Ultra-supercritical coal-fired power generator pipeline weld joint online creep monitoring method

An ultra-supercritical and generator technology, applied in the detection field, can solve problems such as complex detection methods, poor timeliness of early warning, and low accuracy of detection data, so as to improve the safety of use, reduce errors, and measure accurately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

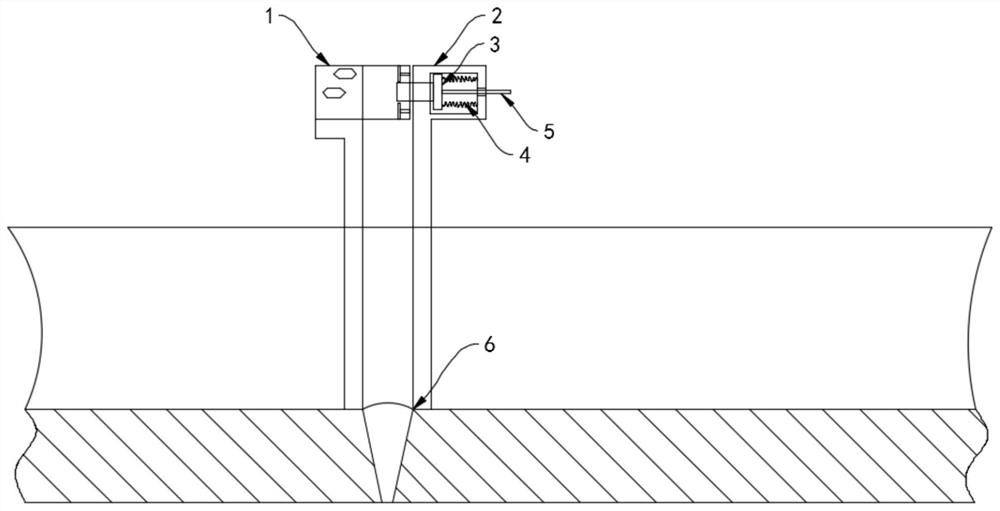

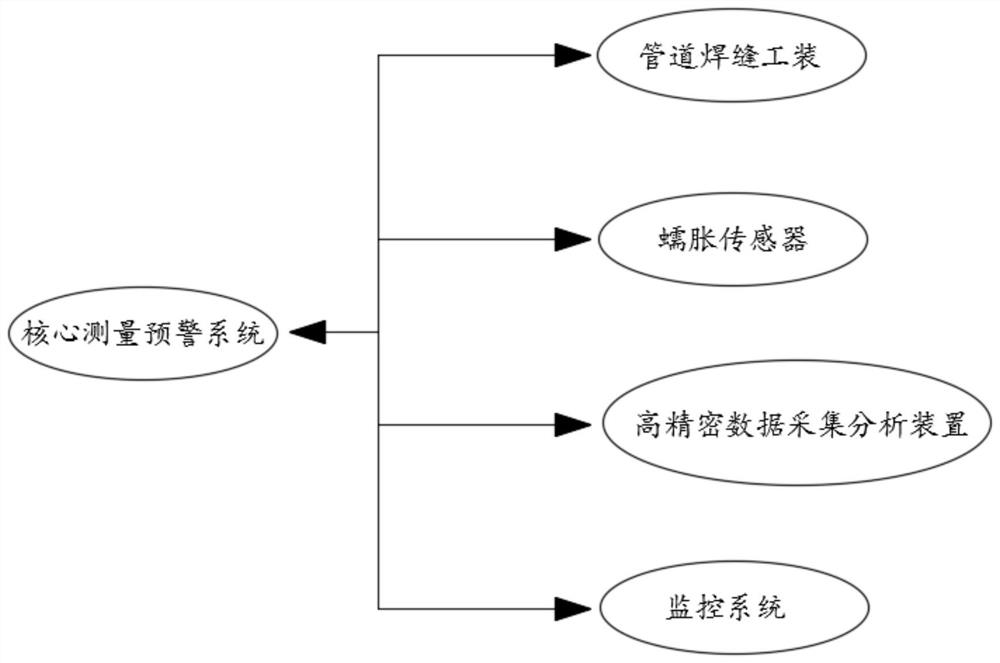

[0039] refer to Figure 1-3 , an online creep monitoring method for ultra-supercritical coal-fired generator pipeline welds. , The material deforms continuously under the continuous action of the stress. Therefore, the strength of the material at high temperature is related to the time of the load.

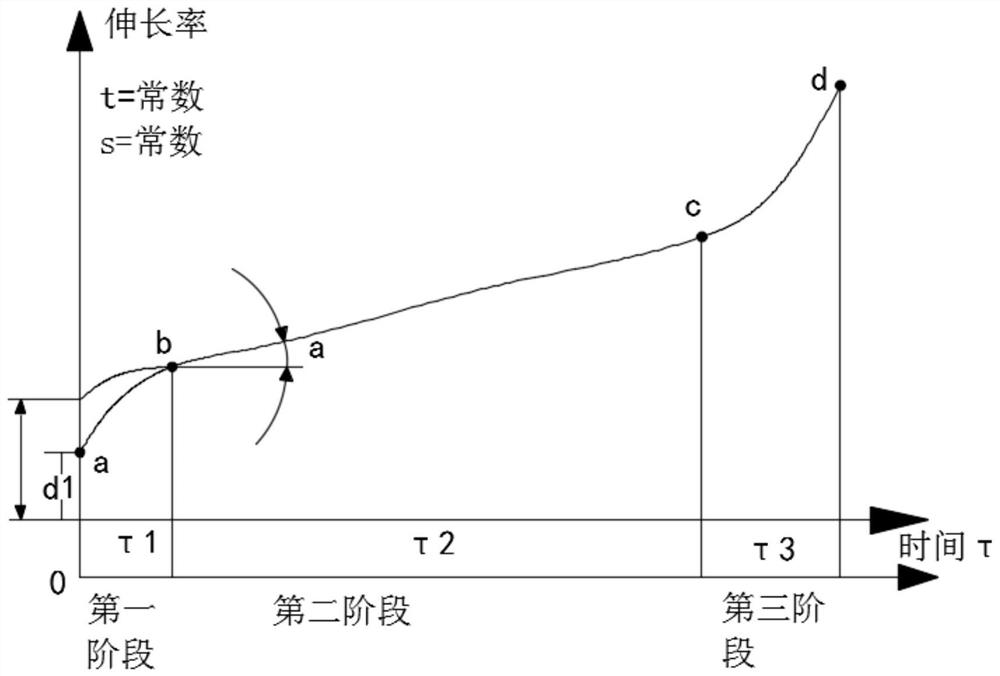

[0040] Creep of metal materials is usually in accordance with the creep rate The creep process is divided into three stages.

[0041] The first stage ab is the deceleration creep stage, also known as the transition creep stage. The creep rate at this stage is very large. As time increases, the creep rate gradually decreases, and reaches the minimum value at point b; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com