Diaphragm for alkaline water electrolysis, method for producing same, and method for producing inorganic-organic composite membrane

A manufacturing method and composite membrane technology, which can be used in diaphragms, electrolysis components, electrolysis processes, etc., can solve the problems of generating surplus power, unable to achieve balance between power supply and demand, and achieve low cost, excellent ion permeability, and dissolution of inorganic components. inhibiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0258] (1. Preparation of magnesium hydroxide dispersion)

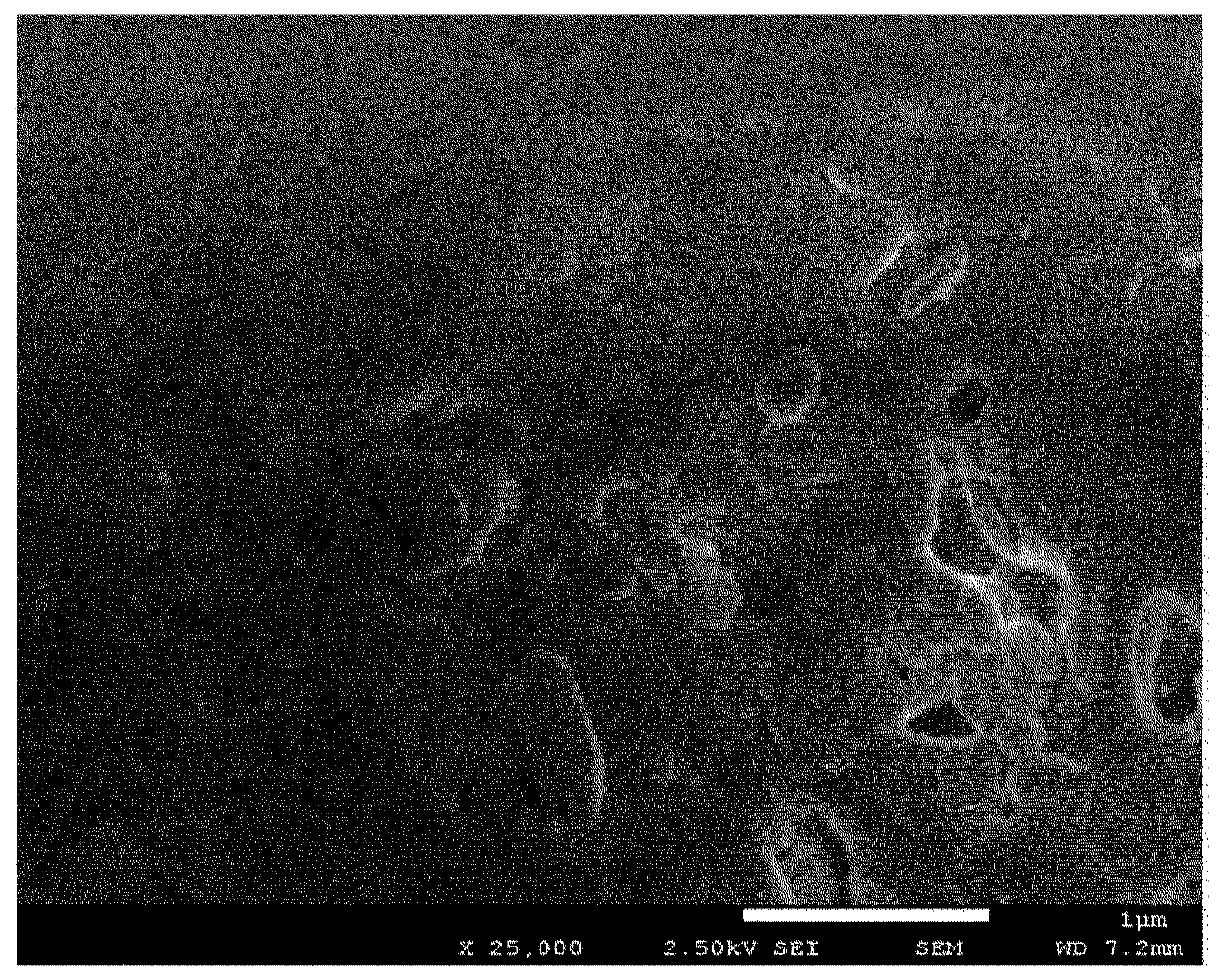

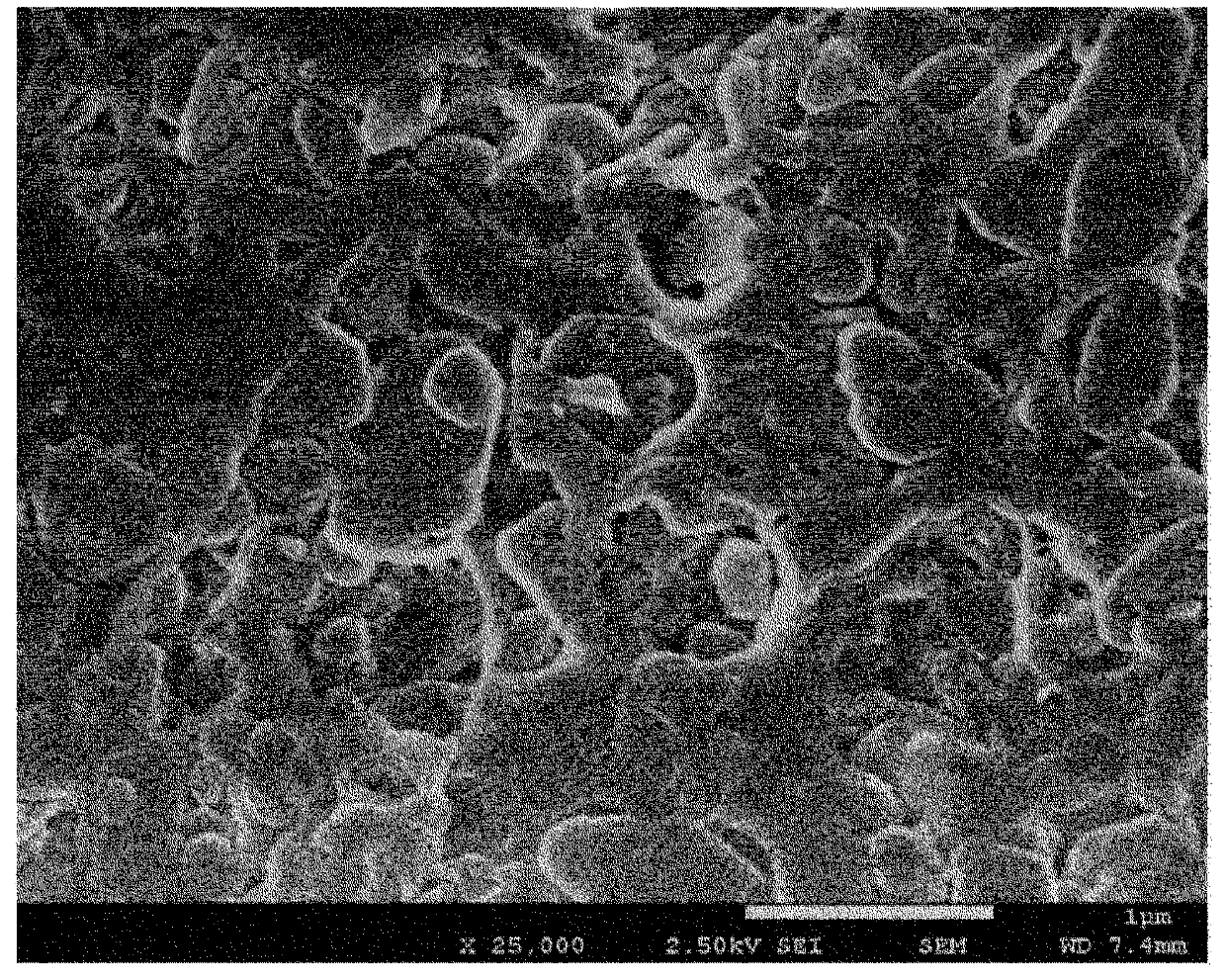

[0259] Magnesium hydroxide (manufactured by Kyowa Chemical Industry Co., Ltd., product number 200-06H, average particle size 0.54 μm, aspect ratio 3.52, and the crystallite diameter in the direction perpendicular to the (110) plane is 70.7 nm) and N-methyl- 2-Pyrrolidone (manufactured by Wako Pure Chemical Industries, Ltd.) was mixed at a mass ratio of 1:1, and dispersed at room temperature for 6 hours using a pot mill equipped with zirconia media balls to prepare a magnesium hydroxide dispersion .

[0260] (2. Preparation of polysulfone resin solution)

[0261] Prepared by thermally dissolving polysulfone resin (manufactured by BASF Corporation, product number Ultrason S3010) in N-methyl-2-pyrrolidone (manufactured by Wako Pure Chemical Industries, Ltd.) at a concentration of 30% by mass at 80 to 100°C. Get out polysulfone resin solution.

[0262] (3. Preparation of coating solution)

[0263] The above-obtained m...

Embodiment 2

[0267] In Example 1, (4. Formation of coating film) was performed as follows, and the separator for alkaline water electrolysis was obtained by the method similar to Example 1 except this.

[0268] (4'. Formation of coating film)

[0269] Use an applicator to apply the coating solution so that the weighing value of the dried coating solution is 12.0 mg / cm 2 The method is coated on the PET film, on which the polypropylene (PP) non-woven fabric (manufactured by Japan Vilene Company, product number OA16728F, thickness 160 μ m, basis weight 60 g / m 2) in contact with it, thereby completely impregnating the coating solution into the nonwoven fabric. Thereafter, the nonwoven fabric impregnated with the coating solution was placed in a water bath at room temperature for 10 minutes to solidify the coating solution to form a film, and the film was peeled from the PET film together with the nonwoven fabric in water. After the water bath, the obtained membrane was dried at 80° C. for 30...

Embodiment 3

[0271] A separator for alkaline water electrolysis was obtained in the same manner as in Example 1 except that polyethersulfone (PESU) (manufactured by BASF Corporation, Ultrason E3010) was used instead of the polysulfone resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com