Online detection device and method for cylindrical component butt joint

A detection device and component technology, applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing, etc., can solve the problems of single point or within a certain range of detection, unable to detect, unable to detect the attitude of parts and components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

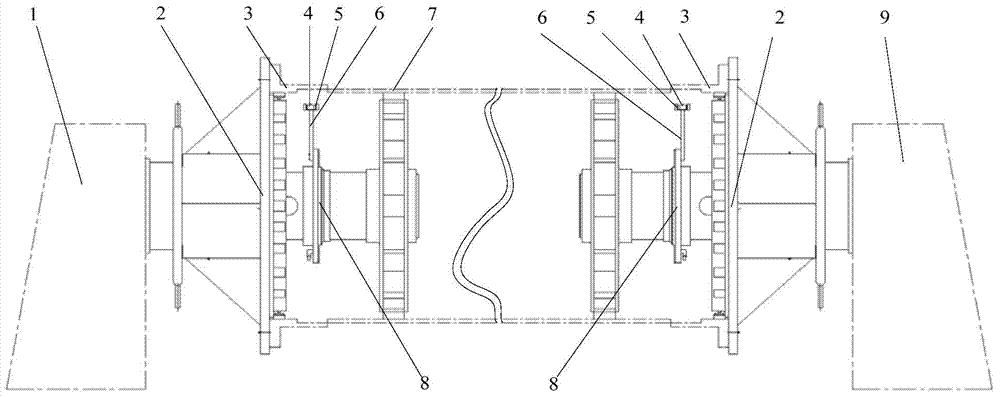

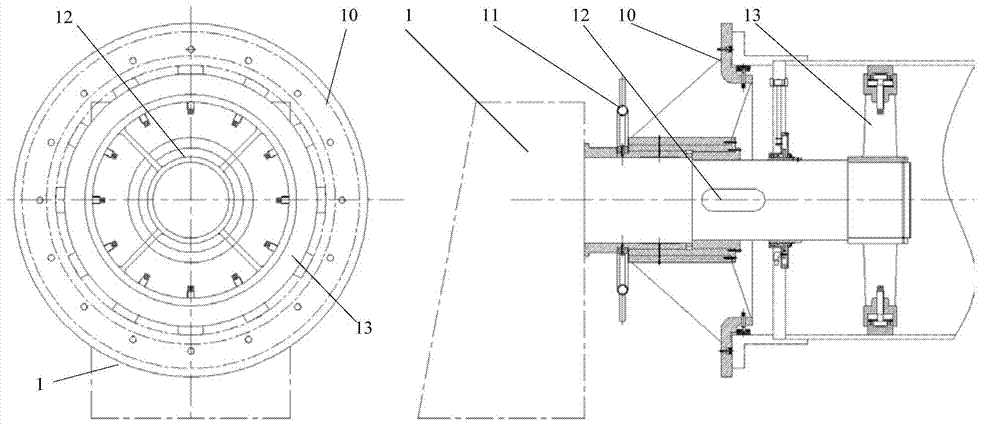

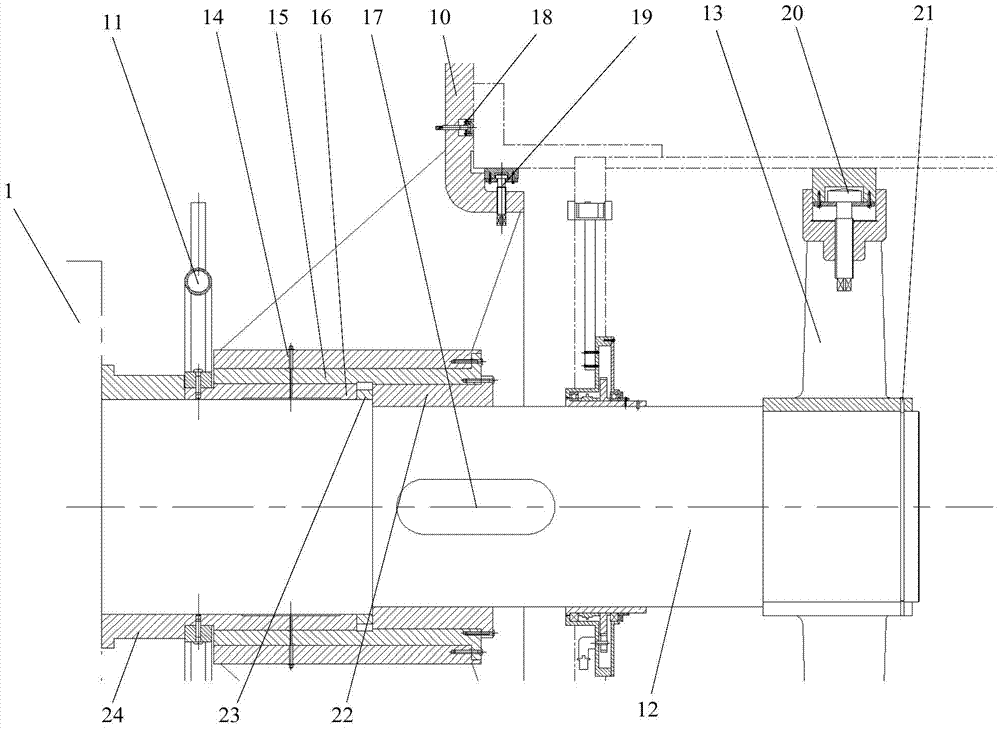

[0064] An on-line detection device for butt jointing of cylindrical components includes a butt joint tool 2 , a transmission structure 8 , a sensor 4 , a sensor mounting seat 5 and a measuring frame 6 .

[0065] The inner diameters of the first cylindrical member 3 and the second cylindrical member 7 to be docked are both 1800 mm, the length of the first cylindrical member 3 is 600 mm, and the length of the second cylindrical member 7 is 2500 mm.

[0066](1) Install two sets of docking tooling 2 on the headstock 1 of the horizontal lathe and the tailstock 9 of the horizontal lathe, and the second radial regulator 20 is evenly distributed on the second support plate 13; on the first support plate 10 First radial adjusters 19 and end face adjusters 18 are evenly distributed. Reversely rotate the radial adjustment screw 28 on the second radial adjuster 20 or the first radial adjuster 19 to make the outer diameter of the radial support block 27 smaller than the inner diameter of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com