Patents

Literature

83results about How to "No manual measurement required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Visual technology-based stone mine forklift with weight measuring function and weight measuring method of stone mine forklift

ActiveCN106044663AReduce accident rateExtended service lifeSafety devices for lifting equipmentsUsing optical meansComputer visionMiddle line

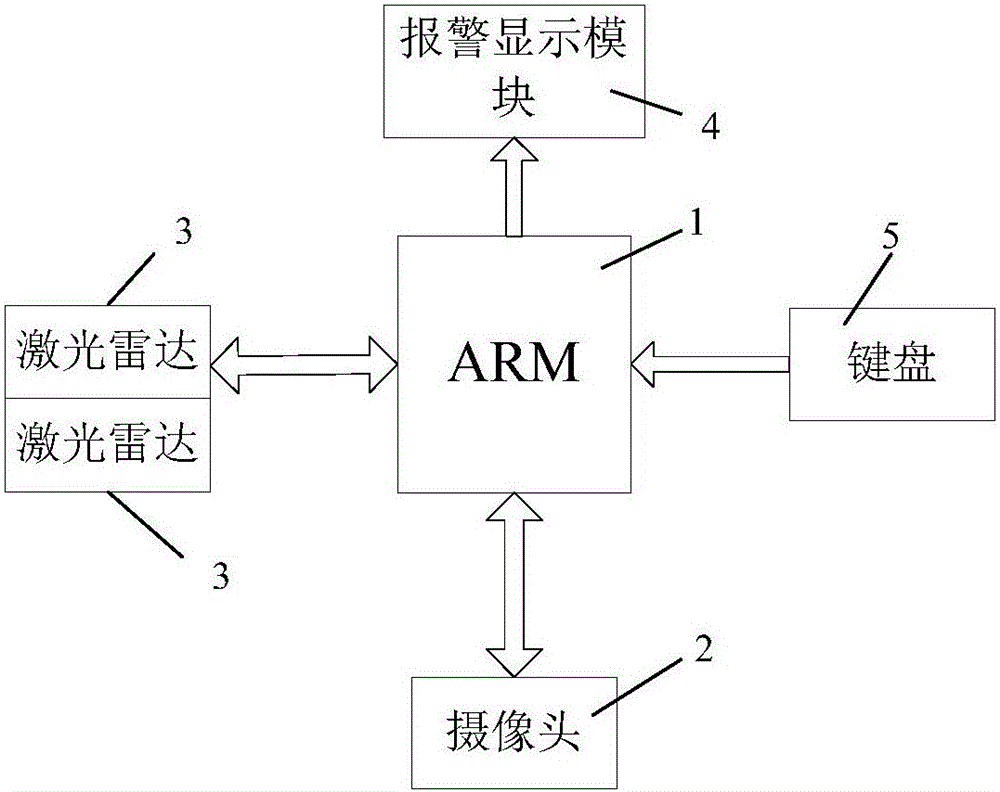

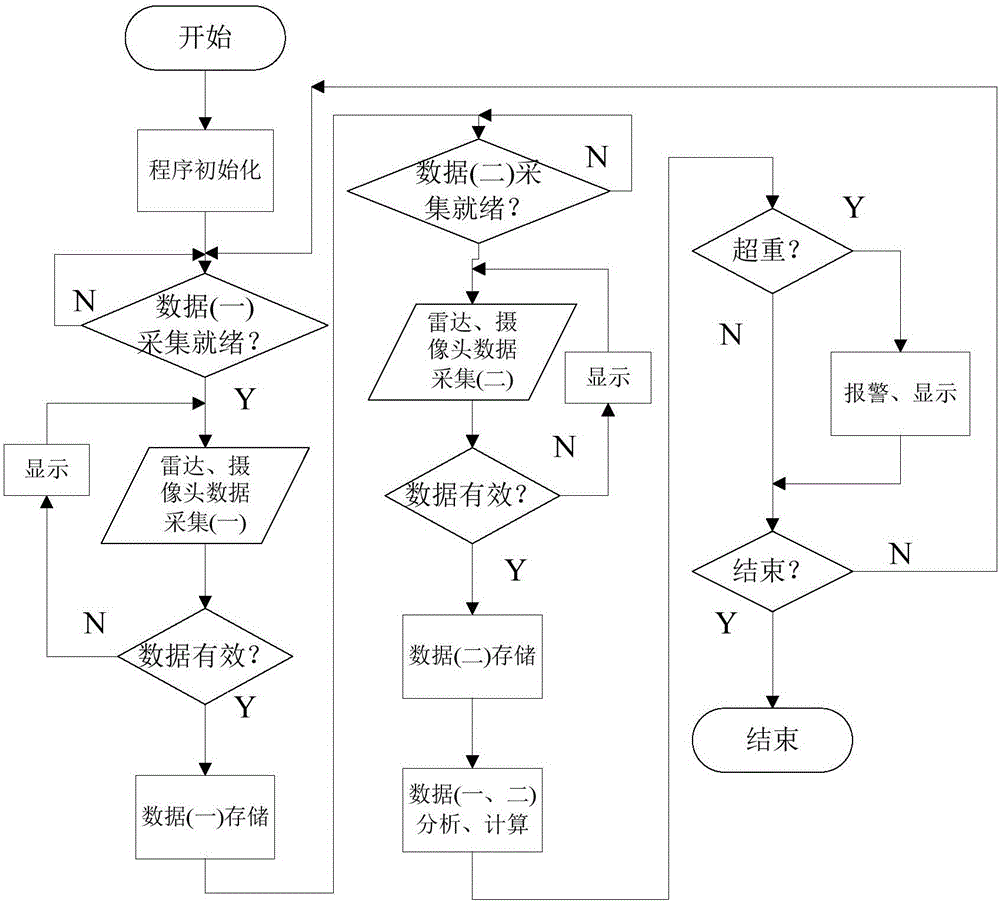

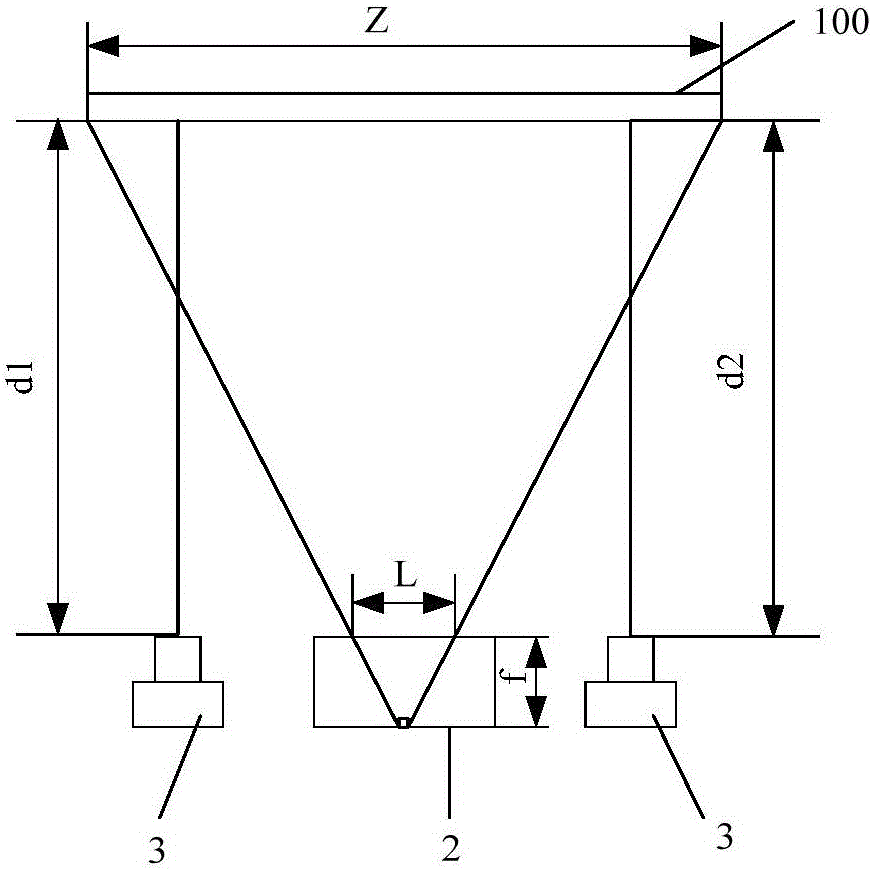

The invention provides a visual technology-based stone mine forklift with a weight measuring function and weight measuring method of the stone mine forklift. The stone mine forklift comprises a forklift body and a weight measuring system, wherein the weight measuring system comprises an ARM main controller, a camera and two laser radars; the ARM main controller is connected with the camera and the two laser radars respectively; the camera is mounted in a center line in front of the forklift body; the two laser radars are also mounted in front of the forklift body and are symmetrically arranged on two sides of the camera; the camera and the two laser radars are located on the same horizontal line; and an imaging face of the camera and signal emission points of the laser radars are located on the same plane. According to the visual technology-based stone mine forklift, the camera and the laser radars are used as information acquisition means, so that the weight of rough stone blocks to be loaded or unloaded can be measured accurately, the phenomenon that the forklift is in overload operation due to inaccurate estimation of an operator is avoided, the accident rate is reduced, and the service life of the equipment is prolonged.

Owner:FUJIAN UNIV OF TECH

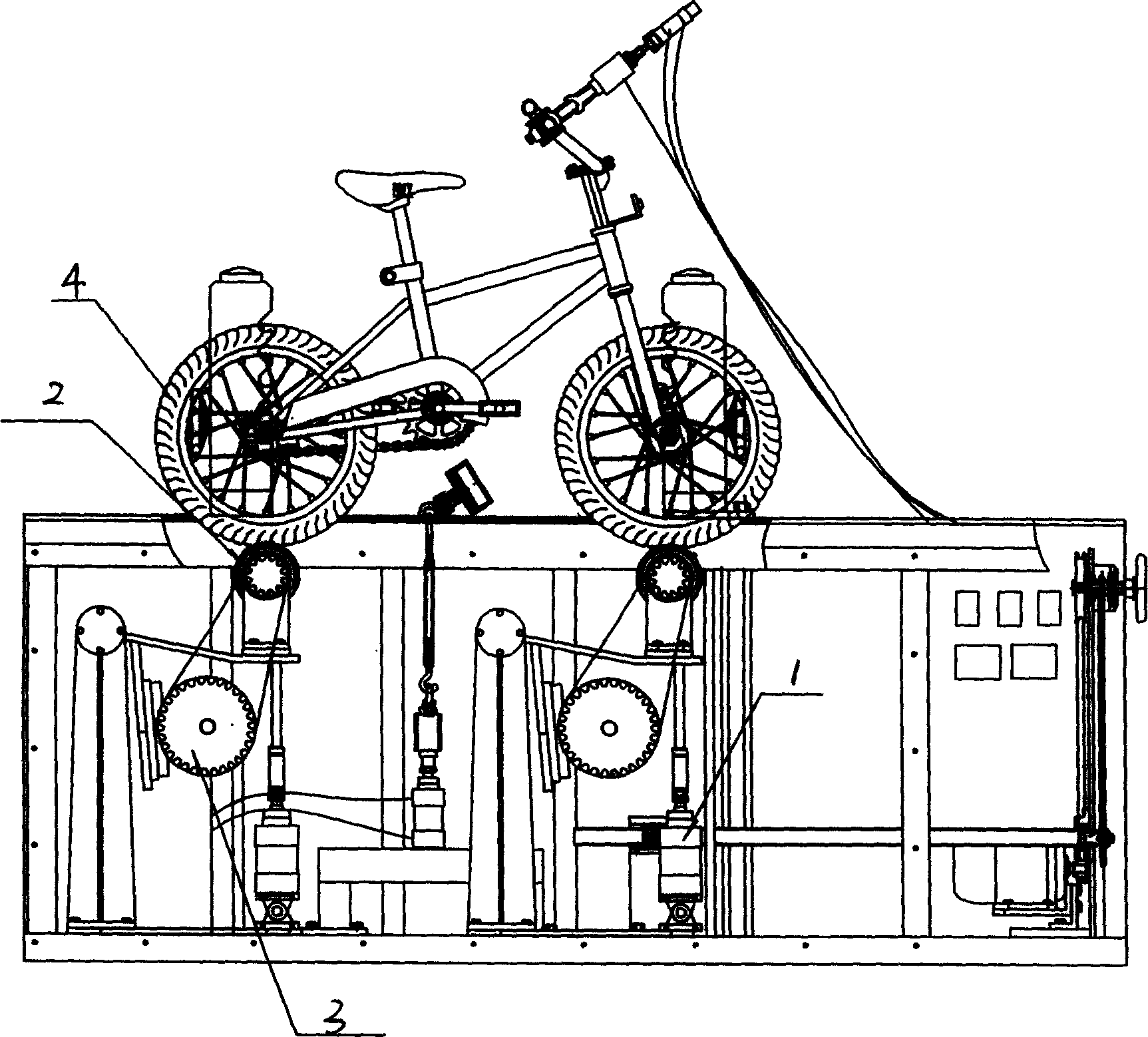

Machine for testing braking performance of bicycle

InactiveCN1760653ALabor savingEasy to useVehicle testingApparatus for force/torque/work measurementDrive motorEngineering

The testing machine includes mechanism for mounting and clipping bicycle to be fixed, mechanism for applying force on brake, device for measuring torque, cylinder for applying force, and electric control unit. The mechanism for applying force on brake is connected to brakes. Device for measuring torque includes a driving motor and friction roller, which is connected to the output shaft of the driving motor. The friction roller is under wheel of bicycle mounted and clipped on the mounting and clipping mechanism. Torsion sensor is installed on the shaft of the motor. Device for measuring torque is connected to piston rod of cylinder for applying force fixedly. Being connected to output end of revolution speed sensor and control wire of drive set of cylinder for applying force, the electric control unit keeps revolution speed at rated value of speed. Advantages are: automatic operation and accurate result tested.

Owner:中华人民共和国慈溪出入境检验检疫局

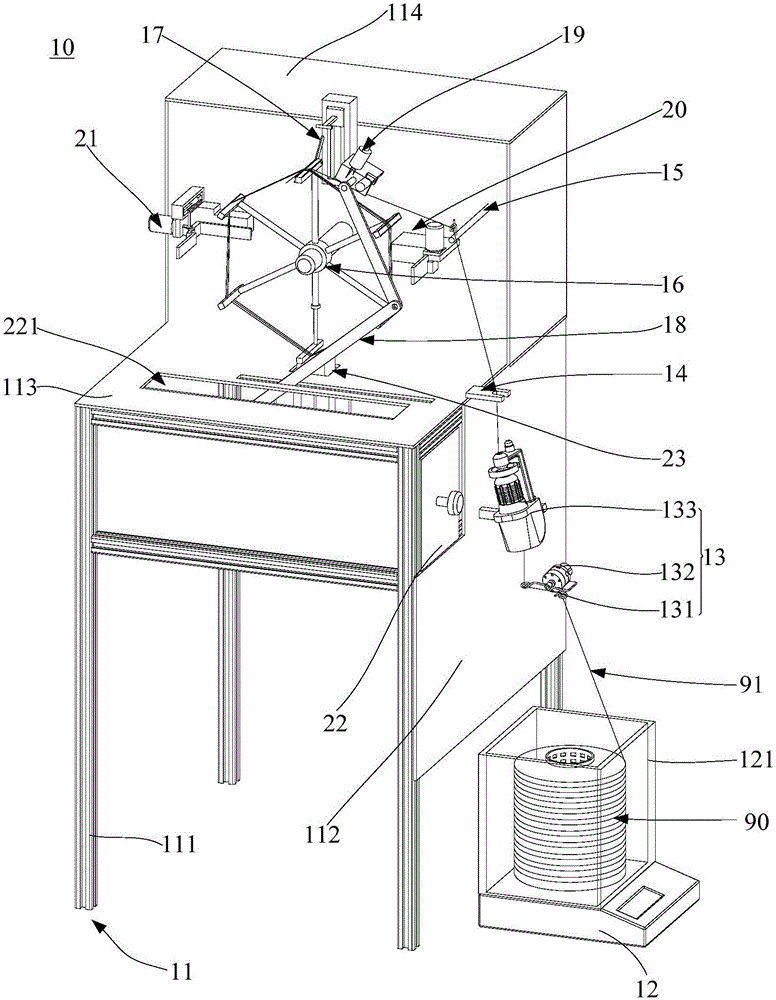

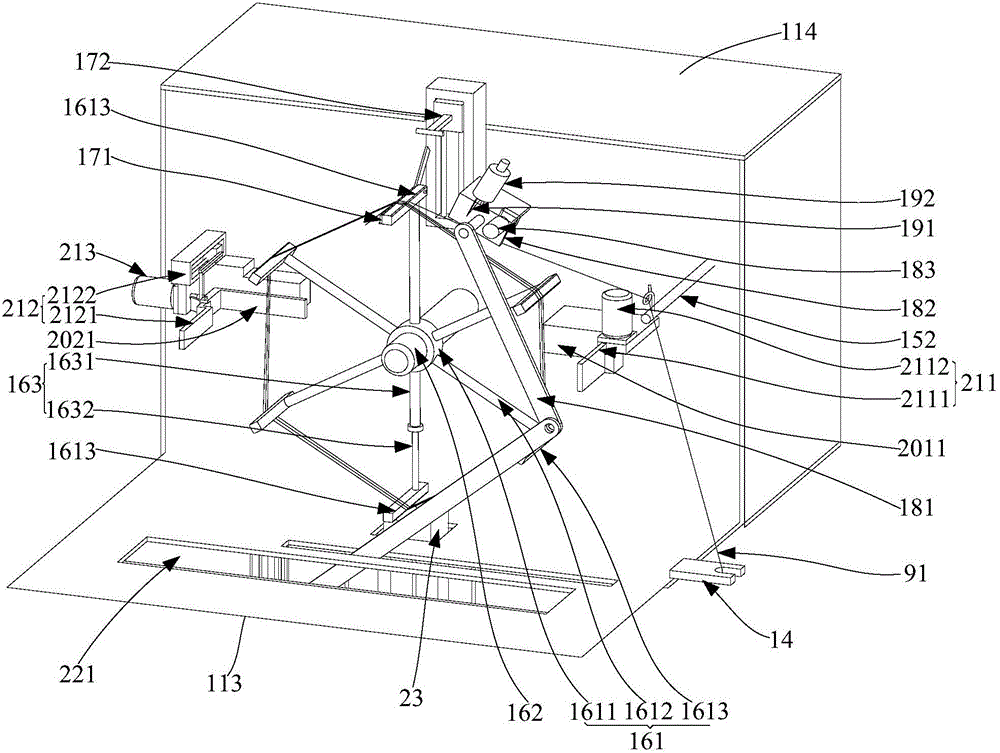

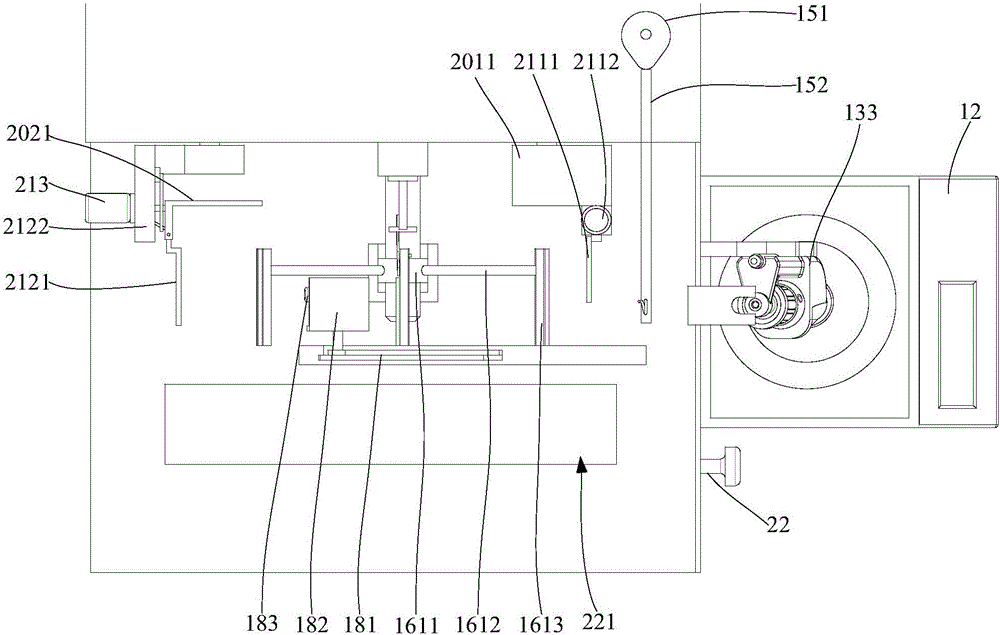

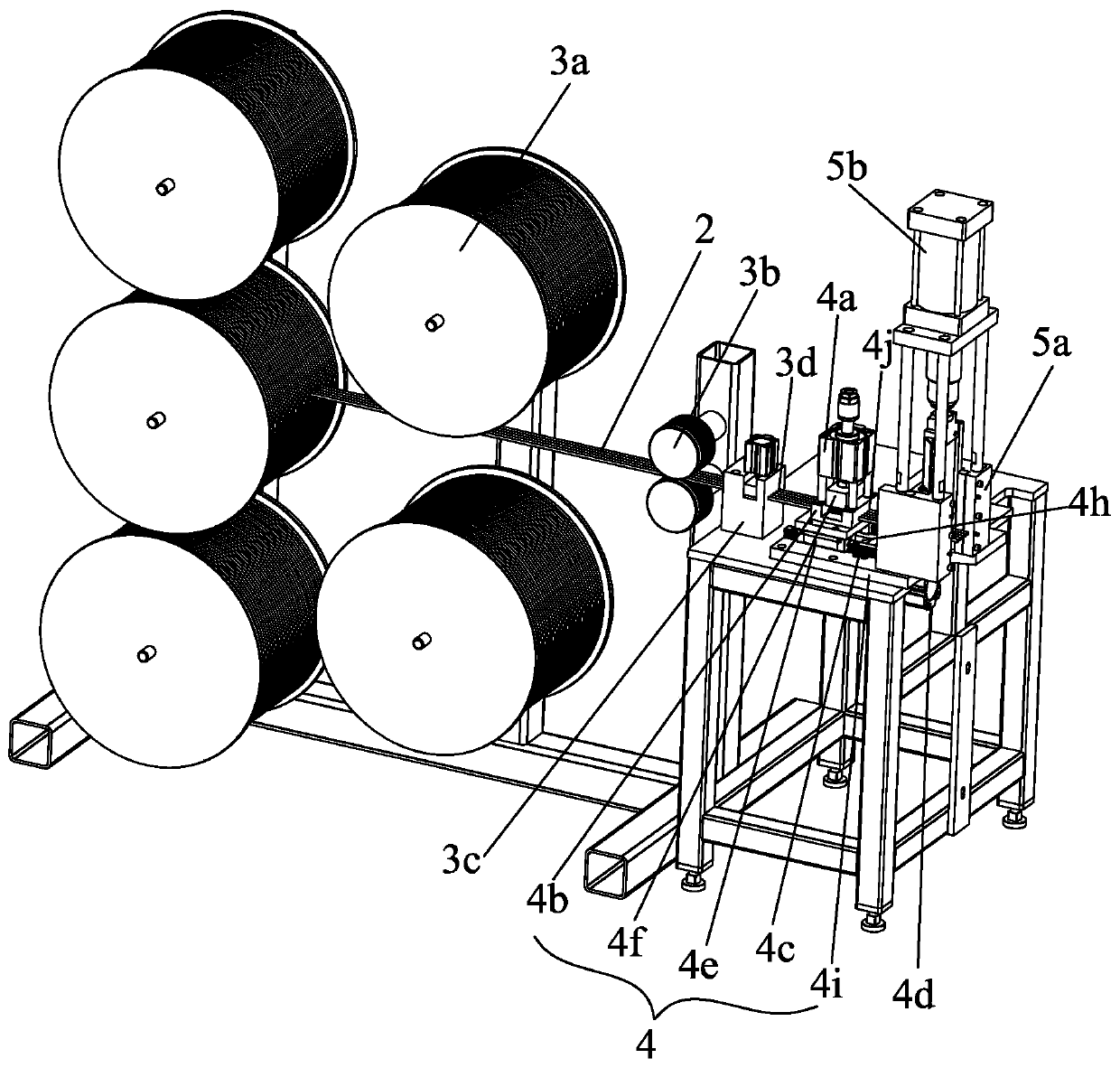

Yarn on-line weighing and sampling device and method

ActiveCN105890726AAvoid affecting weighing resultsNo need to affect weighing resultsWeighing apparatus for materials with special property/formYarnBobbin

The invention relates to a yarn on-line weighing and sampling device and method. The yarn on-line weighing and sampling device comprises a stage, an electronic scale, a tension regulating mechanism, a yarn winding mechanism and a control mechanism. According to the yarn on-line weighing and sampling device and method, the weight of bobbin yarns is monitored in real time through the electronic scale; and the control mechanism controls the yarn winding mechanism to wind yarns or stop winding yarns according to the weight of the bobbin yarns monitored by the electronic scale, and controls a tension frame driving device to drive a tension frame to rotate by a preset angle after controlling the yarn winding mechanism to stop winding yarns, so as to make the yarns of the bobbin yarns become relaxed from a tensioned state, and the electronic scale is adopted to weigh the yarns, and therefore, influence on a weighing result, which is brought about by a pull force applied to the bobbin yarns by tensioned yarns, can be avoided, and the weighing result can be more accurate, and therefore, the improvement of the precision of sampling can be benefitted. According to the yarn on-line weighing and sampling device and method, automatic on-line weighing and sampling are carried out through machines, and manual measurement and correction are not required, and therefore high efficiency can be achieved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

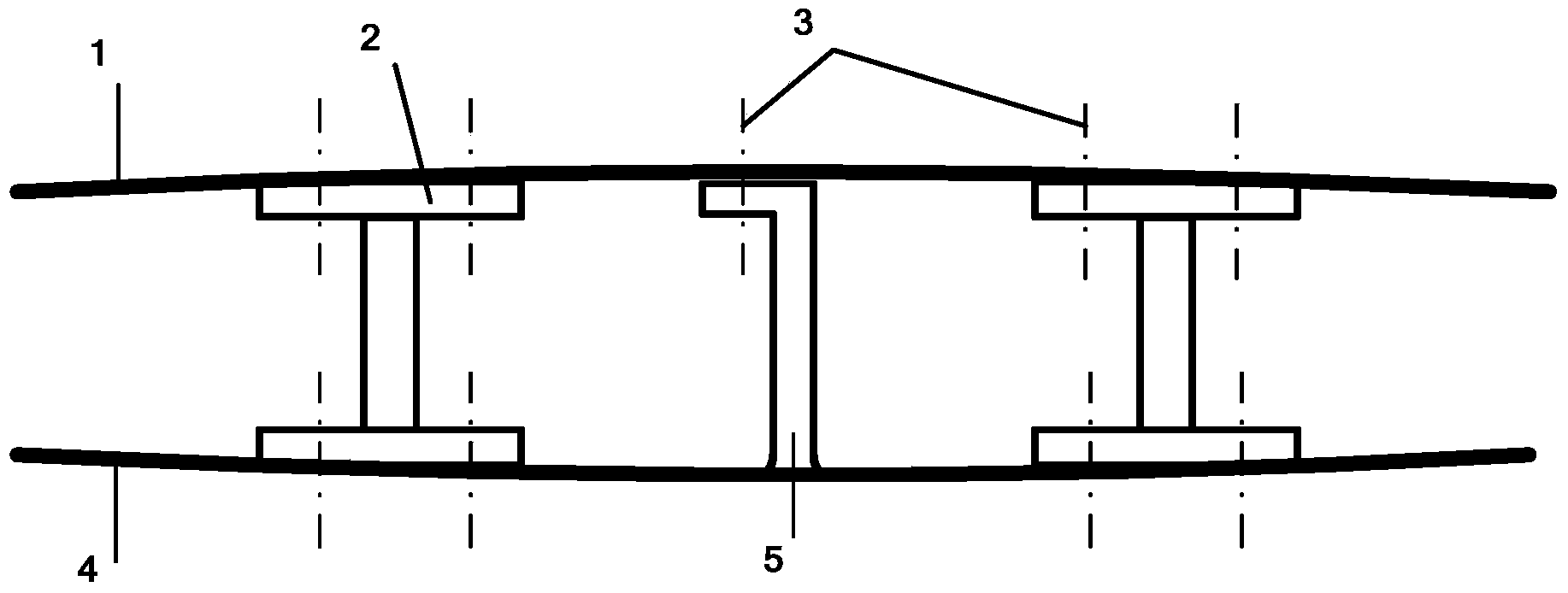

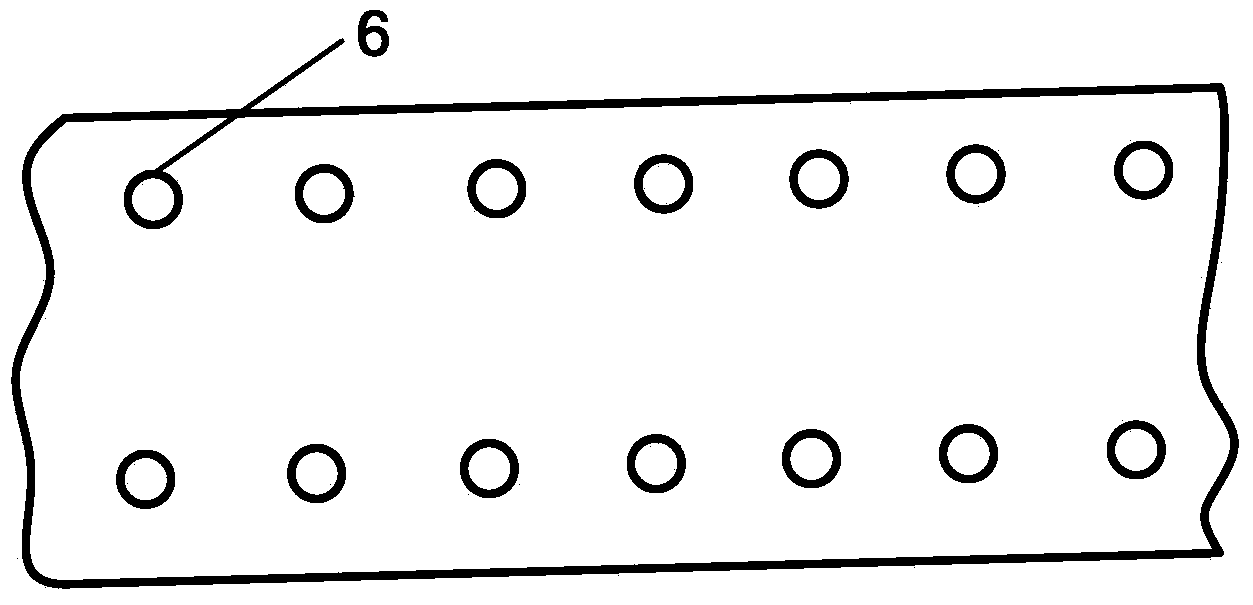

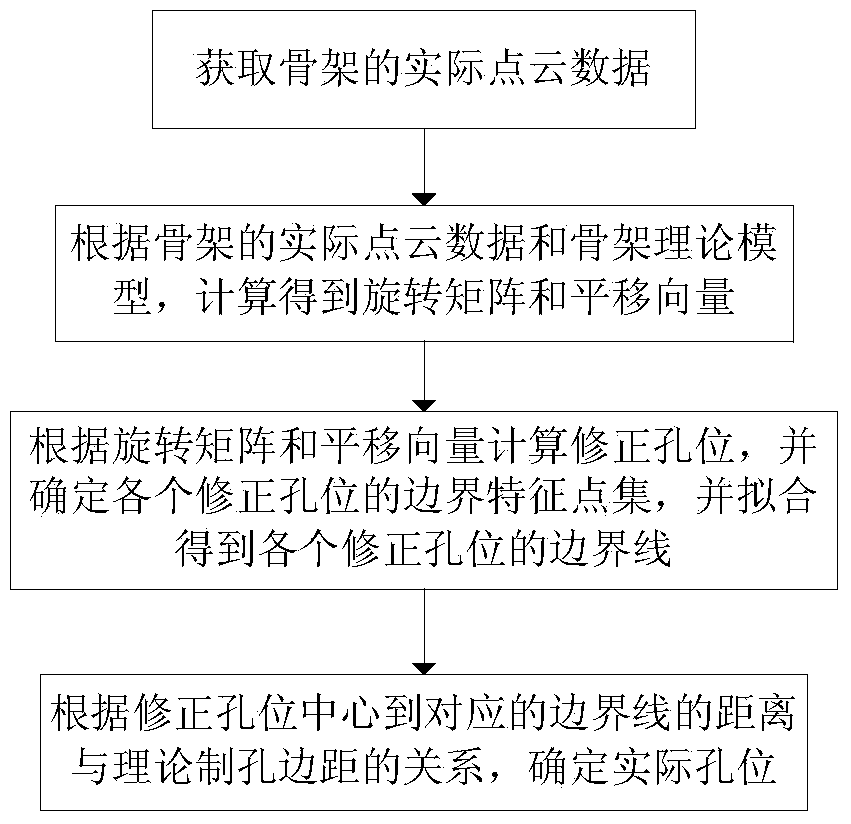

Method for correcting hole sites on basis of framework scanning measurement

ActiveCN103895877AEliminate inaccuraciesSolve the problem of unpredictable marginsAircraft assemblyPoint cloudComputer science

The invention provides a method for correcting hole sites on the basis of framework scanning measurement. The method for correcting the hole sites includes computing rotation matrixes and translation vectors according to actual point cloud data and theoretical models of frameworks; correcting theoretical hole sites on the frameworks by the aid of the rotation matrixes and the translation vectors to obtain corrected hole sites; determining boundary lines of the various corrected hole sites; utilizing distances from the centers of the corrected hole sites to the boundary lines as corrected hole drilling edge distances. The method has the advantages that the problem of difficulty in measuring edge distances of closed structures can be solved; integral procedures are implemented on the basis of digitalization, accordingly, manual measurement can be omitted, and technological processes can be simplified; the problem of hole site inaccuracy due to the fact that hole sites are manually corrected after involution is performed by the aid of an existing method can be solved, and the automatic hole drilling precision can be guaranteed; the hole sites are firstly corrected before the hole drilling edge distances are determined, and the corrected hole sites can be acquired, so that hole site inaccuracy due to deformation, positioning and coordination can be eliminated, and the automatic hole drilling precision can be guaranteed.

Owner:ZHEJIANG UNIV

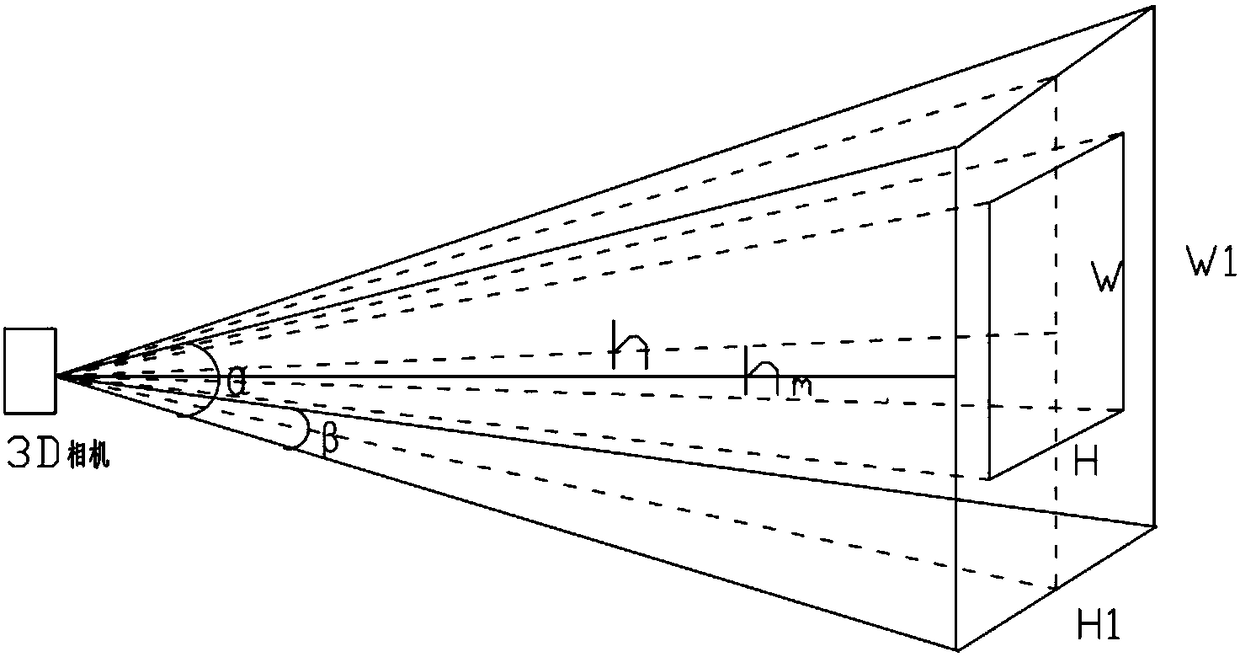

3D camera volume measuring method and system

The invention relates to a 3D camera volume measuring method and system. The 3D camera volume measuring method includes the following steps: acquiring a depth map of a measured object, wherein the depth map includes the depth information of the measured object; according to the depth information, extracting the measured object from the depth map, and obtaining the pixel area of the measured object; according to the distance between a 3D camera and a measuring platform and the depth information, obtaining the height of the measured object; according to the invariance of the view field ratio ofthe 3D camera and the pixel area, acquiring the length and the width of the measured object; and according to the length, the width and the height of the measured object, obtaining the volume of the measured volume. The 3D camera volume measuring method has the advantages of being simple in measurement, being convenient to implement, having no demand for artificial measurement, and greatly improving accuracy and efficiency.

Owner:SF TECH

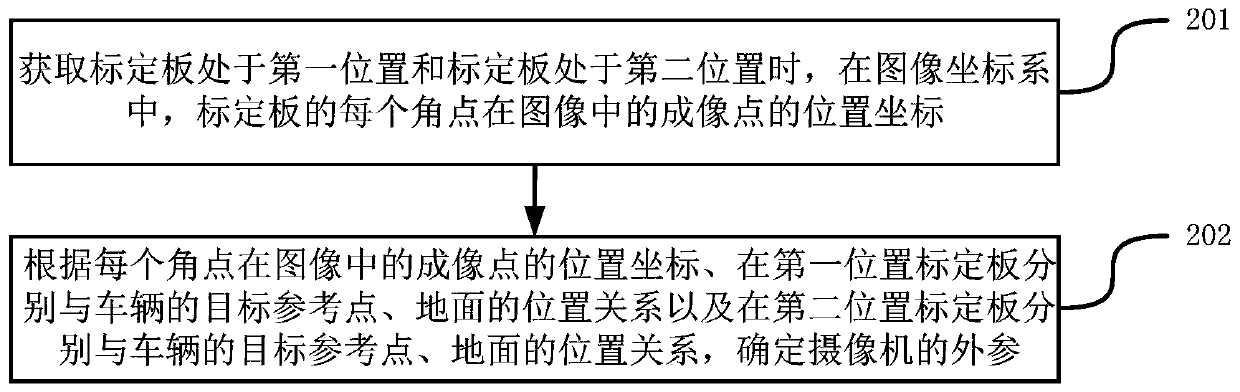

Camera external parameter calibration method and device

PendingCN111508027ASave calibration timeNo manual measurement requiredImage analysisInternal combustion piston enginesAngular pointIntelligent transport

The invention provides a camera external parameter calibration method and device, and belongs to the field of intelligent transportation. The method comprises the following steps of: when calibratingthe external parameters of the camera, in an image coordinate system, obtaining calibrating position coordinates of each angular point of the calibration plate in an imaging point of the image when acalibration plate is located at a first position and a second position; and then determining the external parameters of the camera according to the position coordinates of the imaging point of each angular point in the image, the position relationship between the first position calibration plate and the target reference point of the vehicle and the position relationship between the second positioncalibration plate and the ground and the position relationship between the second position calibration plate and the target reference point of the vehicle and the ground. By adopting the method and the device, the calibration time of the external parameters can be saved.

Owner:HANGZHOU HIKVISION DIGITAL TECH

Settlement measuring method and device for building and storage medium

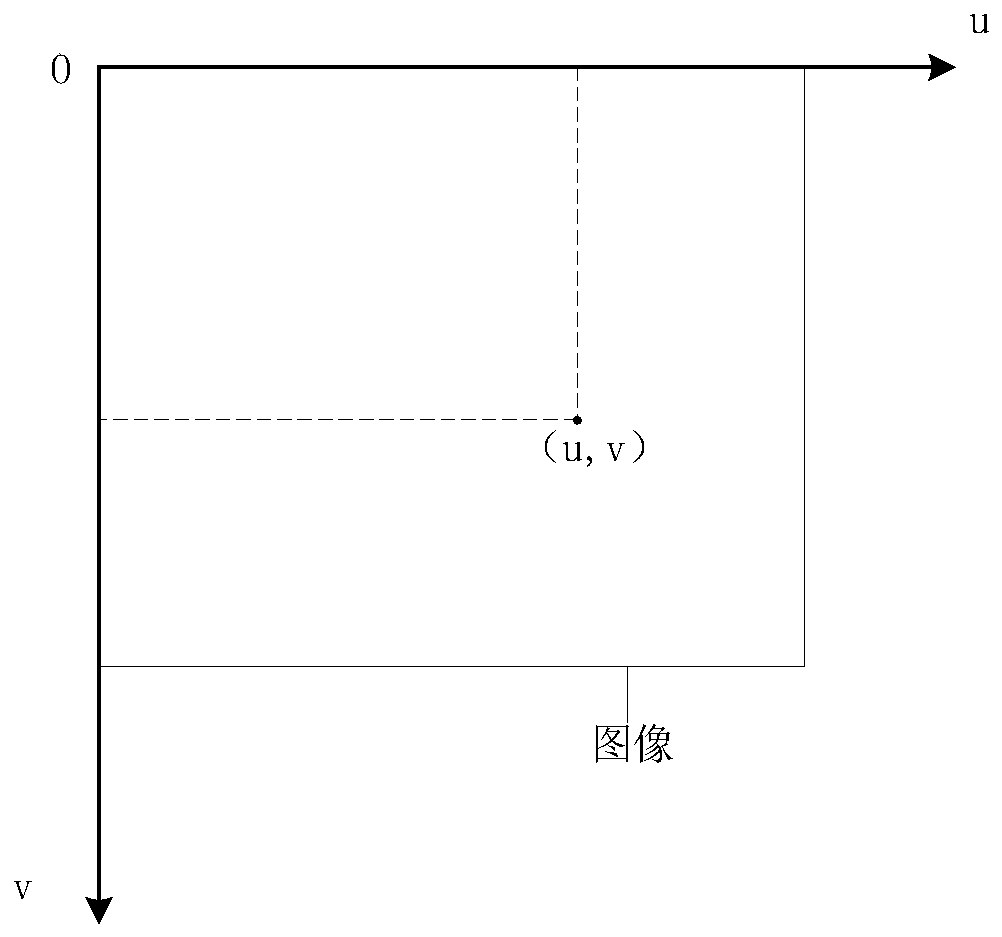

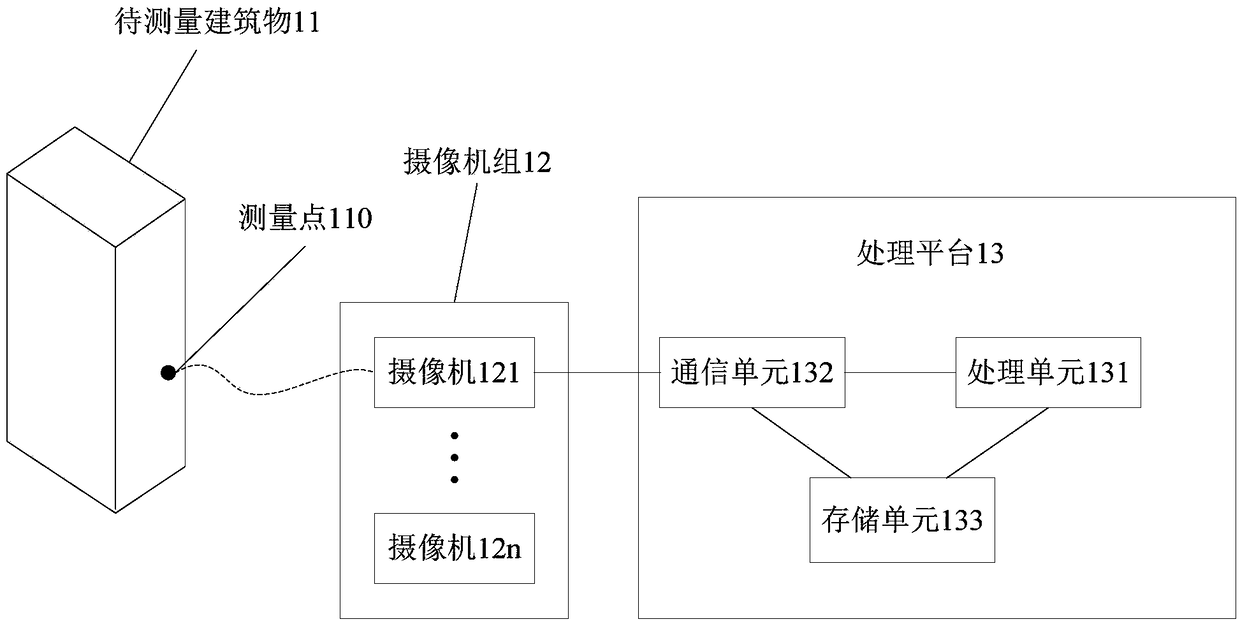

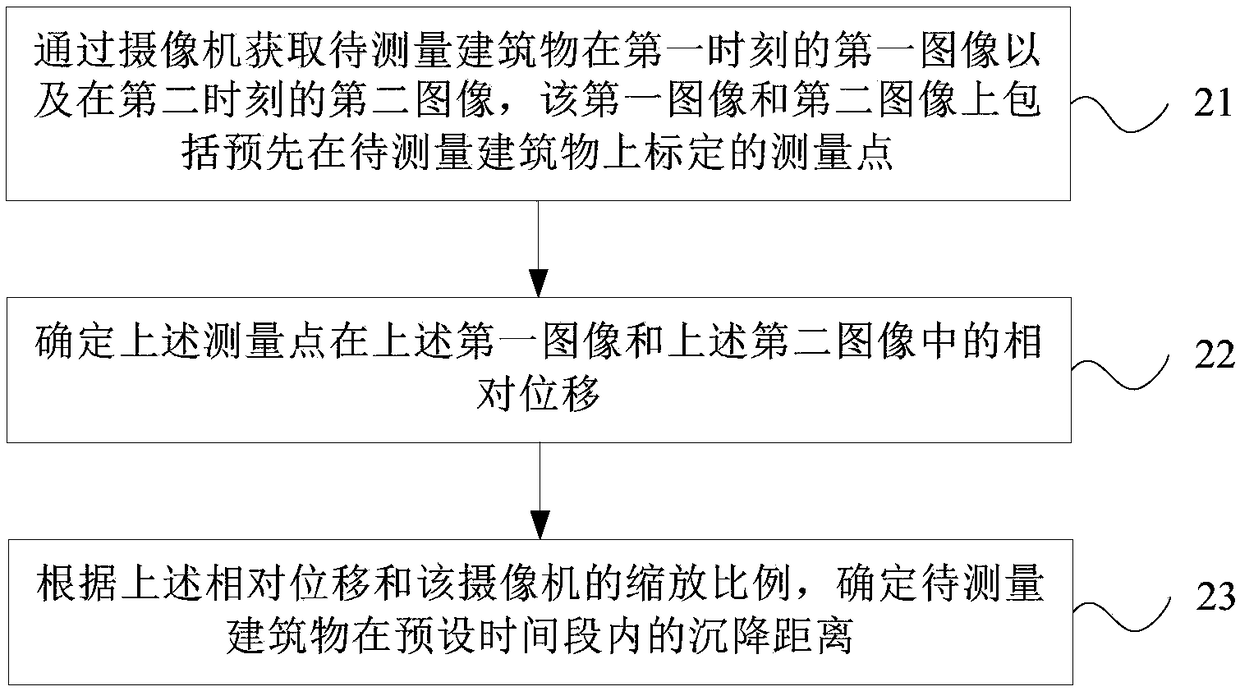

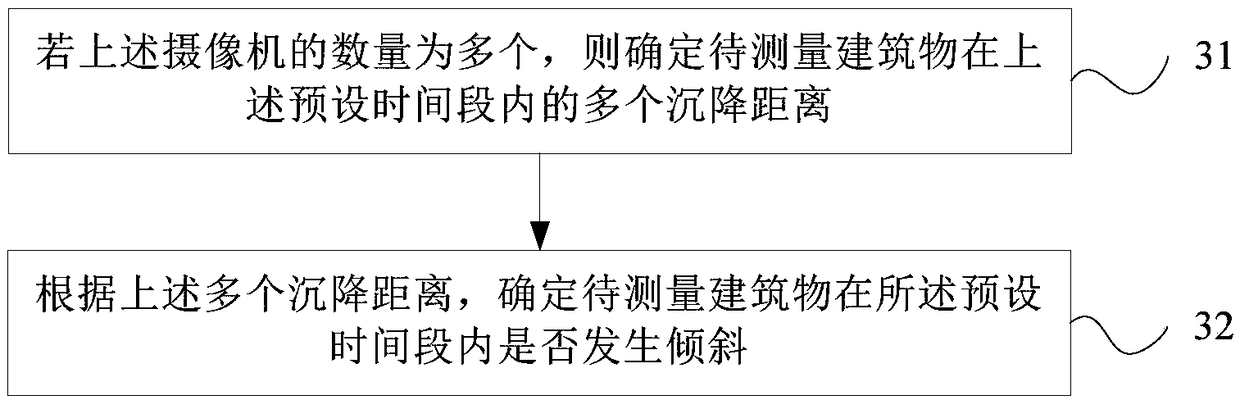

PendingCN109163698AHigh degree of automationNo manual measurement requiredHeight/levelling measurementRelative displacementMeasurement point

The invention provides a settlement measuring method and device for a building and a storage medium. The method comprises steps as follows: a first image of the to-be-measured building at the first moment and a second image of the to-be-measured building at the second moment are acquired through cameras, the first image and the second image include a measuring point marked on the to-be-measured building in advance, the relative displacement of the measuring point in the first image and the second image is determined, according to the relative displacement and the scaling ratio of the cameras,the settlement distance of the to-be-measured building within the preset time period is determined, and the preset time period is the time period from the first moment to the second moment. Accordingto the technical scheme, the settlement distance of the to-be-measured building within the preset time period can be calculated according to the images shot by the cameras at different moments, the automation degree is high, manual measurement is not required, the workload and the cost are reduced, and the work efficiency is improved.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

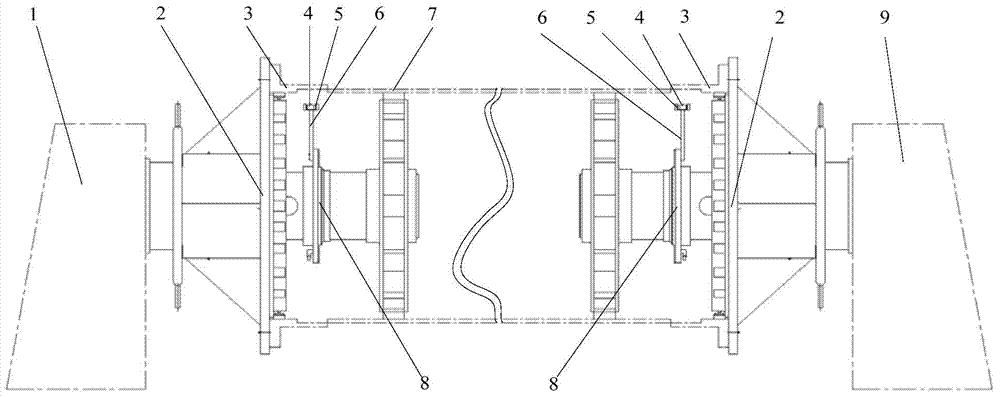

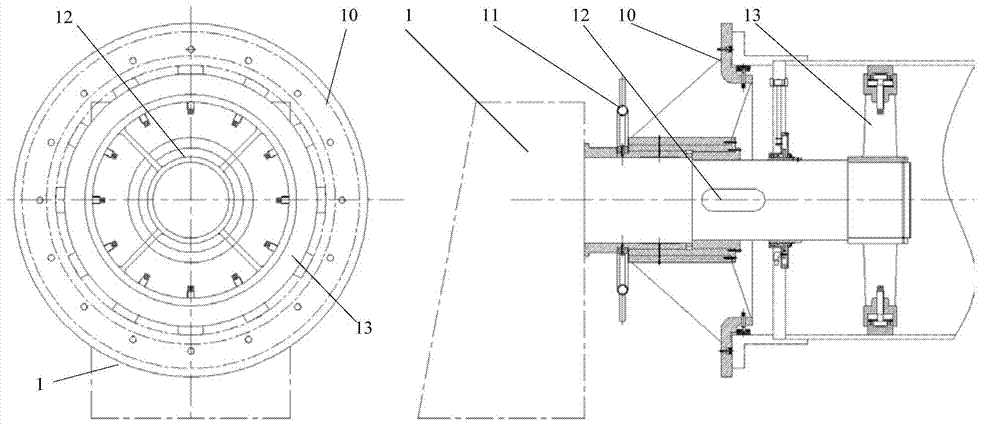

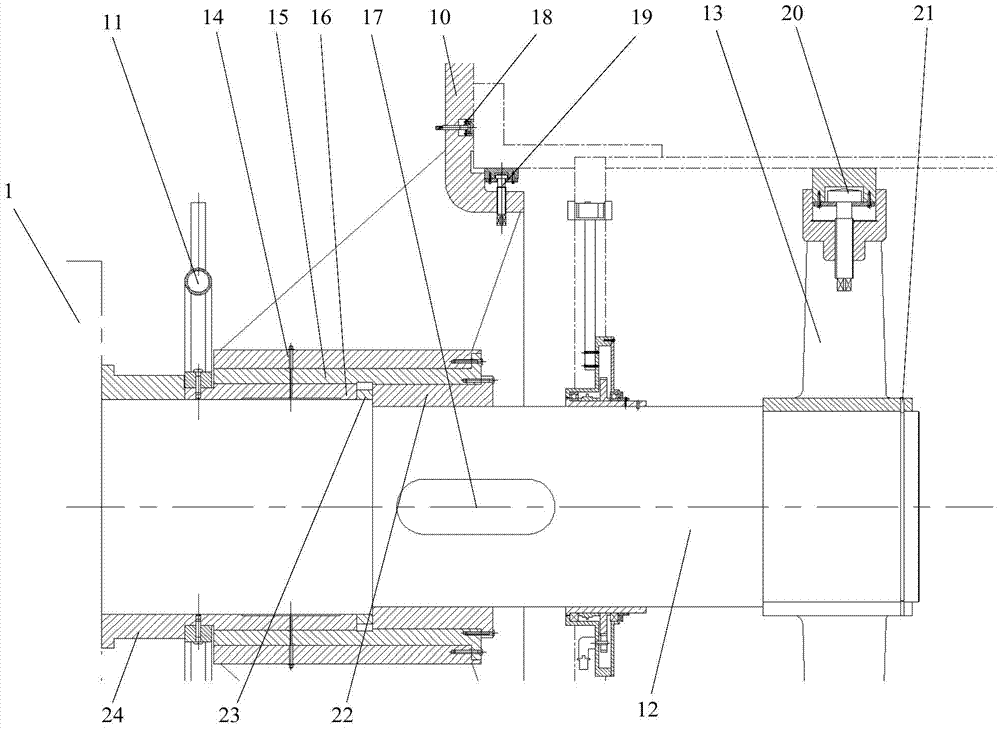

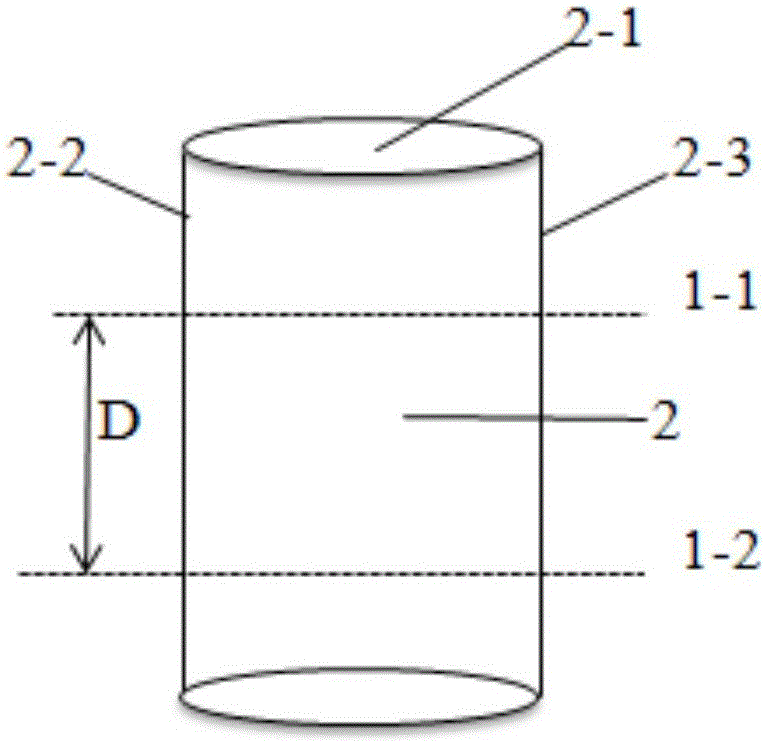

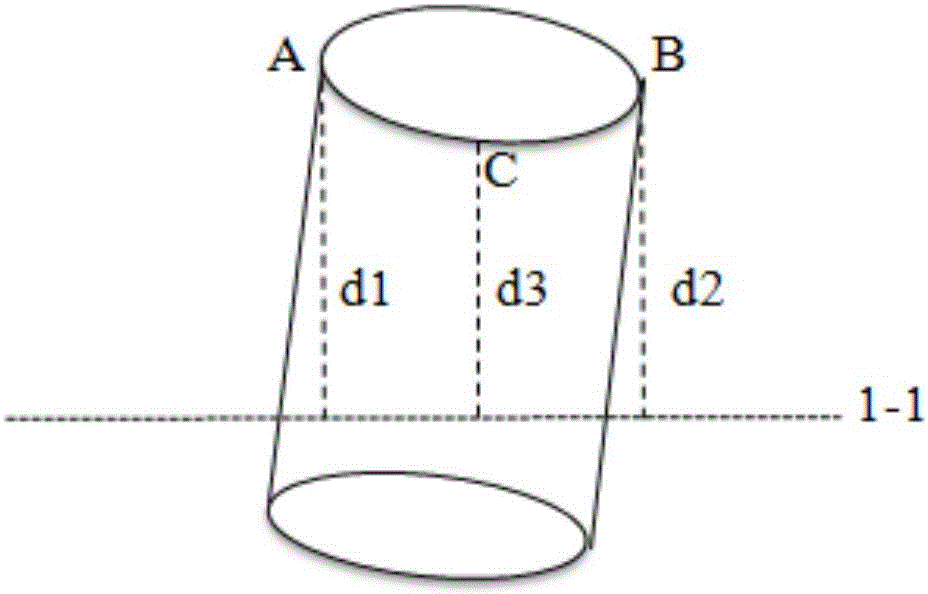

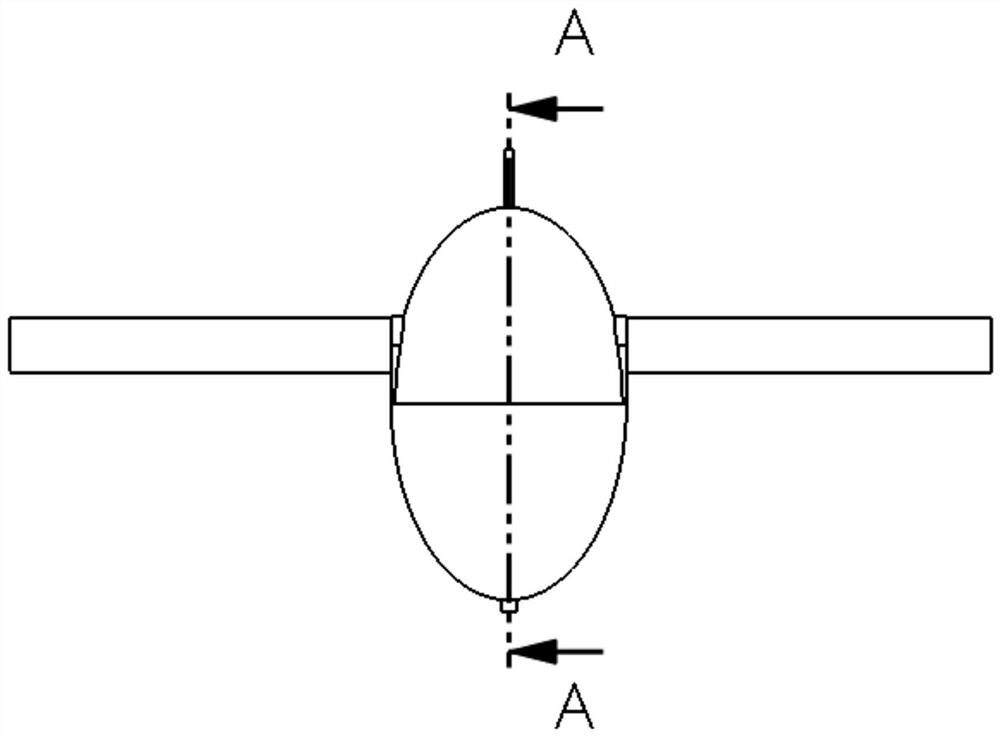

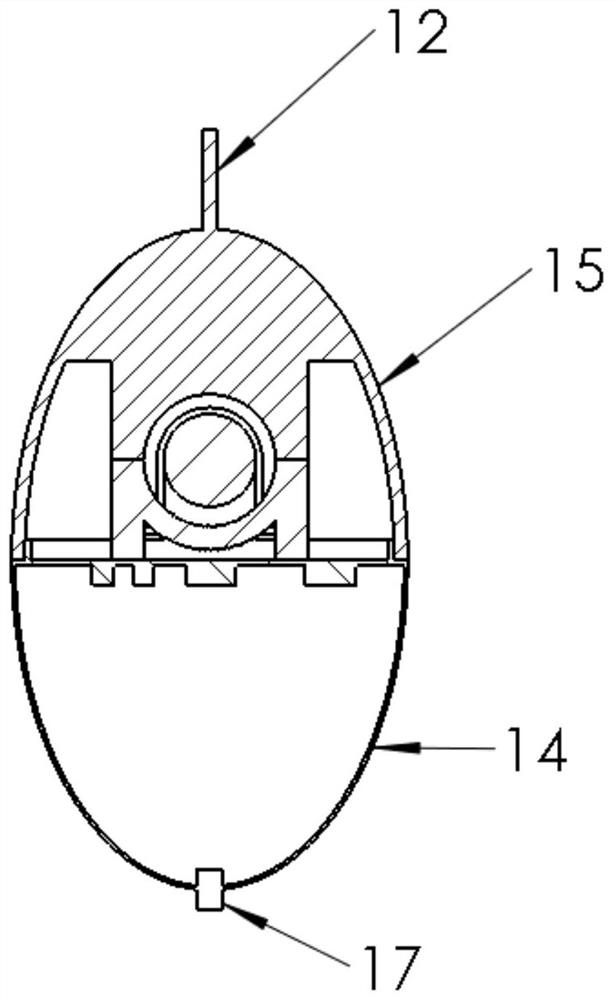

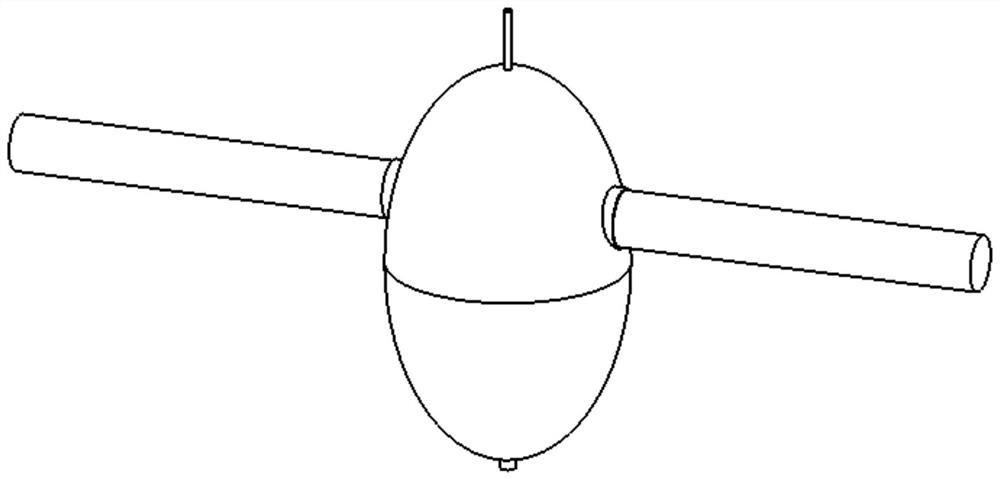

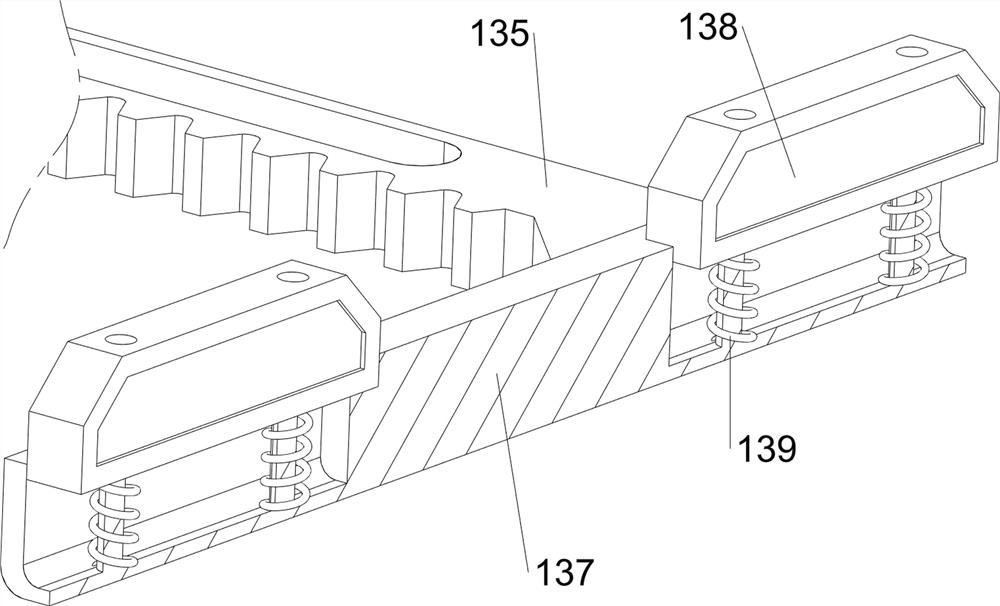

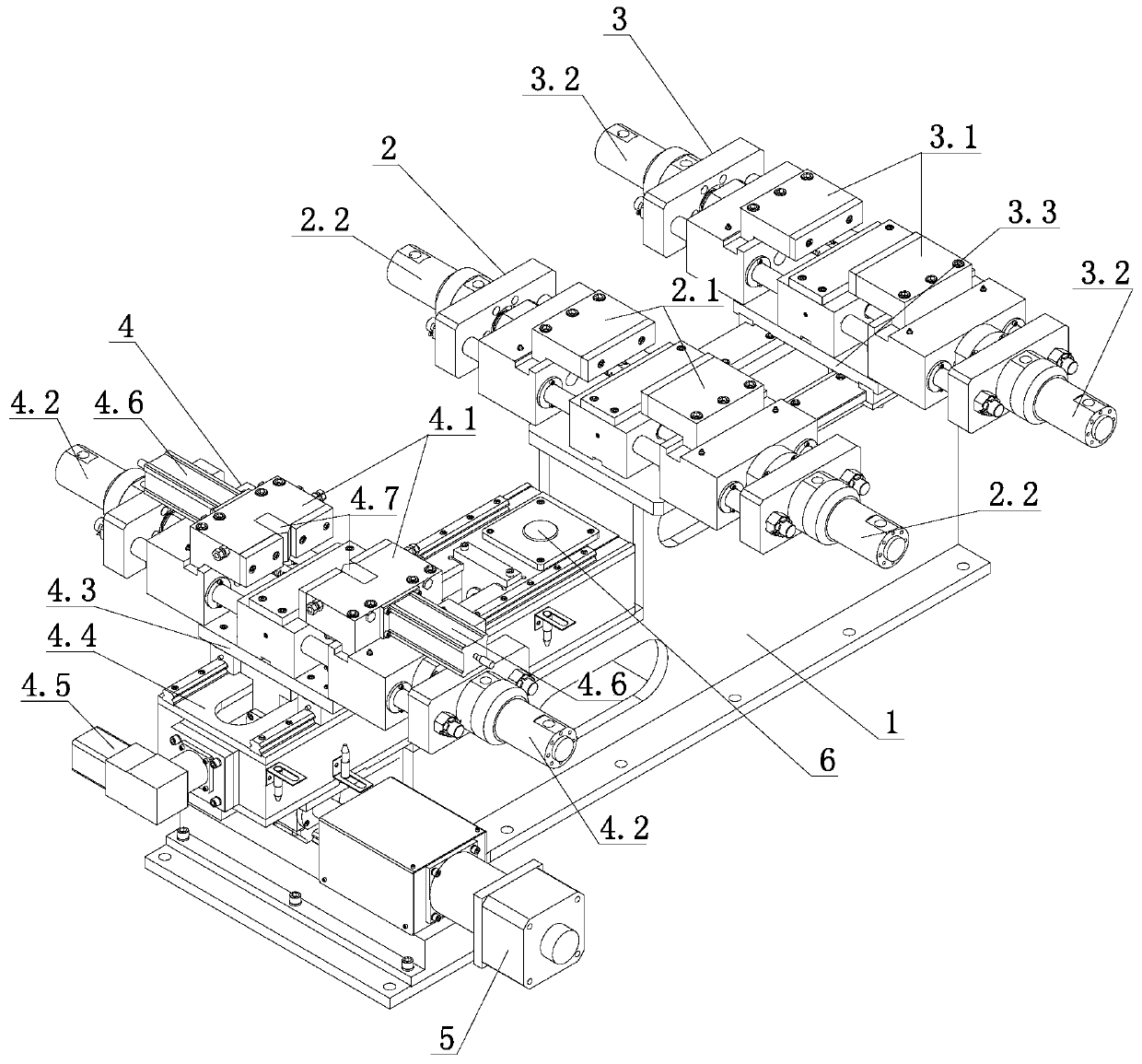

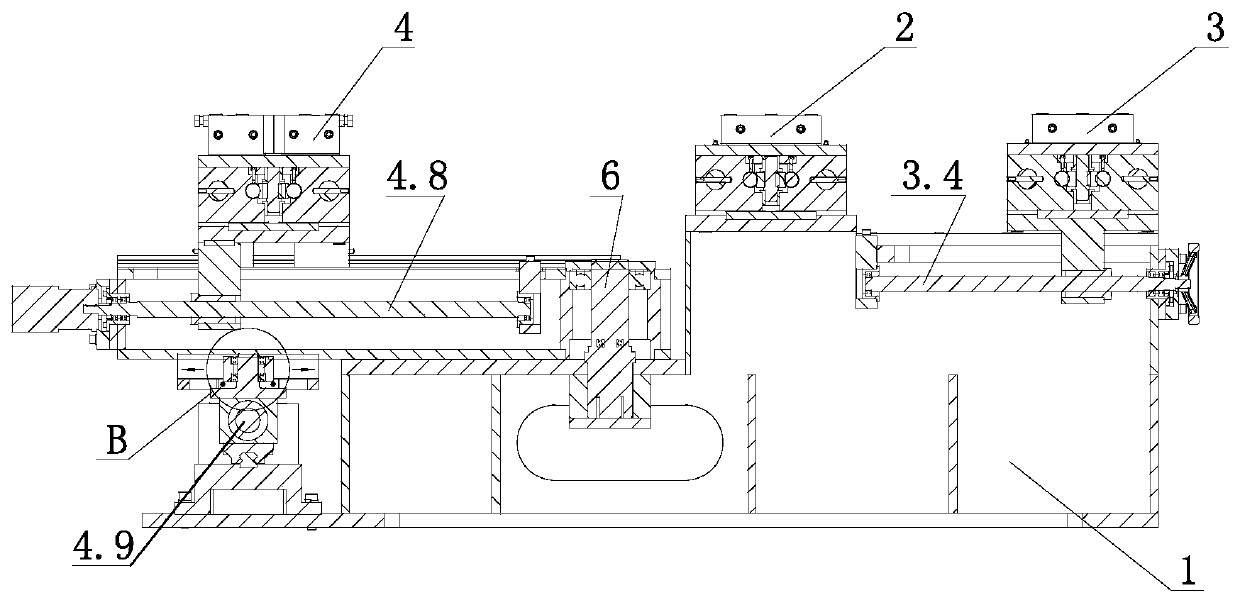

Online detection device and method for cylindrical component butt joint

ActiveCN104708494ARealize automatic measurementNo manual measurement requiredMeasurement/indication equipmentsMetal working apparatusEngineeringControllability

The invention relates to an online detection device and method for cylindrical component butt joint, and belongs to the technical field of advanced assembling manufacturing. The online detection device applicable to cylindrical components aims at achieving real-time online detection in the cylindrical component butt joint process, meeting the high butt joint precision of the cylindrical components and the like. The device can detect the coaxiality of the cylindrical components and a gap between butt joint faces in real time in the butt joint process, the butt joint process precision is controllable, and finally the product precision is improved. In order to overcome the technical defect that real-time online detection cannot be achieved during cylindrical component butt joint, the online detection device for the cylindrical component butt joint process is developed. The postures of the cylindrical components are detected through real-time and dynamic detection of the gap d between the butt joint faces, the distance between a sensor and the inner circle faces of the cylindrical components and other technological key features, the relative positions of the cylindrical components are adjusted according to the measured result, online detection and real-time controllability in the butt joint process are achieved, and the butt joint precision of the cylindrical components is improved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

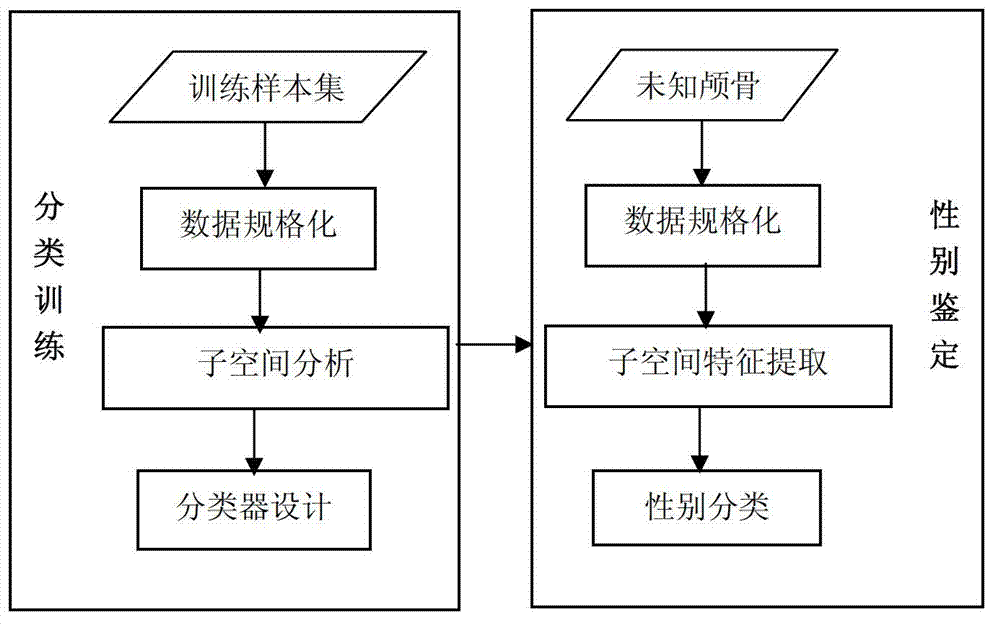

Skull sex determining method based on spatial analysis

ActiveCN102831443ARemove the effect of sizeHigh degree of automationCharacter and pattern recognitionData setCharacteristic space

The invention relates to a skull sex determining method based on spatial analysis. The method comprises the following steps: carrying out data standardization on skull data of a training sample; carrying out sub-spatial analysis on a standardized training sample data set so as to obtain a sub-spatial projection matrix; projecting the training sample to a low dimensional sub-space from a high dimensional original feature space, wherein a classifier is designed in the low dimensional sub-space; projecting standardized unknown skull data to the low dimensional sub-space by using a sub-spatial projection matrix obtained from the training; and classifying in the low dimensional sub-space by using the designed classifier. With the adoption of the method, complex manual measurement or expert knowledge is not needed, and the accuracy can be more than 94%, so that the method has important application values in criminal investigation fields.

Owner:BEIJING NORMAL UNIVERSITY

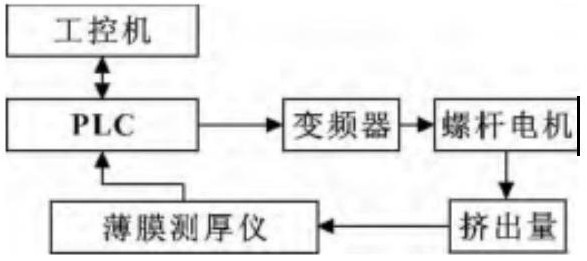

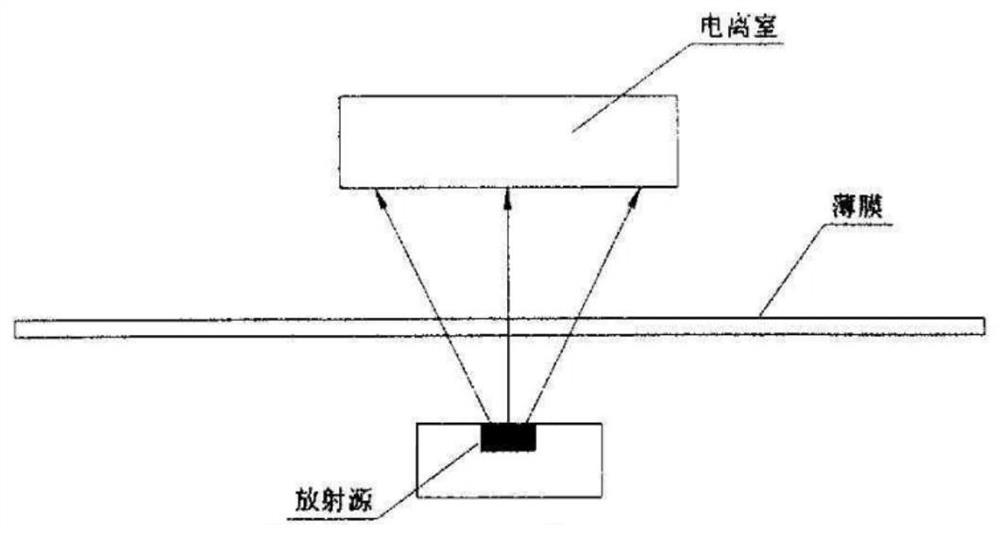

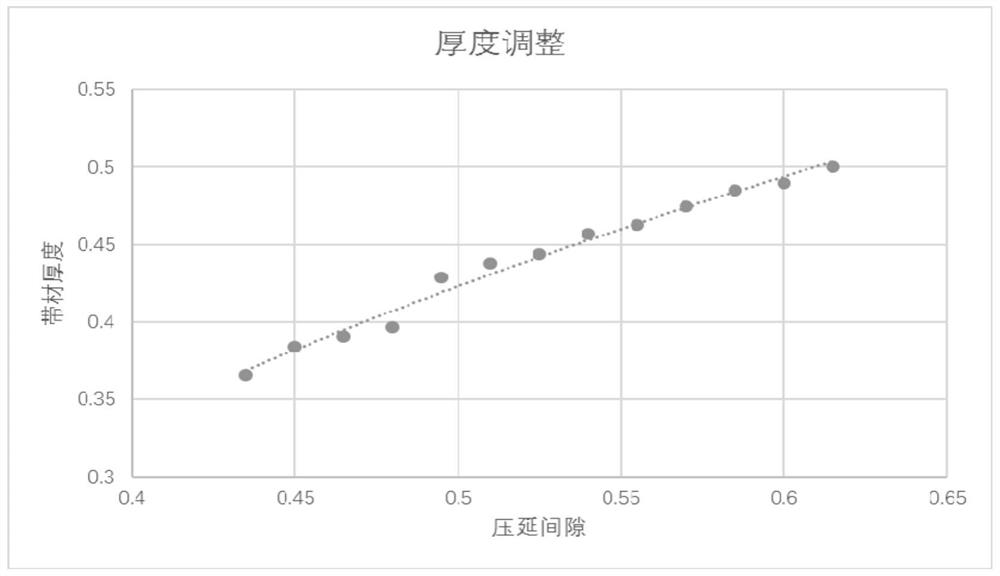

Automatic control method for thickness of calendered film

InactiveCN112140440AEasy to controlNo manual measurement requiredFlat articlesAutomatic controlControl manner

The invention discloses an automatic control method for the thickness of a calendered film. The automatic control method comprises the following steps that when a detection device finds that the thickness is about to exceed a tolerance range or is unqualified, feedback is immediately performed through a feedback device, parameters to be adjusted are calculated and input into a calender adjusting system, and the adjusting system achieves specific adjusting work, so that the the calendered film with the thickness meeting the requirement is obtained. Specifically, when the detection device findsthat the thickness is about to exceed the tolerance range or is unqualified, a real-time thickness value is immediately transmitted to a curve fitting algorithm through the feedback device, judgment is made according to a comparison result of the measured thickness value and a target value input in advance, and whether the value is within the tolerance range or not is judged. According to the control method, manual measurement is not needed, and software control is rapid and accurate; and then three automatic thickness control methods are provided, so that the thickness control manner is flexible.

Owner:安徽省众望科希盟科技有限公司

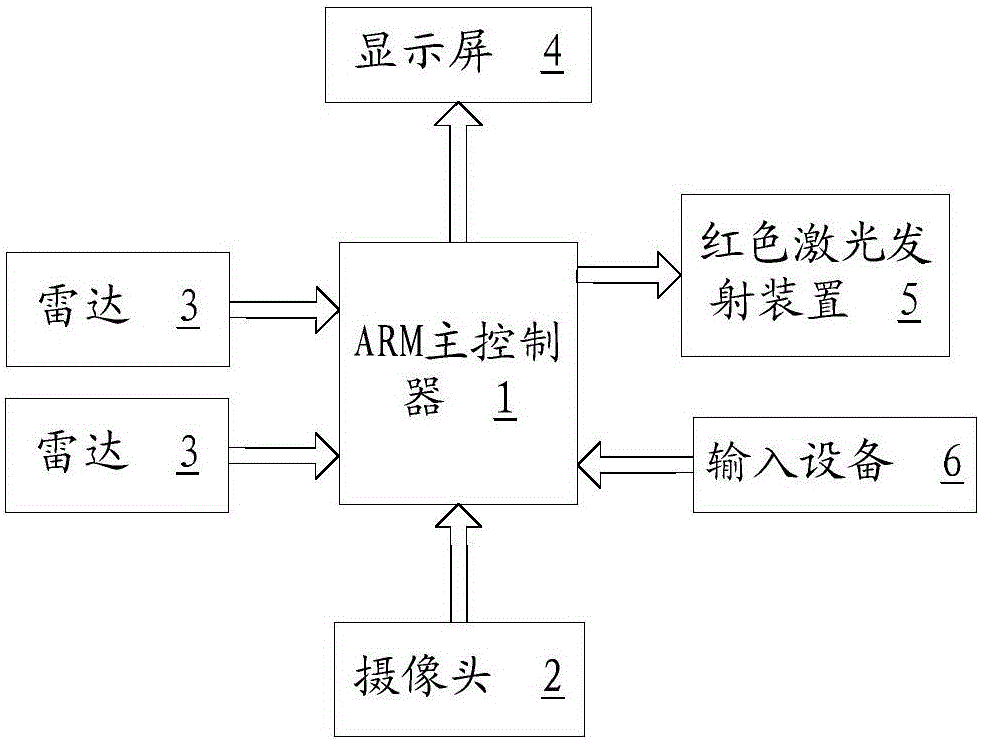

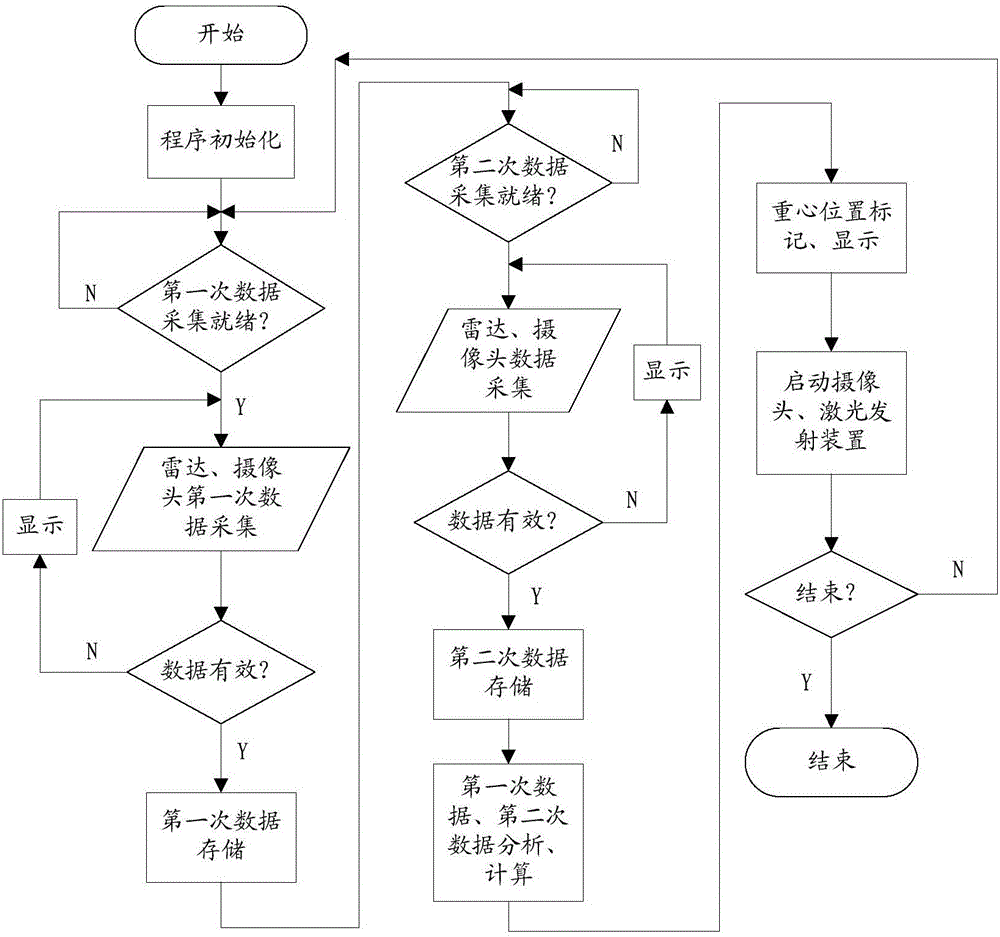

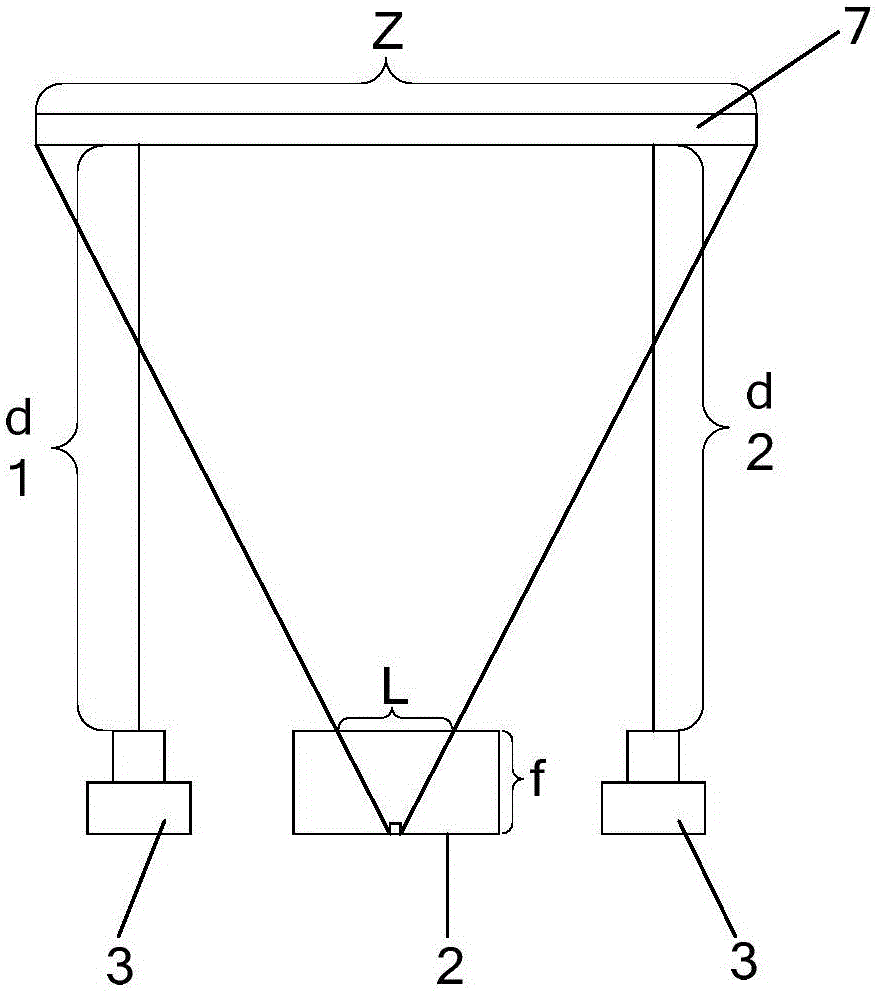

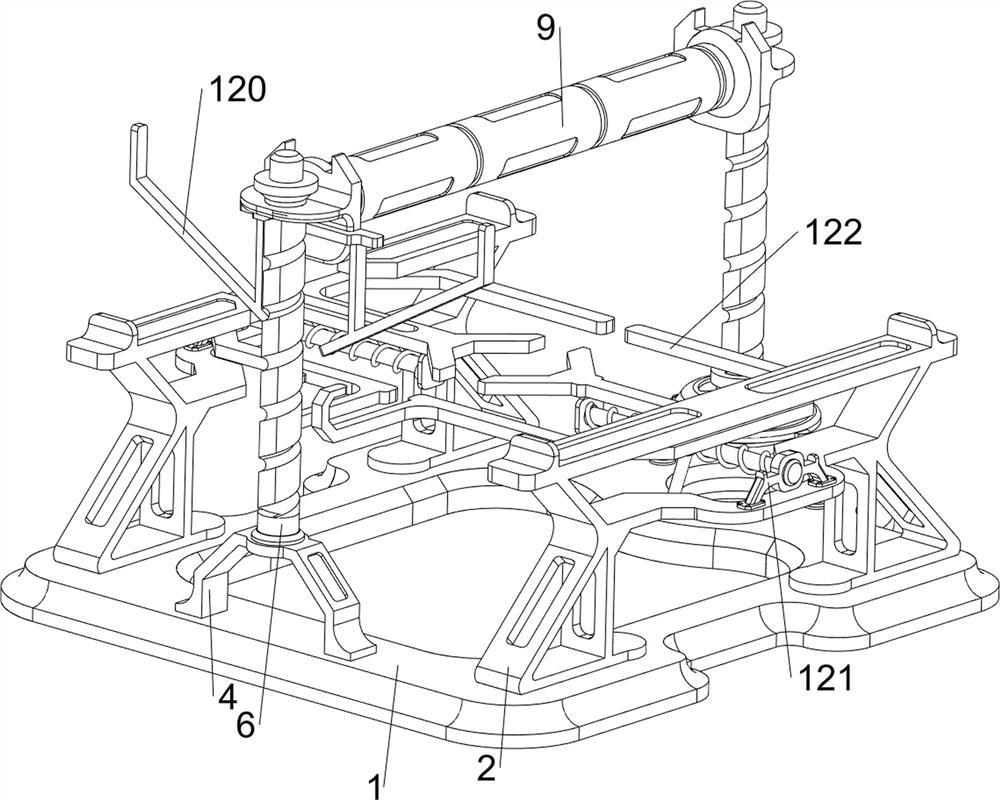

Intelligent auxiliary operation device and method for stone mine fork loading truck

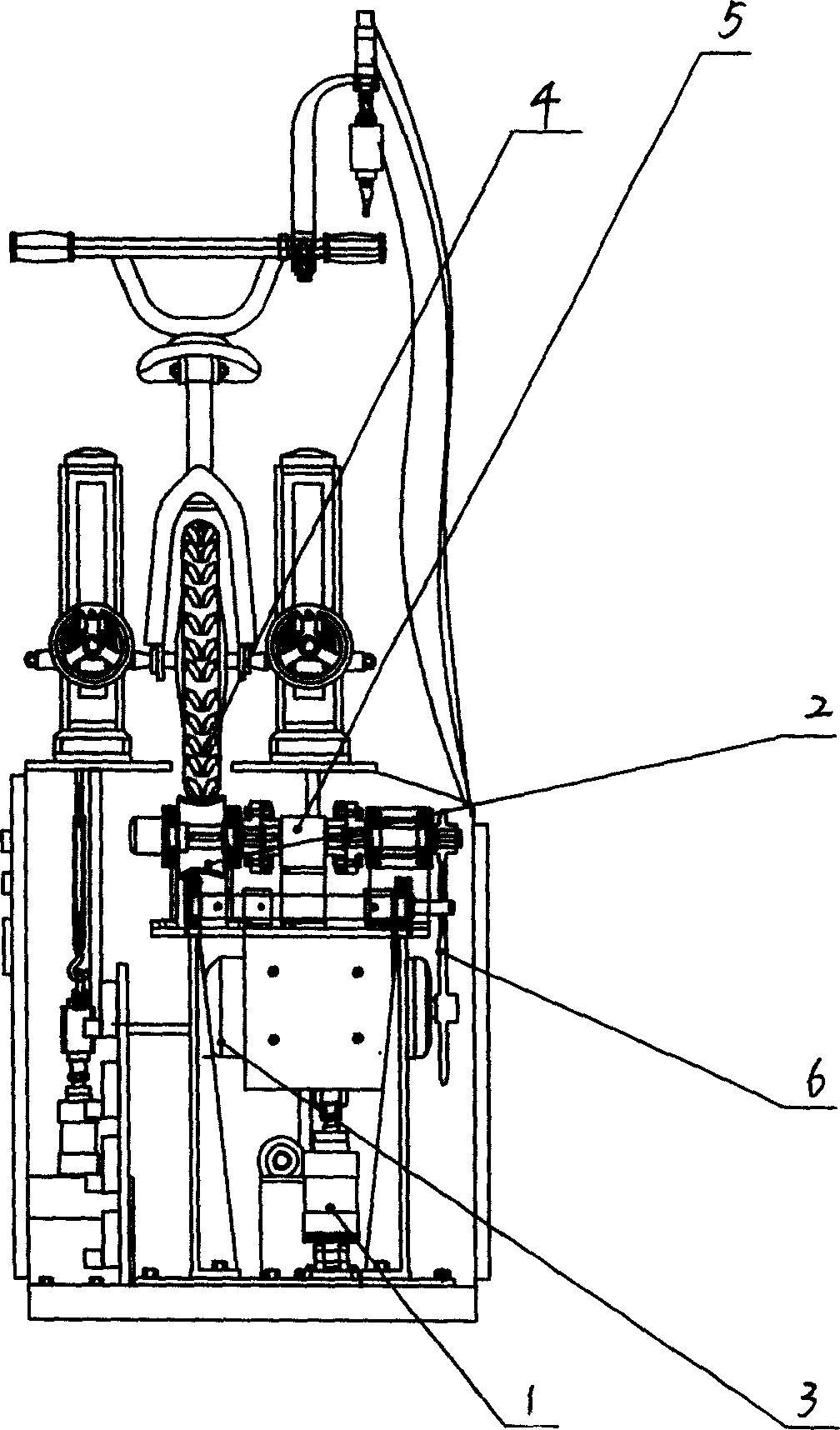

InactiveCN105806563AAvoid failureAvoid dangerTelevision system detailsStatic/dynamic balance measurementRed laserStructural engineering

The invention provides an intelligent auxiliary operation device for a stone mine fork loading truck.The intelligent auxiliary operation device is arranged on the fork loading truck, and comprises an ARM main controller, a camera, at least two radars, a display screen and a red laser emitting device.The camera, the two radars, the display screen and the red laser emitting device are connected with the ARM main controller, and the camera is installed between pallet forks of the fork loading truck; the two radars are symmetrically installed on the two sides of the camera, and meanwhile the two radars and the camera are in the same height, and are parallel in central axis; the red laser emitting device is installed under the camera, lasers emitted by the red laser emitting device are parallel to the horizontal plane, and the camera, the two radars and the red laser emitting device can vertically move along the pallet forks of the fork loading truck.By means of the intelligent auxiliary operation device and method, the center-of-gravity shift phenomenon, caused by inaccurate estimation of an operator, of rough stone blocks is avoided.

Owner:FUJIAN UNIV OF TECH

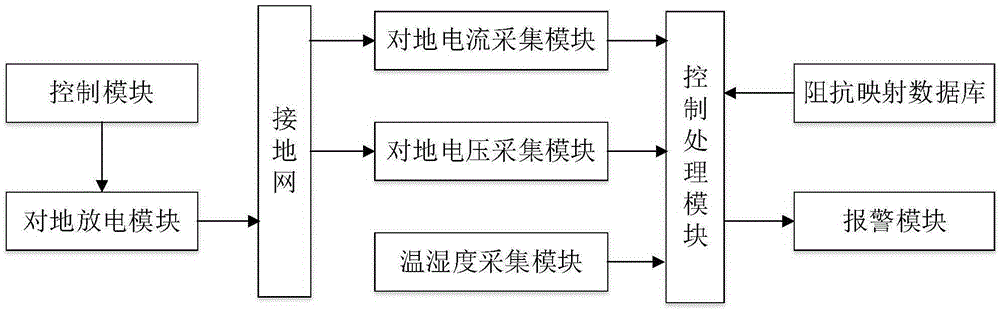

Grounding impedance monitoring collecting analyzer

ActiveCN105277795AConducive to real-time, objectivityMaster the current status in real timeEarth resistance measurementsEngineeringPower flow

The invention discloses a grounding impedance monitoring collecting analyzer comprising a control module, a ground discharging module, a ground current collecting module, a ground voltage collecting module, a temperature and humidity collecting module, an impedance mapping database and a data processing module. The analyzer provided by the invention uses the ground discharging module to discharge to a ground net, then collects current and voltage values by means of the ground current collecting module and the ground voltage collecting module, calculates the impedance of the ground net, collects the temperature and the humidity of soil in the region of the ground net by means of the temperature and humidity collecting module, and combines the ground net impedance and the soil temperature and humidity for determination of the ground net, so that the analyzer can obtain information of the ground net precisely and learn current status of the ground net in real time.

Owner:ANHUI ZHONGPU LIGHTNING PROTECTION TECH CO LTD

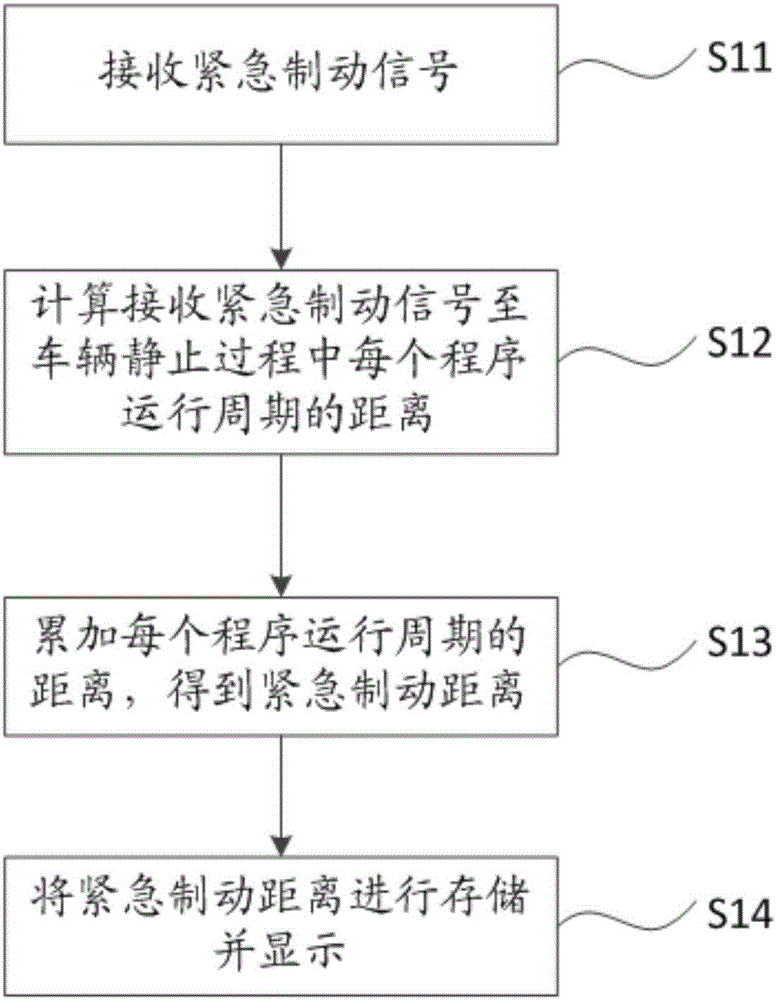

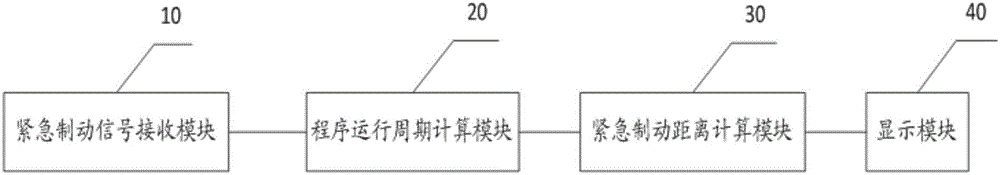

Control method and system of automotive emergency braking distance calculation and recording

InactiveCN106809204AReduce labor costsImprove accuracyBrake safety systemsAutomotive engineeringBraking distance

The invention discloses a control method and system of automotive emergency braking distance calculation and recording. The control method comprises the steps of receiving an emergency braking signal; calculating and receiving a braking distance of a vehicle in every program running cycle in the process from the emergency braking signal to the moment the vehicle is stationary; accumulating the braking distance of every program running cycle to obtain an emergency braking distance; storing and displaying the emergency braking distance. By using the control method and system of automotive emergency braking distance calculation and recording, calculation and storage of the emergency braking distance of the vehicle can be automatically achieved, the manual measurement is not needed, the manual cost is lowered, and the accuracy is improved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

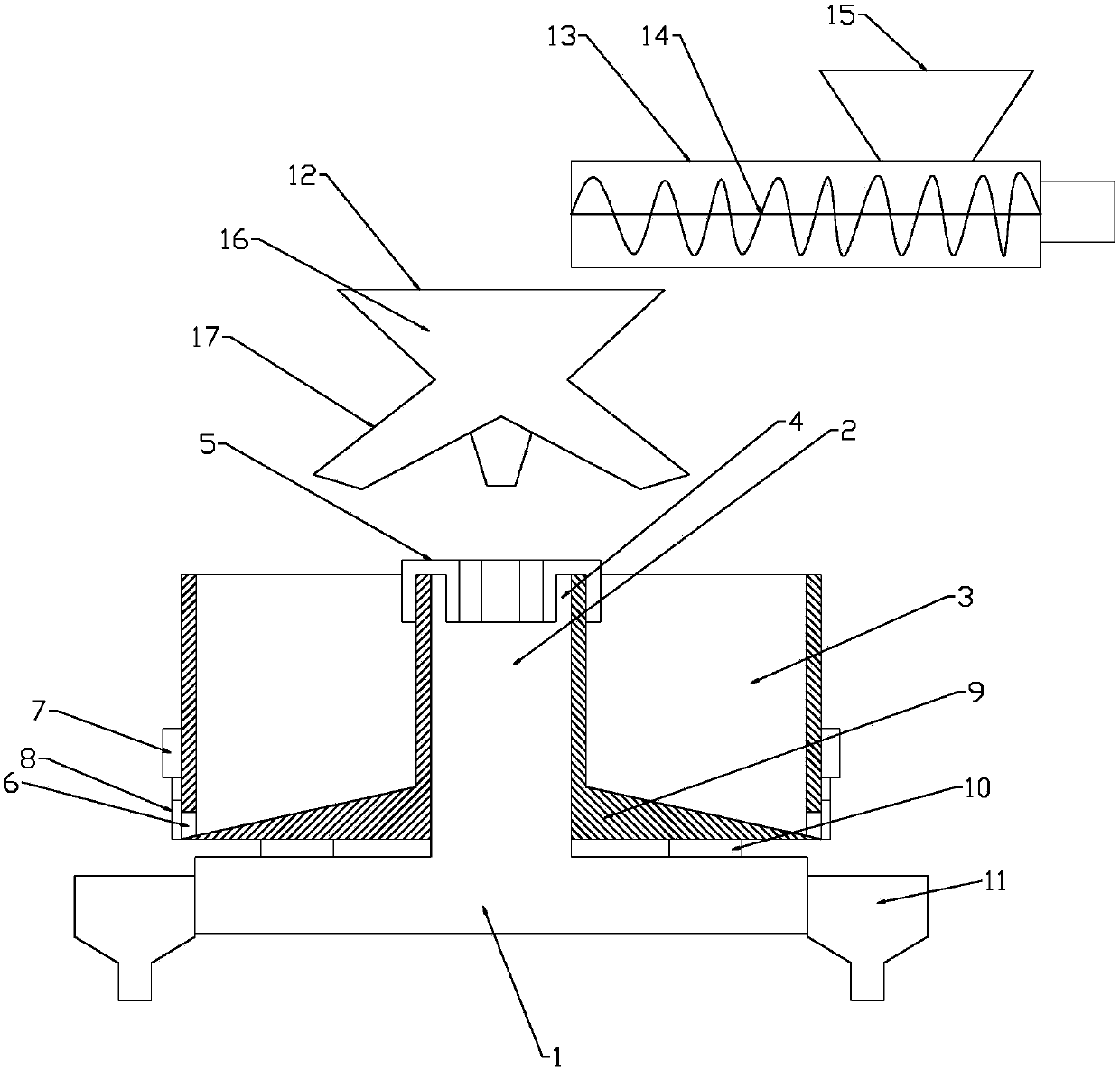

Disc-type measuring and subpackaging device

The invention relates to the technical field of material subpackage, in particular to a disc-type measuring and subpackaging device. The disc-type measuring and subpackaging device comprises a base and measuring hoppers, wherein of the middle of the base is provided with a supporting seat; the position, close to the supporting seat, of the base is provided with at least three measuring hoppers inthe circumferential direction; one side of the upper end, abut against the measuring hoppers, of the supporting seat is provided with a connecting plate; U-shaped clamping members are arranged betweenthe connecting plate and the upper end wall of the measuring hoppers; the lower end of each measuring hopper is provided with a discharging port; and the upper end of each discharging port is provided with a cylinder; a driving rod of each cylinder is connected with a door panel for opening and closing the discharging ports; the door panel is closely attached to the outer wall of the measuring hoppers in sliding fitting mode; the inner bottom wall of each measuring hopper is a slope inclined to the discharging ports gradually; a gravity sensor is arranged between the measuring hoppers and thebase; and the outer side of the base corresponding to the discharging ports is provided with receiving hoppers in the circumferential direction. By means of the disc-type measuring and subpackaging device, automatic weighing and transferring of the materials are achieved, and the device has the advantage of high subpackaging efficiency.

Owner:四川开维农业发展有限公司

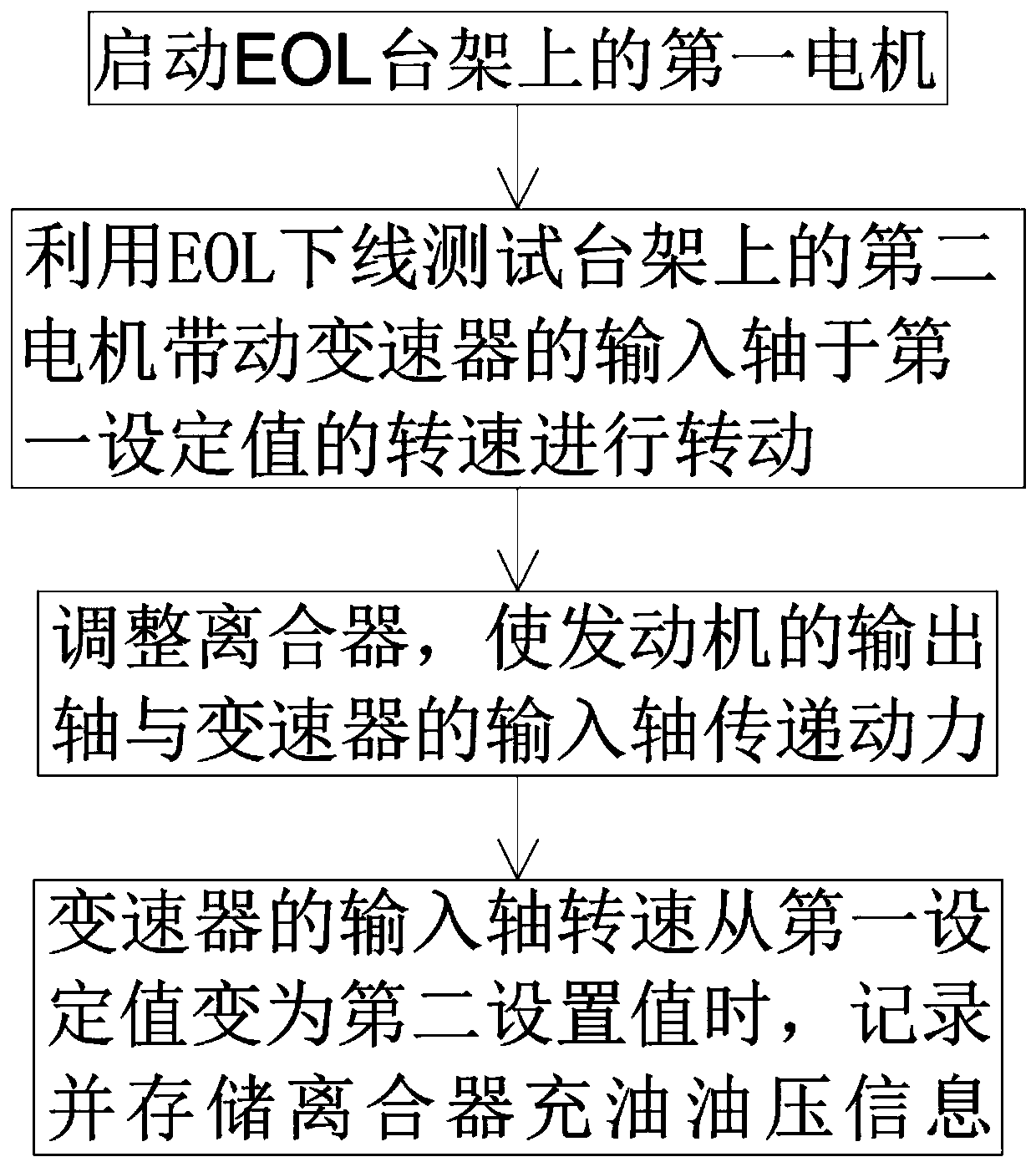

Gear shifting self-learning method and automobile

InactiveCN110953335AGood conditionNo manual measurement requiredGearing controlAutomatic transmissionElectric machinery

The invention provides a gear shifting self-learning method and an automobile, and relates to the technical field of automobiles. The gear shifting self-learning method comprises the following steps:starting a first motor located on a production line offline detector rack and shifting an automobile automatic transmission to an N gear; driving the automobile automatic transmission to operate through a second motor on the production line offline detector rack to make the rotating speed of an input shaft of the automatic transmission be at a first set value; adjusting the oil charging pressure of a clutch to make the output shaft of the first motor on the production line offline detector rack transmit power to the input shaft of the automatic transmission; and when the rotating speed of theinput shaft of the automatic transmission is changed from the first set value to a second set value, determining that the position information of the clutch is half-joint point information and storingthe half-joint point information. When the gear shifting self-learning method is applied to the automobile, a technical effect of saving manpower is achieved.

Owner:SHENGRUI TRANSMISSION

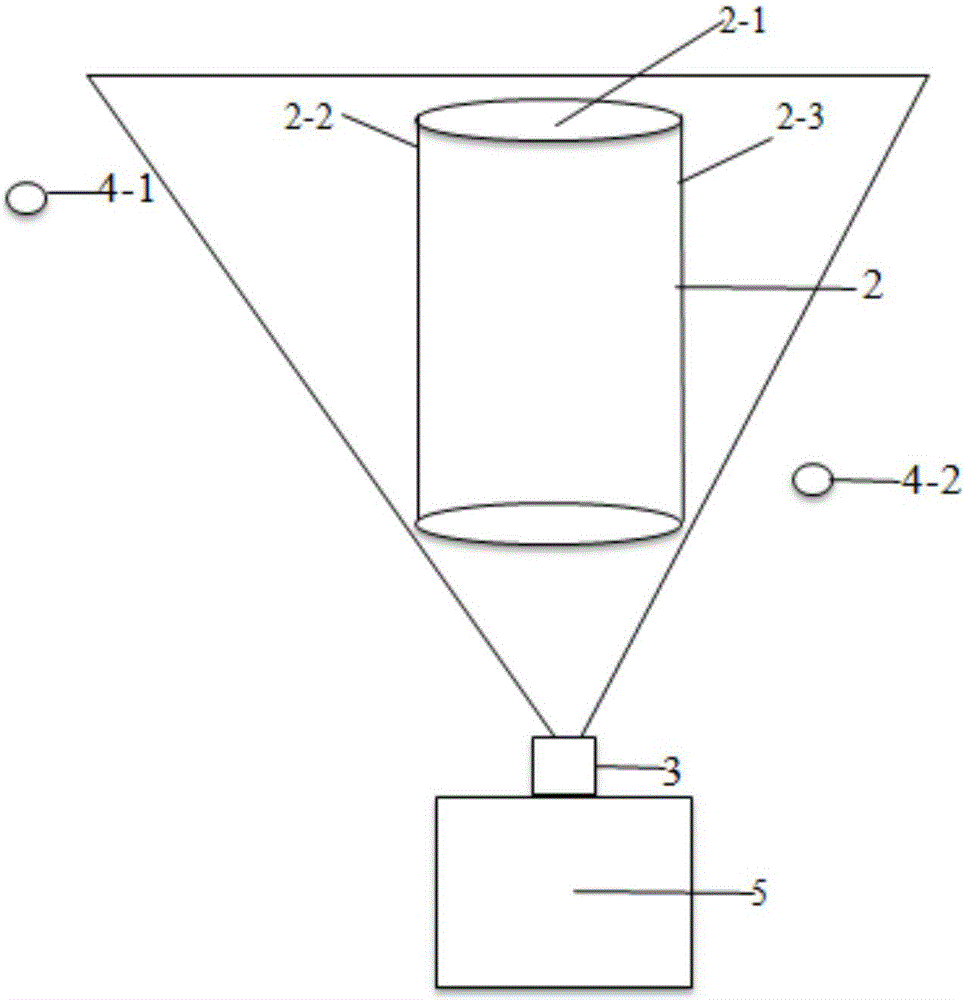

Cylindrical object verticality noncontact detection device and method

InactiveCN106441162AEasy to operateNo manual measurement requiredUsing optical meansMeasurement deviceReference line

The invention discloses a cylindrical object verticality noncontact detection device and method. Real-time verticality detection of a cylindrical object is realized by the device through a camera and laser rays. The laser rays act as the horizontal reference, and the camera performs imaging of the cylindrical object so that calibration of the edge position of the top part of the cylindrical object can be realized through an edge detection method with the laser rays acting as the reference, and the verticality of the cylindrical object is detected by comparing the distance from different positions of the top part of the object to the reference line. Cylindrical high-precision noncontact verticality detection can be realized by the scheme. The measurement precision of the camera is 0.05 degree, the field range of the camera is theta=60 degrees and the resolution is 5Kx5K, two laser devices are erected at the two sides of the measured object and emit a horizontal laser ray, and the length of the laser ray is greater than the diameter of the cylindrical object. Verticality measurement of the cylindrical object is realized by one small industrial control computer so that the manufacturing cost of the system is low, the measurement device is simple and easy to operate and the measurement accuracy is high.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

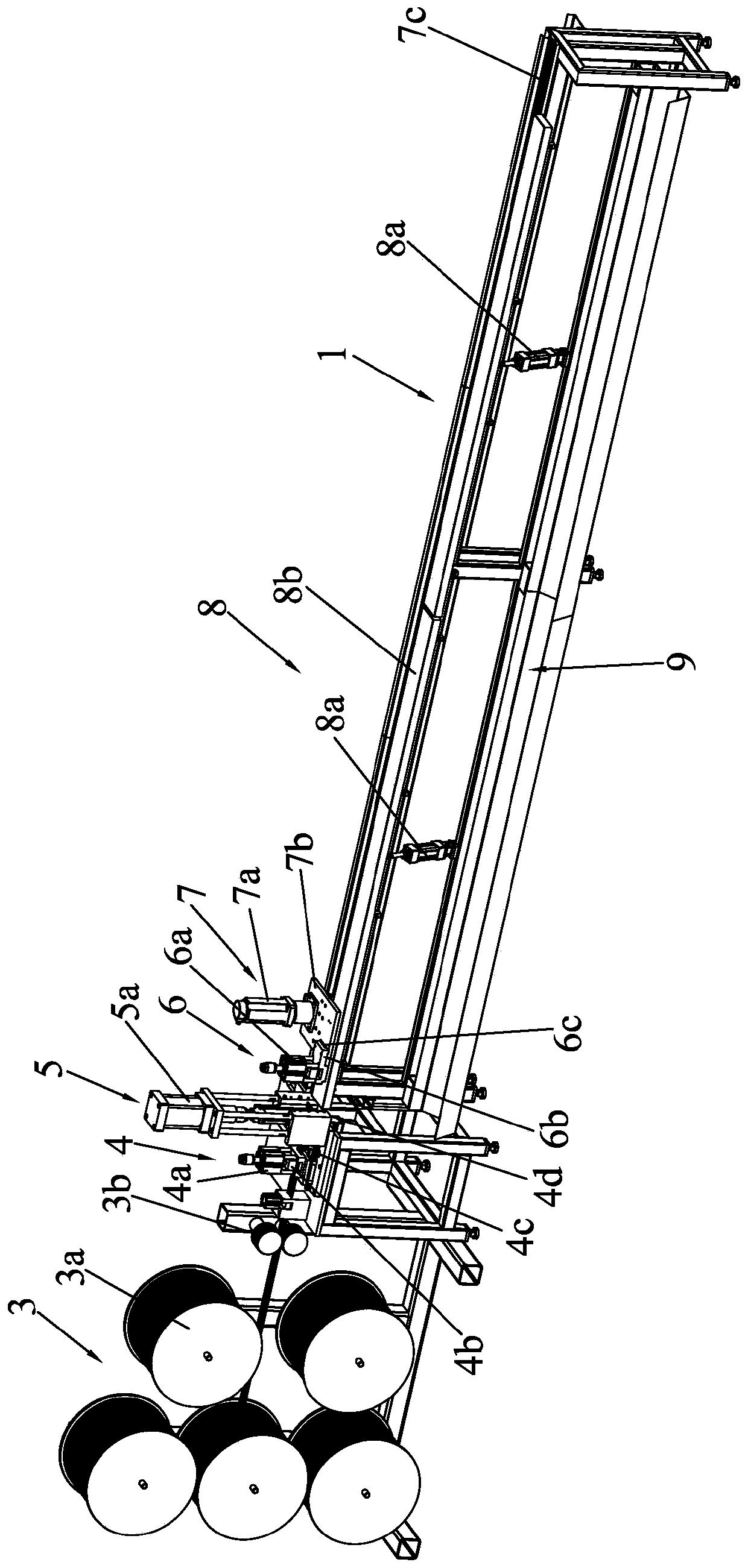

Intelligent road marking vehicle

ActiveCN108517756ARealize autonomous drivingNo manual measurement requiredRoads maintainenceLine drawingsAutomotive engineering

The invention discloses an intelligent road marking vehicle, which comprises a vehicle body, wheels, a distance measuring device, a road marking device and a fast drying device, wherein the vehicle body comprises a bottom surface next to the wheels; the distance measuring device, the line drawing device and the fast drying device are arranged on the bottom surface; the wheels comprise a left frontwheel, a right front wheel, a left back wheel and a right back wheel; the distance measuring device is arranged on the bottom surface near the vehicle head in front of the front wheels; the road marking device is arranged in a position, between the front wheels and the back wheels, on the bottom surface near the vehicle head; the fast drying device is arranged in a position, between the front wheels and the back wheels, on the bottom surface near the vehicle tail. The intelligent line drawing vehicle disclosed by the invention can realize the automation operation of the road marking.

Owner:管玲飞

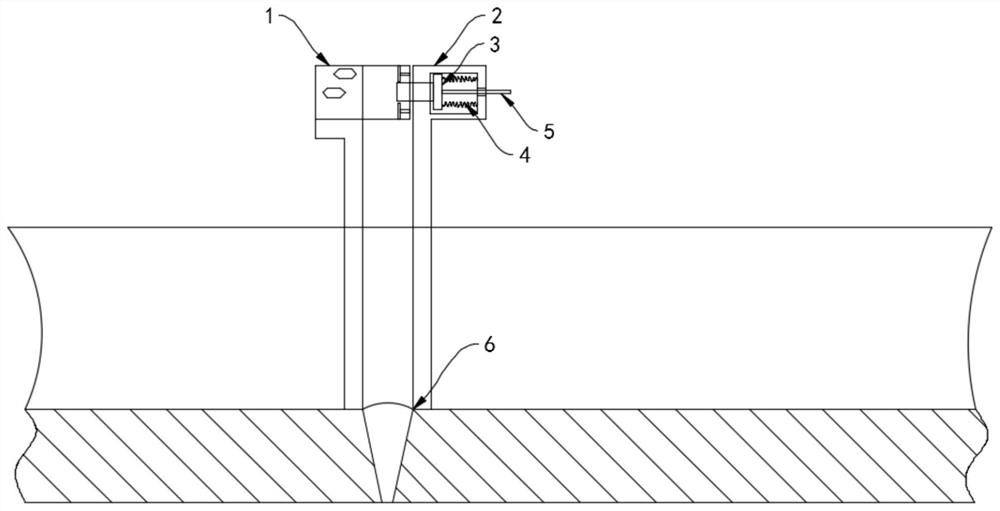

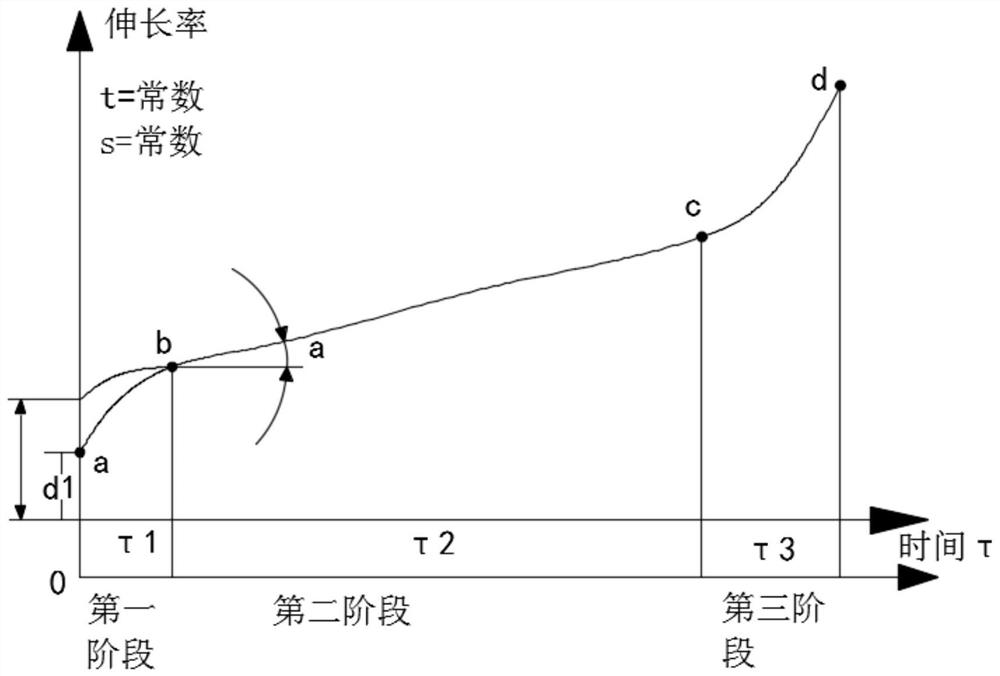

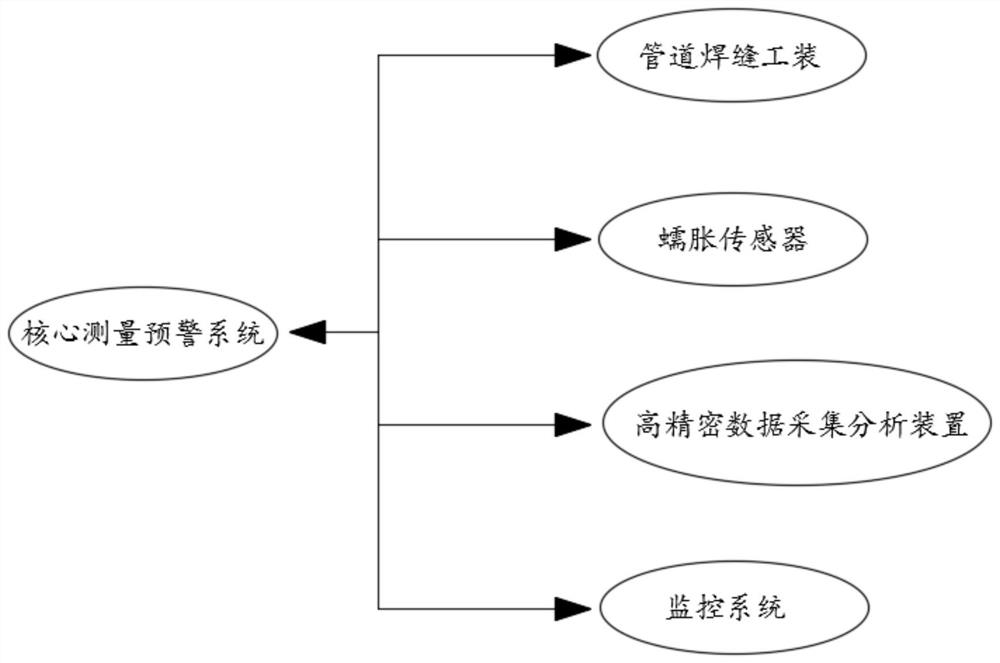

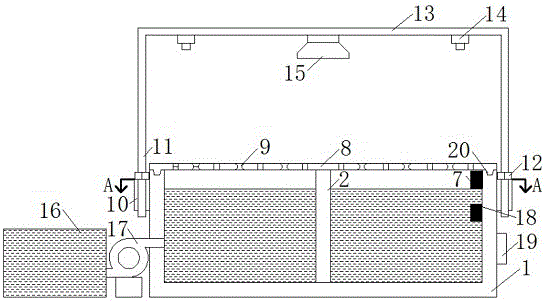

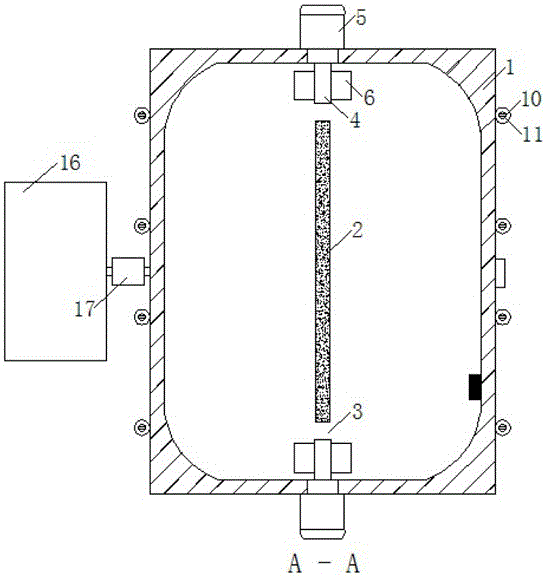

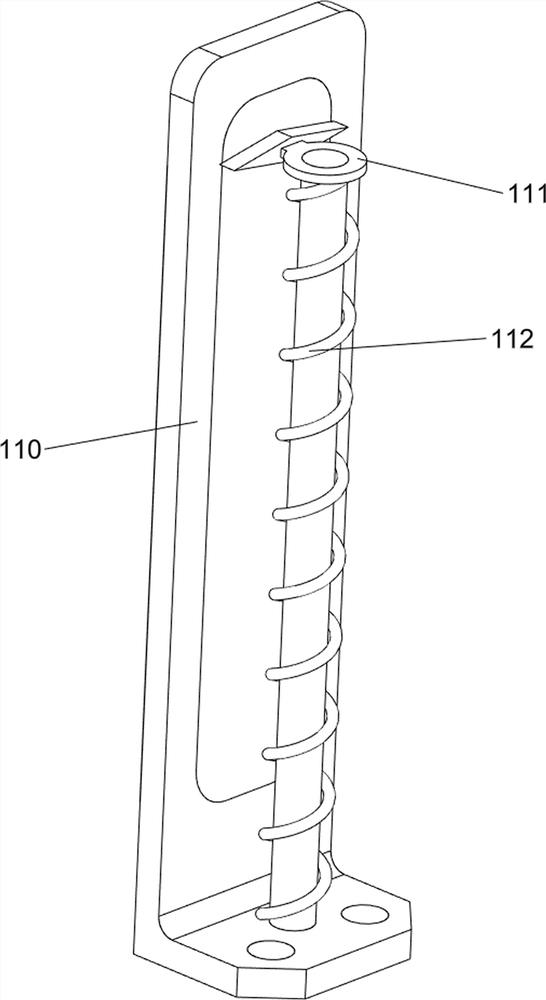

Ultra-supercritical coal-fired power generator pipeline weld joint online creep monitoring method

PendingCN113607041ARealize tracking and monitoringRealize early warningUsing electrical meansElectrical/magnetic solid deformation measurementCapacitanceThermal dilatation

The invention discloses an ultra-supercritical coal-fired power generator pipeline weld joint online creep monitoring method. According to the method,a pipeline weld joint measuring tool is configured, the pipeline weld joint measuring tool comprises a tool A, a tool B, a probe, a spring loading device, an access signal acquisition and transmission device and a weld joint. The monitoring method comprises the following steps of: the tool A and the tool B are respectively arranged on two sides of the weld joint; and the probe is fixedly connected to the tool B. In order to avoid the situation that due to the fact that the service temperature of a pipeline is high, the weld joint can be subjected to thermal expansion, and the steps cannot be further operated. According to the method disclosed by the invention, the online measurement of the creep of the weld joint is successfully implemented for the first time, and a measurement result is closer to an actual situation; the limitation of pipe cutting is small; capacitance impedance measurement and high-temperature metal creep expansion measurement are combined for the first time, the three-stage mechanism of metal creep failure and weld joint creep deformation online detection are fused; and tracking monitoring and early warning of metal weld joint creep deformation are achieved.

Owner:CLEAN ENERGY BRANCH OF HUANENG (ZHEJIANG) ENERGY DEV CO LTD

Dendrobium candidum water-planting device

InactiveCN106561437ARehydration is convenientImprove liquidityAgriculture gas emission reductionCultivating equipmentsDendrobium candidumNutrition

The invention discloses a dendrobium candidum water-planting device, which comprises an incubator. A controller is arranged on an outer wall of the incubator; a concentration sensor is arranged on an inner cavity wall of the incubator; outer ends of rotary rods penetrate through the incubator so as to be connected with motors; telescopic rods are inserted into guiding pipes; nuts are in threaded connection onto the telescopic rods and are located on the upper sides of the guiding pipes; the upper ends of the two opposite telescopic rods are connected through a cross rod; infrared distance measurement sensors and an illuminating lamp are arranged on the lower end of the cross rod; and a mother liquor tank is arranged at one side of the incubator. According to the dendrobium candidum water-planting device, the motors work at regular times, and a nutrient solution in the incubator is stirred through stirring blades, so that the flowability is improved, the nutrition is more balanced, a value measured by the concentration sensor is more accurate, and liquor supplement of the mother liquor tank can be carried out conveniently; and through data measured by multiple groups of infrared distance measurement sensors and the height of the telescopic rods, the height of dendrobium candidum can be known without the need for manual measurement.

Owner:GUIZHOU SHIBING WANFU AGRI TECH DEV CO LTD

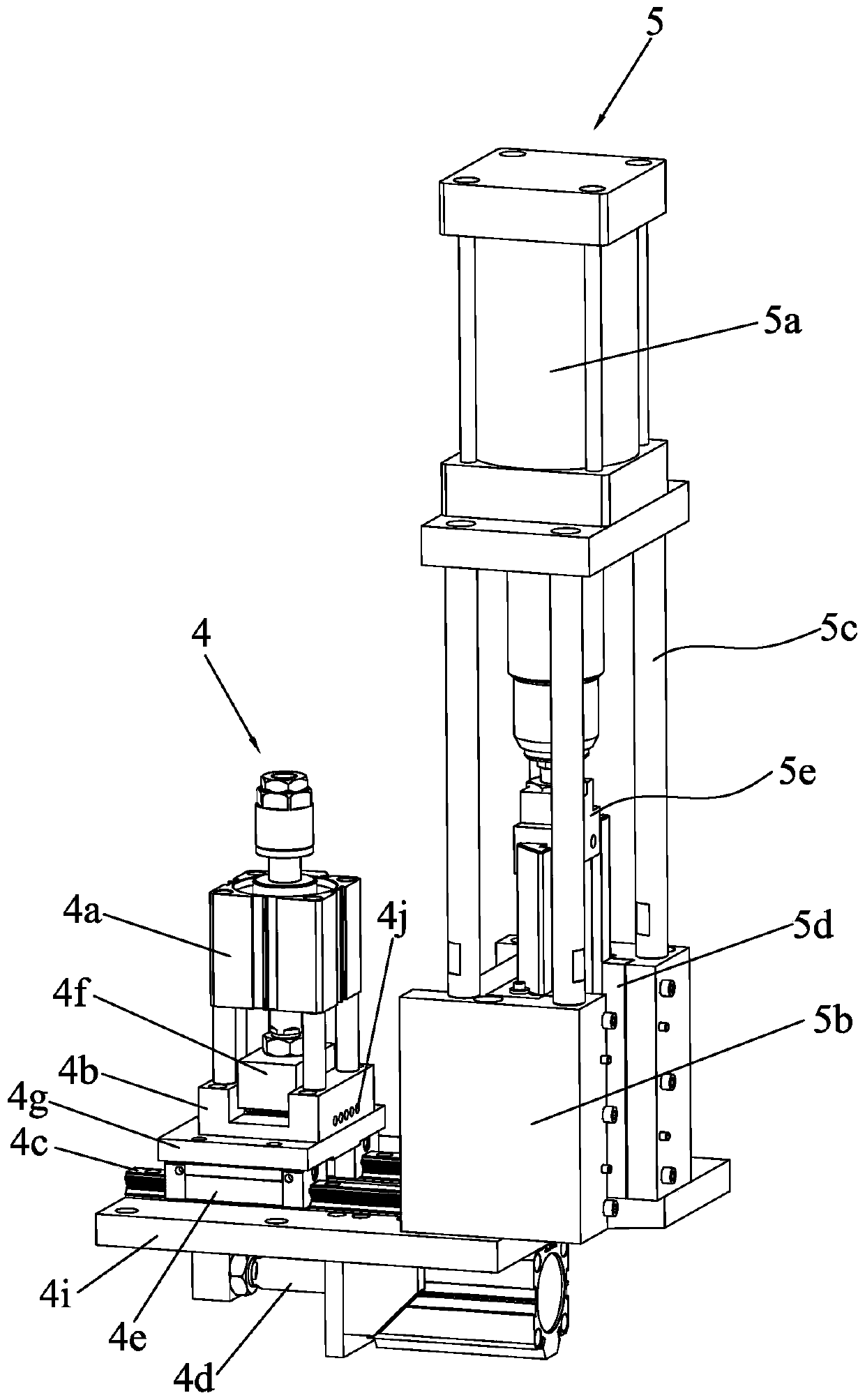

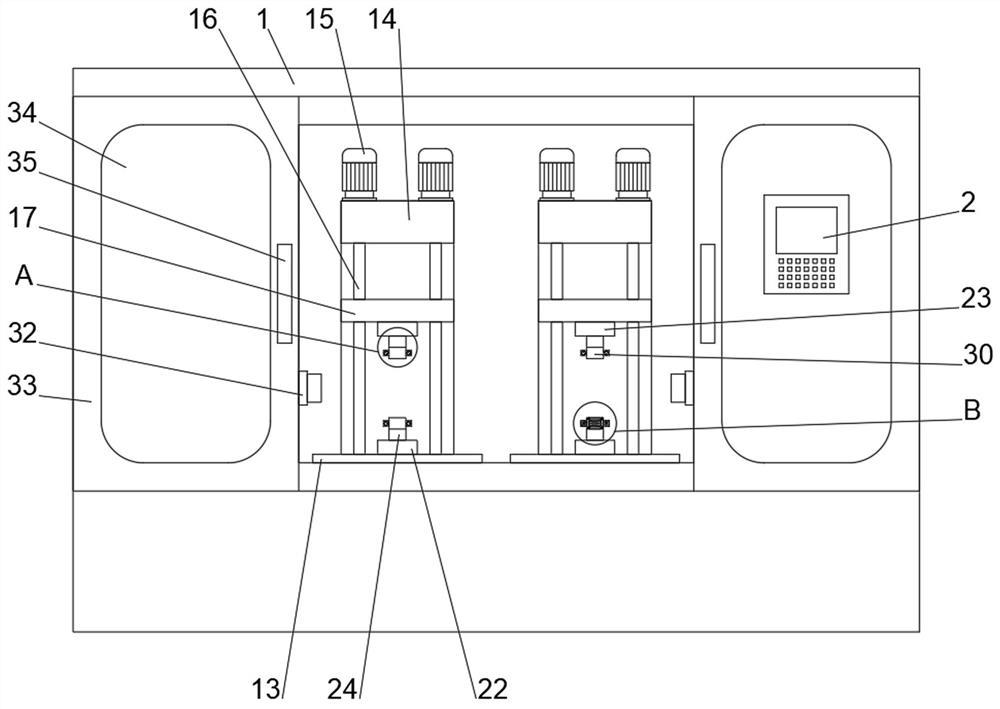

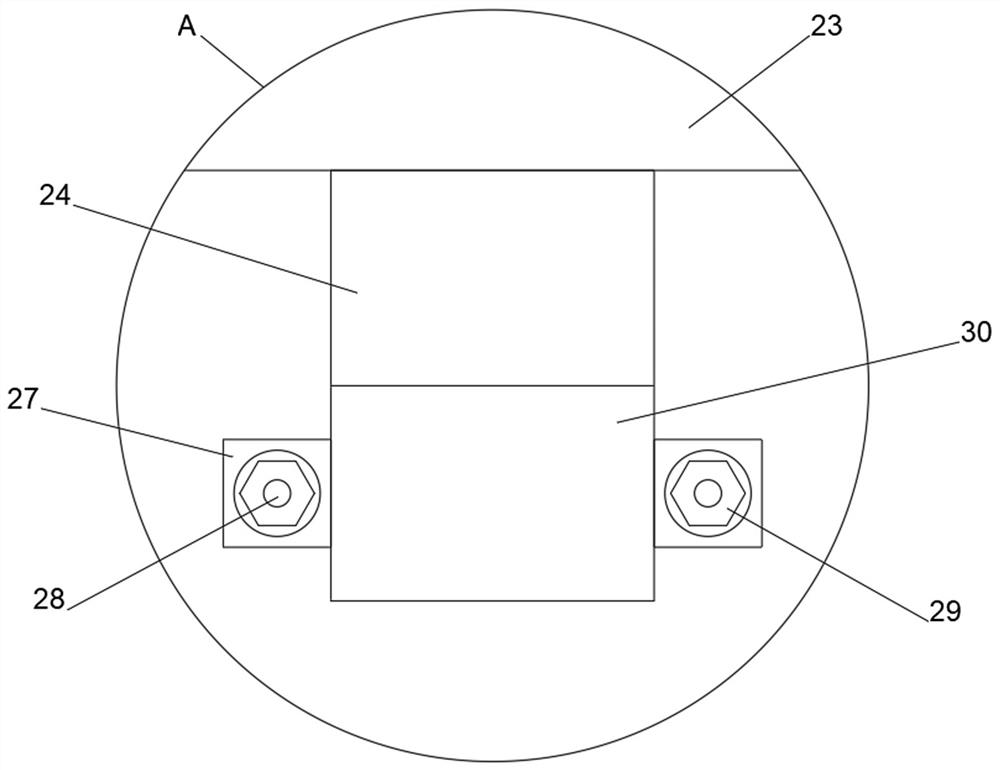

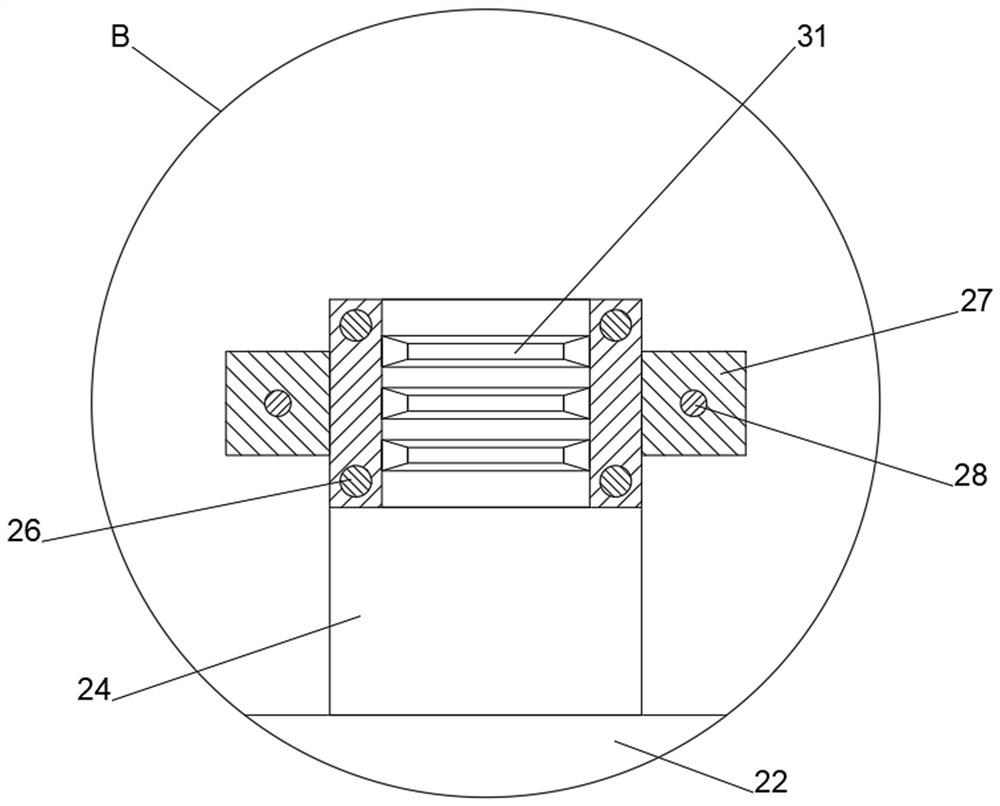

Automatic cutting device of steel wire ropes

The invention discloses an automatic cutting device of steel wire ropes. The automatic cutting device comprises a feeding mechanism, a rack, a first pressing mechanism, a second pressing mechanism, amaterial receiving and walking mechanism and a cutting mechanism. The feeding mechanism comprises at least one feeding disc used for steel wire rope feeding and guide wheels used for steel wire rope pulling. The first pressing mechanism is movably arranged between the guide wheels of the feeding mechanism and the cutting mechanism. The material receiving and walking mechanism is movably arranged on the side deviating from the cutting mechanism and is connected together with the second pressing mechanism, and therefore a tensioning moving component capable of being used for steel wire rope moving is formed by the second pressing mechanism and the material receiving and walking mechanism. A cutting air cylinder of the cutting mechanism is connected to a cutting table in the vertical direction of steel wire rope walking, a cutter is perpendicular to the steel wire rope walking direction on the rack, the cutting air cylinder is started, and the cutter can rapidly cut off steel wire ropes passing through the cutting table. According to the automatic cutting device, multiple steel wire ropes can be rapidly cut at the same time, and the problem that the steel wire rope cutting efficiencyis low in the prior art is solved.

Owner:LAND AMERICA HEALTH & FITNESS

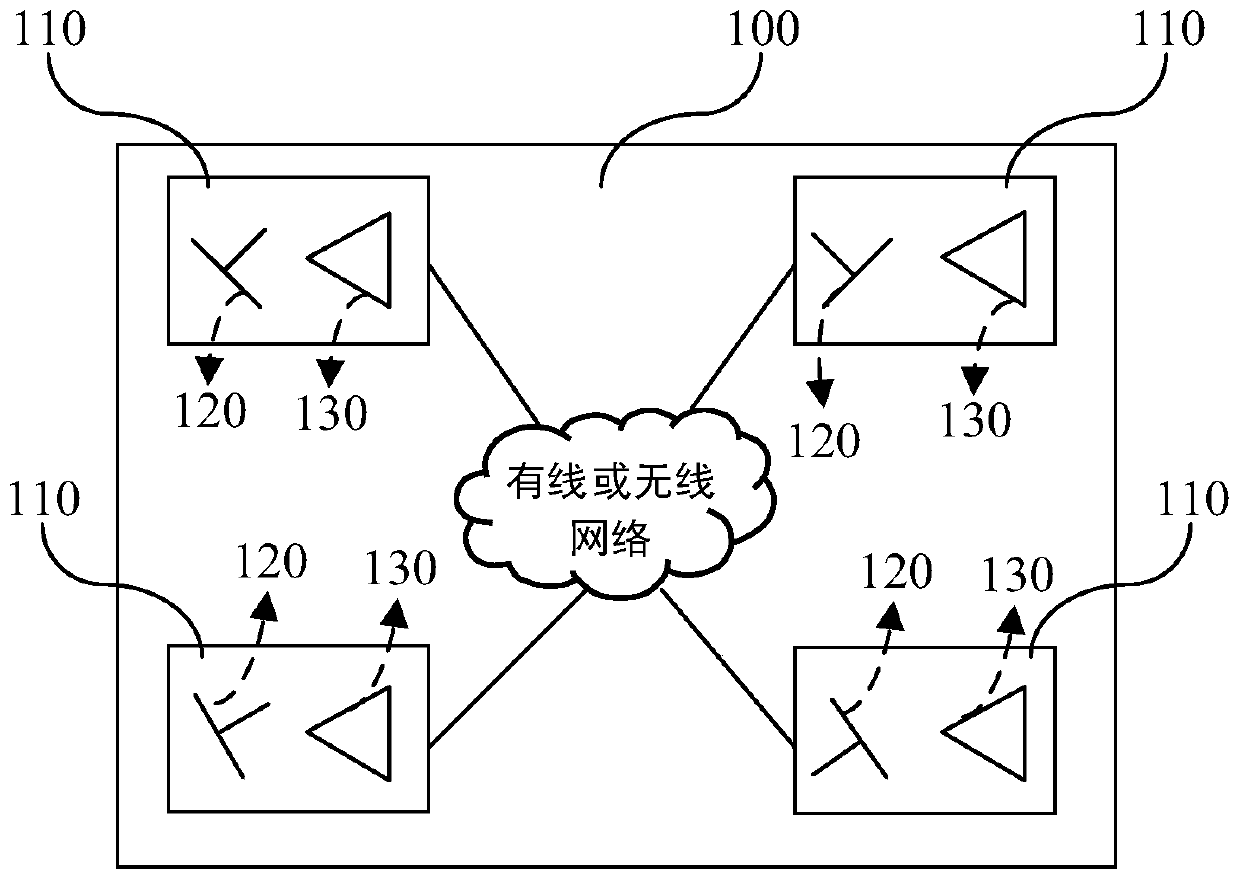

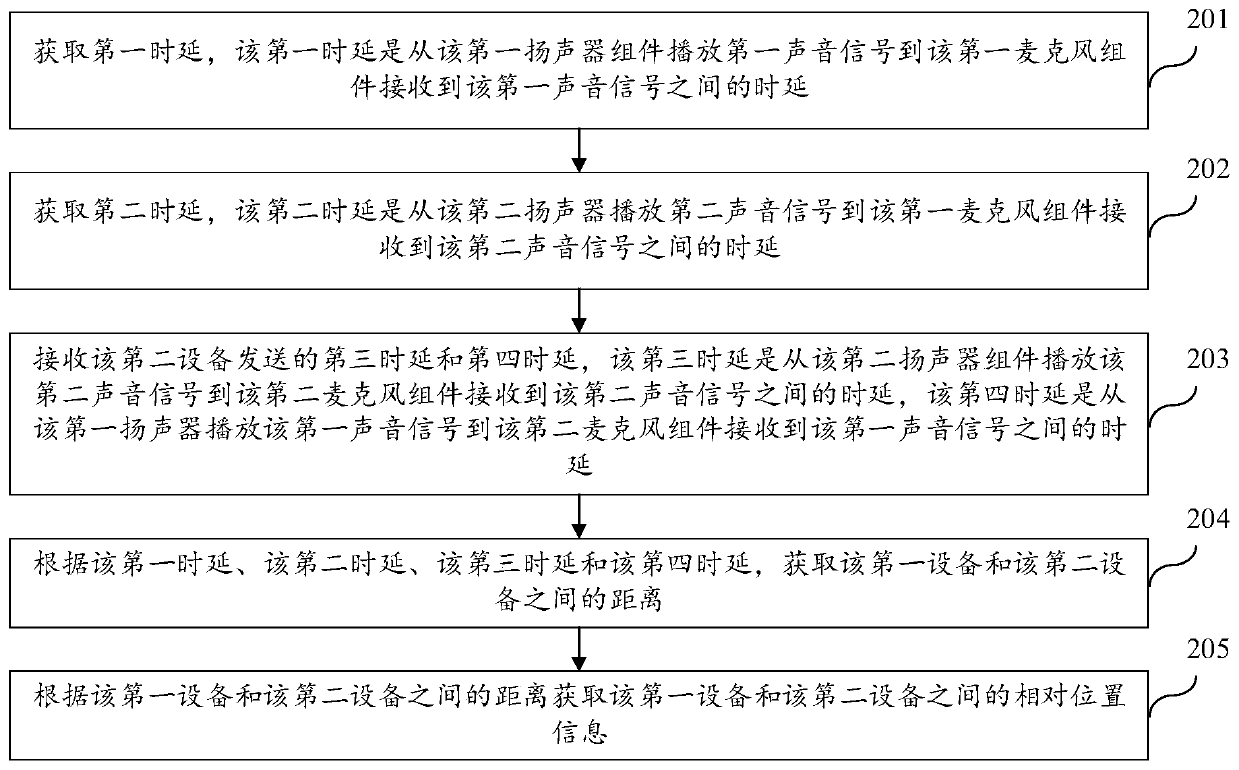

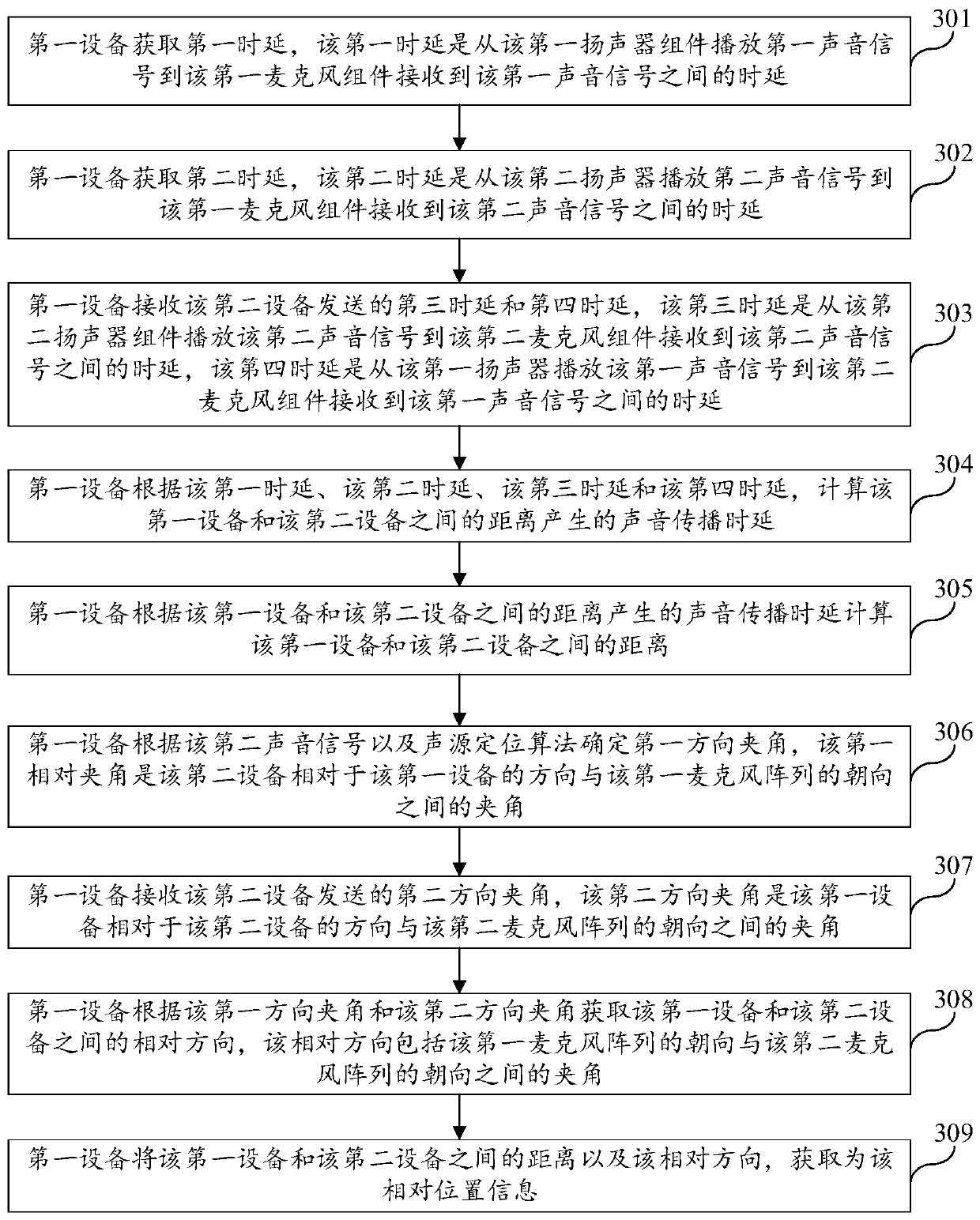

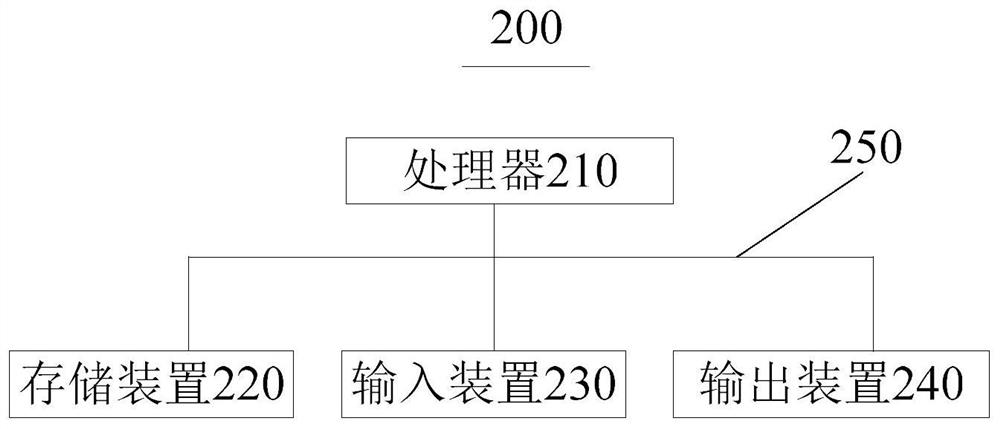

Equipment relative position information acquisition method and device, and storage medium

ActiveCN111060875ANo manual measurement requiredImprove debugging efficiencyPosition fixationData switching networksTime delaysEngineering

The invention discloses an equipment relative position information acquisition method, an equipment relative position information acquisition device and a storage medium, which belong to the technicalfield of distributed conference systems. The equipment relative position information acquisition method comprises the steps of acquiring first time delay and second time delay, receiving third time delay and fourth time delay sent by means of second equipment, acquiring a distance between the first equipment and the second equipment according to the first time delay, the second time delay, the third time delay and the fourth time delay, and acquiring relative position information between the first equipment and the second equipment according to the distance between the first equipment and thesecond equipment. According to the equipment relative position information acquisition method and the equipment relative position information acquisition device, the two sets of equipment receive thedelay of each party receiving sound signals from the other party and from itself through interaction, the distance between the two sets of equipment is calculated based on the delay, the process is automatically completed by each set of equipment in the system, and manual measurement is not needed, so that the debugging time of the distributed conference system is greatly shortened, and the debugging efficiency of the distributed conference system is improved.

Owner:SOUNDAI TECH CO LTD

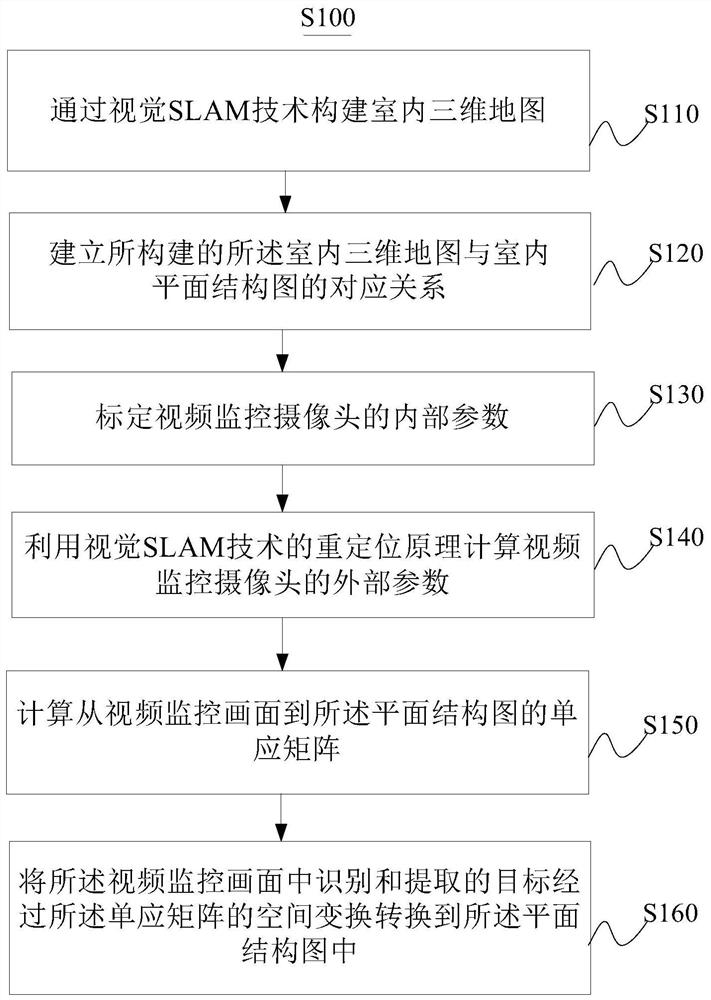

Map positioning method and system applied to indoor video monitoring system

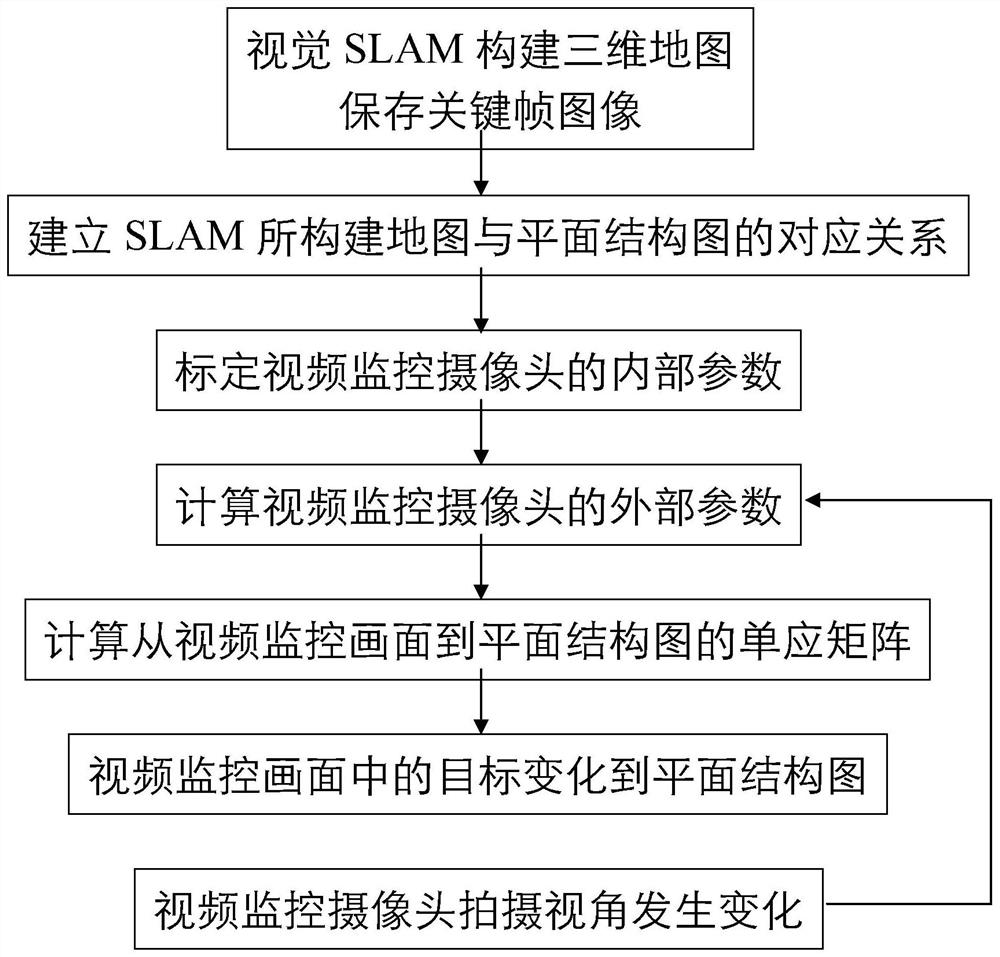

ActiveCN112669392ARealize automatic calibrationAutomatically calculate positional relationshipImage analysis3D modellingComputer graphics (images)Video monitoring

The invention provides a map positioning method and system applied to an indoor video monitoring system, and the method comprises the steps: building an indoor three-dimensional map through a visual SLAM technology, and building a corresponding relation between the built indoor three-dimensional map and an indoor plane structure diagram; calculating the position and posture of a video monitoring camera by using a repositioning principle in a visual SLAM technology, thereby calculating a homography matrix from a video monitoring picture to a plane structure diagram; and converting the identified and extracted target in the video monitoring picture into a plane structure chart through the spatial transformation of the homography matrix, thereby realizing the display and marking of the target in the plane structure chart. According to the invention, the position relationship between the video monitoring image and the plane structure diagram can be automatically calculated without manual measurement, so that the target in the video monitoring image is marked at the corresponding position in the plane structure diagram. Even if the angle of the video monitoring camera is adjusted in the subsequent using process, the map positioning function can still be automatically achieved.

Owner:INFORMATION SCI RES INST OF CETC

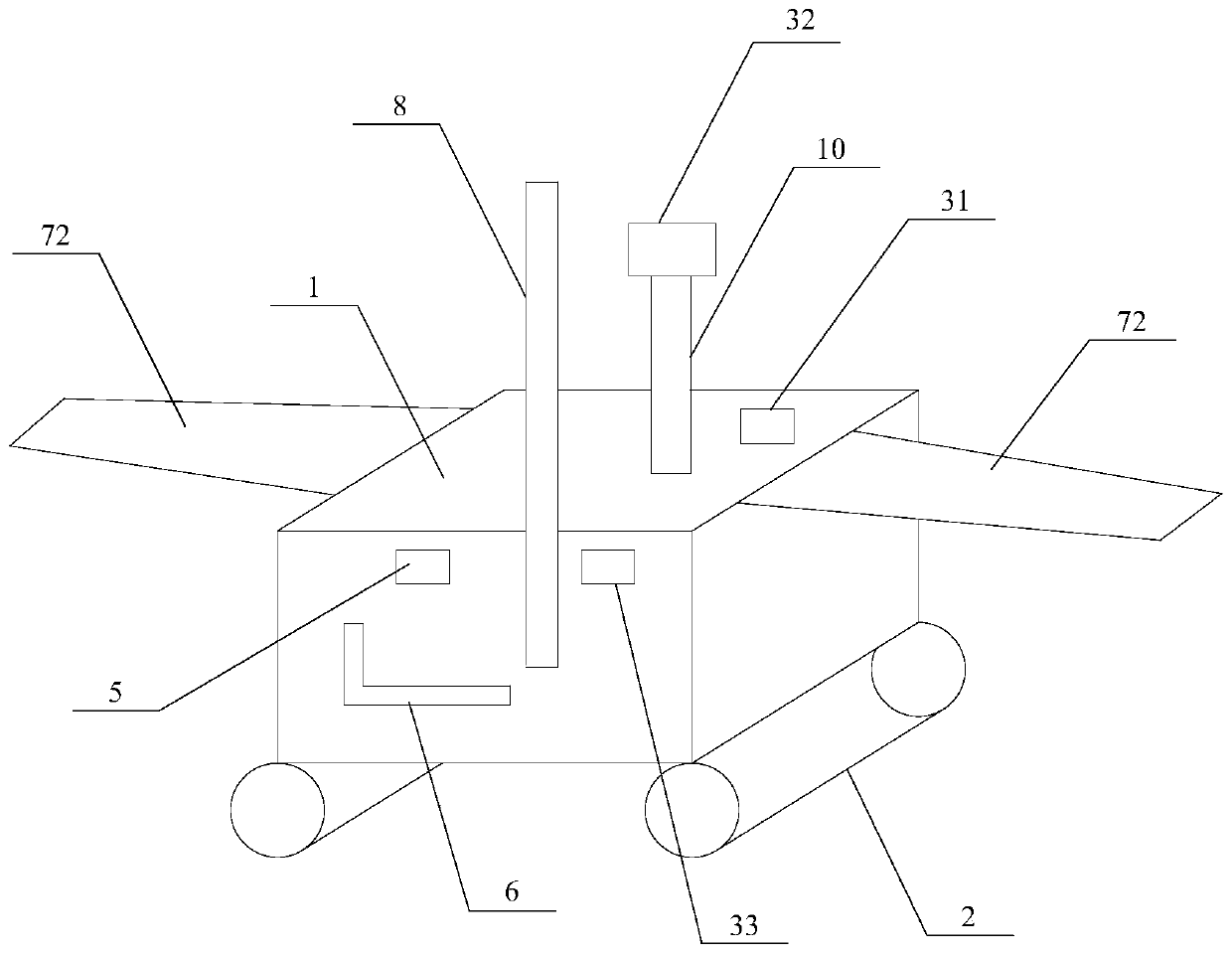

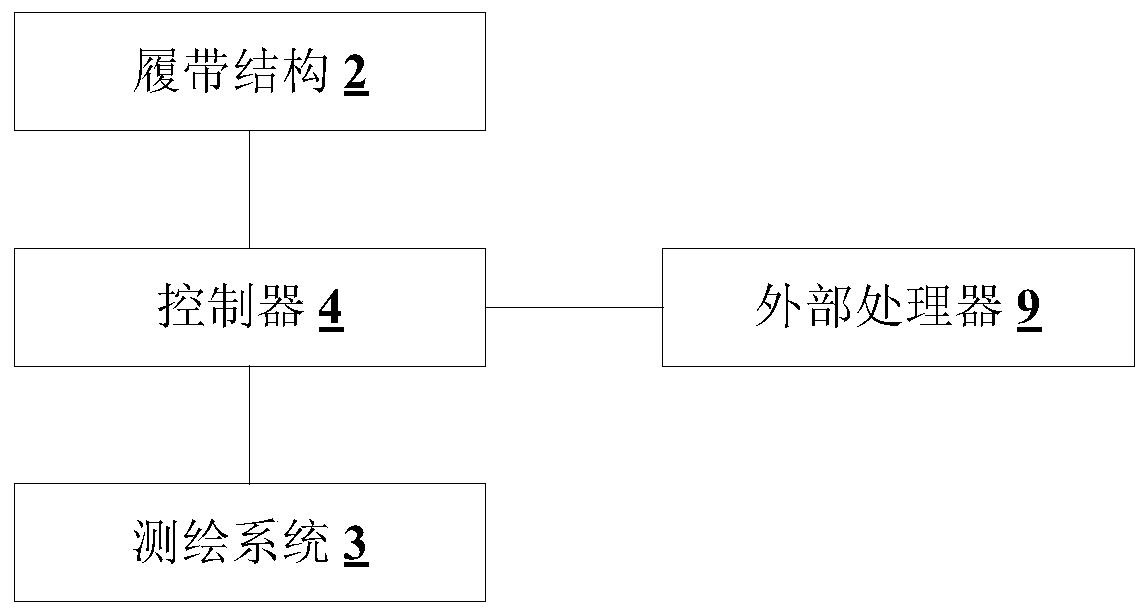

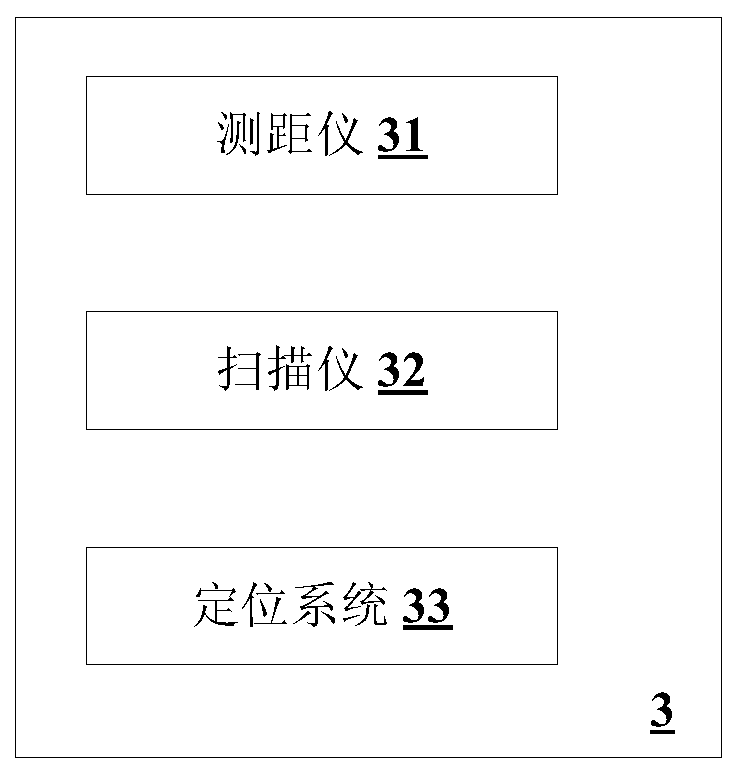

Surveying and mapping robot and surveying and mapping system

PendingCN111102921ANo manual measurement requiredImprove accuracySurveying instrumentsUsing optical meansInformation controlEngineering

The invention provides a surveying and mapping robot and a surveying and mapping system. The surveying and mapping robot comprises a vehicle body; two crawler structures which are arranged on the twosides of the bottom of the vehicle body correspondingly; the surveying and mapping system which is arranged on the outer wall of the vehicle body and used for detecting geographical environment information of a to-be-tested site; and a controller which is arranged in the vehicle body and is electrically connected with the two crawler structures and the surveying and mapping system and is further used for being electrically connected with an external processor and is used for receiving a detection instruction sent by the external processor, driving the two crawler structures to move according to the detection instruction, controlling the surveying and mapping system to conduct detection and sending the detected geographical environment information to the external processor. The vehicle bodycan move to any required position, the surveying and mapping data can be obtained by processing and analyzing the geographical environment information detected by the surveying and mapping system without manual measurement, the measurement accuracy is improved, the operation is simple and convenient, the measurement efficiency is improved, the contact area with the ground can be increased by thecrawlers structure and the vehicle body is more stable and flexible.

Owner:CHINA MCC 2 GRP CO LTD

Automobile valve tappet surface runout detection device

InactiveCN106931844AImprove work efficiencyHigh precisionMechanical measuring arrangementsElectric machineryElectricity

The invention provides a detection device for the beating amount of the end surface of an automobile valve tappet, which includes a base, a leveler, a V-shaped iron, a fixing clip, a U-shaped iron, a detection probe, a rotating shaft, a connecting rod, a dial indicator, a detection platform, a tightening Fixing clip, motor, numerical control instrument, positioning plate, the left end of the base is equipped with a leveler to ensure the level of the base, the right side of the leveler is equipped with a V-shaped iron for placing the main body of the valve lifter, and a fixed clip is installed on the V-shaped iron , The right side of the V-shaped iron is provided with a U-shaped iron for placing the end face. The clip is fixed on the detection platform, the left side of the dial indicator is connected with a connecting rod, the left end of the connecting rod is provided with a rotating shaft driven by a motor, and the detection probe is connected to the rotating shaft, and the right side of the dial indicator is provided with a numerical control instrument, which is connected with the electric motor of the dial indicator. connect. The invention has the beneficial effects of high work efficiency, high precision and high degree of automation.

Owner:TIANJIN RUIPU TIANSHENG AUTO PARTS MFG

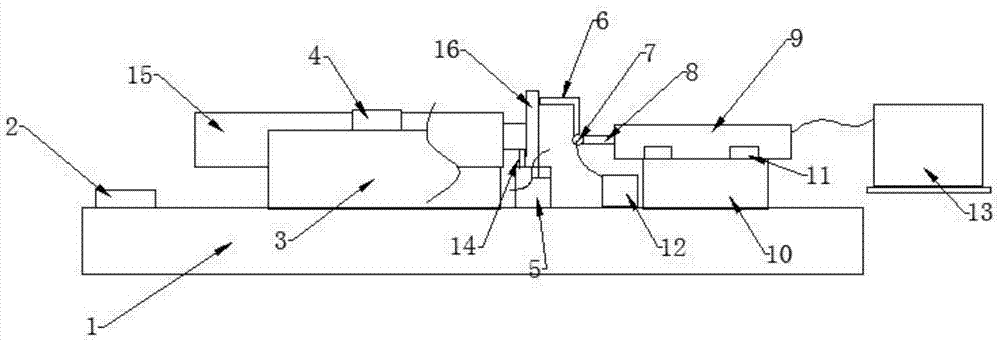

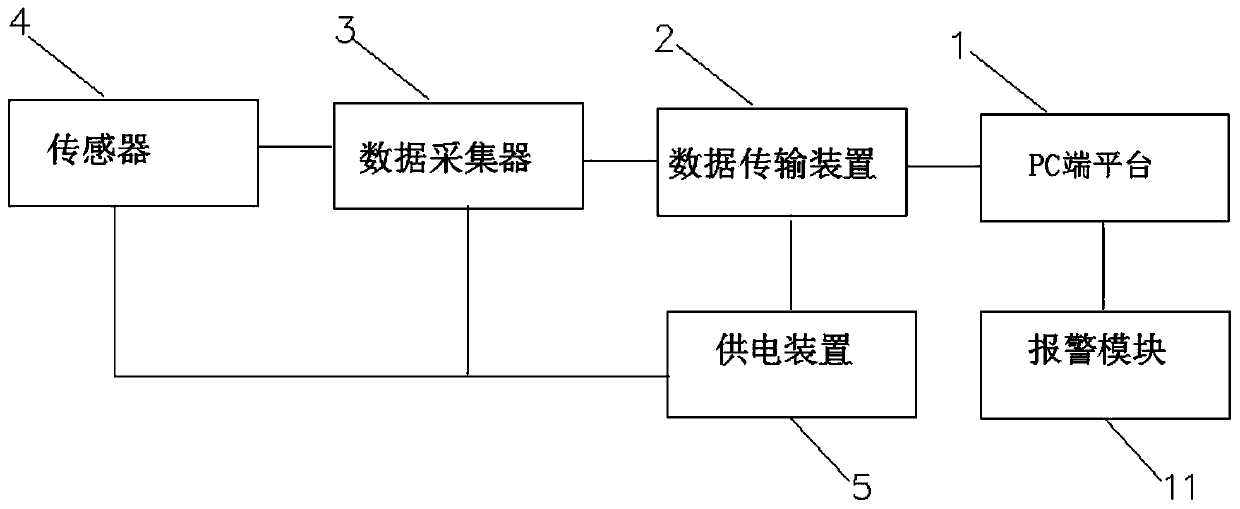

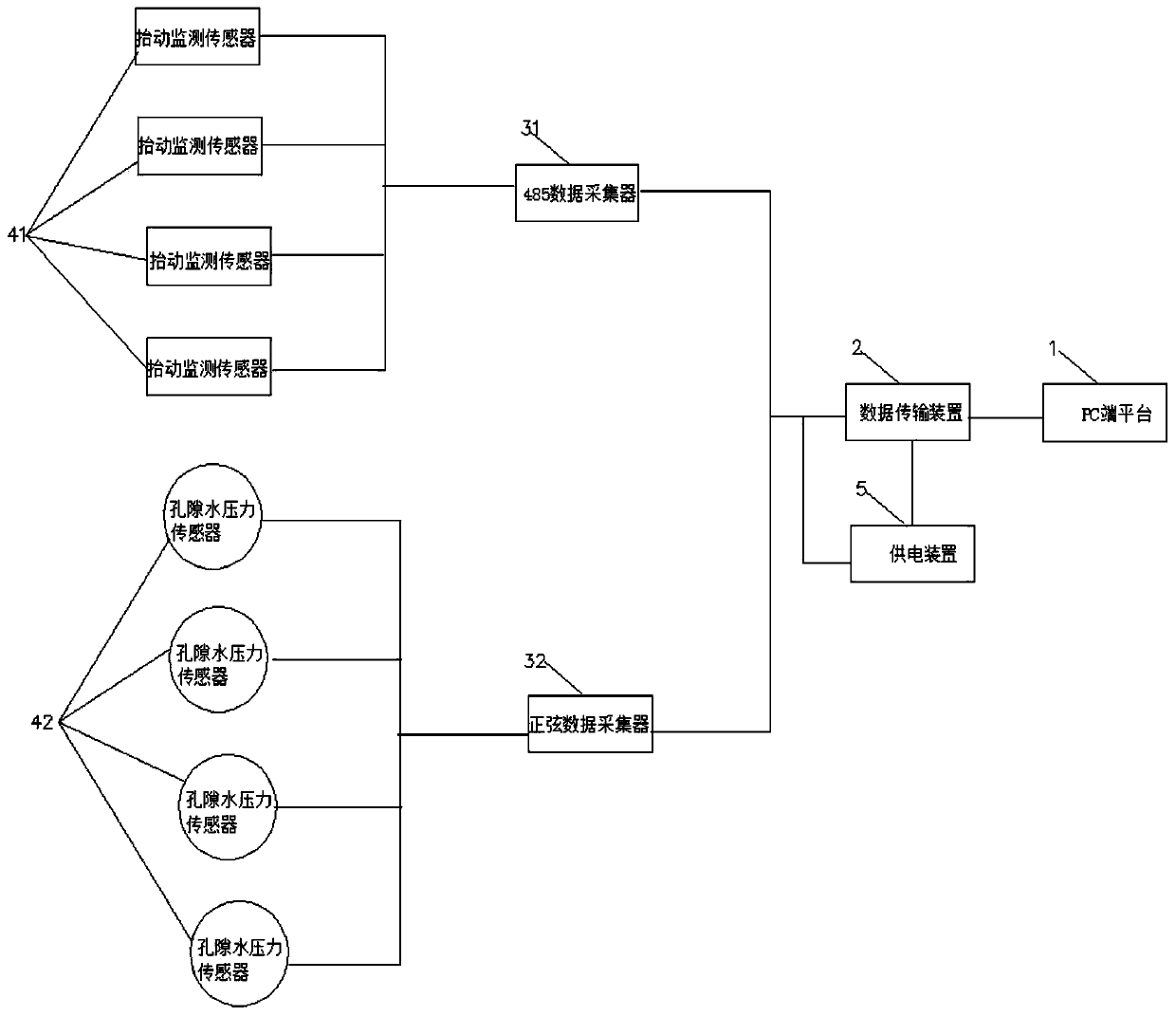

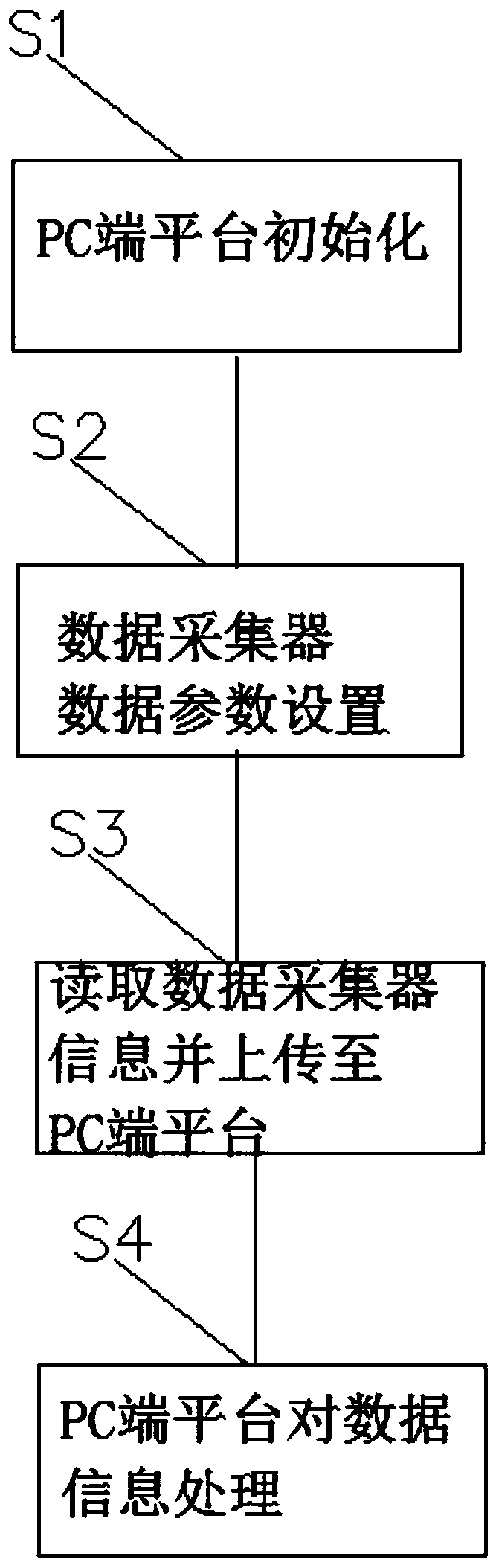

System and method for monitoring influence of bedrock grouting construction on surrounding environment

InactiveCN110987058ASave energyNo manual measurement requiredMeasurement devicesTransmission systemsSoil scienceData information

The invention discloses a system and a method for monitoring the influence of bedrock grouting construction on the surrounding environment. The system comprises a sensor, a data collector, a data transmission device, a PC end platform and a power supply device. The sensor is connected with the data collector through an industrial bus interface, and the data collector transmits collected data information to the PC end platform through the data transmission device. The method comprises the following steps: 1) initializing the PC end platform; 2) setting data parameters by the data collector; 3)reading data information of the data collector and uploading the data information to the PC end platform; 4) processing the acquired data information by the PC end platform. The monitoring system andthe monitoring method for the influence of the bedrock grouting construction on the surrounding environment have the advantages that the monitoring information is accurate, the monitoring efficiency is high, the influence of the environment is avoided, and the labor cost is saved.

Owner:SHENZHEN INVESTIGATION & RES INST

Beidou-based power transmission line galloping monitoring system and control method

PendingCN111982209ADance in real timeEasy to findMeasurement devicesTransmission systemsMonitoring systemComputer science

The invention discloses a Beidou-based power transmission line galloping monitoring system. The Beidou-based power transmission line galloping monitoring system comprises a controller, and an acceleration sensor which is fixedly connected with a body, and the acceleration sensor is electrically connected with the controller; the system further comprises the body, the upper portion of the body is fixedly connected with a hoop structure, and a fixing hole of the hoop structure matches a wire; the system further comprises a Beidou communication module which is fixedly connected with the body, andthe Beidou communication module is electrically connected with the controller; the system further comprises a 5G module which is fixedly connected with the body, and the 5G module is electrically connected with the controller; the system further comprises a storage battery which is electrically connected with the controller, the acceleration sensor, the 5G module and the Beidou communication module, and a cloud server which is in wireless connection with the Beidou communication module. The problems of low detection efficiency and high detection cost in the prior art are solved.

Owner:PANJIANG COAL & ELECTRICITY GROUP INSITUTE OF COAL MINING DESIGN

Equipment suitable for detecting compressive strength of glass fiber plate

PendingCN113884380AAvoid breakingNot easy to breakMaterial strength using tensile/compressive forcesElectric machineryElectrical and Electronics engineering

The invention relates to detection equipment, and in particular relates to equipment suitable for detecting the compressive strength of a glass fiber plate. The invention provides the equipment suitable for detecting the compressive strength of the glass fiber plate, which can remind workers of the detection progress in time and is convenient for recording the detection data. The equipment suitable for detecting compressive strength of the glass fiber plate comprises a bottom plate, the top of which is symmetrically provided with bearing racks used for placing the glass fiber plate; a first supporting frame is arranged on one side of the top of the bottom plate; a first supporting block is arranged on one side of the top of the bottom plate; and a motor is arranged at the top of the first supporting frame. An installation block moves downwards to drive a lower pressing block to move downwards, then a pointer is driven to move downwards, the pointer moves downwards along with the extrusion degree of the glass fiber plate, people can record data on the calibrated scale aligned with the pointer and record data of the impact strength of the glass fiber plate, through the operation, people can more accurately know the strength data of the glass fiber plate, and manual measurement is not needed.

Owner:文慧

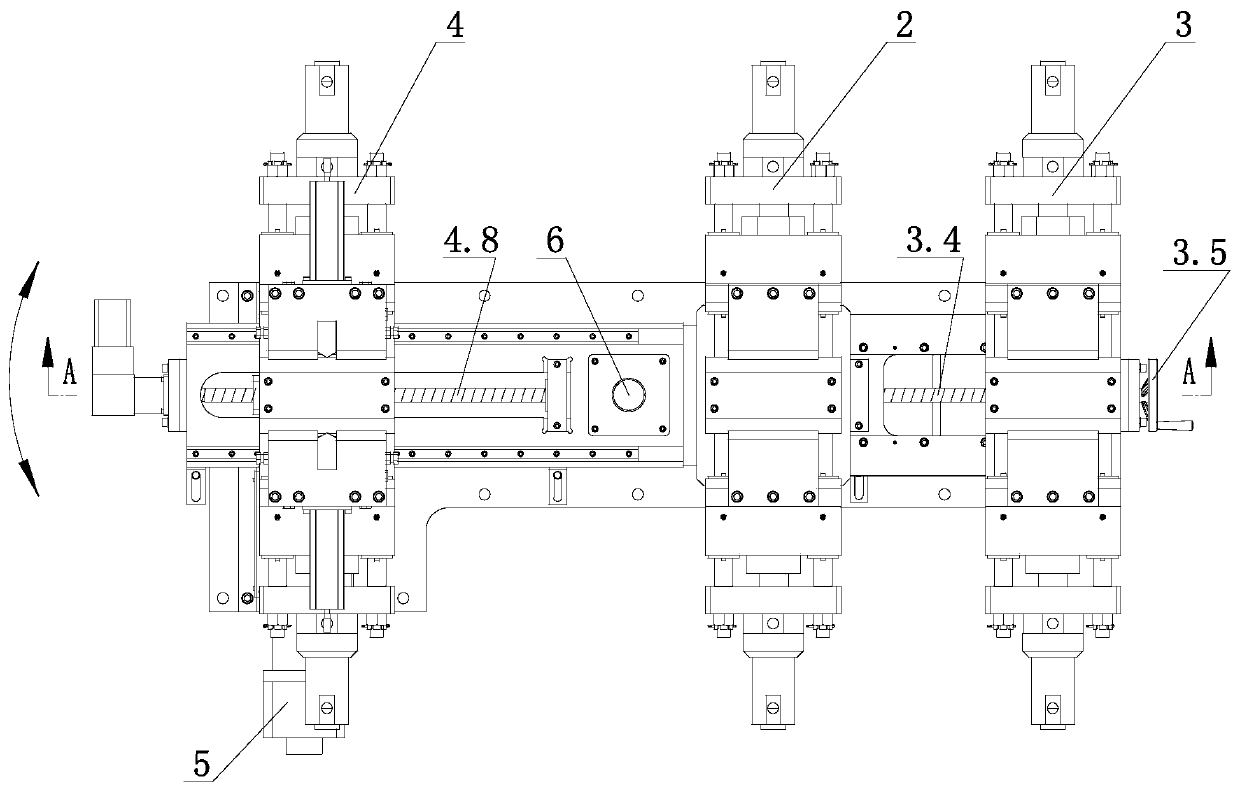

Servo swing type measurement straightener after automobile leaf spring rolling

InactiveCN111318592AHigh bending accuracyHigh precisionMetal working apparatusControl engineeringMotor control

The invention belongs to the technical field of leaf spring straightening equipment, and particularly relates to a servo swing type measurement straightener after automobile leaf spring rolling. The straightener comprises a base, wherein an adjustable cold end clamping device, a fixed cold end clamping device and a hot end swing clamping device are sequentially arranged on the base, the fixed coldend clamping device is fixedly mounted in the middle of the base, the adjustable cold end clamping device is slidably mounted at one end of the base through a cold end lead screw, and the hot end swing clamping device is mounted at the other end of the base and is driven by a driving device to be capable of swinging left and right around a rotating shaft. The straightener is used for side bendingmeasurement and straightening on a leaf spring, and the straightening efficiency is high. Different degrees of straightening can be achieved according to different side bending degrees of the leaf spring, online monitoring is achieved, a servo motor controls a swing angle, the bending degree precision of a straightened leaf spring is high, and on-line measurement and recording after the leaf spring is straightened are realized. Straightening and detecting are completed on one device, the cycle of operation is shorted, manual measurement is not needed, and work time is saved.

Owner:山东中元自动化设备有限公司 +1

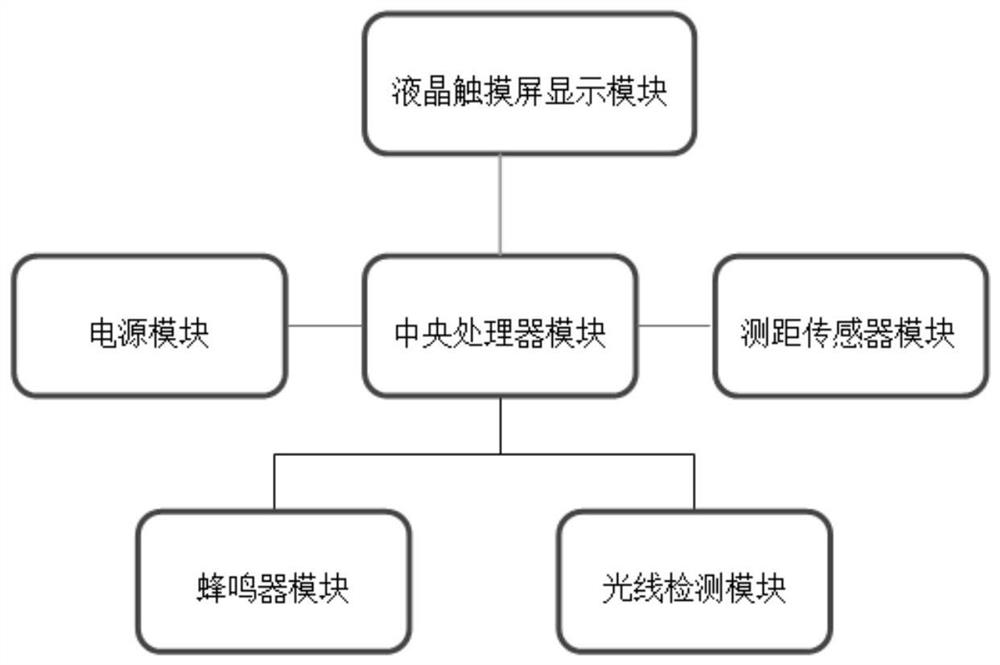

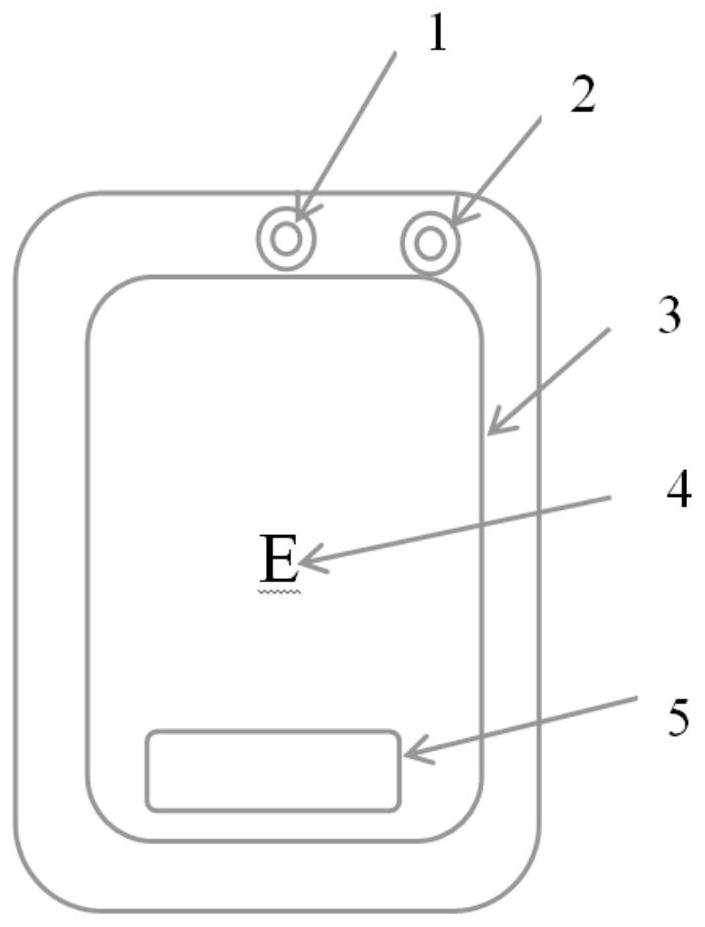

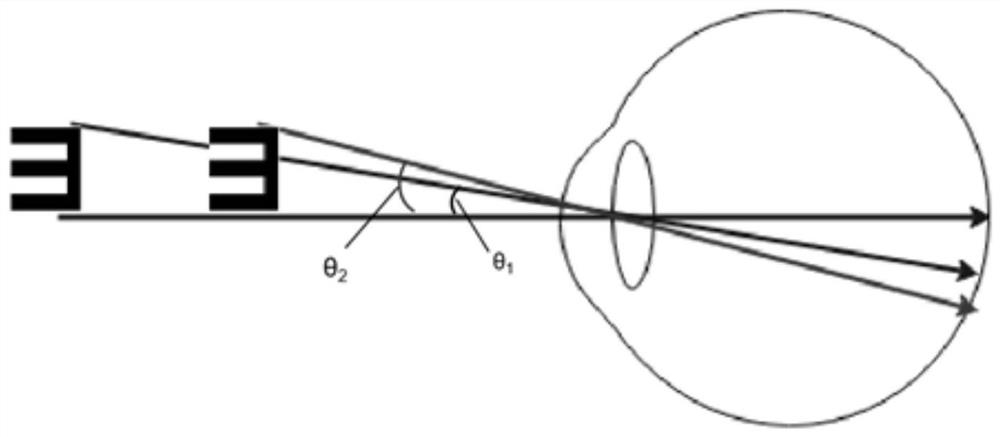

Adjusting amplitude tester and testing method thereof

PendingCN112244758AHigh distance measurement accuracyReduce precisionEye diagnosticsLiquid crystalLight detection

Owner:TIANJIN VOCATIONAL INST

Wire rod performance quality detection system and detection method

ActiveCN113776924AEasy to disassemble and replaceHigh degree of automationMaterial strength using tensile/compressive forcesNumerical controlImage manipulation

The invention discloses a wire rod performance quality detection system and method, and the system comprises a machine tool, a numerical control panel, a station plate, a cantilever, a stretching plate, a lug plate, and a visual camera.A numerical control panel is arranged at the top end of one side of the front face of the machine tool. The center and four corners of the back surface of the numerical control panel are electrically connected with the front surfaces of the central processing module, the image acquisition module, the image processing module, the numerical control driving module and the performance detection module respectively; the four sides of the back surface of the numerical control panel are electrically connected with the front surfaces of a data receiving module, a data processing module, a model construction module, a model optimization module and a data transmission module respectively; according to the invention, numerical control driving is adopted, the automation degree is high, the labor intensity of personnel is reduced, the detection cost of wires is saved, a performance quality detection model is constructed by using big data, a visual image technology is matched, the detection is intelligent, manual measurement and calculation are not needed, the detection efficiency is high, the cost is low, scientific data support is provided, and the detection precision is high.

Owner:深圳市勤诚鑫科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com