Automatic cutting device of steel wire ropes

An automatic cutting device and steel wire rope technology, which is applied in the field of cutting devices, can solve the problems of low cutting efficiency of steel wire ropes, and achieve the effects of improving cutting efficiency, improving wear resistance, and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

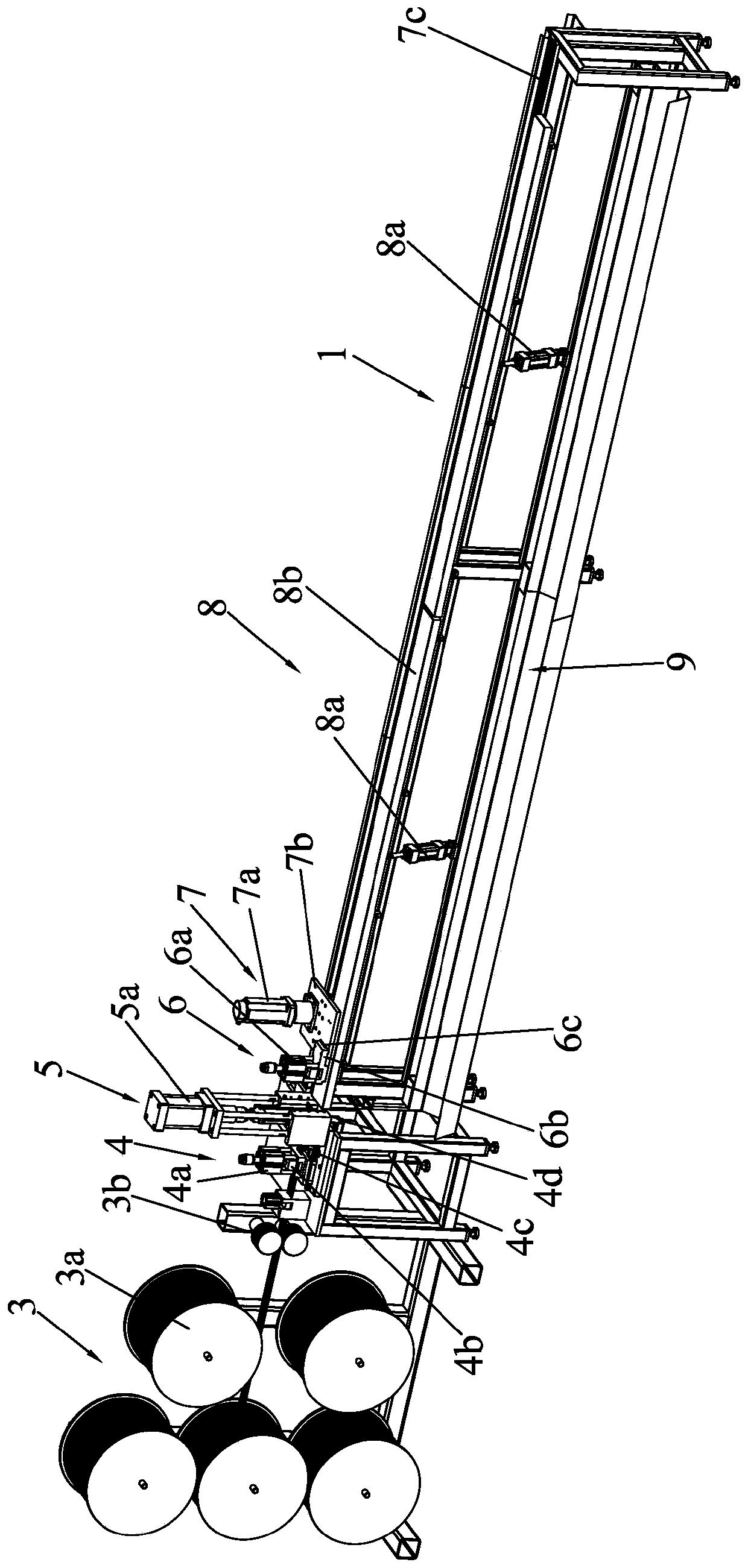

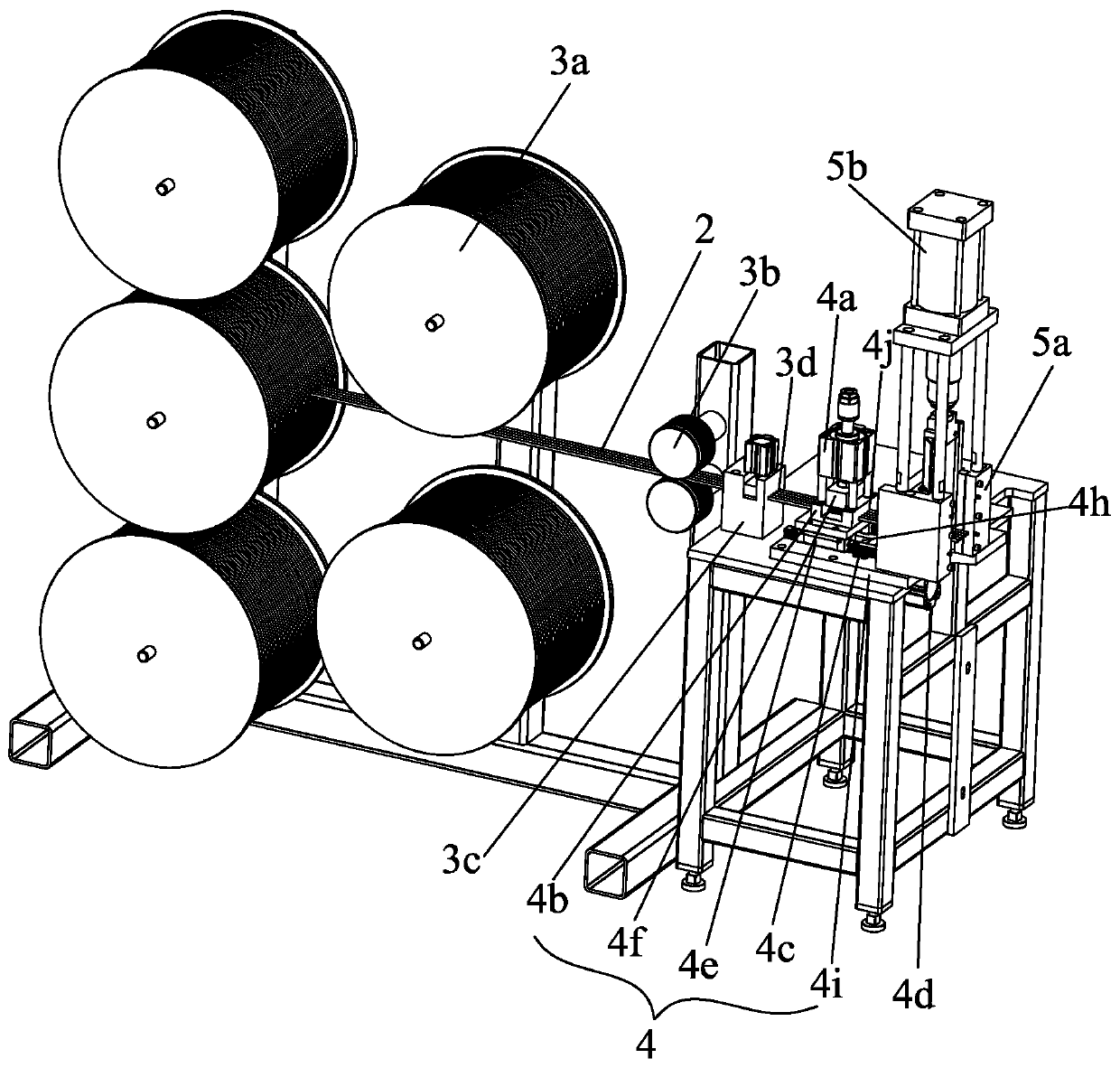

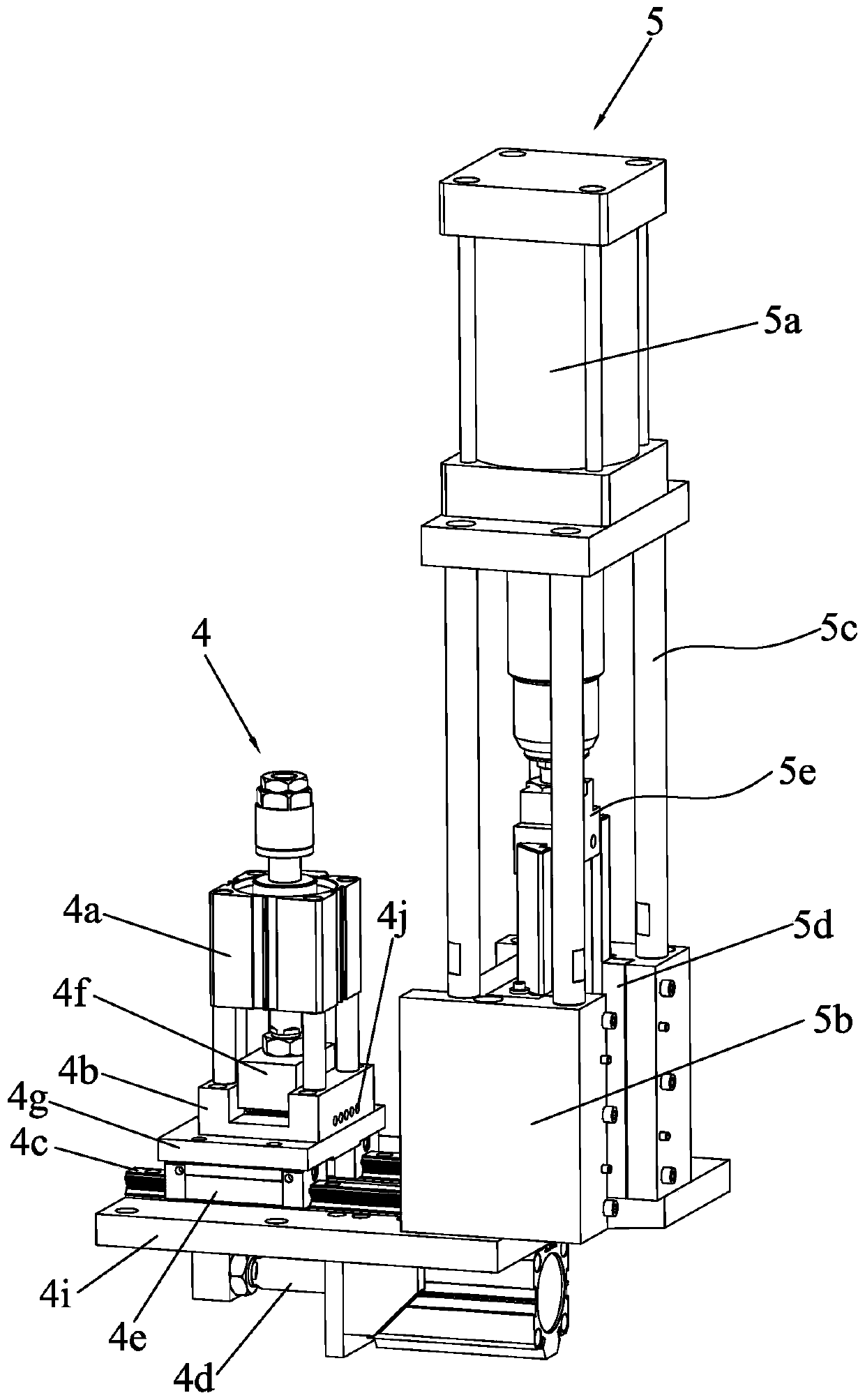

[0025] like Figure 1 to Figure 5 Shown, the present invention discloses a kind of automatic cutting device of wire rope, with reference to figure 1 , the cutting device is provided with a frame 1 and a feeding mechanism 3, a first pressing mechanism 4, a cutting mechanism 5, a second pressing mechanism 6 and a material-receiving traveling mechanism 7 arranged on the frame 1 in sequence, and the traveling mechanism 7 is arranged on the unloading mechanism 8, the bottom of the unloading mechanism 8 is provided with a storage tank 9, and the feeding mechanism 3 includes at least one feeding tray 3a for feeding the wire rope 2, a guide wheel 3b for pulling the wire rope 2 and Guide block 3c for steel wire rope 2 guide. The steel wire rope 2 passes through the gap between the two guide wheels 3b. Under the guidan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com