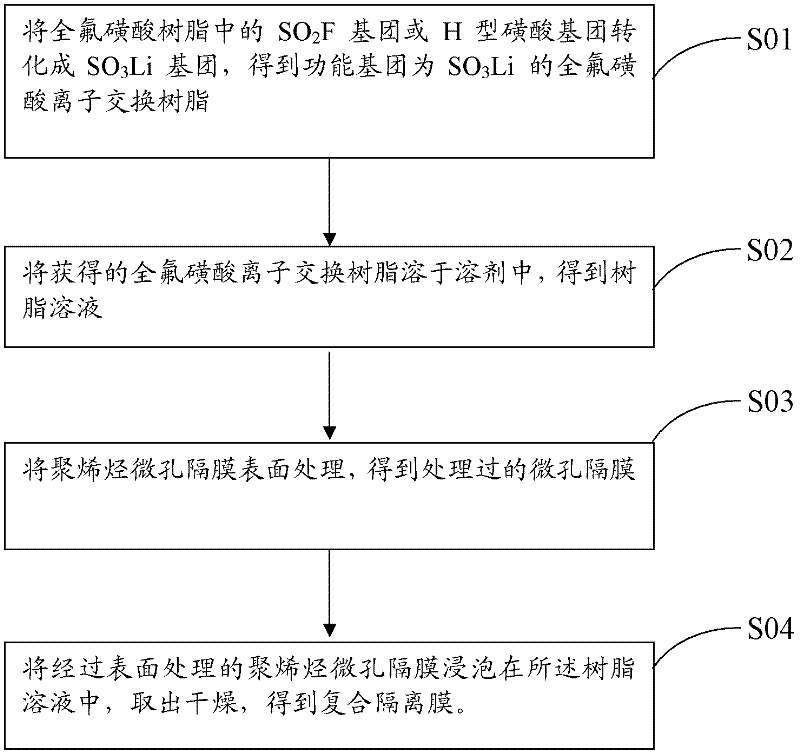

Composite isolation membrane and formation method thereof

ActiveCN102311559AImprove liquid absorption capacityImprove heat resistanceCell component detailsAbsorption capacityPolyolefin

The invention provides a composite isolation membrane and a formation method thereof, and the method comprises the following steps: transforming a SO2F group or a H-type sulfonic group in perfluorosulfonate resin into a SO3Li group to obtain a perfluorosulfonate ion exchange resin with a SO3Li functional group; dissolving the obtained perfluorosulfonate ion exchange resin in a solvent to obtain a resin solution; performing surface treatment of a polyolefin micropore diaphragm to obtain a treated micropore diaphragm; soaking the polyolefin micropore diaphragm after surface treatment in the resin solution, taking the diaphragm out and drying to obtain a composite isolation membrane. According to the invention, by combining the perfluorosulfonate ion exchange resin which has a Li ion exchange function after ion transformation with the polyolefin micropore diaphragm after surface treatment, the polyolefin micropore diaphragm is modified; because of the high thermal stability, hydrophilicity, and ion exchange capability of the perfluorosulfonate ion exchange resin, the liquid absorption capacity, heat resistance and ion penetration capability of the isolation membrane are increased.

Owner:SHENZHEN SENIOR TECH MATERIAL

Non-aqueous secondary battery separator and non-aqueous secondary battery

InactiveUS20140315068A1Excellent adhesion to electrodesImprove ion permeabilityJackets/cases materialsLi-accumulatorsPorous substratePorous layer

The present invention provides a separator for a non-aqueous secondary battery, including a porous substrate and an adhesive porous layer that is formed at at least one side of the porous substrate and contains the following polyvinylidene fluoride-based resin A and the following polyvinylidene fluoride-based resin B. (1) Polyvinylidene fluoride resin A selected from the group consisting of vinylidene fluoride homopolymers, and vinylidene fluoride copolymers containing a structural unit derived from vinylidene fluoride and a structural unit derived from hexafluoropropylene, the total content of structural units derived from hexafluoropropylene in each of the vinylidene fluoride copolymers being 1.5 mol % or less of the total content of structural units in each of the vinylidene fluoride copolymer. (2) Polyvinylidene fluoride resin B selected from the group consisting of vinylidene fluoride copolymers having a weight average molecular weight of from 300,000 to 2,500,000 and containing a structural unit derived from vinylidene fluoride and a structural unit derived from hexafluoropropylene, the total content of structural units derived from hexafluoropropylene in each of the vinylidene fluoride copolymer being greater than 1.5 mol % of the total content of structural units in each of the vinylidene fluoride copolymer.

Owner:TEIJIN LTD

Electrospinning technique-based ceramic diaphragm and preparation method thereof

InactiveCN106638007AHigh porosityThe overall thickness is thinSynthetic fibresSecondary cellsPorosityElectrospinning

The invention discloses an electrospinning technique-based ceramic diaphragm and a preparation method thereof. The preparation method comprises the steps of using a spinning nanofiber layer as a base membrane, and then coating / cast coating the base membrane with ceramic slurry or a ceramic precursor solution so as to obtain the final product. The ceramic diaphragm prepared by the method is high in porosity, thin in thickness and good in ion permeability; ceramic particles are introduced into the ceramic diaphragm, so that the thermal contraction of the ceramic diaphragm is greatly reduced, and the high temperature resistance of the ceramic diaphragm is improved.

Owner:烟台森森环保科技有限公司

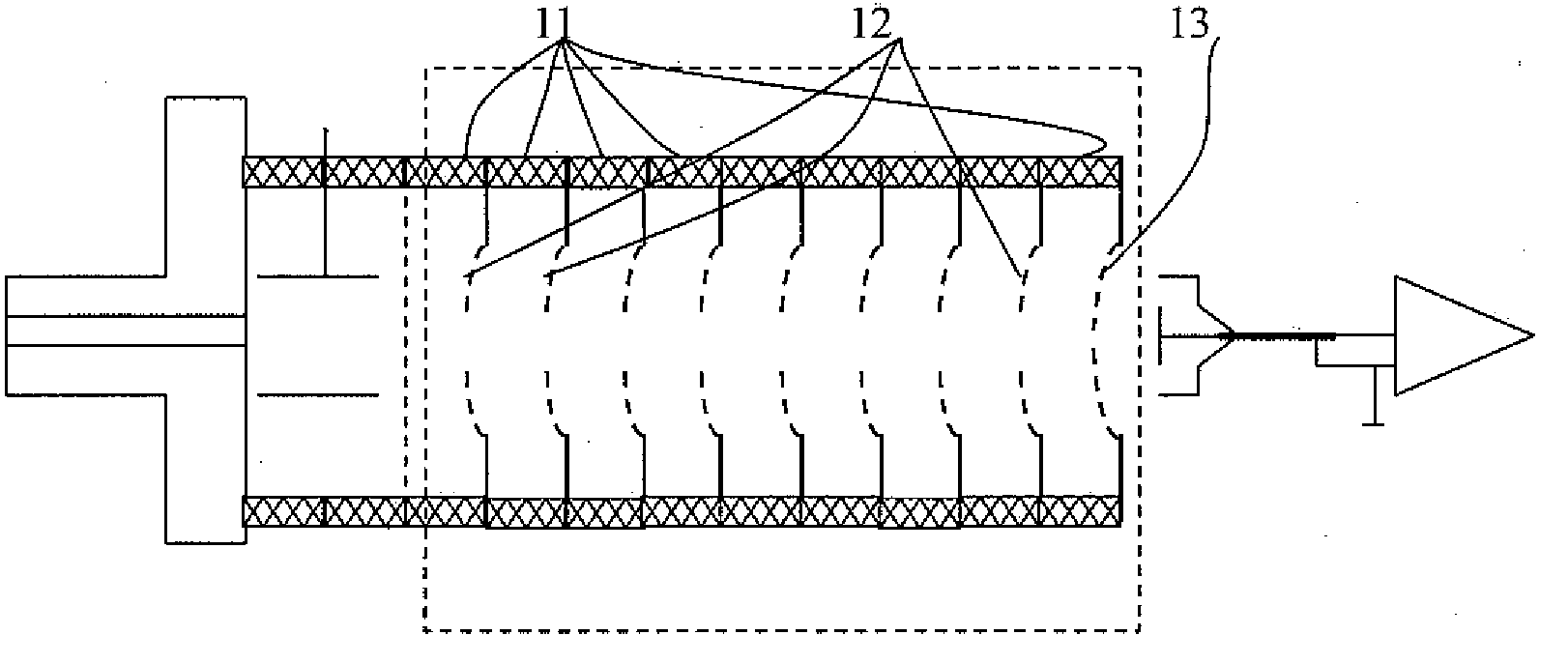

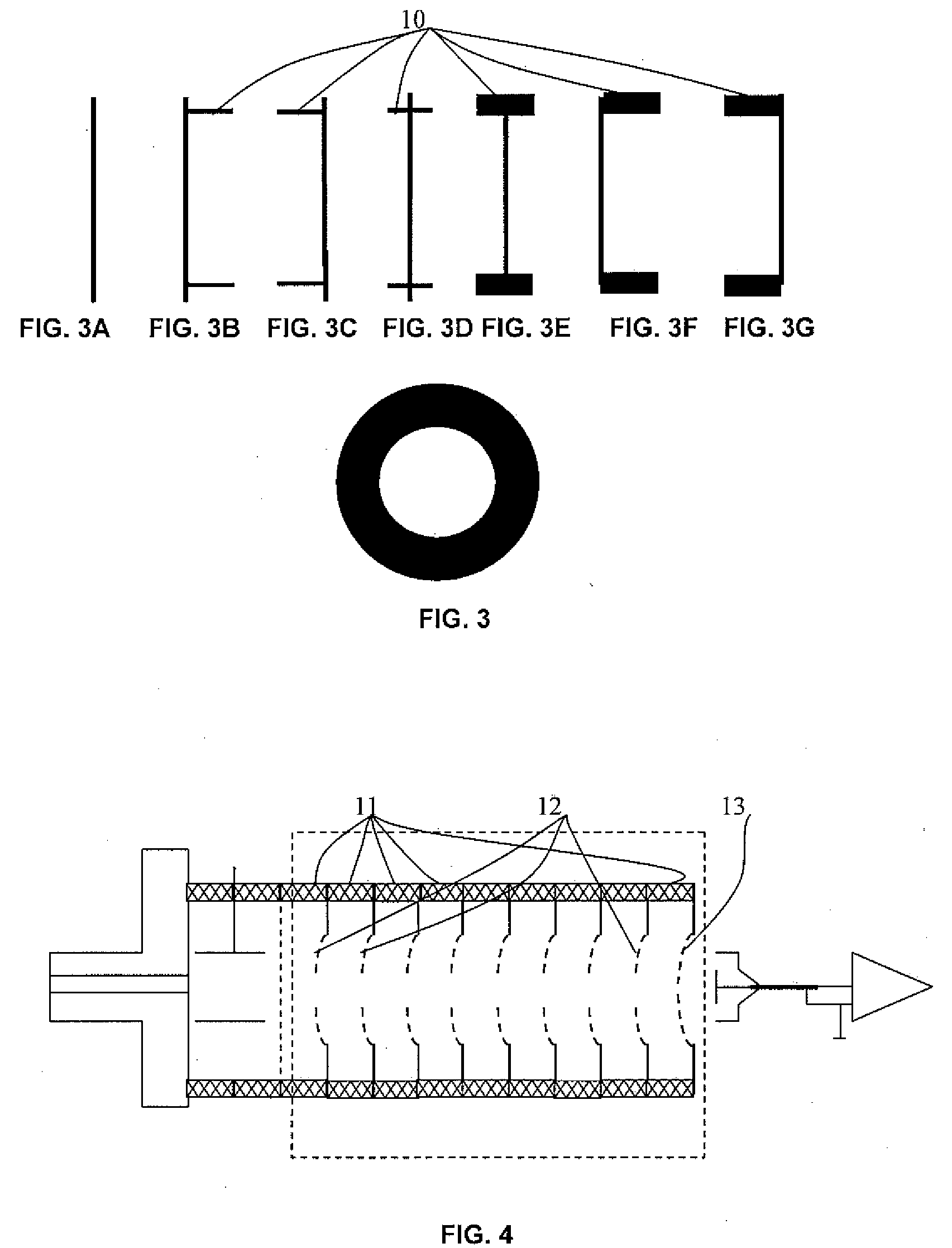

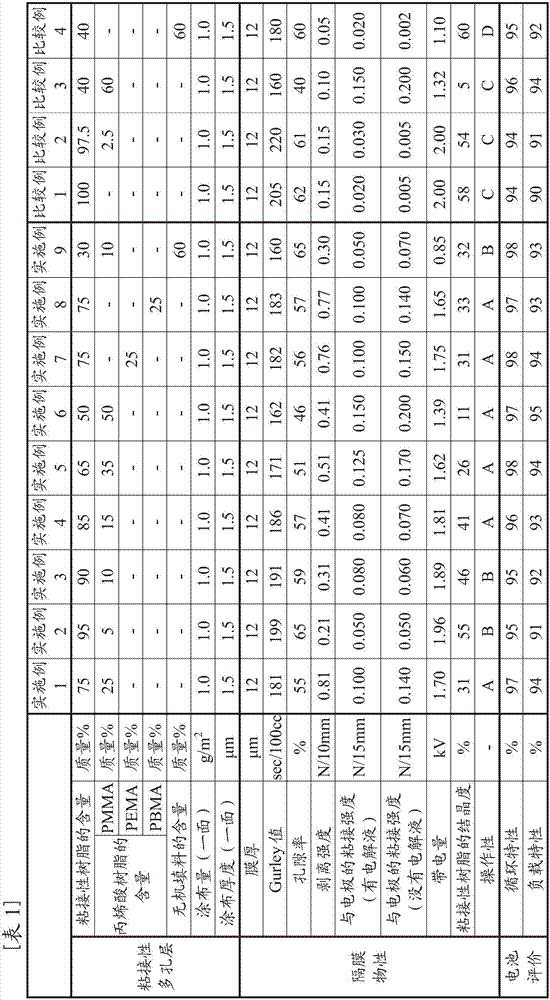

Drift tube structure for ion mobility spectrometer

ActiveUS20090166532A1High light transmittanceReduce input capacitanceTime-of-flight spectrometersMaterial analysis by electric/magnetic meansDrift tubeMetal sheet

A drift tube structure for ion mobility spectrometer is disclosed comprising electrode sheets and insulation parts arranged in alternation, with each electrode sheet being a mesh metal sheet having a radian or taper portion which is convexly curved toward an ion input. Further, the radian or taper portion of the electrode sheet has meshes of higher transparency. With the above structure of the present invention, an electric field having a periphery of uniform focusing center can be formed in the migration zone. The circular ring configuration of the electric field periphery can shield the migration electric field from any influence of external electric fields. The electrodes are each meshlike and have a circular hole at the center, thus they can focus and collect as many as possible ions that do not move along the central axis, and those ions moving along the central axis can pass through the electrodes transparently.

Owner:NUCTECH CO LTD

Separator for nonaqueous electrolyte cell, nonaqueous electrolyte cell, and method for manufacturing nonaqueous electrolyte cell

ActiveCN107004812AEasy to operateExcellent ion permeabilityFinal product manufactureEster polymer adhesivesPorous substrateAcrylic resin

An embodiment according to the present disclosure provides a separator for a nonaqueous electrolyte cell, comprising a composite membrane provided with a porous substrate and an adhesive porous layer provided on one or both faces of the porous substrate and including an adhesive resin, the adhesive porous layer further including acrylic resin in a state in which the acrylic resin is mixed with the adhesive resin, the peel strength between the porous substrate and the adhesive porous layer being 0.20 N / 10 mm or more, and the Gurley value being 200 seconds / 100 cc or less.

Owner:TEIJIN LTD

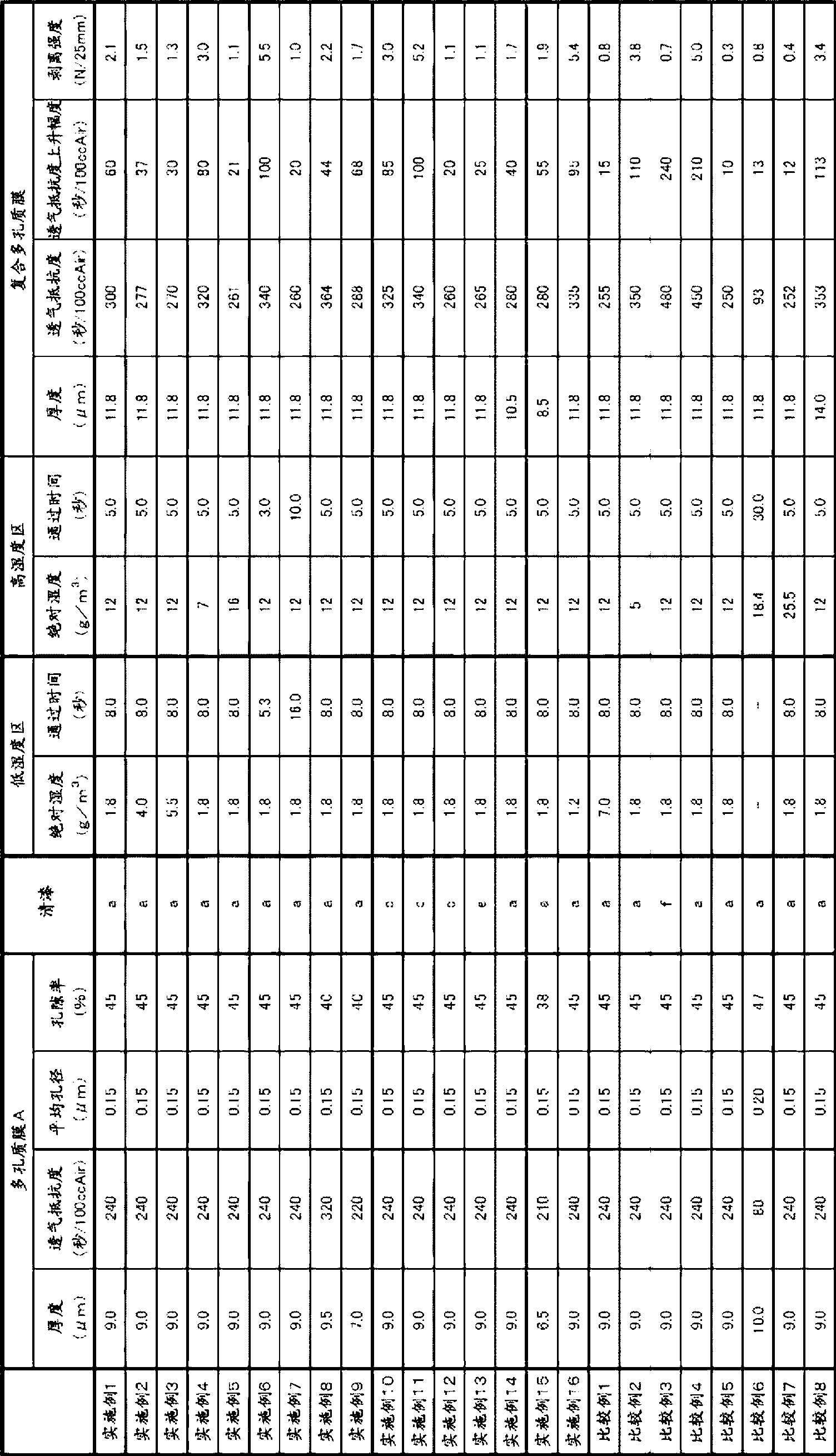

Composite porous membrane, method for producing composite porous membrane and battery separator using same

ActiveCN102958694AExcellent ion permeabilityGood adhesionCell seperators/membranes/diaphragms/spacersSynthetic resin layered productsPorous membranePolyolefin

Disclosed is a composite porous membrane which can achieve both an excellent adhesiveness of a heat-resistant resin layer and a small rise in gas permeation resistance even in the case of further reducing the thickness of membranes to be used, for example, battery separators. Specifically disclosed is a composite porous membrane comprising a porous membrane (A) formed of a polyolefin-based resin and a porous membrane (B) containing a heat-resistant resin, said porous membrane (B) being laminated on said porous membrane (A), wherein said porous membrane (A) has a thickness being within a specific range, an average pore size being within a specific range and a porosity being within a specific range and the thickness of the entire composite porous membrane is within a specific range, characterized in that, in said composite porous membrane, the peel strength at the interface between the specific porous membrane (A) and porous membrane (B) is within a specific range and the difference between the gas permeation resistance of the entire composite porous membrane and the gas permeation resistance of the porous membrane (A) is also within a specific range.

Owner:TORAY IND INC

Reactive-polymer-carrying porous film and process for producing the same

InactiveCN101032042AExcellent battery characteristicsExcellent ion permeabilityCell seperators/membranes/diaphragms/spacersSynthetic resin layered productsHigh ratePolymer science

It is intended to provide a reactive polymer-supported porous film that is capable of achieving sufficient adhesion between the electrode and the separator; reduced in internal resistance; and excellent in high rate characteristics, the porous film being useful as a battery separator which, after production of the battery, is not melted or broken under a high temperature and functions as a separator having a small heat shrinkage ratio as well as to provide a process for producing batteries using the reactive polymer-supported porous film. According to this invention, there is provided a reactive polymer-supported porous film for a battery separator, characterized in that the reactive polymer-supported porous film has: a substrate porous film of a porous film, the porous film has a temperature, at which a thickness of the porous film is reduced to 1 / 2 of a thickness when a prove is placed on the porous film in the case that the thickness of the porous film is measured by placing the probe having a diameter of 1 mm on the porous film under a load of 70 g and heating the porous film from a room temperature at a temperature-increase rate of 2 DEG C / minute, of 200 DEG C or more; and a reactive polymer supported on the substrate porous film, the reactive polymer is obtainable by reacting: a crosslinkable polymer obtainable by copolymerizing: a crosslinkable monomer having in a molecule at least one reactive group selected from a 3-oxetanyl group and an epoxy group; and a crosslinkable monomer having a reactive group capable of reacting with an isocyanate group; and a polyfunctional isocyanate to be partially crosslinked.

Owner:NITTO DENKO CORP

Separator for a non-aqueous electrolyte battery, non-aqueous electrolyte battery, and method of manufacturing non-aqueous electrolyte battery

InactiveUS20170338459A1Improved handling propertyExcellent ion permeabilityFinal product manufactureEster polymer adhesivesPorous substratePorous layer

In an embodiment of the present disclosure, provided is a separator for a non-aqueous electrolyte battery, the separator being composed of a composite membrane comprising: a porous substrate; and an adhesive porous layer provided on one side or both sides of the porous substrate and containing an adhesive resin, wherein the adhesive porous layer further contains an acrylic resin in a state in which the acrylic resin is mixed with the adhesive resin, a peel strength between the porous substrate and the adhesive porous layer is 0.20 N / 10 mm or more, and a Gurley value is 200 sec / 100 cc or less.

Owner:TEIJIN LTD

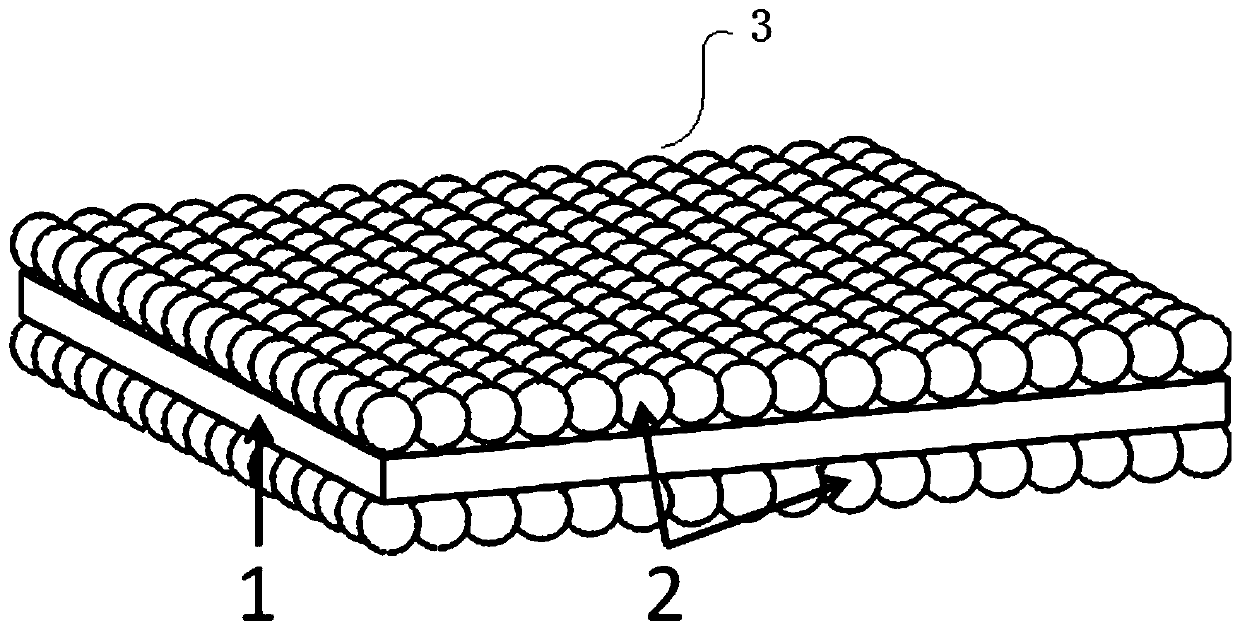

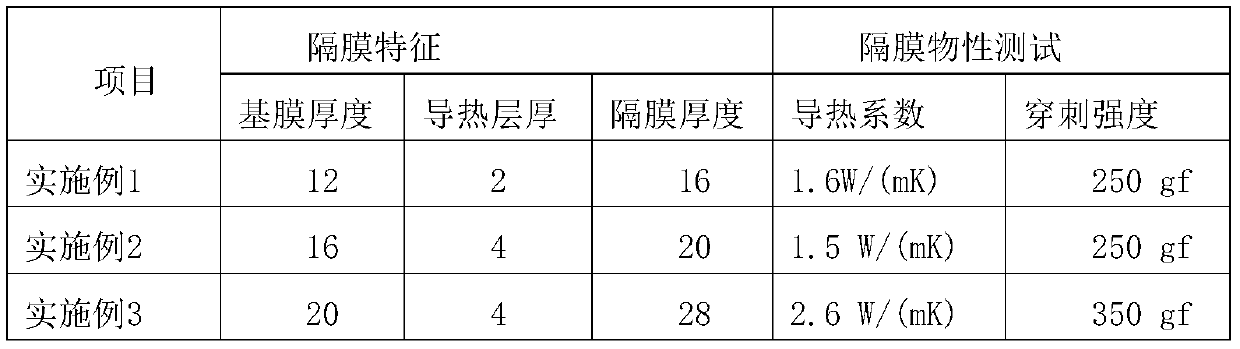

Composite diaphragm with high conductivity material layer and preparation method thereof

InactiveCN109860477AHigh thermal conductivityImprove flexibilitySecondary cellsCell component detailsThermal conductivityIon permeability

The present invention relates to a composite diaphragm with a high conductivity material layer. The composite diaphragm comprises a composite diaphragm main body consisting of a polymer diaphragm andan inorganic nanometer material layer, the polymer diaphragm constructs the polymer diaphragm main body structure bearing and fixes the inorganic nanometer material layer, and the inorganic nanometermaterial layer coats one-side surface or two-sides surfaces of the polymer diaphragm. The preparation method of the composite diaphragm with the high conductivity material layer comprises the steps of: selecting mixed high conductivity nanometer materials, configuring coating slurry, and employing a micro-concave coating process to perform coating of a thermal conductivity material layer at the surface of the polymer diaphragm. The composite diaphragm with the high conductivity material layer has the insulativity, high thermal conductivity feature and the high mechanical strength of the thermal conductivity material and the flexibility, the insulativity and the ion permeability of the polymer diaphragm material to achieve the chemical inertness, the fast heat conduction and the high strength mechanics of the composite heat conduction diaphragm with high heat conduction and high mechanical strength.

Owner:TIANJIN LISHEN BATTERY

Ion mobility spectrometer and ion-mobility-spectrometry/mass-spectrometry hybrid spectrometer

InactiveUS20080277575A1Low costExcellent ion permeabilityTime-of-flight spectrometersMaterial analysis by electric/magnetic meansMass Spectrometry-Mass SpectrometryIon-mobility spectrometry

A low-cost and high-ion-transmission-ratio ion-mobility spectrometry filter, including an ion source, a first drift region in which a gas flow direction and a DC electric-field direction are opposite to each other, a second drift region in which a gas flow direction is provided, the gas flow direction being different from the gas flow direction in the first drift region, and being opposite to a DC electric-field application direction in the second drift region, an intermediate region having an electric field for causing ions to travel between the first drift region and the second drift region, and a detector for detecting ions which have passed through the first drift region and the second drift region.

Owner:HITACHI LTD

Method for preparing PVDF (Polyvinylidene Fluoride) lithium ion battery diaphragm by electrostatic spinning

ActiveCN104157814AExcellent ion permeabilityFlexible thickness controlSecondary cellsCell component detailsPolyvinylidene difluoridePolyvinylidene fluoride

The invention discloses a method for preparing a PVDF (Polyvinylidene Fluoride) lithium ion battery diaphragm by electrostatic spinning. The method comprises the following steps: firstly, preparing polyvinylidene fluoride glacial acetic acid solution with the concentration of 17-20 percent by weight; secondly, stirring the polyvinylidene fluoride glacial acetic acid solution to be uniform; thirdly, completely cooling the polyvinylidene fluoride glacial acetic acid solution at room temperature of 25DEG C to obtain spinning solution; fourthly, taking a proper amount of spinning solution by using an injector, placing the injector on an injection pump, connecting a needle head, clamping an anode of a high voltage static generator on the needle head, enabling a cathode of the high voltage static generator to be connected with a receiving screen, and laying tin foil paper on rollers; fifthly, setting the spinning speed, adjusting the spinning voltage and the spinning distance and then performing static spinning; after the spinning is ended, taking off the tin foil paper from the rollers to obtain the lithium ion battery diaphragm. The method disclosed by the invention has the advantages of simple process, low energy consumption, low production cost and high performances of products; the pore size and the film thickness can be flexibly controlled, the improvement on both the ionic transparency of the diaphragm and the cycle performance of the battery is facilitated, and a good marker prospect is obtained.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Layered porous film, and non-aqueous electrolyte secondary battery

ActiveUS20170117525A1Improve ion permeabilityReduce penetrationSynthetic resin layered productsLi-accumulatorsPorous substratePolyolefin

A laminated porous film includes a porous base material layer containing polyolefin as a main component; a filler layer containing inorganic particles as a main component; and a resin layer containing resin particles as a main component, the resin particles showing an endothermic curve satisfying conditions (1) and (2) below, the endothermic curve being obtained by differential scanning calorimetry. Condition (1): a temperature at which DDSC is not less than 0.10 mW / min / mg is not less than 70° C. Condition (2): endothermic amount calculated from an area of the endothermic curve in a range of not less than 50° C. and not more than 70° C. is not less than −20.0 J / g.

Owner:SUMITOMO CHEM CO LTD

Diaphragm for alkaline water electrolysis, method for producing same, and method for producing inorganic-organic composite membrane

PendingCN110945161ALow costExcellent ion permeabilityOrganic diaphragmsLayered productsPhysical chemistryMacromolecule

The present invention addresses the problem of providing a diaphragm for alkaline water electrolysis, which does not undergo the elution of inorganic components in an alkaline solution, at low cost. The present invention is a diaphragm for alkaline water electrolysis, characterized by containing magnesium hydroxide and an organic polymeric resin.

Owner:NIPPON SHOKUBAI CO LTD

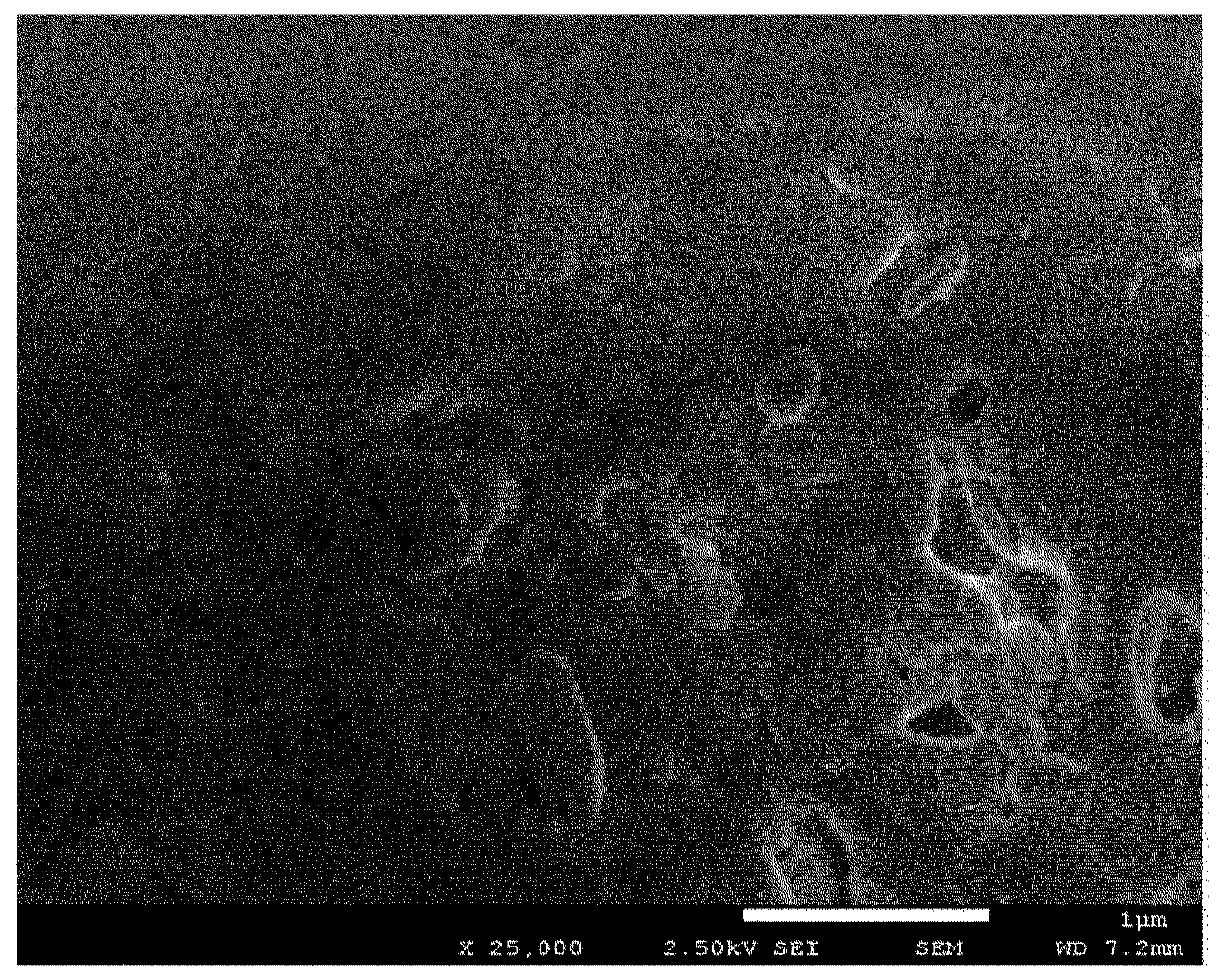

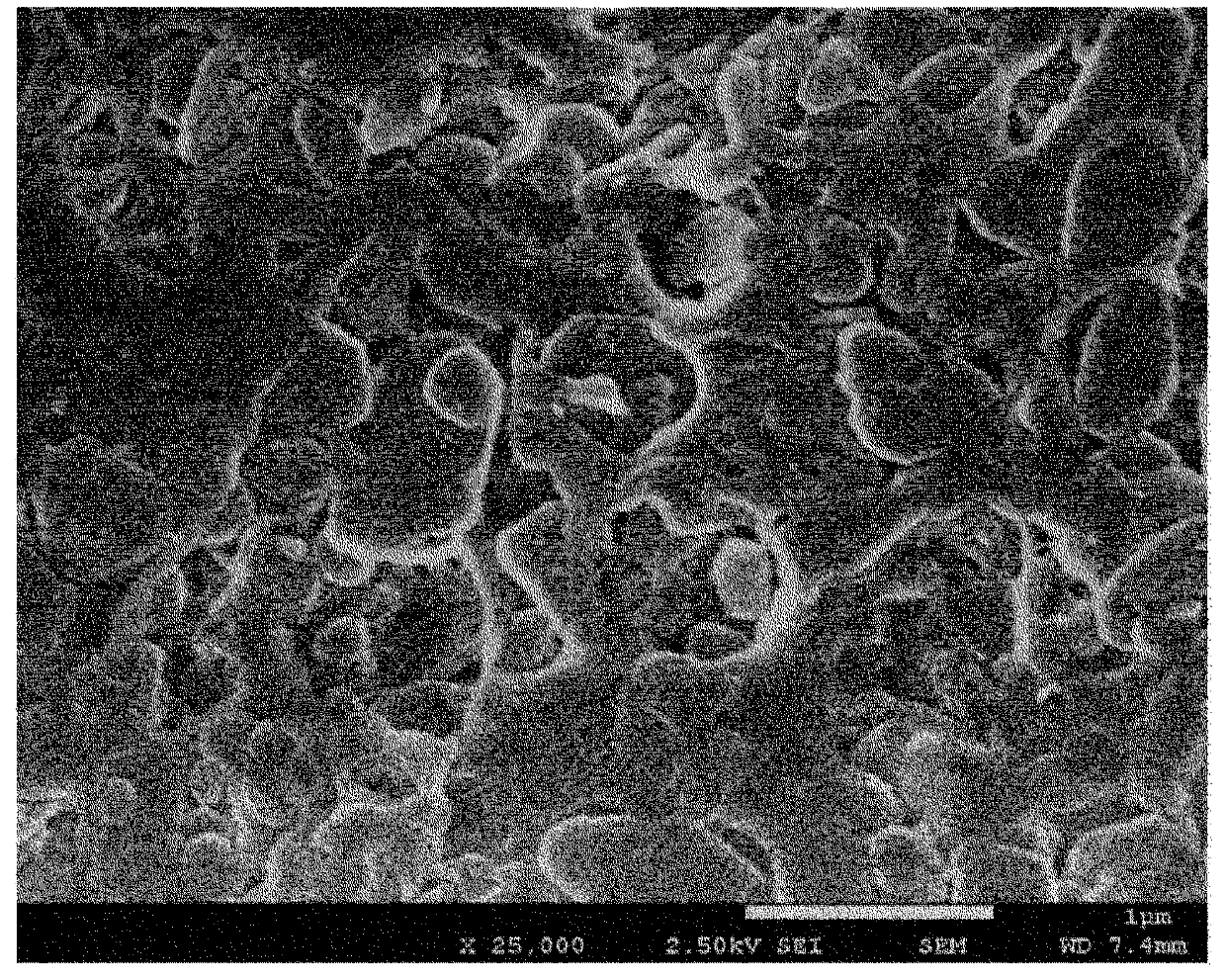

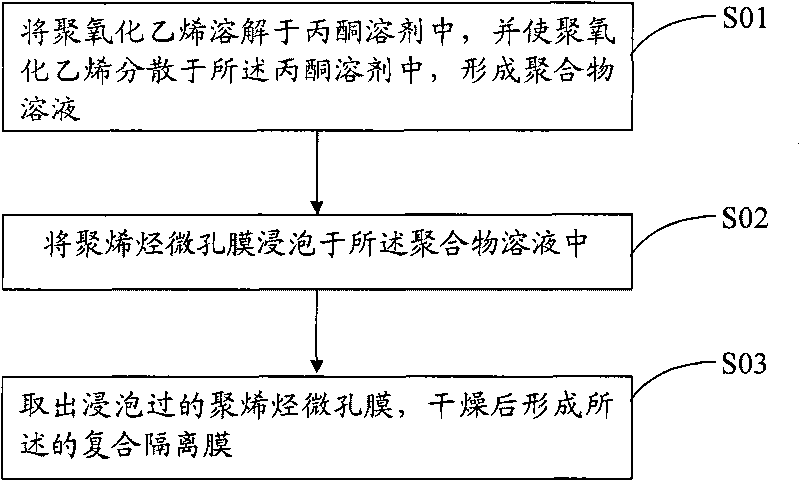

Compound isolating film and formation method thereof

InactiveCN101702426AImprove liquid absorption capacityExcellent ion permeabilityCell component detailsPolyolefinPolymer science

The invention provides a compound isolating film and a formation method thereof. The method comprises the following steps of: dissolving polyethylene glycol oxide in an acetone solvent; dispersing the polyethylene glycol oxide in the acetone solvent to form a polymer solution; soaking a polyolefine microporous film in the polymer solution; taking out the soaked polyolefine microporous film; and drying the polyolefine microporous film to form the compound isolating film. In the method, the acetone solvent is used for compounding the polyethylene glycol oxide and the polyolefine microporous film; and the polyolefine microporous film is modified to obviously enhance the solution absorption capability and the ion penetrating capability of the isolating film. Moreover, the acetone solvent has low price and does not have harm basically, and therefore, the production cost is reduced and the production operating safety is enhanced.

Owner:SHENZHEN SENIOR TECH MATERIAL

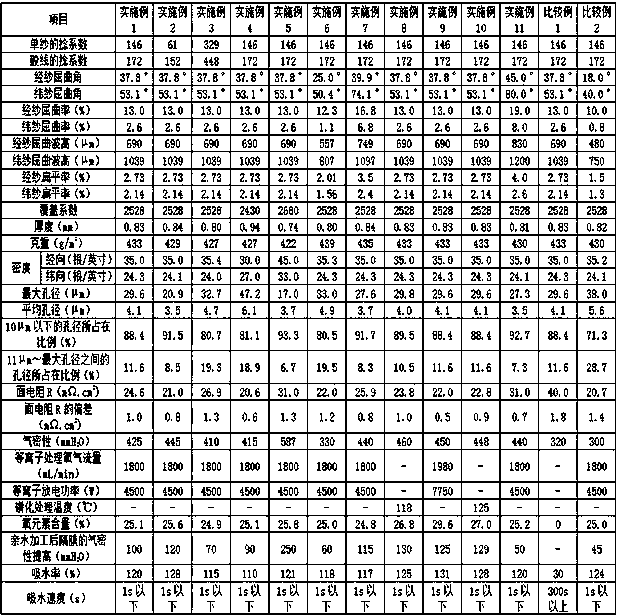

Water electrolysis diaphragm and manufacturing method thereof

InactiveCN109554724AExcellent ion permeabilityImprove hydrophilicityCellsWoven fabricsFiberElectrolysis

The invention discloses a water electrolysis diaphragm and a manufacturing method thereof, and the diaphragm is a woven fabric diaphragm, the woven fabric diaphragm is fromed by high-temperature-resistant acid and alkali resistant fiber which is frequently used at temperature of 150 DEG c or higher; the maximum pore diameter of the woven fabric diaphragm is 15-55 microns, pores wuth the pore diameter less than 10 [mu] m accounts for 80.0-95.0%, and pores wuth the pore diameter between 11 microns and the maximum pore diameter accounts for 5.0-20.0 %. The water electrolysis diaphragm provided bythe invention has high ion permeability and excellent hydrophilicity, and has the characteristics of simple production process and no pollution to the environment.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com