Machine for testing braking performance of bicycle

A bicycle and testing machine technology, which is applied in vehicle testing, machine/structural component testing, force/torque/power measuring instruments, etc., can solve the problems of cumbersome and complex, large data randomness, large calculation workload, etc., to achieve Easy to use, simple structure, labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

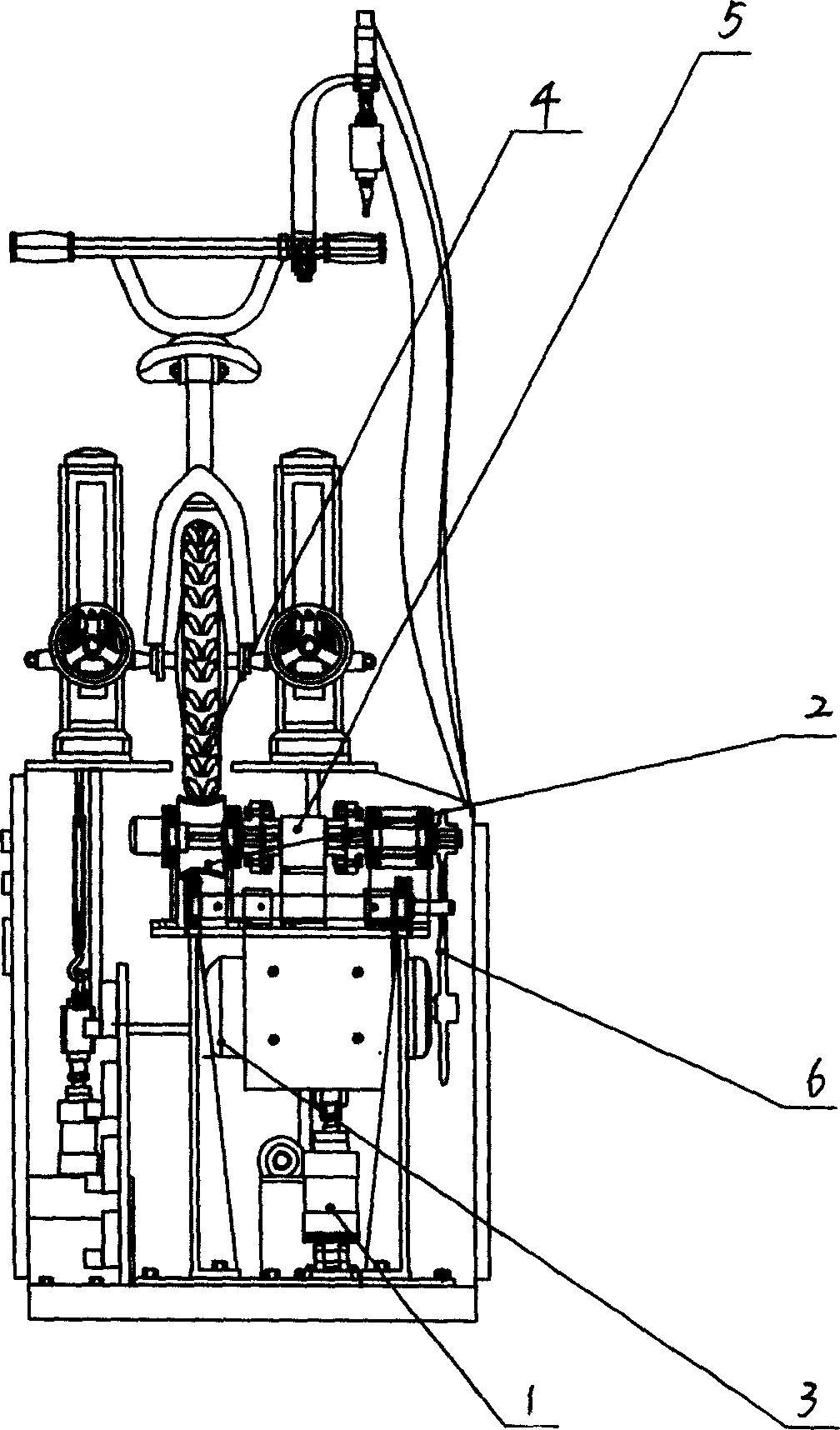

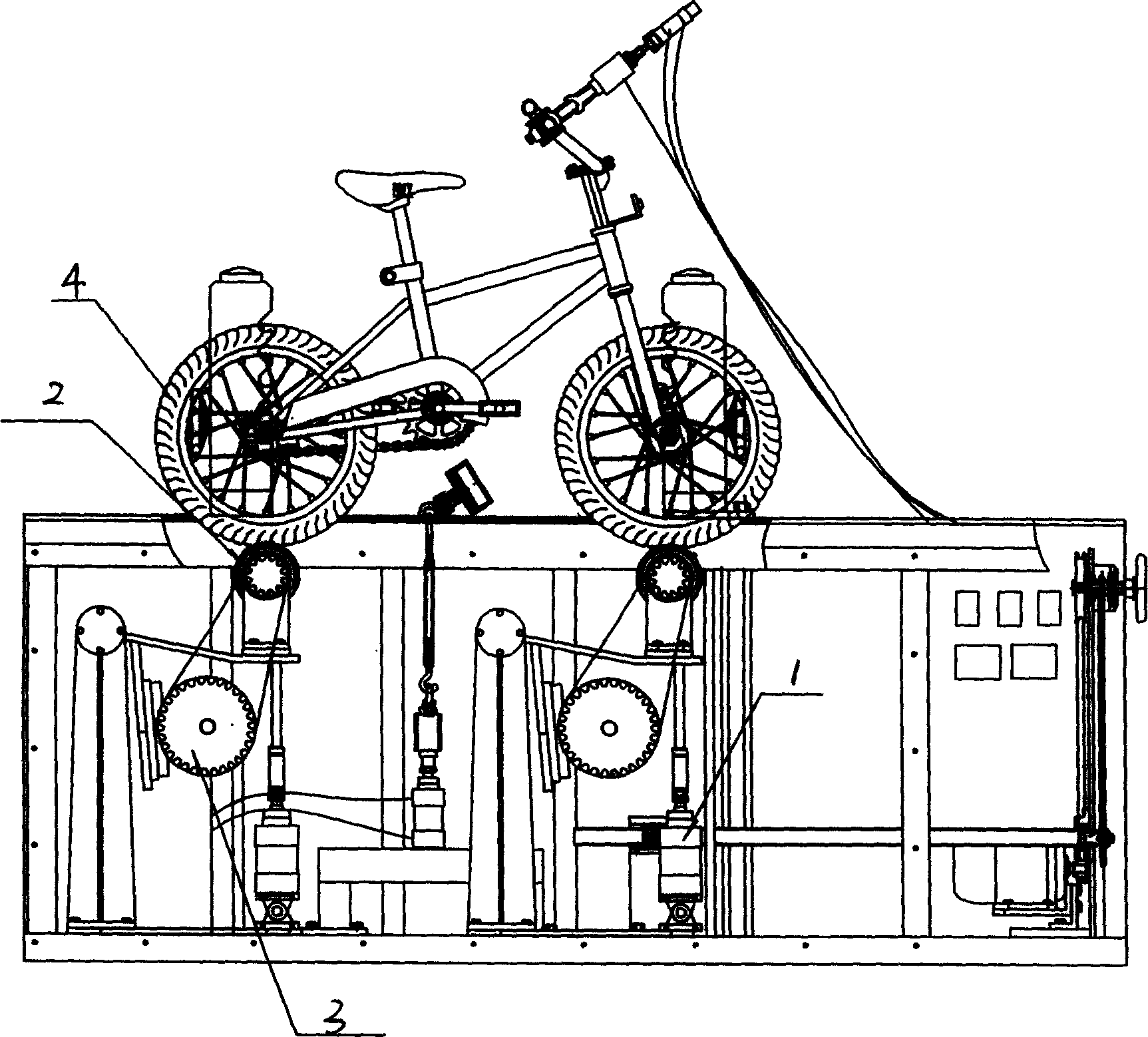

[0013] Embodiment 1: With reference to the accompanying drawings, a bicycle braking performance testing machine includes a clamping mechanism for fixing a bicycle, a brake force applying mechanism, a torque measuring device, a force applying cylinder 1 and an electric control device; The force mechanism is connected with the brake of the bicycle; the torque measuring device includes a friction roller 2 and a drive motor 3, and the drive motor is connected with a sprocket 6, and the friction roller is connected with the sprocket, and the sprocket Connect with the drive motor output shaft. The friction roller is located directly below the corresponding position of the wheel 4 when the clamping mechanism fixes the bicycle, and the torque sensor 5 is installed on the rotating shaft of the friction roller; the torque measuring device is affixed to the piston rod of the force cylinder; the electric control device Connect the output end of the vehicle speed sensor and the control lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com