Patents

Literature

57results about How to "Flexible thickness control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

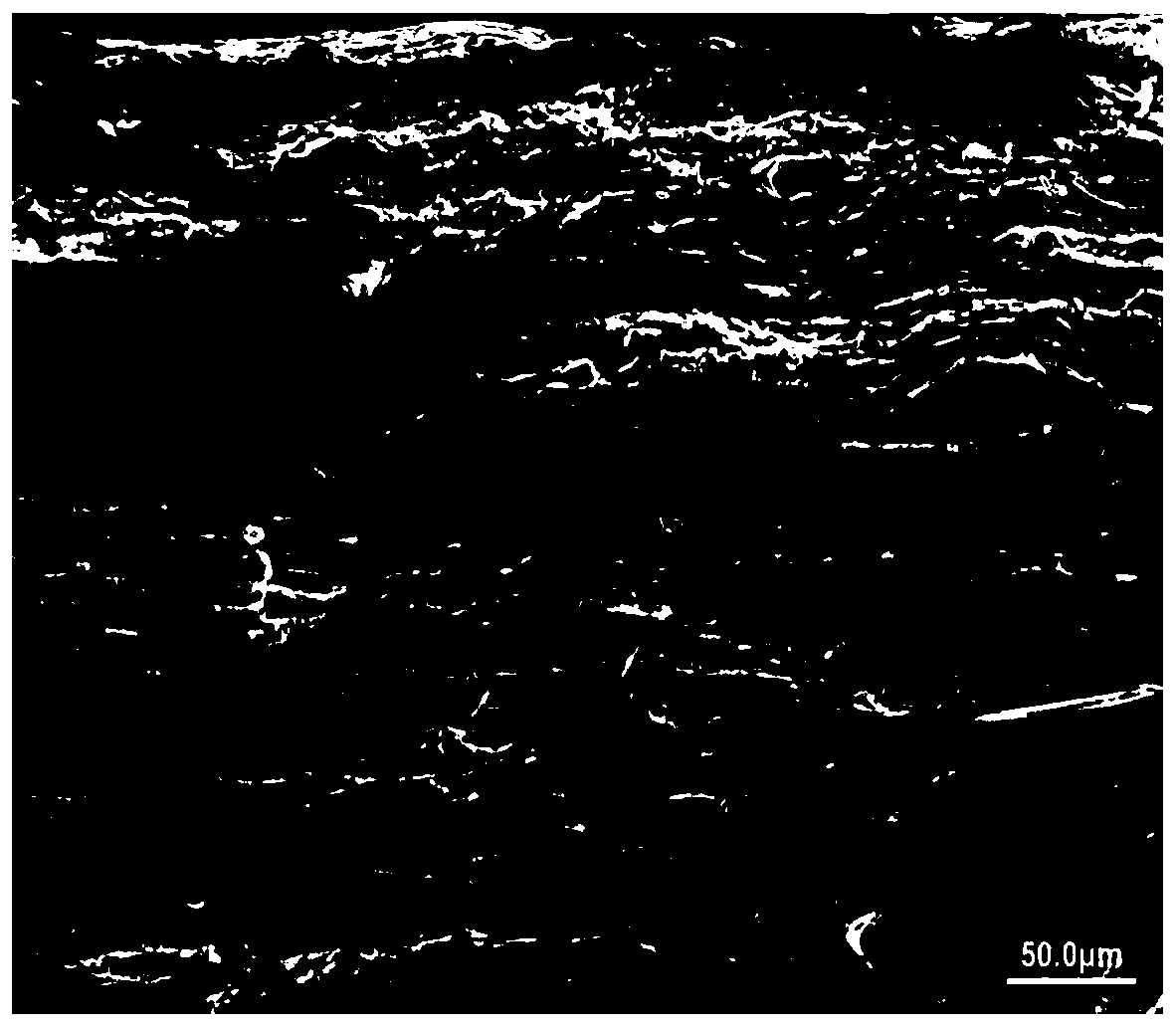

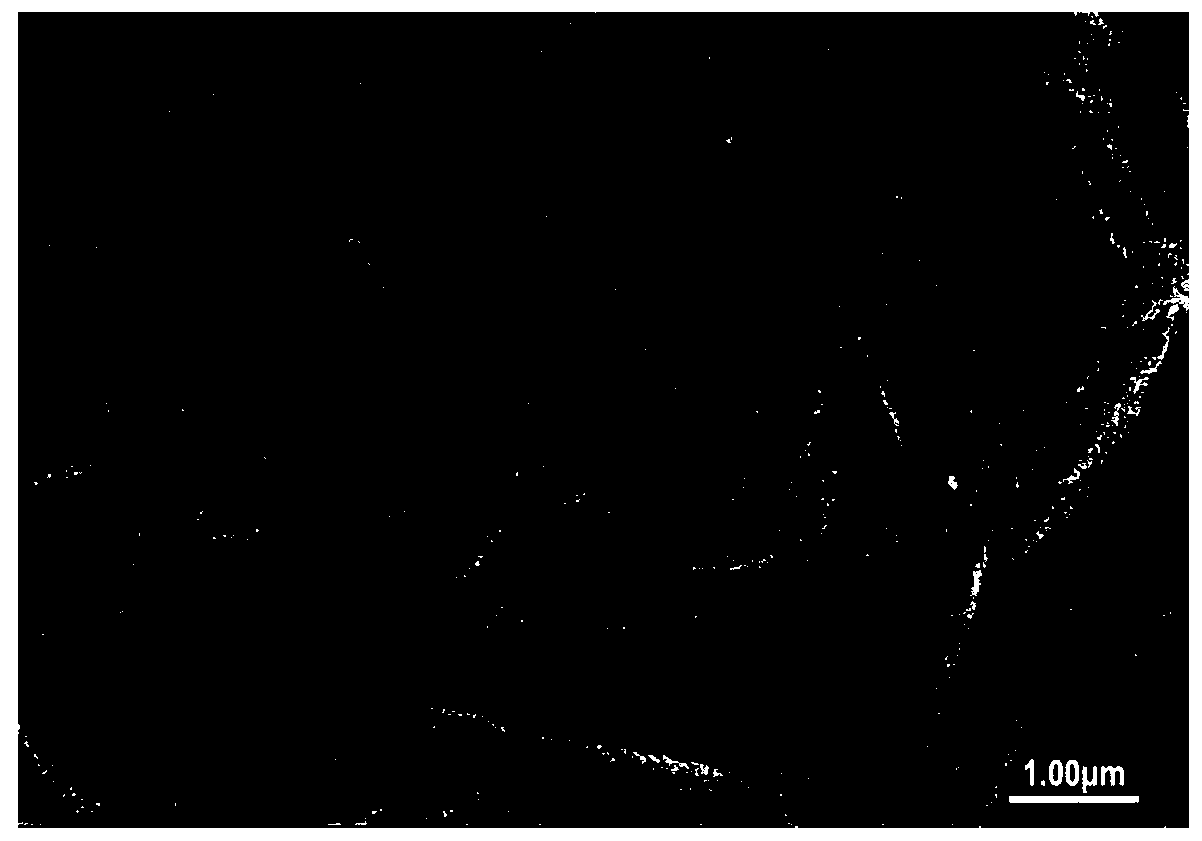

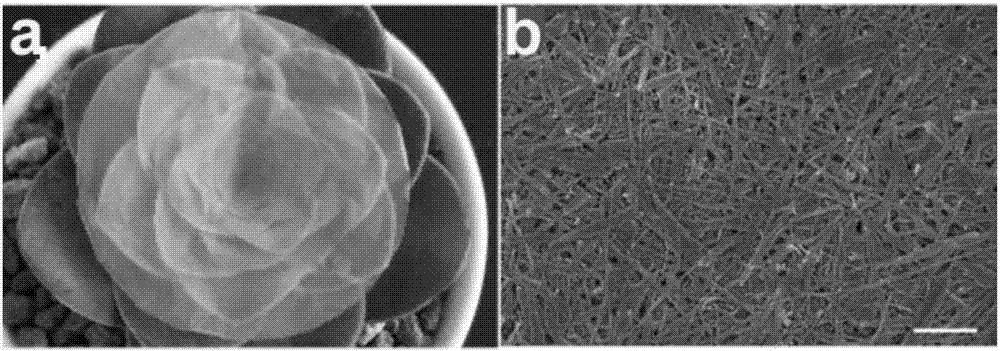

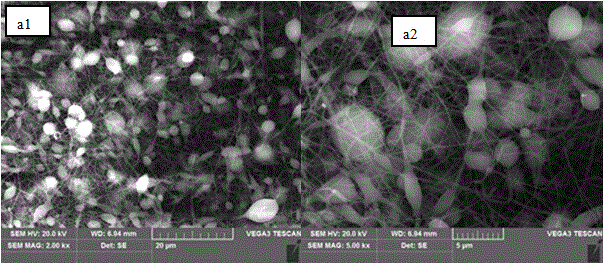

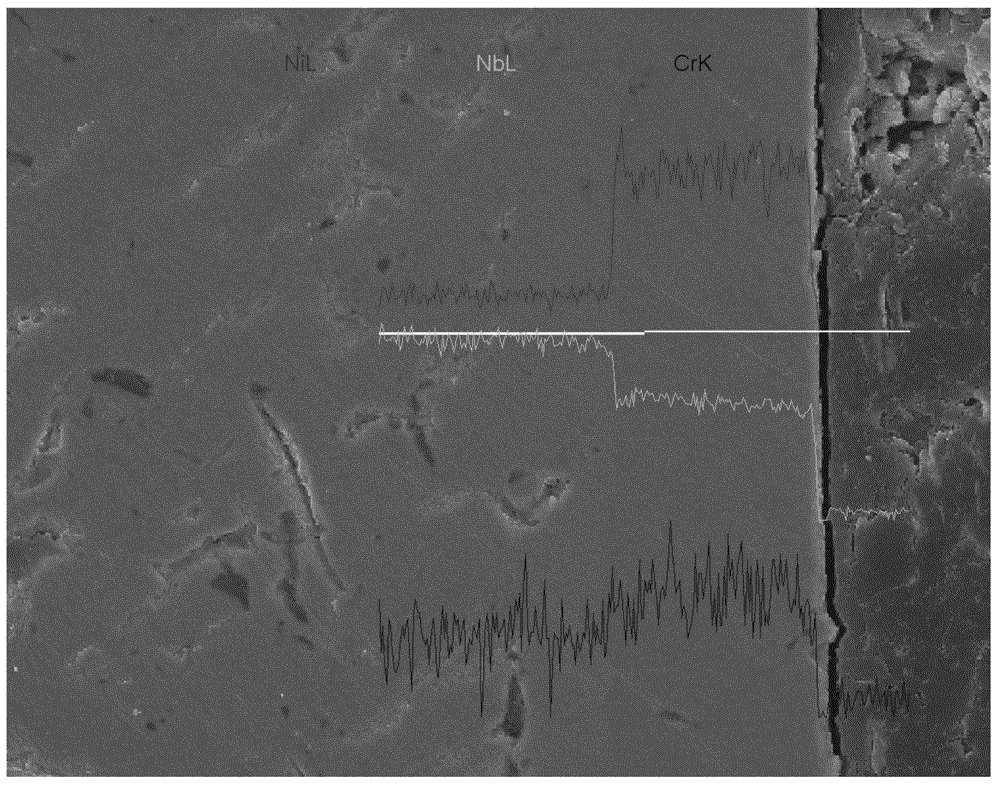

Electrochemical combined deposition method for preparing structure of composite membrane of Nano carbon tube - metal

InactiveCN101003909AEvenly dispersedFlexible thickness controlElectrolytic coatingsCarbon nanotubeElectrochemistry

This invention discloses a method for preparing carbon nanotube-metal composite film structure by electrochemical-combined deposition. The method comprises: preparing electrophorectic solution of stably dispersed carbon nanotubes after purification, shearing and dispersion, applying a voltage onto the electrodes to deposit a uniform layer of carbon nanotube film onto the substrate, placing the film in the electroplating solution, and forming a metal conductive film within the intertube microstructure by electrochemical method. The electrophorectic solution comprises carbon nanotubes, electrophorectic dispersing agent and charge auxiliary salt for charge decoration. This invention reduces the contact resistance between metal and carbon nanotubes, thus can fulfill the excellent electricity and heat conductivity of carbon nanotubes, and can improve the bonding strength of carbon nanotubes and conductive substrate. This invention has good compatibility with fine processing, and has such advantages as simple process, large scale preparation, controllable operation, and high efficiency, and low cost.

Owner:SHANGHAI JIAO TONG UNIV

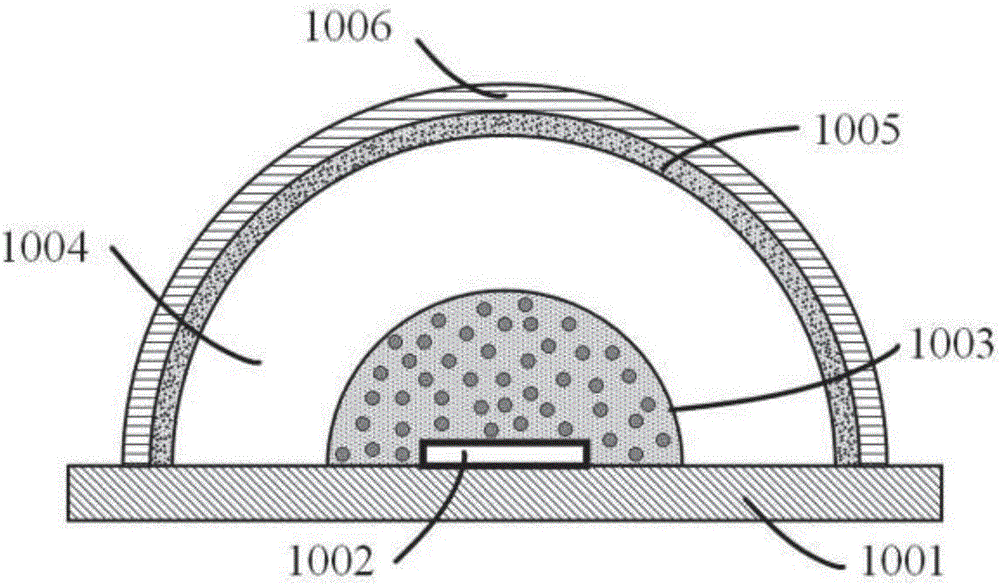

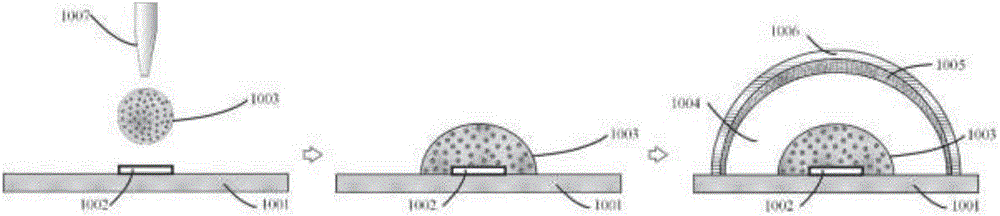

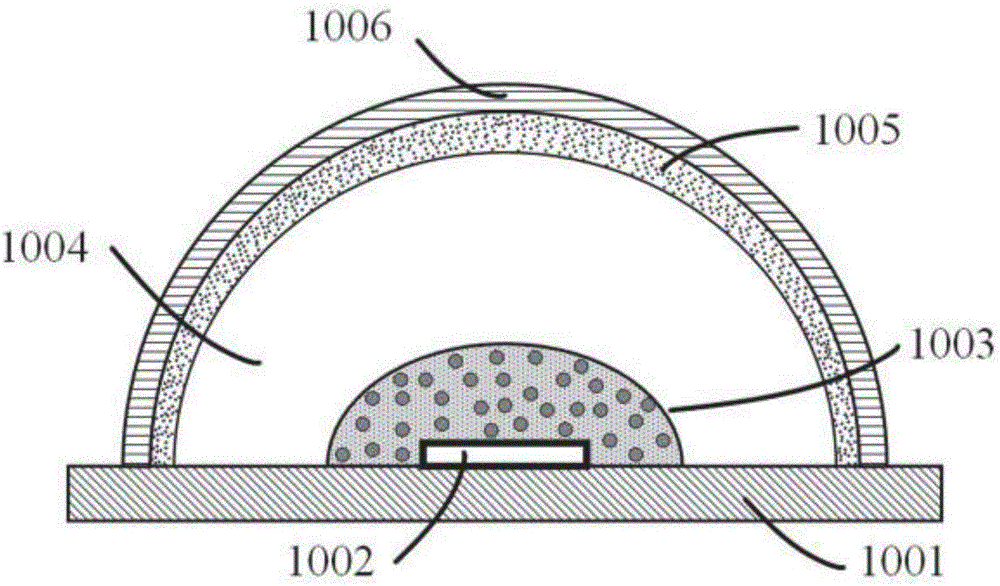

Composite white light LED and preparation method

InactiveCN106058012AReduce total reflectionImprove light extraction efficiencySemiconductor devicesFluorescenceAbsorption effect

The invention discloses a composite white light LED which comprises a substrate, an LED chip and a transparent casing. The bottom of the LED chip is fixed to the surface of the substrate. The upper part of the substrate is sleeved by a transparent shell. The upper part of the LED chip is covered with phosphor colloid. The inner surface of the transparent shell is attached with a quantum dot film. An air gap is between the quantum dot film and the phosphor colloid. The invention also discloses a preparation method of the composite white light LED. Since the air gap is between the phosphor colloid and a quantum dot shell, the air gap can prevent the absorption effect between quantum dot emitting light and fluorescent powder emitting light, the quantum dot film and a fluorescent powder layer are curved surface topographies, the removal of light energy is facilitated, and thus the light emitting efficiency of the composite white light LED is improved significantly. The operation method is simple, the cost is low, the thicknesses, topographies and compositions of the phosphor colloid and the quantum dot film can be flexibly controlled, thus the composite white light LED with high color performance is obtained, and the composite white light LED is suitable for mass production.

Owner:TIANJIN ZHONGHUAN QUANTUM TECH CO LTD

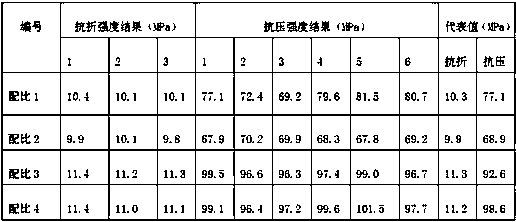

Epoxy resin fiber reinforced concrete for repair and preparation method thereof

The invention relates to an epoxy resin fiber reinforced concrete for repair and preparation and application methods thereof. The epoxy resin fiber reinforced concrete is prepared from the following raw materials in percentage by weight: 55-70% of refined quartz sands, 33-17% of epoxy resin, 11-9% of curing agent and 1-4% of basalt fiber chopped strands. The preparation method comprises the following the following steps: by using the refined quartz sands as aggregates and epoxy resin as a gel material, adding the basalt fiber chopped strands; and mixing according to an appointed proportion. The product provided by the invention is extremely high in viscosity, can be well combined with defected concrete of a base layer and is not easy to peel and bulge. The strength can reach the strength grade of concrete C50. The concrete is simple to manufacture, can be prepared on site and needs not to be heated on site. Epoxy resin needs not to be diluted, and the construction steps are saved and the concrete is convenient to use while no diluents are introduced. The product is short in curing time, and comes into use in 24 hours after repair. The concrete is strong in adaptability, can be suitable for repairing defects of thick and thin layers of a terrace at the same time and can be used for repairing various defects of terrace such as pits formed by collision or high-low difference due to differential settlement of the concrete terrace.

Owner:北京金港建设股份有限公司 +1

Process for preparing ultra-thin brazing fillers by chemical plating and electric plating

ActiveCN104668812AReduce manufacturing costHigh tensile strengthWelding/cutting media/materialsSoldering mediaChemical IngredientsChemical plating

The invention provides a process for preparing ultra-thin brazing fillers by chemical plating and electric plating, and relates to the field of welding material preparation. The process comprises the concrete processes that a copper foil with the thickness being 0.002 to 0.010 mm is selected to be used as a base body, chemical silver plating, electric tin plating and diffusion processing are sequentially carried out, the ultra-thin brazing fillers are prepared, and the prepared brazing fillers comprise the following major chemical ingredients in percentage by mass: 60 to 72 percent of silver, 1 to 8 percent of tin and 26 to 31 percent of copper. The chemical plating and electric plating method is used, and the area and the thickness of the brazing fillers and the contents of each ingredient can be flexibly controlled. Compared with the existing fast solidification method, the process provided by the invention has the advantages that the ultra-thin brazing fillers with the width being higher than 100mm and the thickness being lower than 0.035 mm can be produced, complicated production equipment is not needed, and the production cost is lower.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Multifunctional lithium-sulfur battery diaphragm as well as preparation method and application thereof

ActiveCN110911621AHigh mechanical strengthImprove heat resistanceMaterial nanotechnologyCell component detailsLithium sulfurBoron nitride

The invention discloses a multifunctional lithium-sulfur battery diaphragm which is characterized by comprising a basic diaphragm and a coating layer, wherein the coating layer comprises graphene oxide and a main body material, and the main body material is one of boron nitride, aluminum carbonitride or molybdenum disulfide. The invention further discloses a preparation method and application of the multifunctional lithium-sulfur battery diaphragm. According to the multifunctional lithium-sulfur battery diaphragm disclosed by the invention, the graphene oxide is adopted to induce the main bodymaterial, so that the dispersity problem of the nano materials is solved, the two nano materials are compounded in order, shuttling of polysulfide is more effectively inhibited, and the mechanical strength and heat resistance of the diaphragm are synergistically enhanced. According to the preparation method of the diaphragm, a solvent evaporation induced self-assembly means is adopted, so that ordered compounding of two 2D nano materials is realized, the coating thickness can be flexibly controlled, and large-scale production is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

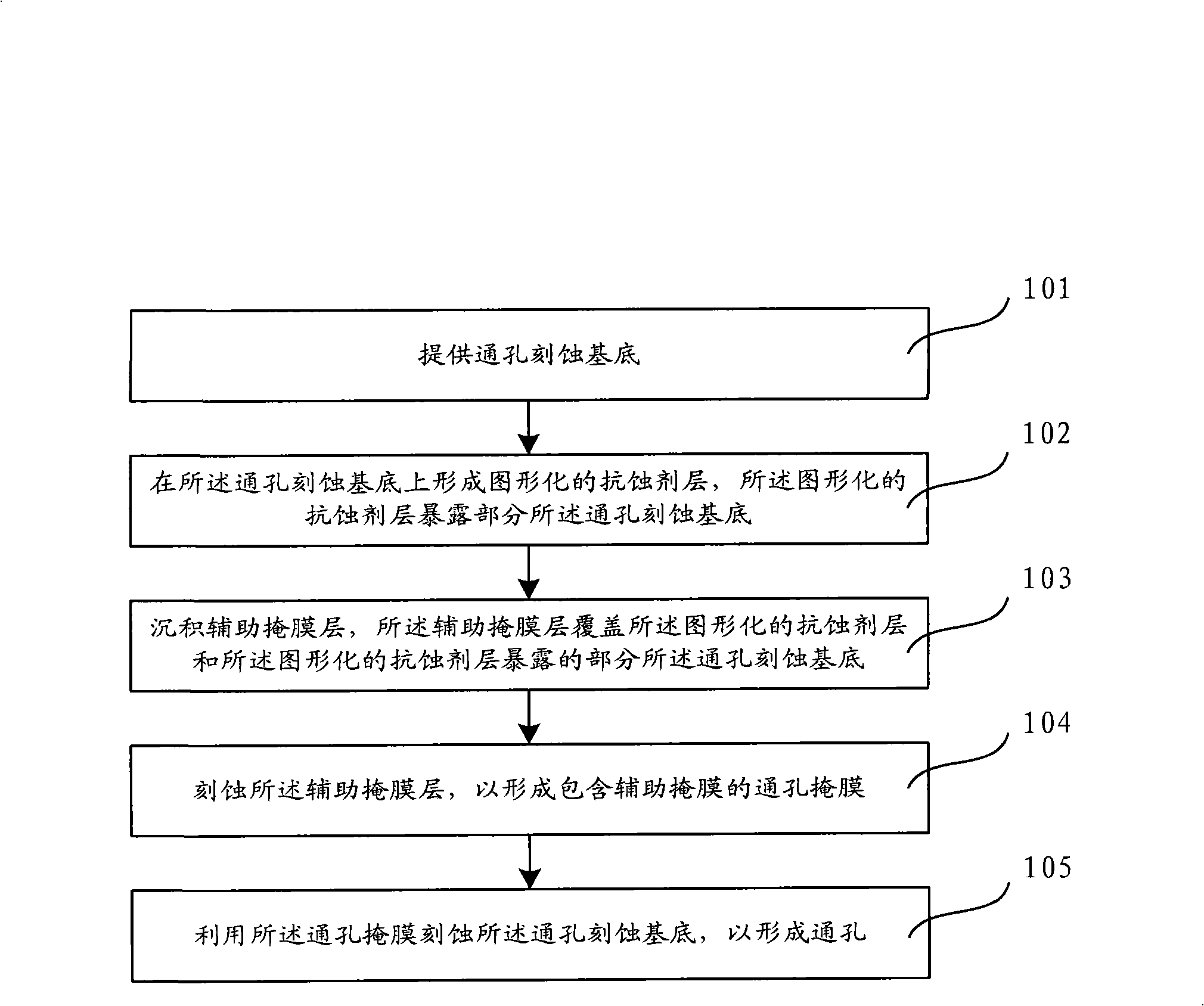

Through hole etching method and through hole mask

InactiveCN101295643ASmall sizeExtended size limitSemiconductor/solid-state device manufacturingMask layerPhysics

A through hole etching method includes the following steps of: providing a through hole etching floor; forming a patterned slushing compound layer on the through hole etching floor; exposing a part of the through hole etching floor by the patterned slushing compound layer; depositing an auxiliary mask layer which covers the patterned slushing compound layer and the part of the through hole etching floor exposed by the patterned slushing compound layer; etching the auxiliary mask layer so as to form a through hole mask which comprises an auxiliary mask; etching the through hole etching floor by the through hole mask so as to form the through hole; the through hole mask includes the slushing compound layer with a confirmed graph which exposes a part of the through hole etching floor; the auxiliary mask which covers the side wall of the slushing compound layer with a confirmed graph; the auxiliary mask is added based on the inherent through hole mask so as to reduce the graph size of the through hole mask under an inherent condition and be beneficial to forming a through hole with expanded size limitation by utilizing the mask.

Owner:SEMICON MFG INT (SHANGHAI) CORP

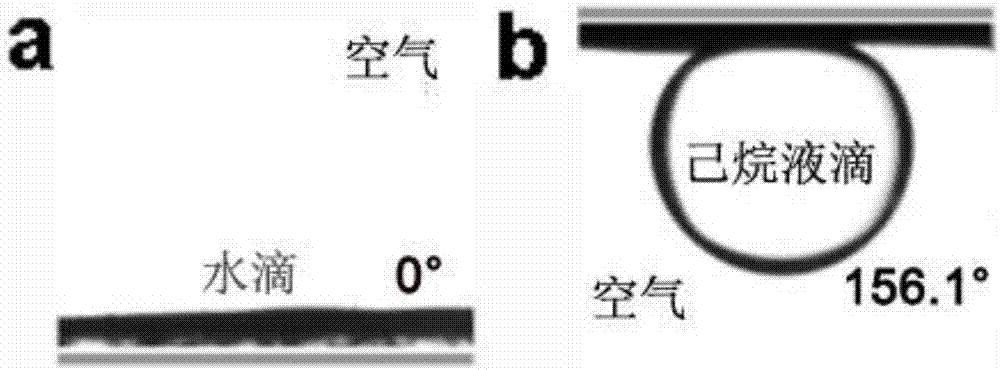

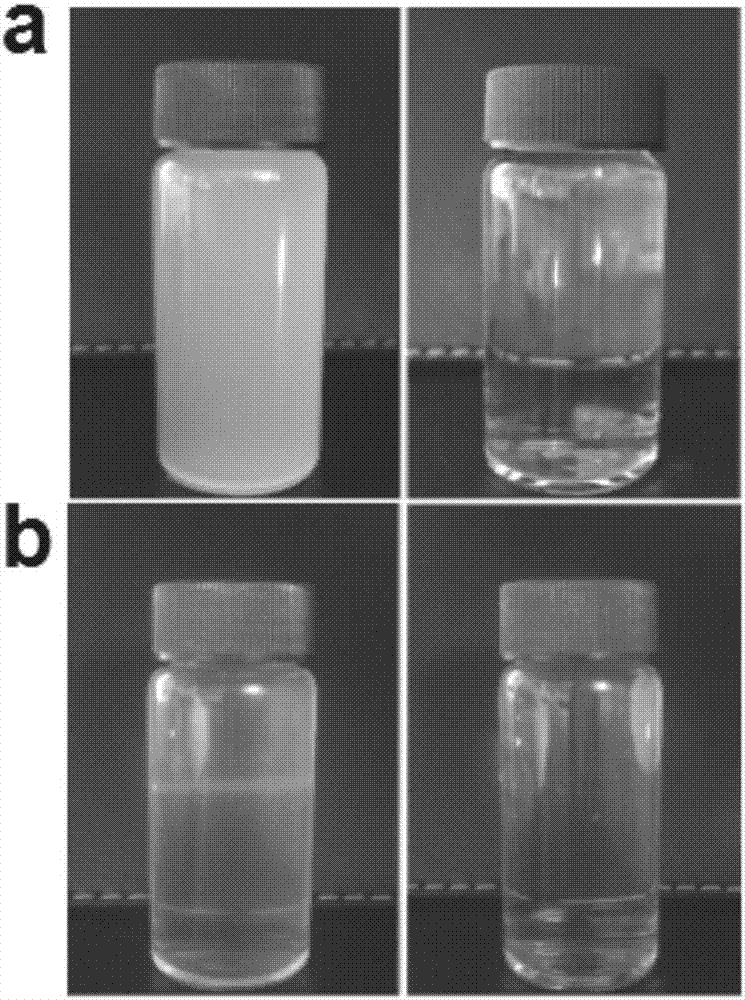

Preparation method of multifunctional nano-crystalline cellulose composite separation filter membrane and application thereof

InactiveCN107983179AFlexible control of aperture sizeControl aperture sizeSemi-permeable membranesWater contaminantsFiltrationOil water emulsion

The invention discloses a preparation method of a multifunctional nano-crystalline cellulose composite separation filter membrane and application thereof. The method comprises the following steps: adding attapulgite into nano-crystalline cellulose suspension to be mixed, and preparing nano cellulose crystal / attapulgite suspension. An ordinary filter membrane serves as a substrate, and the suspension is subjected to vacuum filtration to form the filter membrane. According to the filter membrane, the pore size, thickness and water flux of the membrane can be controlled by regulating the usage amount of cellulose in unit area. According to the wettability characteristic that the filter membrane is super-hydrophilic and is super-oleophobic in oil, application of the filter membrane in aspectssuch as oil-water emulsion, heavy metals and dye separation is realized. The filter membrane disclosed by the invention is simple, feasible, low in cost and non-toxic.

Owner:WUHAN UNIV

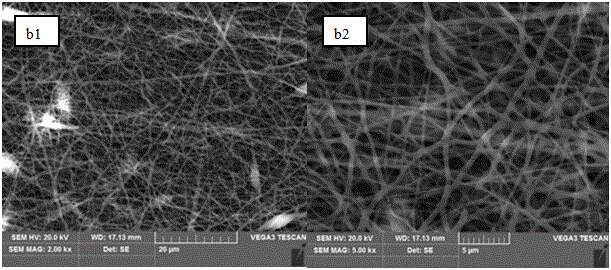

Method for preparing PVDF (Polyvinylidene Fluoride) lithium ion battery diaphragm by electrostatic spinning

ActiveCN104157814AExcellent ion permeabilityFlexible thickness controlSecondary cellsCell component detailsPolyvinylidene difluoridePolyvinylidene fluoride

The invention discloses a method for preparing a PVDF (Polyvinylidene Fluoride) lithium ion battery diaphragm by electrostatic spinning. The method comprises the following steps: firstly, preparing polyvinylidene fluoride glacial acetic acid solution with the concentration of 17-20 percent by weight; secondly, stirring the polyvinylidene fluoride glacial acetic acid solution to be uniform; thirdly, completely cooling the polyvinylidene fluoride glacial acetic acid solution at room temperature of 25DEG C to obtain spinning solution; fourthly, taking a proper amount of spinning solution by using an injector, placing the injector on an injection pump, connecting a needle head, clamping an anode of a high voltage static generator on the needle head, enabling a cathode of the high voltage static generator to be connected with a receiving screen, and laying tin foil paper on rollers; fifthly, setting the spinning speed, adjusting the spinning voltage and the spinning distance and then performing static spinning; after the spinning is ended, taking off the tin foil paper from the rollers to obtain the lithium ion battery diaphragm. The method disclosed by the invention has the advantages of simple process, low energy consumption, low production cost and high performances of products; the pore size and the film thickness can be flexibly controlled, the improvement on both the ionic transparency of the diaphragm and the cycle performance of the battery is facilitated, and a good marker prospect is obtained.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

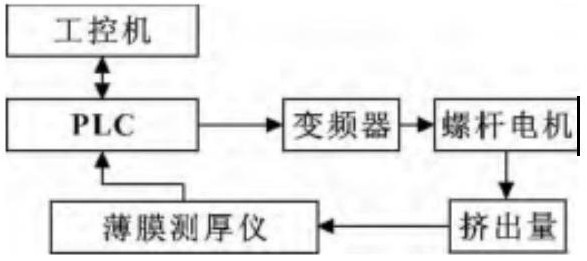

Automatic control method for thickness of calendered film

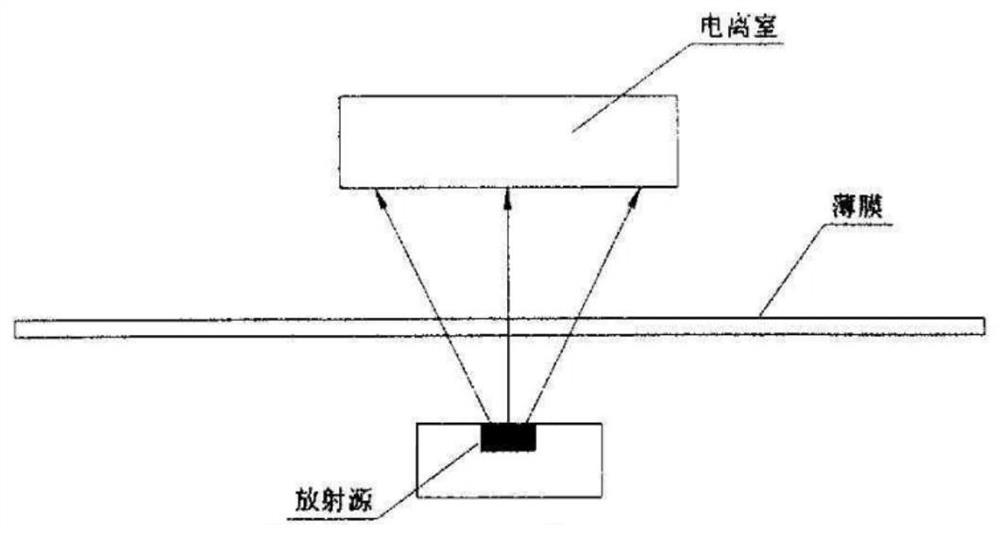

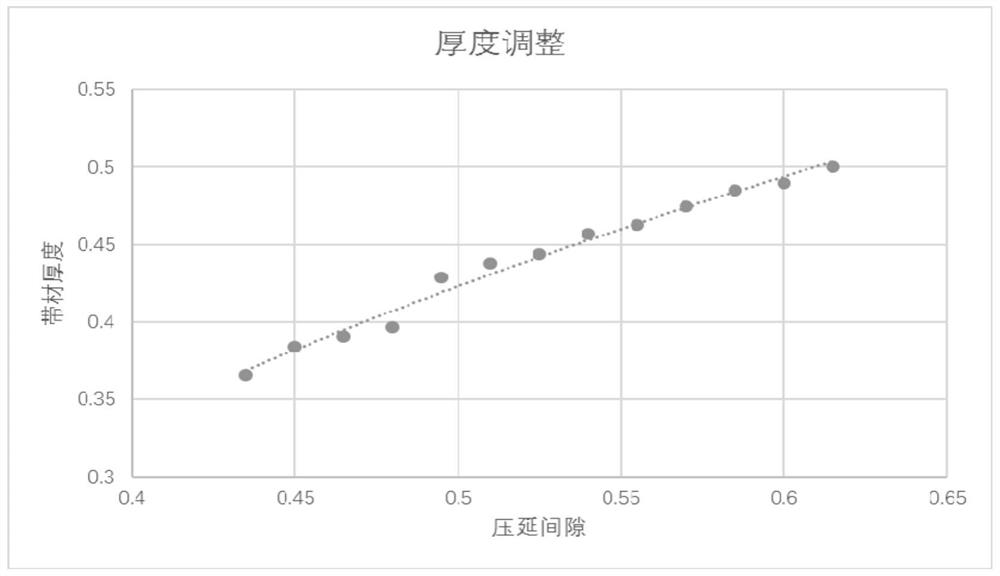

InactiveCN112140440AEasy to controlNo manual measurement requiredFlat articlesAutomatic controlControl manner

The invention discloses an automatic control method for the thickness of a calendered film. The automatic control method comprises the following steps that when a detection device finds that the thickness is about to exceed a tolerance range or is unqualified, feedback is immediately performed through a feedback device, parameters to be adjusted are calculated and input into a calender adjusting system, and the adjusting system achieves specific adjusting work, so that the the calendered film with the thickness meeting the requirement is obtained. Specifically, when the detection device findsthat the thickness is about to exceed the tolerance range or is unqualified, a real-time thickness value is immediately transmitted to a curve fitting algorithm through the feedback device, judgment is made according to a comparison result of the measured thickness value and a target value input in advance, and whether the value is within the tolerance range or not is judged. According to the control method, manual measurement is not needed, and software control is rapid and accurate; and then three automatic thickness control methods are provided, so that the thickness control manner is flexible.

Owner:安徽省众望科希盟科技有限公司

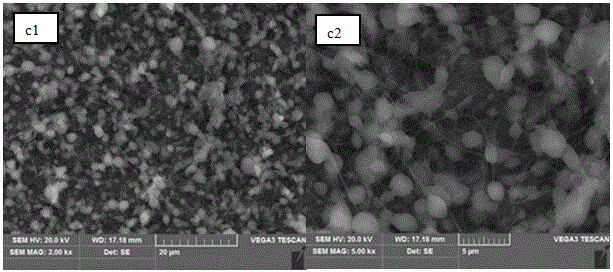

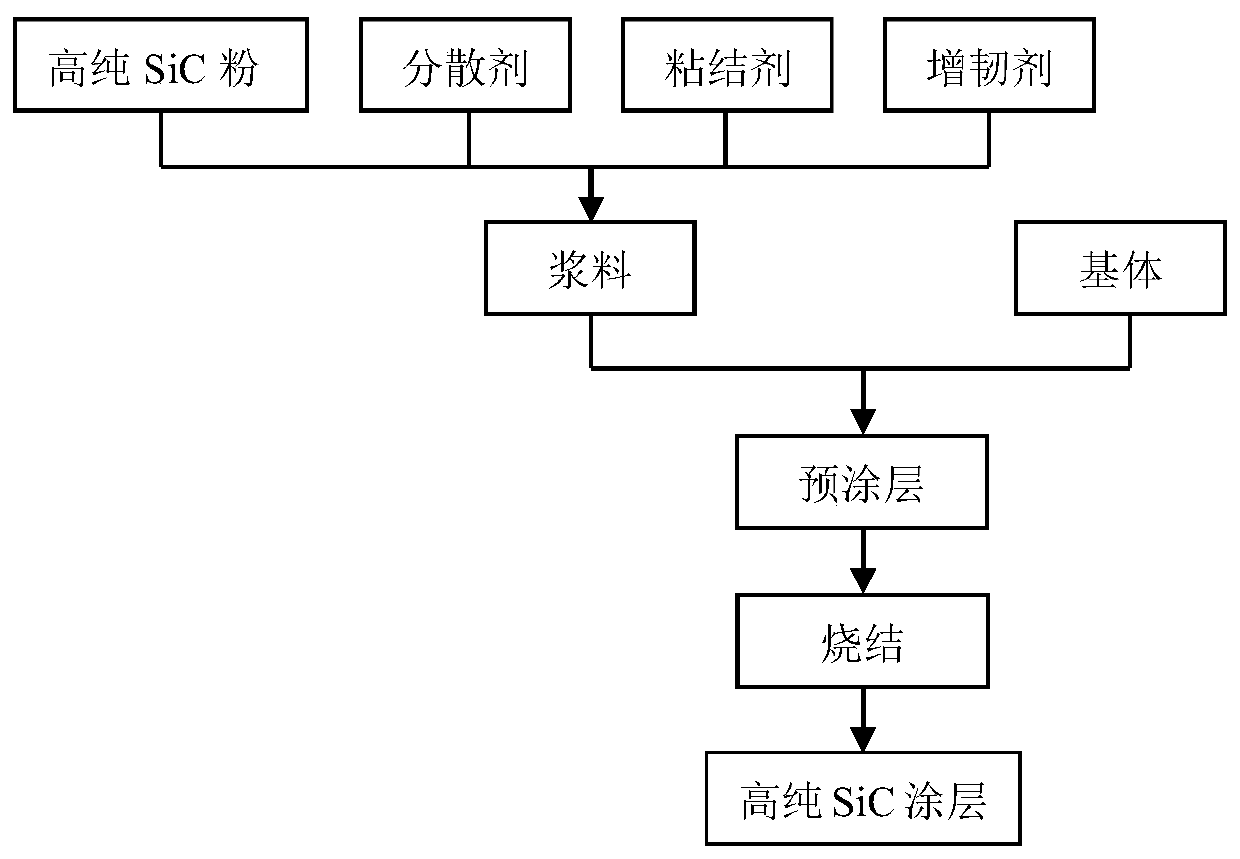

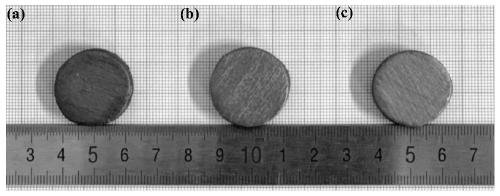

Low-temperature normal-pressure sintering preparation method of mass-producible high-purity SiC ceramic coating

ActiveCN111517797AEffective control of purityLow purityNuclear energy generationCeramic coatingOxidation resistant

The invention relates to a low-temperature normal-pressure sintering preparation method of a mass-producible high-purity SiC ceramic coating, which is applied to the fields needing high-temperature resistance, oxidation resistance, corrosion resistance and other protective properties in the form of coatings. The preparation method is technically characterized by comprising the following steps: preparing high-purity SiC slurry, carrying out brush-coating, and carrying out low-temperature pressureless sintering. According to the technical scheme provided by the invention, the purity and the sintering temperature of the SiC coating are controlled by regulating and controlling the formula of the high-purity SiC slurry, so that normal-pressure sintering and industrial preparation and productionof the high-purity SiC coating at the temperature of 1750-1800 DEG C are realized. The high-purity SiC slurry formula and the brush-coating and sintering processes are flexible and controllable, thecoating and the matrix are well combined, obvious peeling and cracks are avoided, the technological process is easy to operate and short in consumed time, and the cost is greatly reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for manufacturing long-term efficient anti-reflection micro-nano structure on copper surface and application

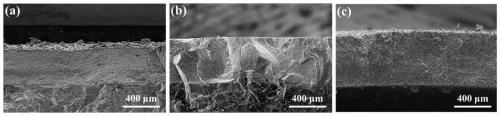

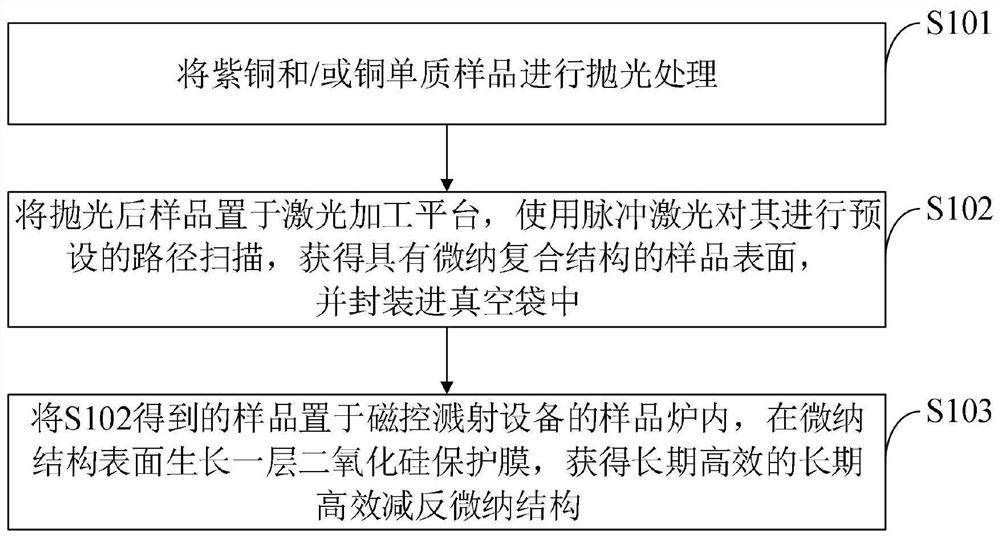

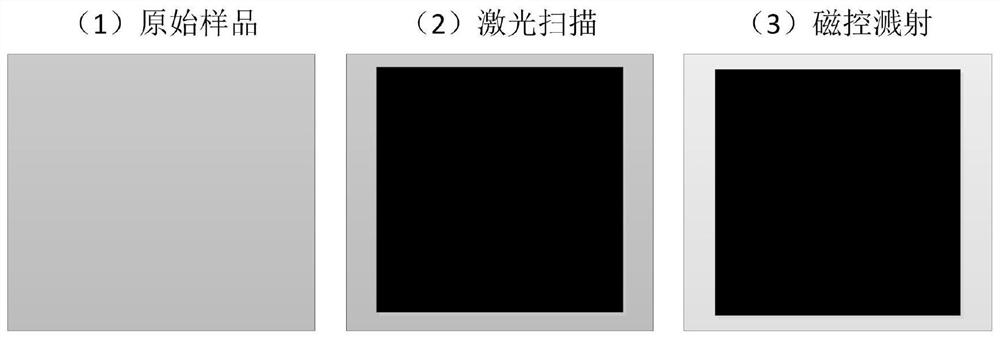

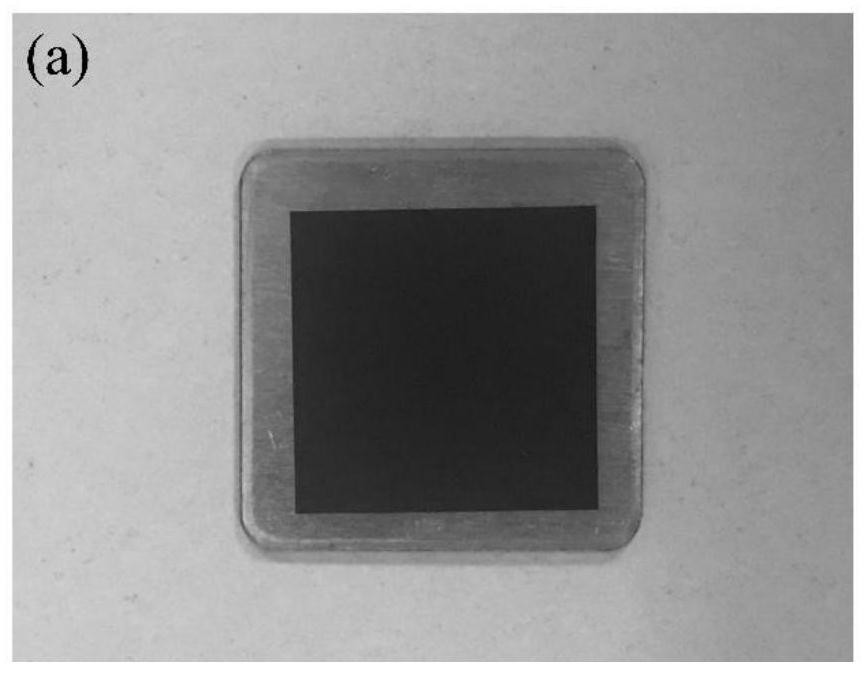

ActiveCN112959005AHas anti-reflective propertiesLong-term high-efficiency anti-reflection function characteristicsVacuum evaporation coatingSputtering coatingSputteringNano structuring

The invention belongs to the technical field of high heat conduction media, and discloses a method for manufacturing a long-term efficient anti-reflection micro-nano structure on a copper surface. The method comprises the following steps: polishing red copper and / or a copper elementary substance sample; placing the polished sample on a laser processing platform, performing preset path scanning on the sample by using pulse laser to obtain a sample surface with a micro-nano composite structure, and packaging the sample into a vacuum bag; and placing the obtained sample in a sample furnace of magnetron sputtering equipment, and growing a layer of silicon dioxide protective film on the surface of the micro-nano structure to obtain the long-term efficient anti-reflection micro-nano structure. According to the method, the micro-nano structure with the anti-reflection characteristic is prepared on the copper surface, and then a layer of inert film is grown on the surface of the micro-nano structure for protection through a film coating method, so that the micro-nano structure has the long-term efficient anti-reflection function characteristic; and the thickness of the silicon dioxide protection layer is flexibly controlled by controlling the coating time of magnetron sputtering, the strength performance of the protection layer is improved, and the problem of failure of the anti-reflection structure on the copper surface is effectively solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

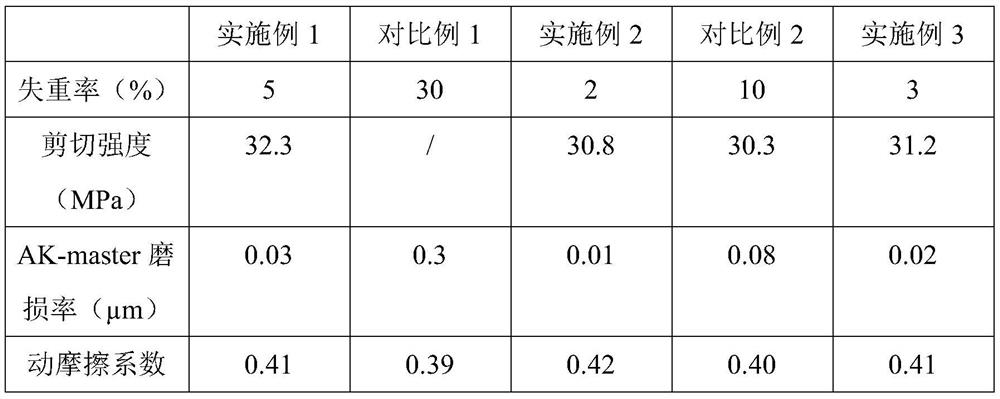

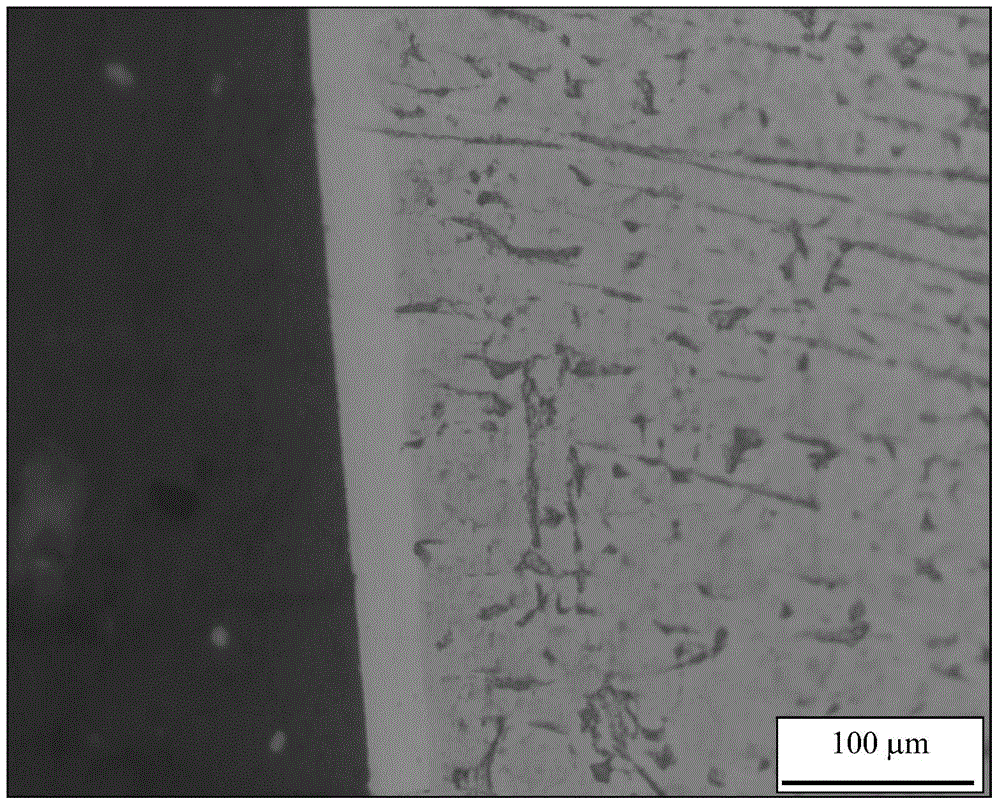

Carbon-ceramic brake disc with wear-resistant and anti-oxidation coating and preparation method of carbon-ceramic brake disc

ActiveCN113277869AHigh bonding strengthUniform compositionBraking discsFriction liningOxidation resistantCarbon composites

The invention discloses a carbon-ceramic brake disc with a wear-resistant and anti-oxidation coating and a preparation method of the carbon-ceramic brake disc. The preparation method comprises the following steps that grooving treatment is conducted on the upper surface and the lower surface of a carbon / carbon composite material disc body, then coating slurry is brushed in a groove in the upper surface till the groove in the upper surface is filled with the coating slurry, and then the carbon / carbon composite material disc body is turned over, the groove in the lower surface is coated with the coating slurry till the groove in the lower surface is filled with the coating slurry, thus the carbon / carbon composite material disc body containing the coating slurry is obtained, curing, carbonization and ceramization treatment are sequentially conducted, and the carbon-ceramic brake disc is obtained. The preparation process of the wear-resistant and oxidation-resistant coating is simple, large-scale industrial mass production is easy to realize, the coating is bright and smooth in appearance, the bonding strength between the coating and the disc body is high, the size precision is easy to accurately control, and the problem that the size is easy to control inaccurately when the ceramic brake disc is subjected to machining treatment can be effectively solved.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

Niobium alloy surface Ni-Cr oxidation-resistant coating and preparation method thereof

InactiveCN104651668ADense tissueGood high temperature oxidation resistanceOxidation resistantNiobium alloy

The invention relates to a niobium alloy surface Ni-Cr oxidation-resistant coating and its preparation method, and belongs to the field of a metal surface coating material and its preparation technology. The coating provided by the invention is composed of 30-40 wt% of Cr, 5-10 wt% of a niobium alloy and the balance Ni. The preparation method comprises the following steps: firstly, electroplating Ni on the surface of the niobium alloy; then, electroplating Cr; and finally, carrying out surface alloying by pulse YAG laser so as to obtain a Ni-Cr coating which is in complete metallurgical bonding to a matrix. By controlling thickness of the electroplated Ni layer and the electroplated Cr layer as well as the pulse YAG laser surface alloying technology, ingredients and thickness of the coating can be flexibly controlled. As content of Cr in the coating reaches 30-40 wt%, the coating has excellent resistance to high temperature oxidation.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Cache-on-board (COB) technology-based integrated light emitting diode (LED) packing method

InactiveCN102437271ALower working temperatureFlexible thickness controlSemiconductor devicesCooking & bakingHeat resistance

The invention relates to a cashe-on-board (COB) technology-based integrated light emitting diode (LED) packing method, which comprises the following steps that: 1. thickness of a mould and diameter of a reserved hole are adjusted; 2. the reserved hole on the mould is aligned to an LED chip which is well fixed on an aluminum circuit board, and the mould covers the aluminum circuit board; 3. after fluorescent glue is sprayed on the aluminum circuit board, the aluminum circuit board is baked, then the mould is removed after the baking so as to obtain an LED packing unit. The method has followinng beneficial effects that: the shape, position, thickness and quantity of the fluorescent flue can be adjusted by adjusting the thickness of a silicone board and the diameter of the reserved hole, so the LED integrated packing procedures can be simplified, the heat resistance and the working temperature of the LED chip can be reduced, the shape, position, thickness and quantity of the fluorescent glue can be flexible to control, the light emitting efficiency and the consistency, stability and service life of the product can be improved, the packing efficiency also can be improved, the waste can be reduced, and the product cost can be reduced. The baking temperature is set as 140 to 160 DEG C, so the packing effect is better.

Owner:秦会斌 +6

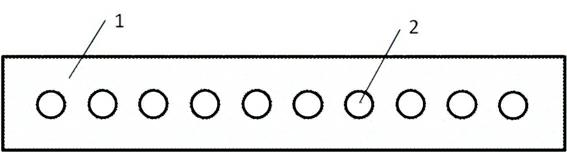

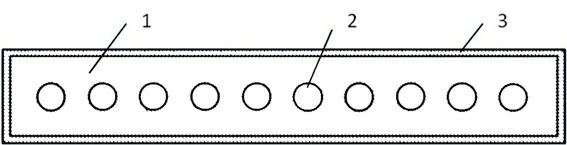

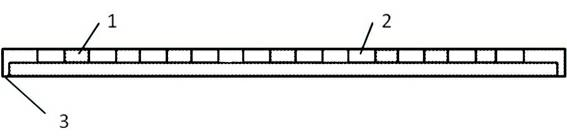

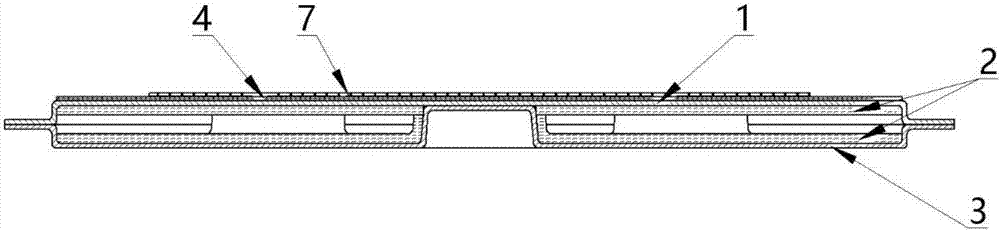

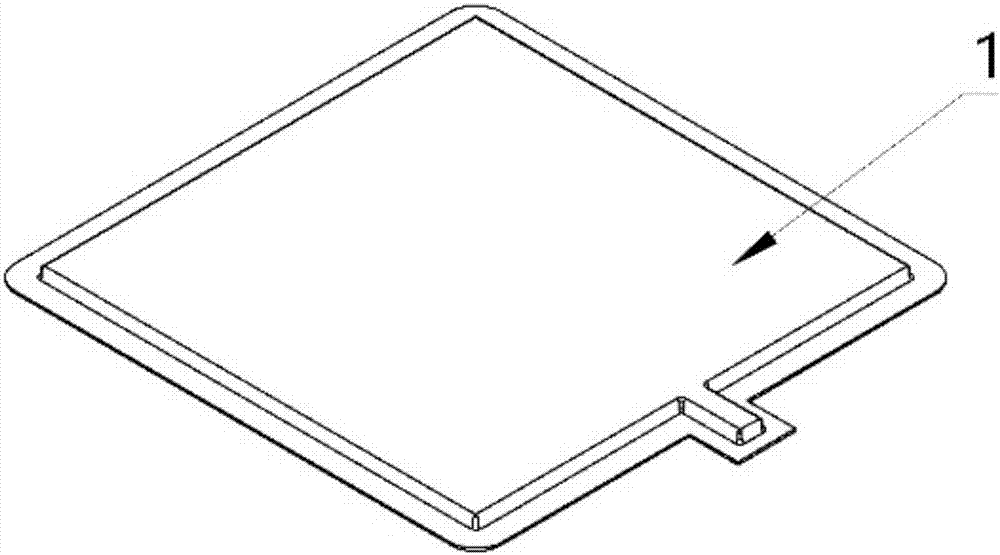

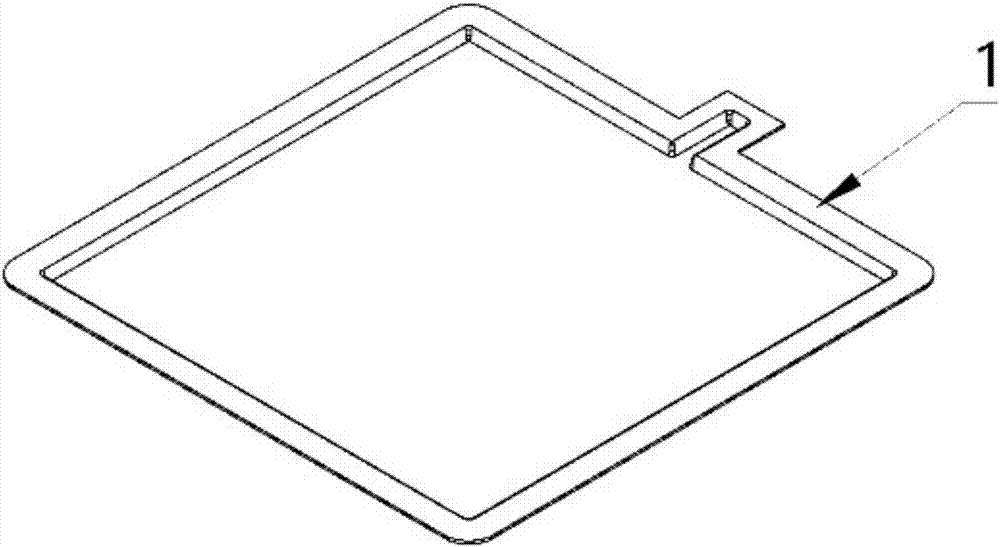

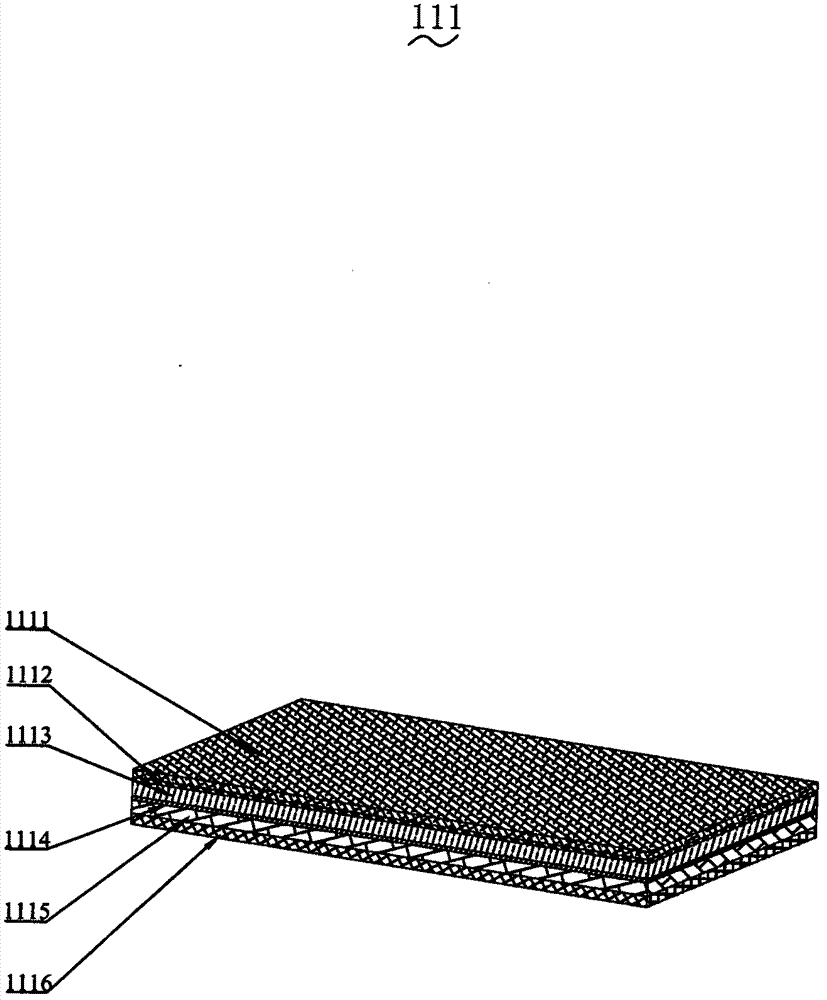

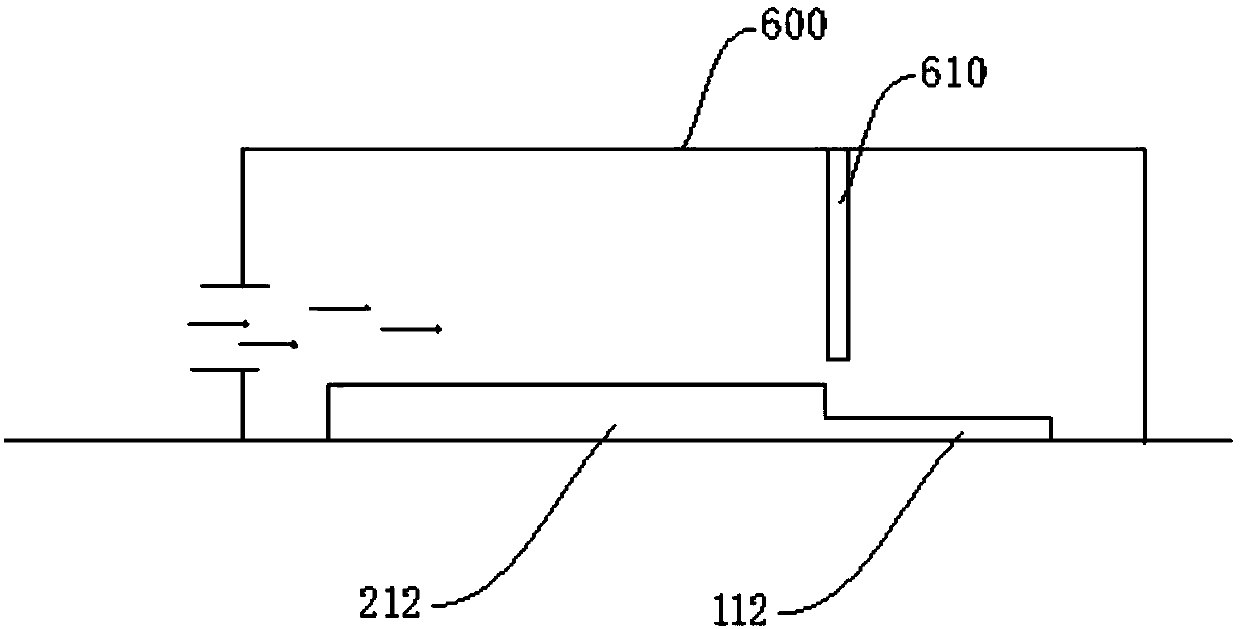

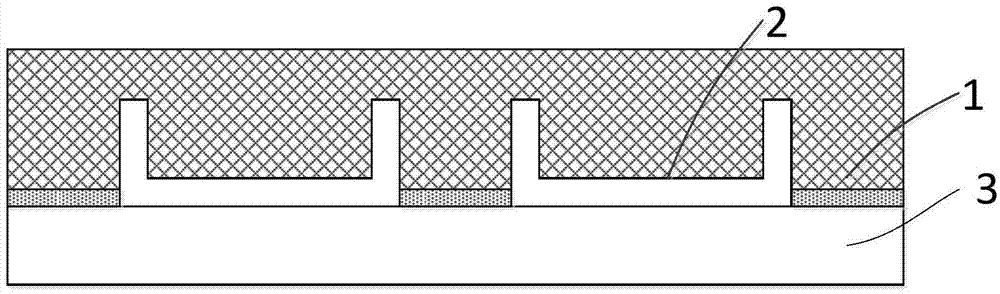

LED phase-change heat radiating substrate and preparation method thereof

PendingCN107068846AAchieve thermal controlGuaranteed stabilitySemiconductor devicesEngineeringMechanical engineering

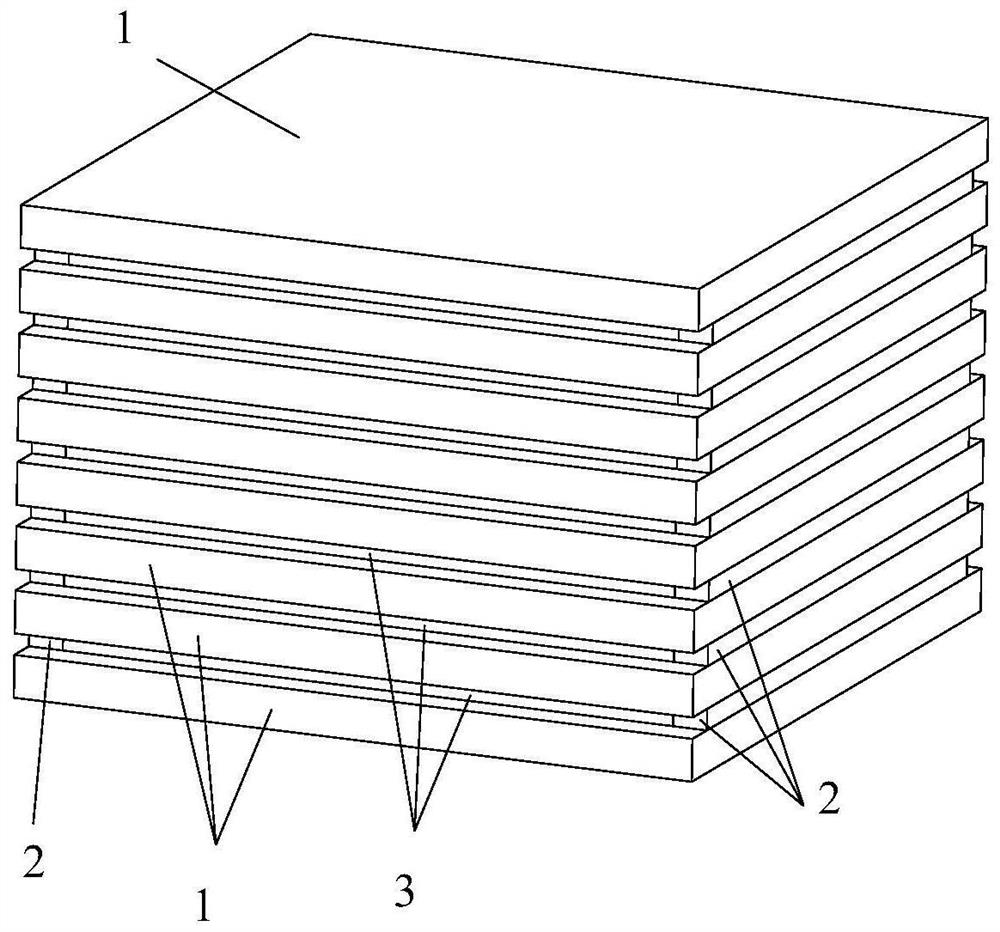

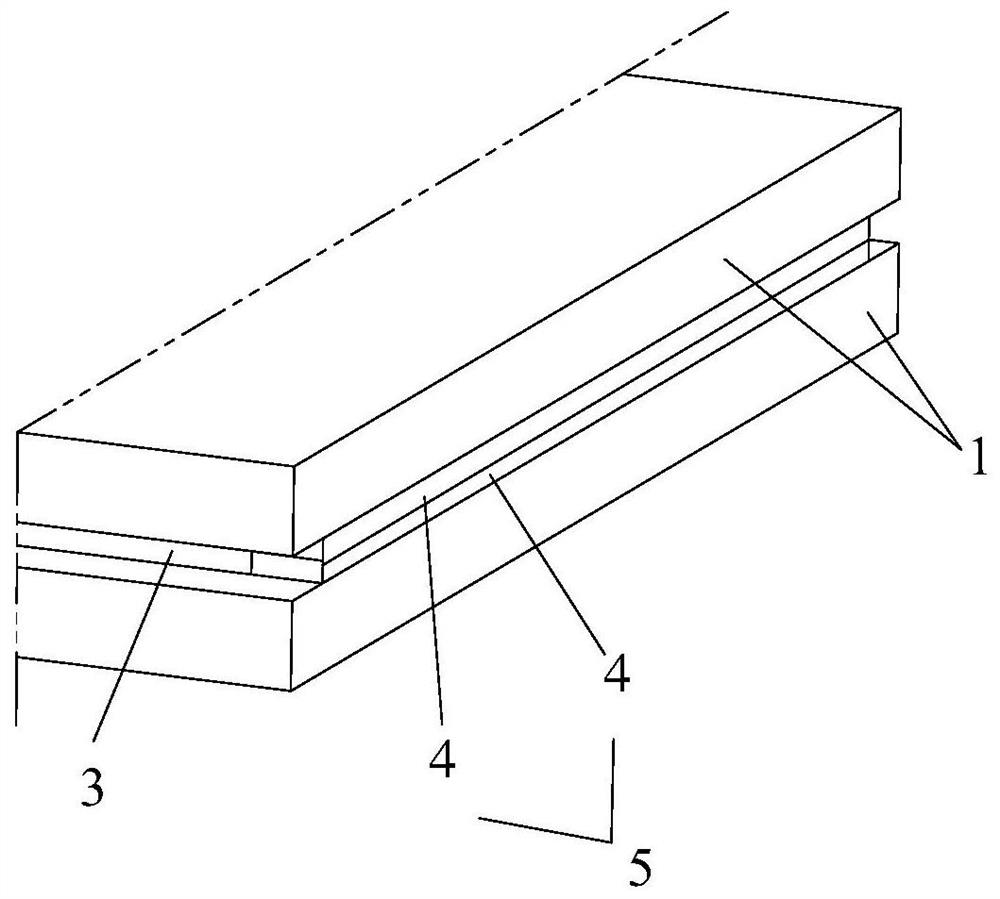

The invention discloses an LED phase-change heat radiating substrate and a preparation method thereof. The substrate comprises an upper cover plate (1), a nano wick (2), a lower cover plate (3), and liquid refrigerant filling the inside of the substrate. The nano wick (2) is sintered on the inner sides of the upper cover plate (1) and the lower cover plate (3). The upper cover plate (1) and the lower cover plate (3) are spliced together by welding. A sealed cavity is formed inside after welding. The cavity is vacuum-pumped and filled with the liquid refrigerant. The preparation method comprises the following steps: (1) preparing plates; (2) preparing a nano wick; (3) welding the plates; and (4) pouring refrigerant and carrying out packaging. The substrate is based on the principle of phase-change heat transfer. The refrigerant absorbs heat efficiently and quickly through phase change, and the heat reflux is uniformly distributed under capillary force of the nano wick after condensation. The LED phase-change heat radiating substrate has more excellent heat transfer performance, and has the characteristics of strong heat transfer ability, low weight, and small thickness.

Owner:SOUTH CHINA UNIV OF TECH

Explosion-proof membrane and preparation method of membrane as well as automobile data recorder

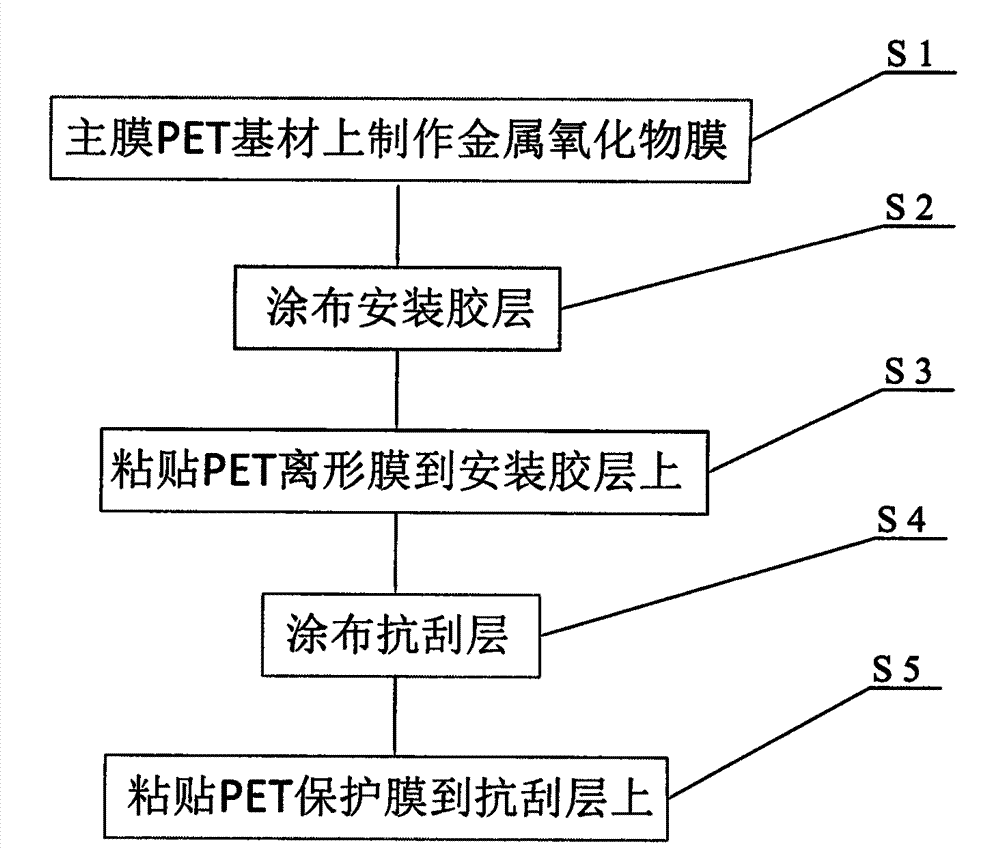

ActiveCN104760377AAppropriate shade of colorDoes not affect light transmittanceSynthetic resin layered productsLaminationPet substrateVacuum evaporation

The invention relates to an explosion-proof membrane, a preparation method of a membrane as well as an automobile data recorder. The explosion-proof membrane comprises an anti-scratch layer, a main membrane PET substrate layer, a metal oxide membrane layer and a mounting glue layer which are arranged from up to bottom in sequence, wherein the metal oxide membrane layer is a non-conductive membrane. The preparation method of the explosion-proof membrane comprises the following steps: preparing the non-conduction metal oxide membrane layer on the back surface of the main membrane PET substrate layer through a non-conduction vacuum evaporation coating method; coating the other side of the main membrane PET substrate layer with the mounting glue layer and coating the front surface of the main membrane PET substrate layer with the anti-scratching layer. According to the explosion-proof membrane, multiple requirements during actual usage can be met and the problems that the explosion-proof membrane is conductive, the rear view mirror function cannot be extended on the automobile data recorder and the processing technique is complicated are solved.

Owner:GUIZHOU TOUCHWORKS OPTOELECTRONICS

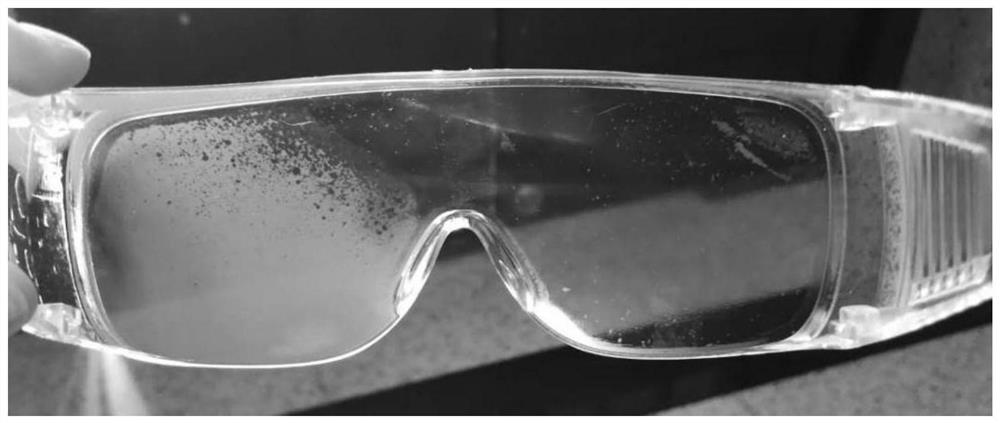

Preparation method and application of bionic high-adhesion long-acting antibacterial antifogging agent

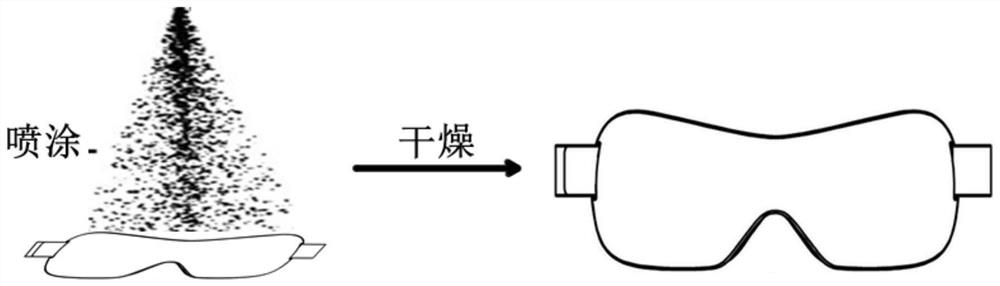

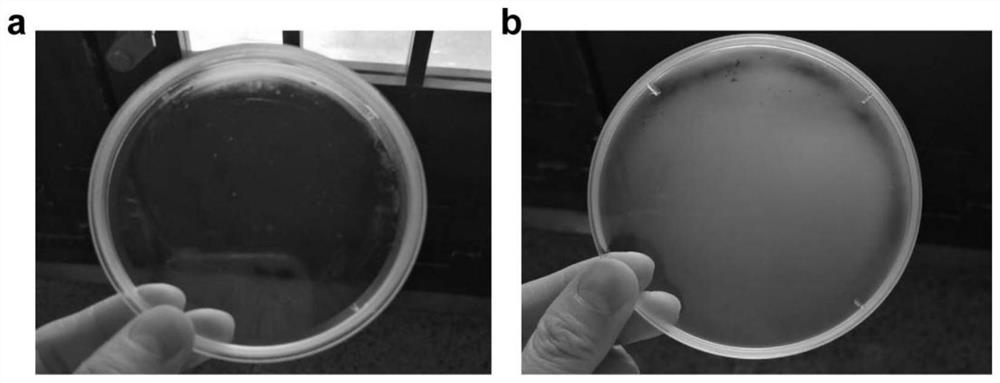

PendingCN113583494APrevent foggingPrevent bacterial growthAntifouling/underwater paintsGogglesPolymer solutionSafety goggles

The invention belongs to the field of biomedical polymer materials, and discloses a preparation method and application of a bionic high-adhesion long-acting antibacterial antifogging agent. The antifogging agent is prepared by the steps that firstly, a hydrophilic bionic high-adhesion polymer is prepared, then the hydrophilic bionic high-adhesion polymer coats a surface to be treated through a solution of the hydrophilic bionic high-adhesion polymer, so as to inhibit surface fogging and bacterium breeding. A hydrophilic bionic high-adhesion polymer solution is prepared by controlling key raw materials, a flow process and the like of the antifogging agent, and the hydrophilic bionic high-adhesion polymer solution can be used as a long-acting antibacterial antifogging agent for antifogging and antibacterial treatment on the surfaces of medical goggles lenses and the like, has good biological safety, and can effectively inhibit fogging and bacterium breeding on the surfaces of the goggles.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Preparation method of titanium dioxide based self-cleaning glass

The invention relates to a preparation method of titanium dioxide based self-cleaning glass, aiming at solving the problems in the preparation process of the self-cleaning glass that because the technology is complex, the requirement for manpower and material resources is high and the coating efficiency is low, large-area popularization is hard to realize. According to the preparation method disclosed by the invention, a simple sol-gel method is adopted for preparing TiO2 (B) crystal phase containing nano particle sol with uniform size and relatively small grains, glass is dipped into the sol,then the glass is drawn out from the TiO2 sol at the speed of 0.5cm / s-1.0cm / s, and a sample is subjected to annealing treatment at the temperature of 300-600 DEG C, thus obtaining the TiO2 based self-cleaning glass with large area and uniform membrane. The TiO2 based self-cleaning glass disclosed by the invention has relatively good organic matter catalytic degradation activity, and is very suitable for being popularized in the fields of external glass walls of buildings, windshields of automobiles and the like. The method disclosed by the invention is low in requirement for equipment, greatly reduces the production cost and is high in production efficiency, and membrane thickness can be flexibly mastered. The prepared glass has relatively high transmittance and is suitable for being applied to daily production and life.

Owner:NORTHEAST NORMAL UNIVERSITY

Multi-step printed circuit board differential through hole processing method and printed circuit board thereof

InactiveCN110418519ASimple processLow costPrinted circuit aspectsElectrical connection printed elementsCopper platingPrinted circuit board

The invention discloses a multi-step printed circuit board differential through hole processing method and a printed circuit board thereof. The problem that multi-through hole copper differentiation and a uniform copper printed circuit board are difficultly processed in the prior art is solved. According to the technical points, a first large through hole is processed in a laminate, and hole copper with the thickness of h10 is formed on the hole wall; an isolation structure is arranged around the opening of the first large through hole, so that the hole copper of the first large through hole and the surface copper of the laminate are insulated and isolated; copper reduction is carried out on the surface copper of the laminate, and then a second intermediate through hole and a third small through hole are processed; hole copper with the thickness of h20 and h30 is formed on the hole walls of the second intermediate through hole and the third small through hole; after the third small through hole is covered and plated, the hole copper of the second intermediate through hole is thickened to h21; an isolation dry film is removed for electroless copper plating, and the hole copper of the first large through hole, the second intermediate through hole and the third small through hole is thickened to the required thicknesses H1, H2 and H3 respectively; and before the third electrolesscopper plating, H1-h10=H2-h21=H3-h30. The method provided by the invention can be used for printed circuit board fabrication.

Owner:BOMIN ELECTRONICS CO LTD

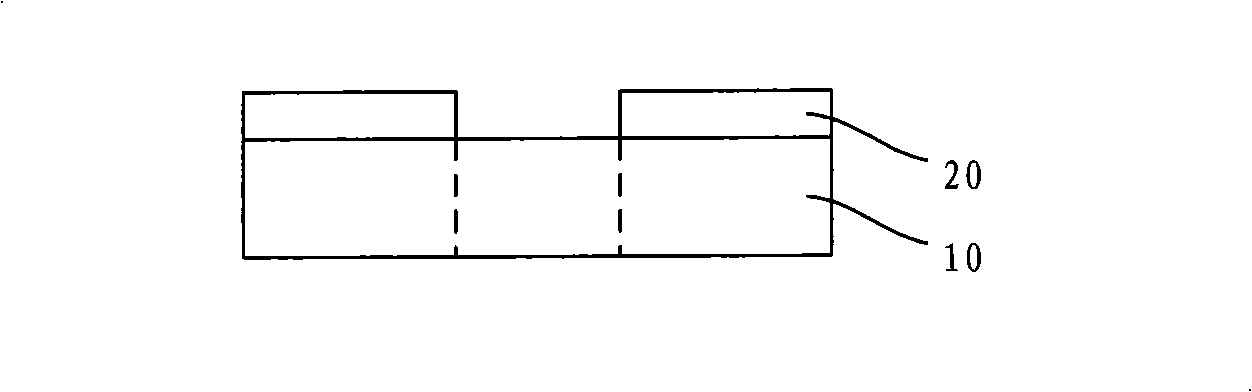

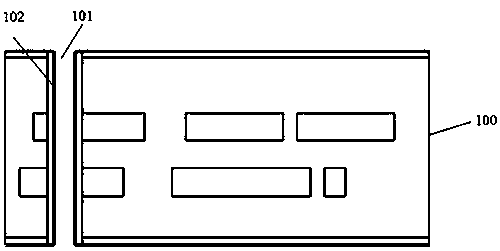

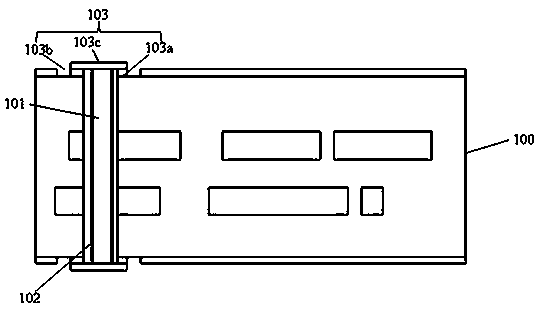

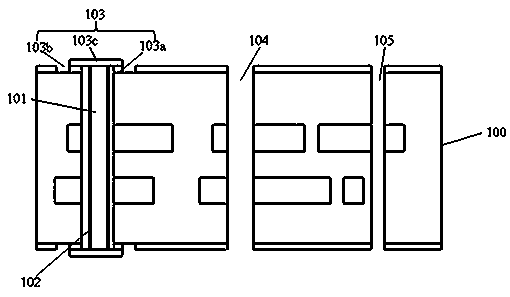

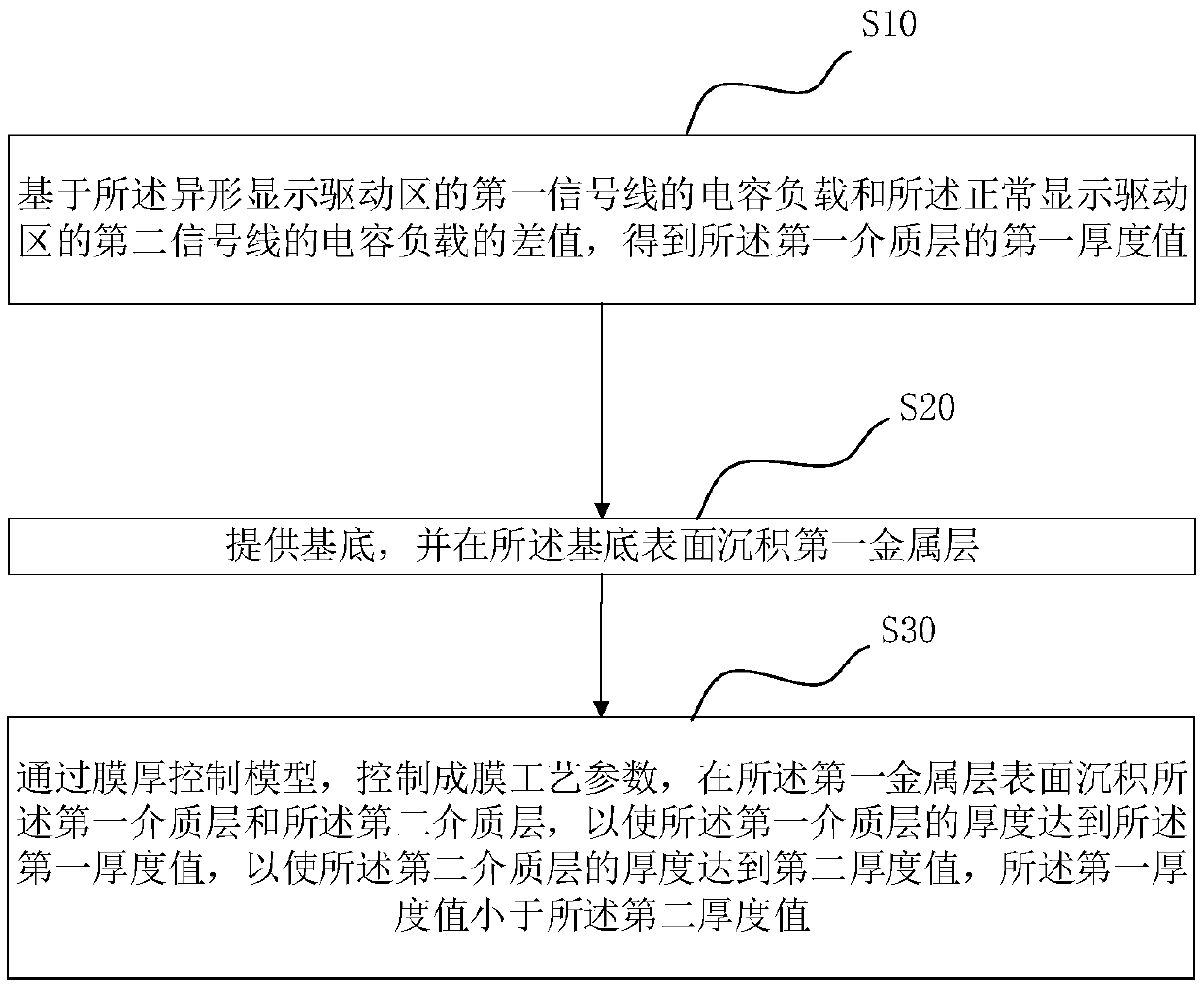

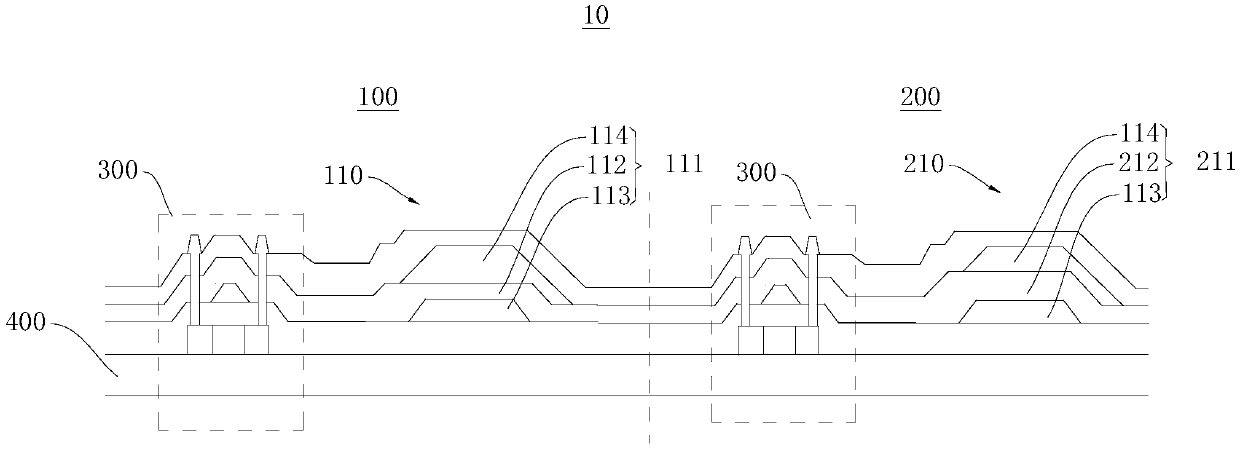

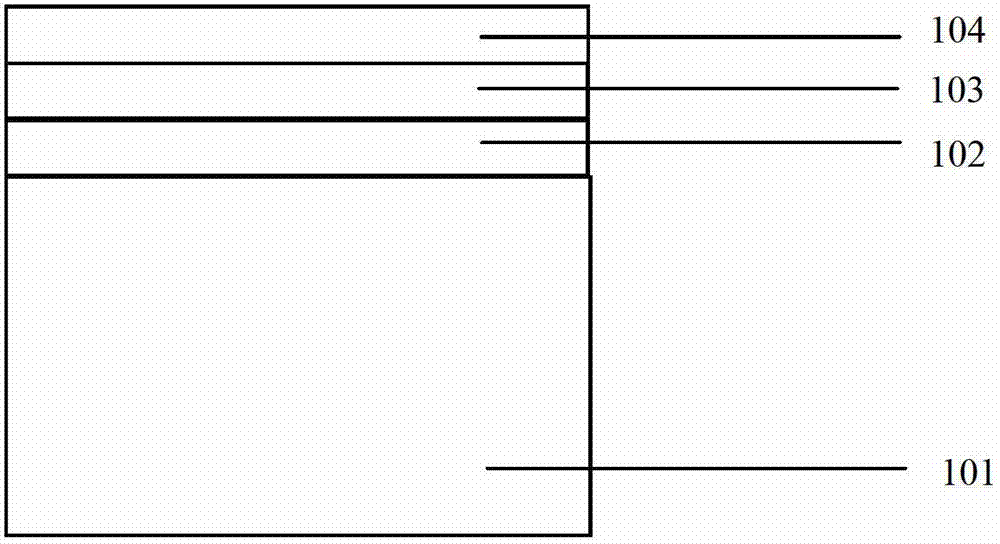

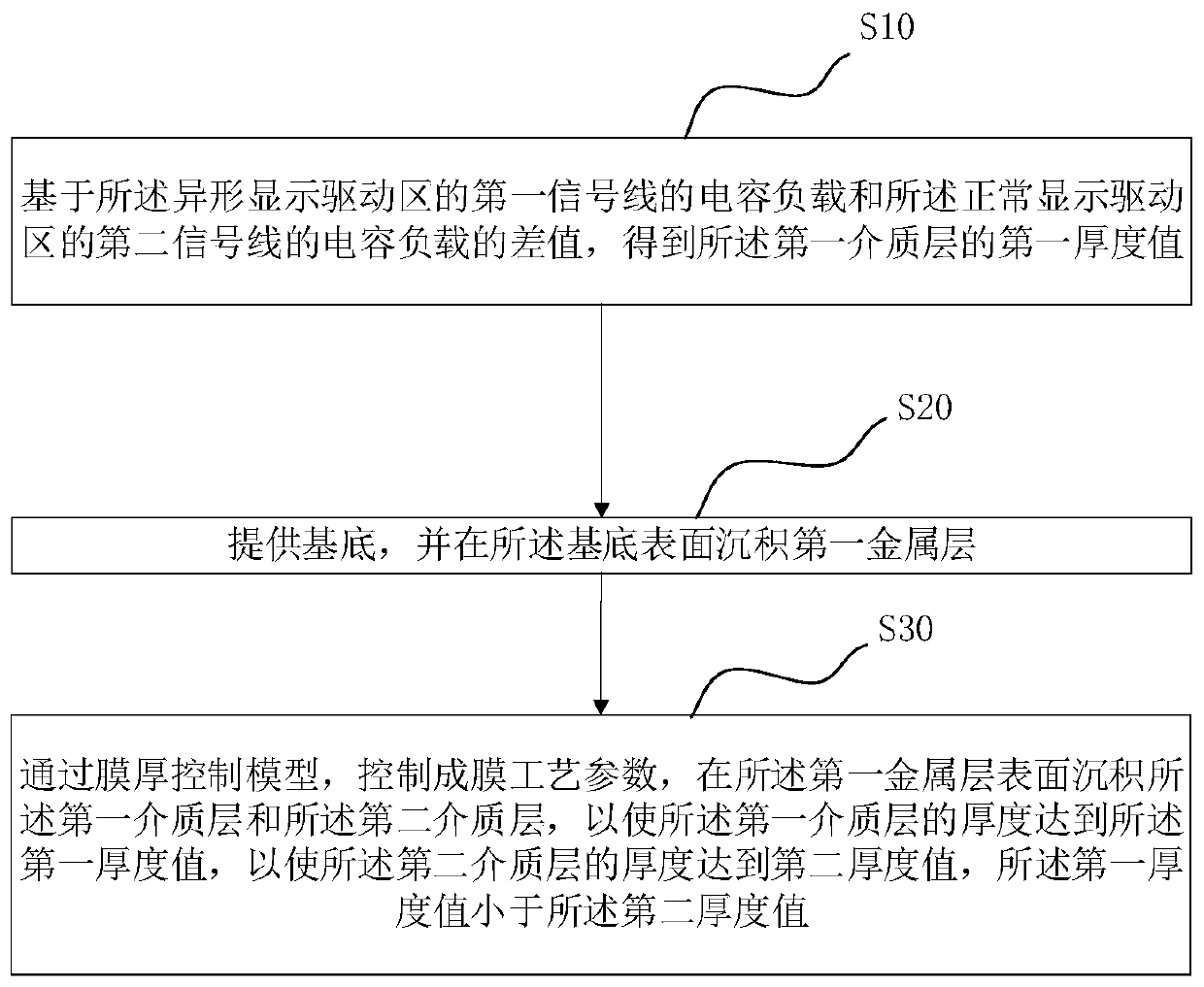

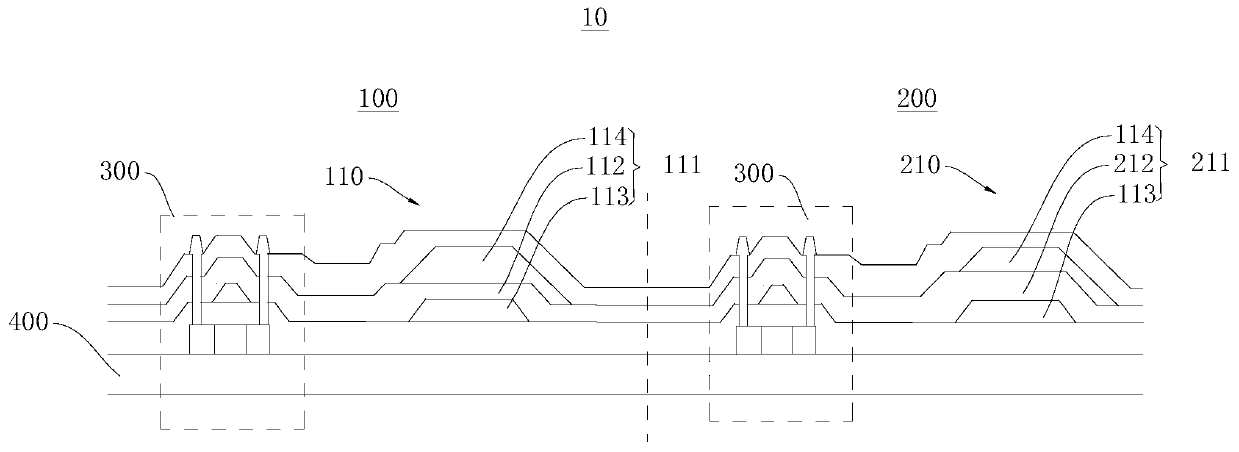

Method for fabricating driving substrate

ActiveCN108682669AFlexible thickness controlAdd capacitive loadTransistorSemiconductor/solid-state device detailsCapacitanceEngineering

The present application relates to a method for fabricating a driving substrate, comprising S10, based on a difference between a load of all first storage capacitors of a special-shaped display driving region and a load of all second storage capacitors of a normal display driving region, obtaining a first thickness value of a dielectric layer; S20, providing a substrate, and depositing a first metal layer on the surface of the substrate; and S30, controlling film formation process parameters by a film thickness control model, and depositing a first dielectric layer and a second dielectric layer on the surface of the first metal layer to enable the thickness of the first dielectric layer to reach a first thickness value and the thickness of the second dielectric layer to reach a second thickness value, wherein the first thickness value is less than the second thickness value. By flexibly controlling the thicknesses of the first dielectric layer and the second dielectric layer, the display brightness of the special-shaped display region of the display screen and the display brightness of the normal display region of the display screen are tend to be the same.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

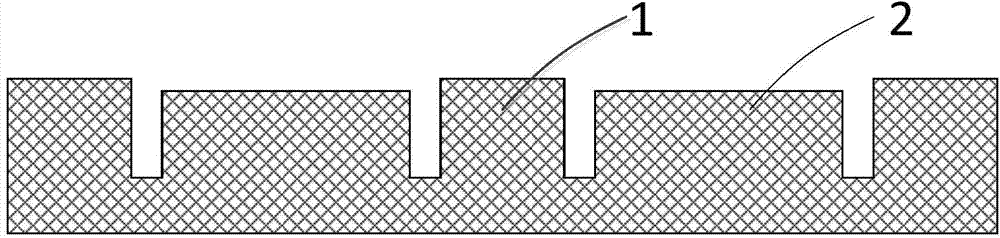

Molding method of photoresist wall

ActiveCN103698969ALarge lumen areaReduce generationOriginals for photomechanical treatmentLithographic artistThermal expansion

The invention provides a molding method of a photoresist wall. A flat panel is molded by using an injection-molding technology, wherein a first lug boss and a second lug boss are formed on the front side of the flat panel, and partitioned by a groove; the front side of the flat panel is glued and laminated with a first substrate, so that the first lug boss is adhered to the first substrate; the back side of the flat panel is grinded and thinned until the bottoms of the first lug boss and the second lug boss are separated; the second lug boss left on the first substrate is removed; residues on the first lug boss are removed by cleaning, so as to form a photoresist wall structure. The molding method of the photoresist wall has the advantages that the photoresist wall structure is independently molded; compared with the traditional photoresist lithography method, the photoresist wall molded by the molding method has the advantage that the probability of unqualified components caused by pollution in the photoresist wall molding process can be greatly reduced. The material for injection molding has the properties of high rigidity, low coefficient of thermal expansion (CTE), low moisture absorption and the like, the structure strength of a photomask of the photoresist wall is improved, and the reliability problems of layering, separating and the like are effectively reduced.

Owner:北京中科微知识产权服务有限公司

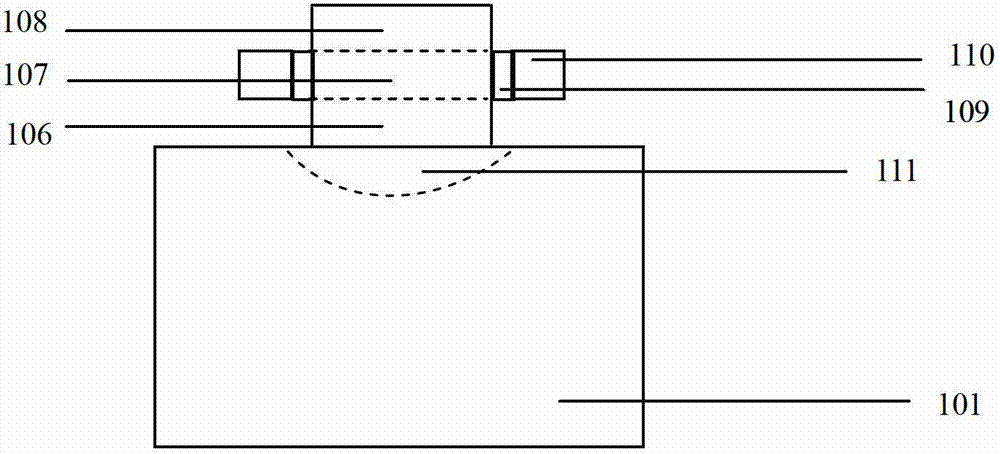

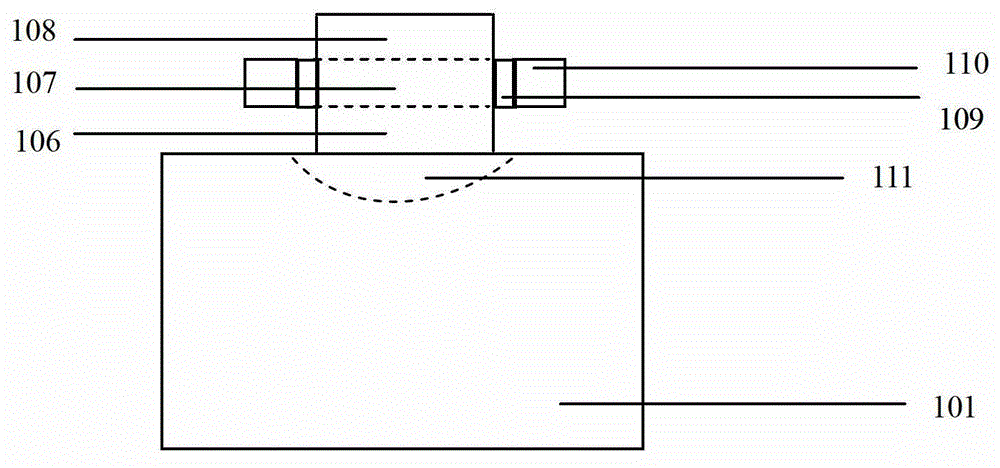

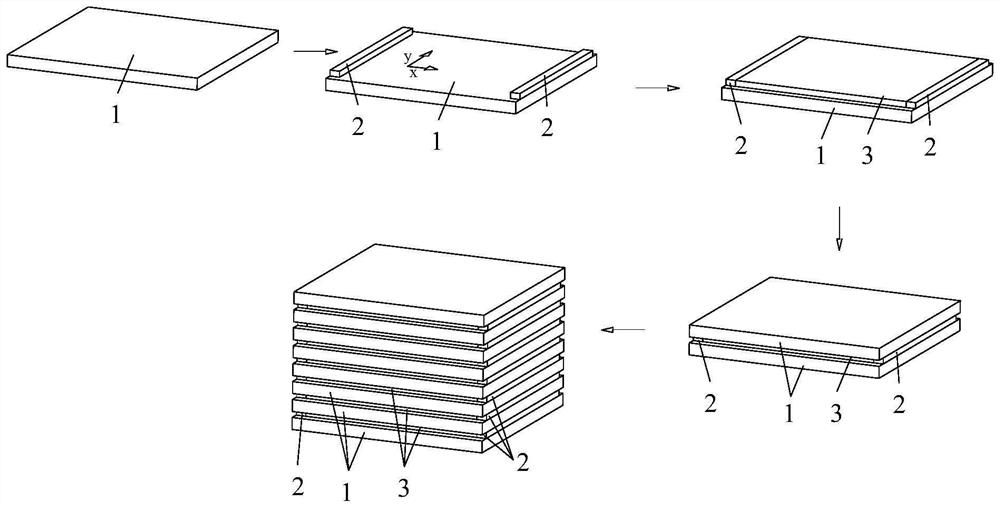

Structure of perpendicular asymmetric ring gating metal oxide semiconductor field effect transistor (MOSFET) device and manufacturing method thereof

InactiveCN102931237AFlexible thickness controlImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesGratingField-effect transistor

The invention provides a structure of a perpendicular asymmetric ring gating metal oxide semiconductor field effect transistor (MOSFET) device and a manufacturing method thereof. The structure of the device comprises a bottom-layer n-type silicon wafer substrate 101, wherein a drain region 111 is positioned at the bottommost end of the device; a drain expansion region 106, a channel region 107 and a source region grow on the substrate 101 in an epitaxial manner; a grating oxidization layer 109 encircles the whole channel region 107; and polycrystalline silicon gratings 110 are deposited on the grating oxidization layer 109. The invention provides the structure of the perpendicular asymmetric ring gating MOSFET with a function of effectively suppressing a short channel effect and a manufacturing method of the perpendicular asymmetric ring gating MOSFET; and by the manufacturing method, the technical process can be simplified and the length of the grating and the thickness of a silicon body region can be flexibly controlled.

Owner:三亚哈尔滨工程大学南海创新发展基地

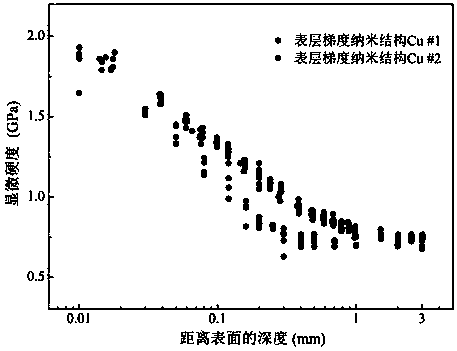

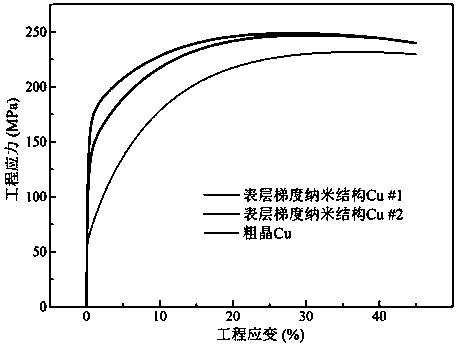

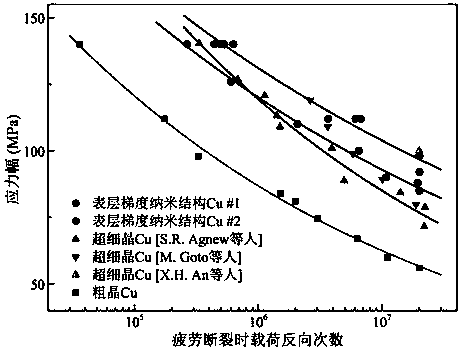

A Gradient Nanostructure with Excellent Comprehensive High-Cycle and Low-Cycle Fatigue Properties

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Structure and fabrication method of vertical junction-free gate-ring mosfet device

InactiveCN102983171BFlexible thickness controlImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringField-effect transistor

The invention provides a structure and a manufacturing method of a vertical junctionless gate-all-round MOSFET (metal oxide semiconductor field effect transistor) device. The structure comprises a bottom-layer n-type silicon wafer substrate 101, wherein a drain region 111 is positioned at the lowest end of the device; a drain expansion region 106, a channel region 107 and a source region 108 grow on the substrate 101 epitaxially; a gate oxide layer 109 surrounds the whole channel region 107; and a polysilicon gate 110 is deposited on the gate oxide layer 109. Doping types and concentrations of the drain expansion region 106, the channel region 107, the source region 108 and the drain region 111 are the same; the doping types are n plus doping; the doping concentrations are 1*10<19>-8*10<19>cm<-3>; the doping type of the polysilicon gate 110 is p plus doping; and the doping concentration of the polysilicon gate 110 is 5*10<19>cm<-3>. The structure of the vertical junctionless gate-all-round MOSFET device can effectively inhibit action of a short channel effect. The invention also provides the manufacturing method of the vertical junctionless gate-all-round MOSFET device, which can simplify the technological process and allow the length of a gate and the thickness of a silicon region to be controlled flexibly.

Owner:HARBIN ENG UNIV

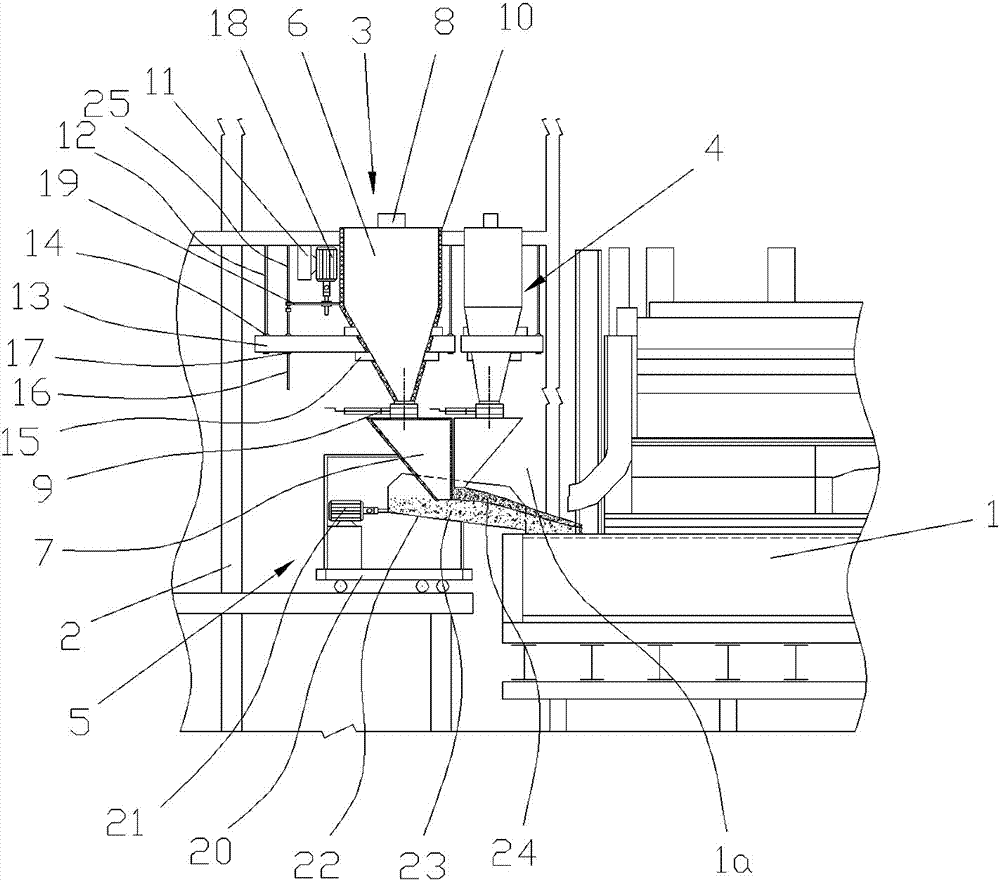

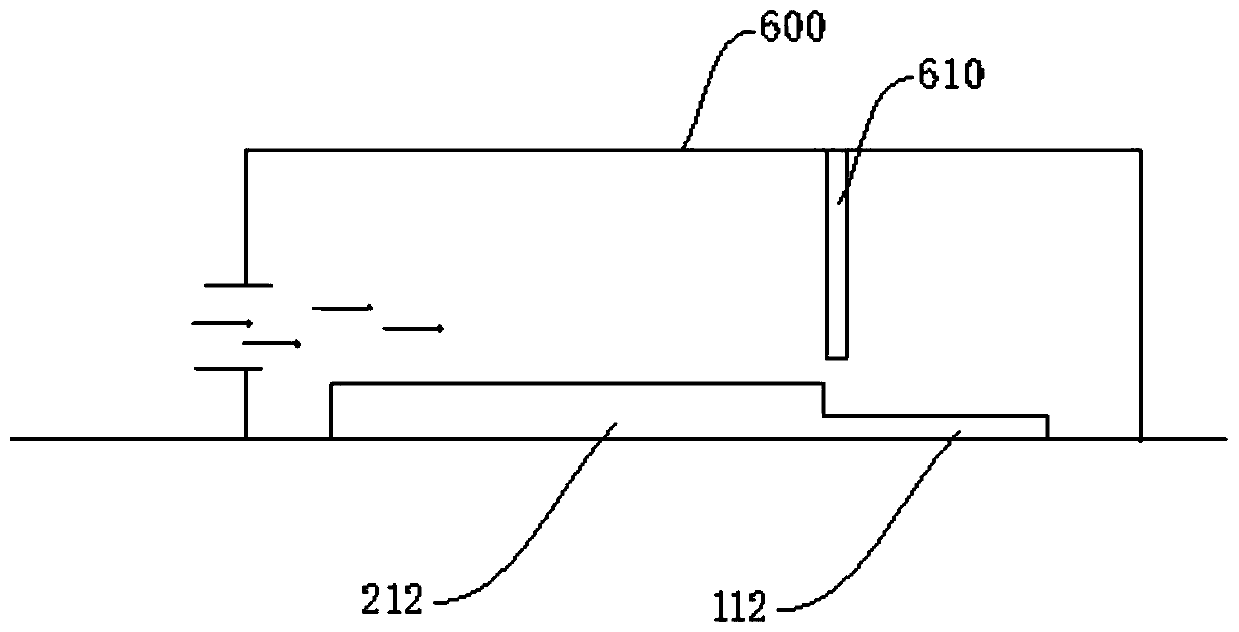

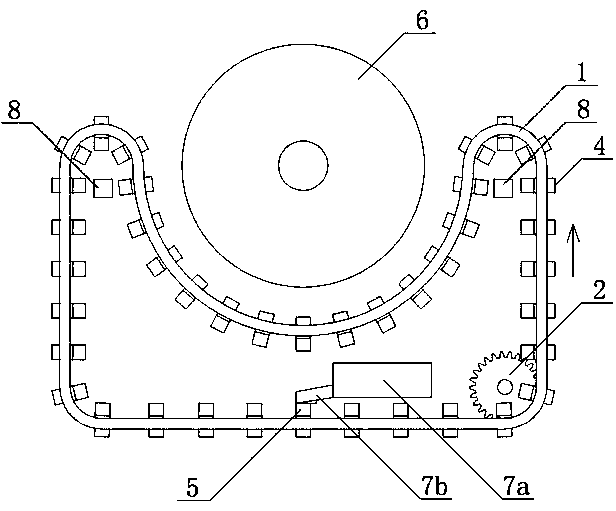

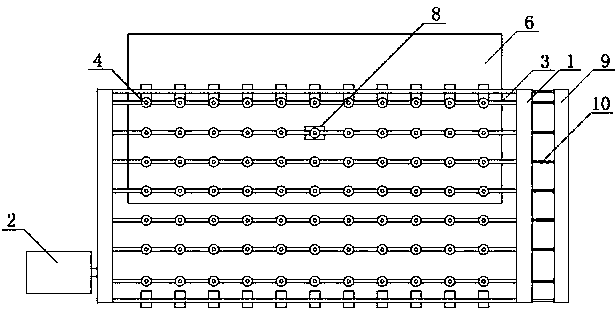

Device for feeding glass mixture material

ActiveCN107365053AReduce energy consumptionReduce erosionCharging furnaceGlass productionProduction lineEngineering

The invention relates to a device for feeding a glass mixture material. The device comprises a bracket, wherein the bracket is arranged at a feeding hole of a melting furnace; a push device for feeding materials is arranged on the bracket; an upper-layer feeding device and a lower-layer feeding device are connected with the bracket at the upper side of the push device; the upper-layer feeding device and the lower-layer feeding device are of a same structure and both comprise storage cabins; a feeding hole is formed in the upper side of the storage cabin; a discharge hopper corresponding to the push device is arranged on the lower side of the storage cabin; and a valve is arranged between the storage cabin and the discharge hopper. The device has the advantages that the device can be applied to a conventional glass production line, with the combination of a mixture material preheating technique, the energy consumption of the melting furnace can be effectively reduced, by adopting a layered feeding mode, an upper layer is uniformly covered by a high-moisture mixture material which is not liable to generate dust, then flying dust and flying loss of a lower-layer mixture material can be effectively prevented, corrosion of the melting furnace by the flying dust can be effectively alleviated, the thickness of material layers are flexibly controlled according to relative heights of hoppers, and the device is applicable to multiple operation working conditions.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

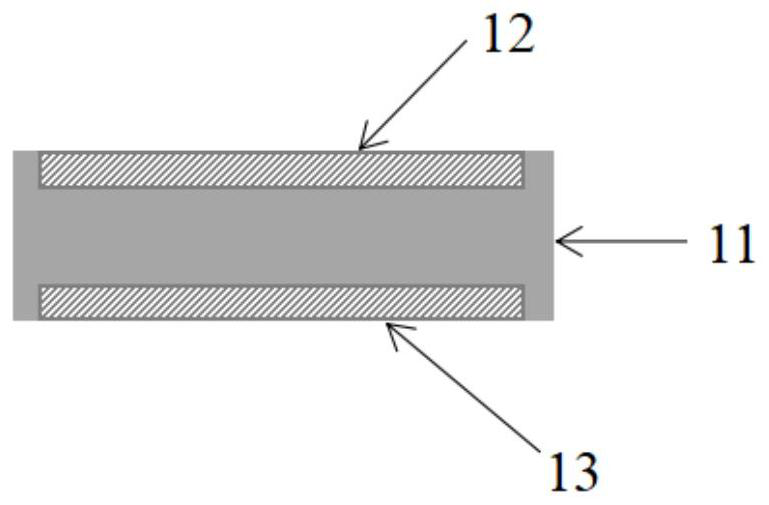

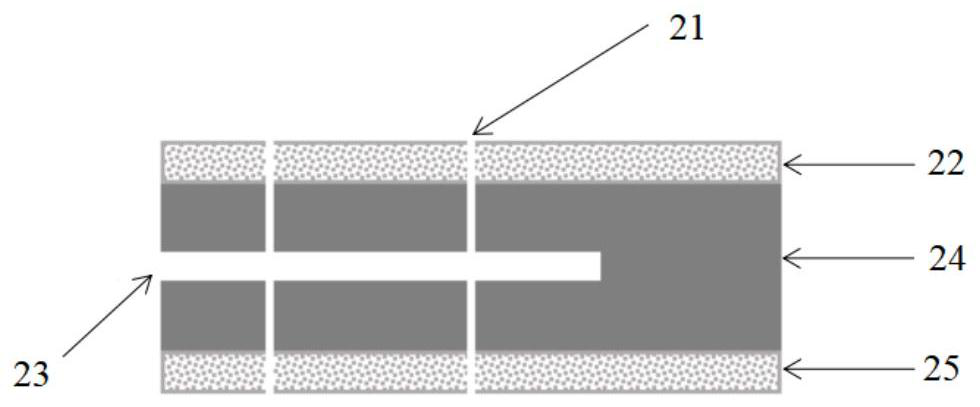

Ultrasonic sensor, piezoelectric composite ceramic chip and preparation method of blank of piezoelectric composite ceramic chip

PendingCN114335324AGood performanceSimple processPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric compositeUltrasound wave

The invention relates to a sensor, in particular to an ultrasonic sensor, a piezoelectric composite ceramic piece and a preparation method of a blank of the piezoelectric composite ceramic piece, and the preparation method comprises the following steps: S1, arranging two division bars on one surface of the piezoelectric ceramic piece at an interval; s2, the area between the two parting strips is filled with a polymer to form a polymer phase, and the polymer phase is flush with the tops of the parting strips; s3, another piezoelectric ceramic piece is attached to the top of the polymer phase, and the parting strip is located between the two corresponding adjacent piezoelectric ceramic pieces; and S4, superposing the piezoelectric ceramic pieces layer by layer to form a piezoelectric composite ceramic piece blank. According to the preparation method of the piezoelectric composite ceramic piece blank, the distance between the adjacent piezoelectric ceramic pieces is only controlled by the thickness of the parting strips and is not limited by the defects of a traditional cutting-pouring method, and the minimum thickness can be achieved. The number of bubbles in the piezoelectric composite ceramic piece blank is smaller, the manufactured piezoelectric composite ceramic piece blank is higher in quality, and the performance of an ultrasonic sensor product is better.

Owner:CHENGDU HUITONG WEST ELECTRONIC CO LTD

Preparation method of driving substrate

ActiveCN108682669BFlexible thickness controlAdd capacitive loadTransistorSemiconductor/solid-state device detailsCapacitanceEngineering

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

A dampening water application method based on ultrasonic atomization and its system and application

ActiveCN109624483BReduce surface tensionReduce dosageOther printing apparatusRotary lithographic machinesEngineeringUltrasonic atomization

The invention discloses a fountain solution application method and system based on ultrasonic atomization as well as an application. The method comprises the following steps that 1) an ultrasonic atomization device is arranged below a form damping roller, and a fountain solution is added into the ultrasonic atomization device; 2) the ultrasonic atomization device is started at the same time and used for conducting ultrasonic atomization on the fountain solution on the form damping roller under the ultrasonic condition of 0.1-100 MHz, so that a water film is formed on the form damping roller; and 3) the form damping roller is started, so that the fountain solution is made to be continuously and uniformly conveyed to a forme from the form damping roller in the form of the water film. According to the fountain solution application method and system based on ultrasonic atomization as well as the application, the ultrasonic atomization mode is adopted to carry out application of the fountain solution, the surface tension of the fountain solution can be greatly reduced, the water film can be stably and uniformly formed on the surface of the form damping roller in an attached mode, the use amount of surface active substances including alcohol in the fountain solution can be greatly reduced, even no surface active substances need to be added for realizing high-quality printing, and high efficiency and environmental friendliness are achieved.

Owner:KUNMING UNIV OF SCI & TECH

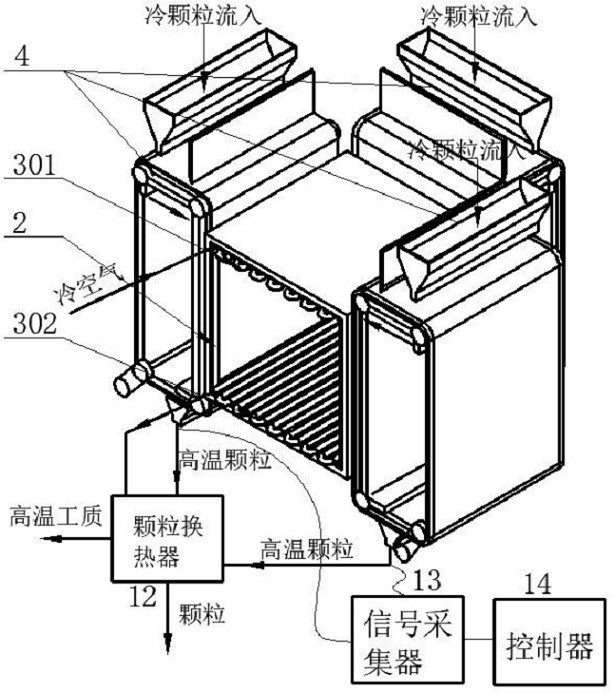

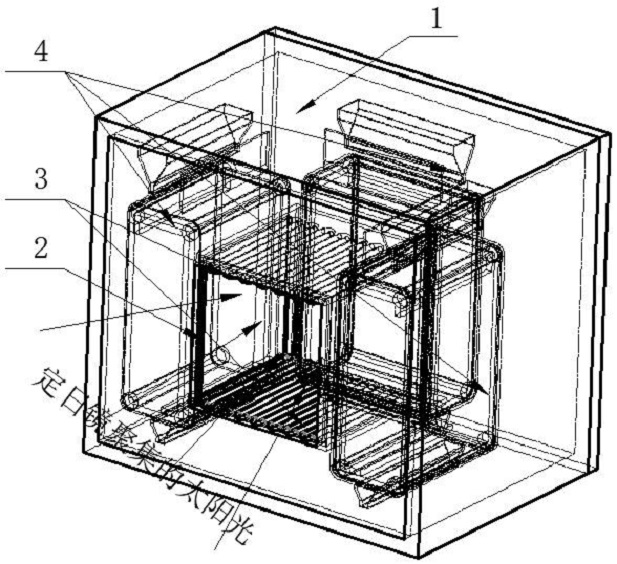

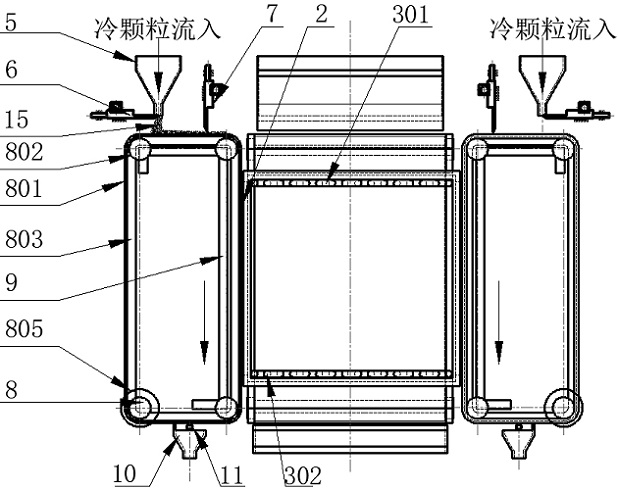

Magnetic adsorption cavity type solar particle heat absorber

PendingCN114811978ASimple structureReliable operationSolar heating energySolar heat collector controllersHeat conservationSunlight

Owner:HUNAN UNIV OF SCI & TECH

Preparation method of graphene film

The invention discloses a preparation method of a graphene film. The method comprises the following steps: implanting carbon into the surface layer of a metal substrate by adopting an ion implantation method in an oxygen-free environment; and corroding the metal substrate with corrosive liquid after the metal substrate is cooled, thus obtaining the graphene film. The preparation method has the beneficial effects that the ion implantation method only needs to be adopted to prepare the graphene film on the surface of the metal substrate, so that short time is required and the efficiency is high; the procedure of additional heating is not needed, so that the energy consumption is low; the graphene film is formed on the surface of the metal substrate and the thickness of the graphene film can be flexibly controlled by controlling the ion implantation quantity, so that the graphene film has a big area and uniform thickness; the ion implantation method is mature in process, so that the obtained graphene film has high quality and is low in production cost.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com