Method for preparing PVDF (Polyvinylidene Fluoride) lithium ion battery diaphragm by electrostatic spinning

A lithium-ion battery and electrospinning technology, applied in secondary batteries, battery components, circuits, etc., can solve the problems of limited range of materials, large pore size, complex preparation process, etc., and achieve high product performance and low production cost , The effect of simple process

Active Publication Date: 2014-11-19

SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

View PDF10 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the range of materials applicable to this method is limited, and fiber raw materials are mainly used for preparation, and the preparation process is relatively complicated, and the pore size is large. Other methods need to be used to modify the separator to meet the needs of lithium-ion battery separators.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

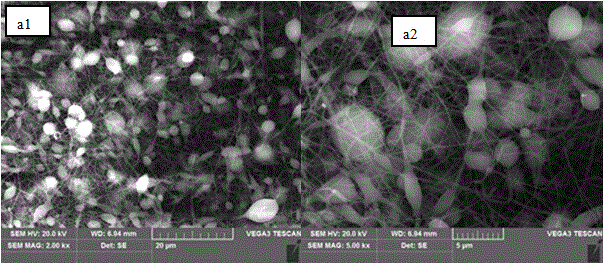

[0051] Example 1: The concentration of PVDF is 20wt%, the spinning voltage is 22kv, and the spinning speed is 0.0006mm / s.

Embodiment 2

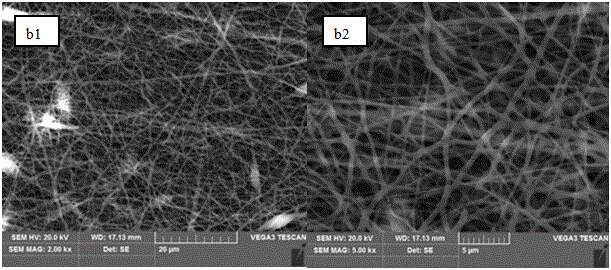

[0052] Example 2: The concentration of PVDF is 18wt%, the spinning voltage is 23kv, and the spinning speed is 0.0007mm / s.

Embodiment 3

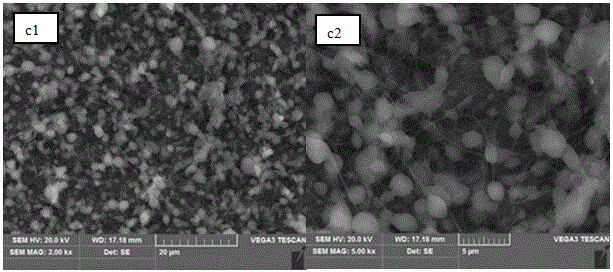

[0053] Example 3: The concentration of PVDF is 17wt%, the spinning voltage is 24kv, and the spinning speed is 0.0008mm / s.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for preparing a PVDF (Polyvinylidene Fluoride) lithium ion battery diaphragm by electrostatic spinning. The method comprises the following steps: firstly, preparing polyvinylidene fluoride glacial acetic acid solution with the concentration of 17-20 percent by weight; secondly, stirring the polyvinylidene fluoride glacial acetic acid solution to be uniform; thirdly, completely cooling the polyvinylidene fluoride glacial acetic acid solution at room temperature of 25DEG C to obtain spinning solution; fourthly, taking a proper amount of spinning solution by using an injector, placing the injector on an injection pump, connecting a needle head, clamping an anode of a high voltage static generator on the needle head, enabling a cathode of the high voltage static generator to be connected with a receiving screen, and laying tin foil paper on rollers; fifthly, setting the spinning speed, adjusting the spinning voltage and the spinning distance and then performing static spinning; after the spinning is ended, taking off the tin foil paper from the rollers to obtain the lithium ion battery diaphragm. The method disclosed by the invention has the advantages of simple process, low energy consumption, low production cost and high performances of products; the pore size and the film thickness can be flexibly controlled, the improvement on both the ionic transparency of the diaphragm and the cycle performance of the battery is facilitated, and a good marker prospect is obtained.

Description

technical field [0001] The invention relates to a lithium ion battery, in particular to a method for preparing a PVDF (polyvinylidene fluoride) lithium ion battery diaphragm by electrospinning, and belongs to the technical field of nanofiber membrane preparation. [0002] Background technique [0003] The diaphragm is an important part of the lithium-ion battery. Its function is to prevent the contact between the positive and negative active materials to cause a short circuit and to maintain the necessary electrolyte to form a channel for ion movement during the electrochemical reaction. The performance of the separator affects the electrochemical performance of the battery, and plays a vital role in the safety performance of the battery. [0004] Lithium-ion battery separators currently on the market mainly use thin-filmed polyolefin materials, such as polyethylene (PE) microporous membranes, polypropylene (PP) microporous membranes, and polypropylene / polyethylene (PP / PE) ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M2/16

CPCH01M10/0525H01M50/403H01M50/411H01M50/44Y02E60/10

Inventor 陈建龚勇胥会吴召洪蒋文平朱晓飞

Owner SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com