Intelligent auxiliary operation device and method for stone mine fork loading truck

A technology for auxiliary operations and forklift trucks, applied in lifting devices, measuring devices, TVs, etc., can solve problems such as stone falling, increased accident rate, and inability to automatically identify the shape and center of gravity of stone blocks to be loaded and unloaded

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

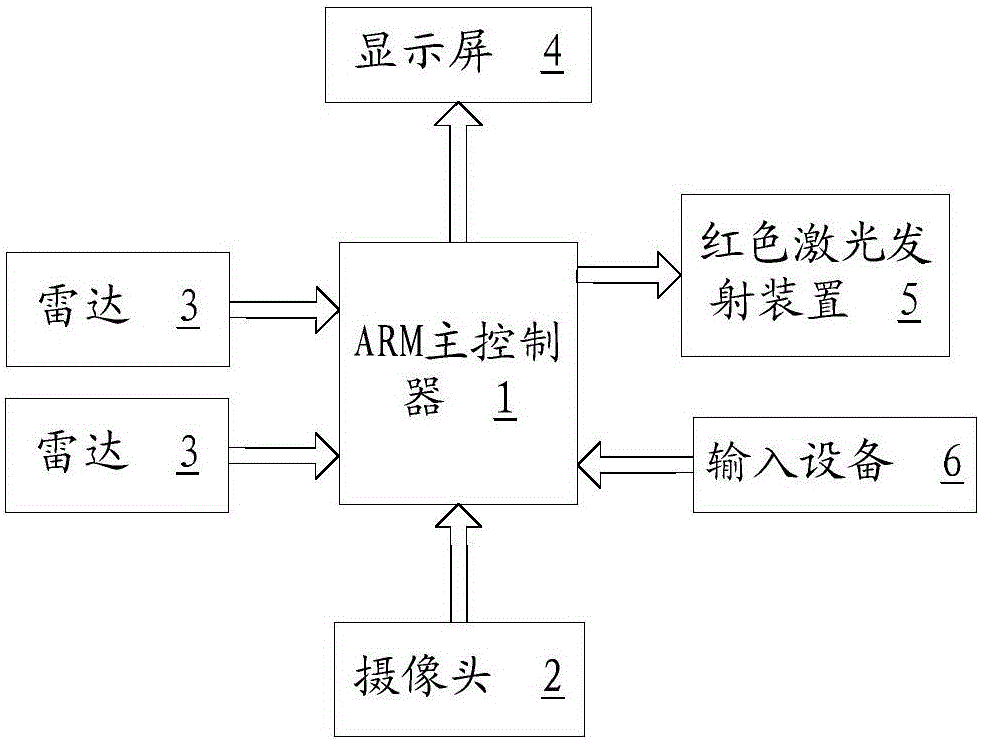

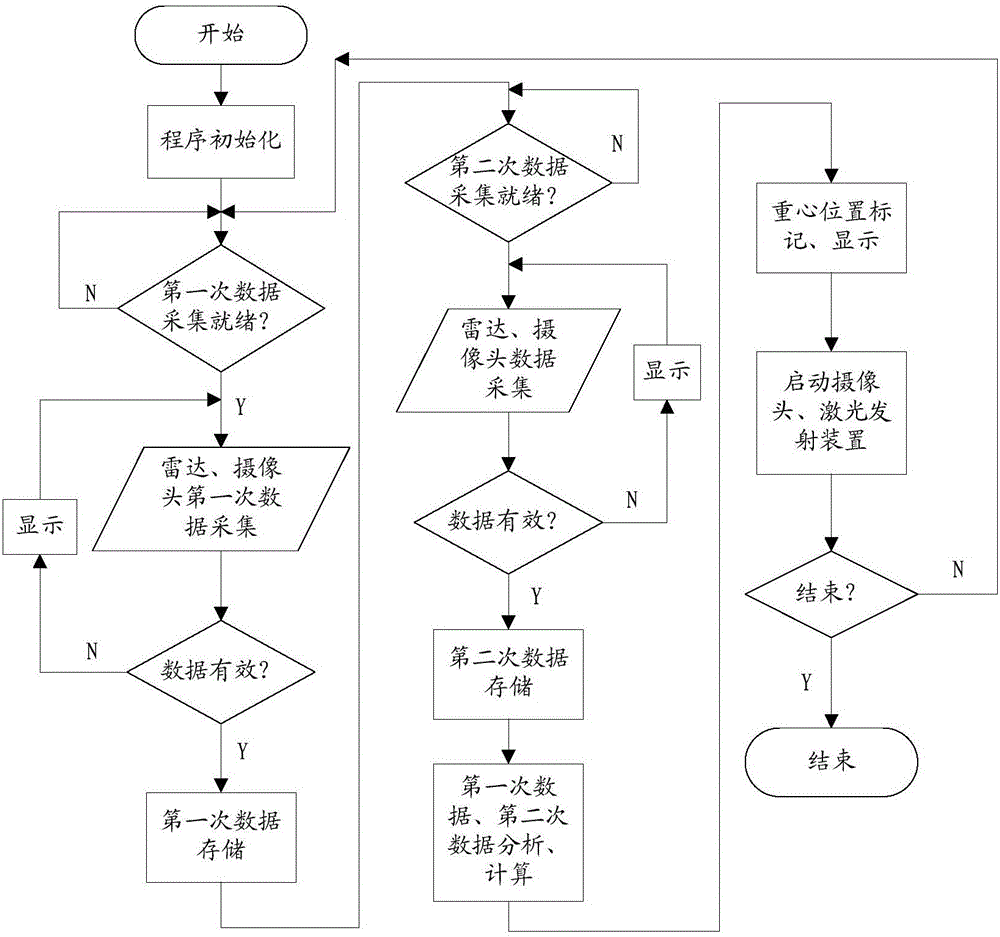

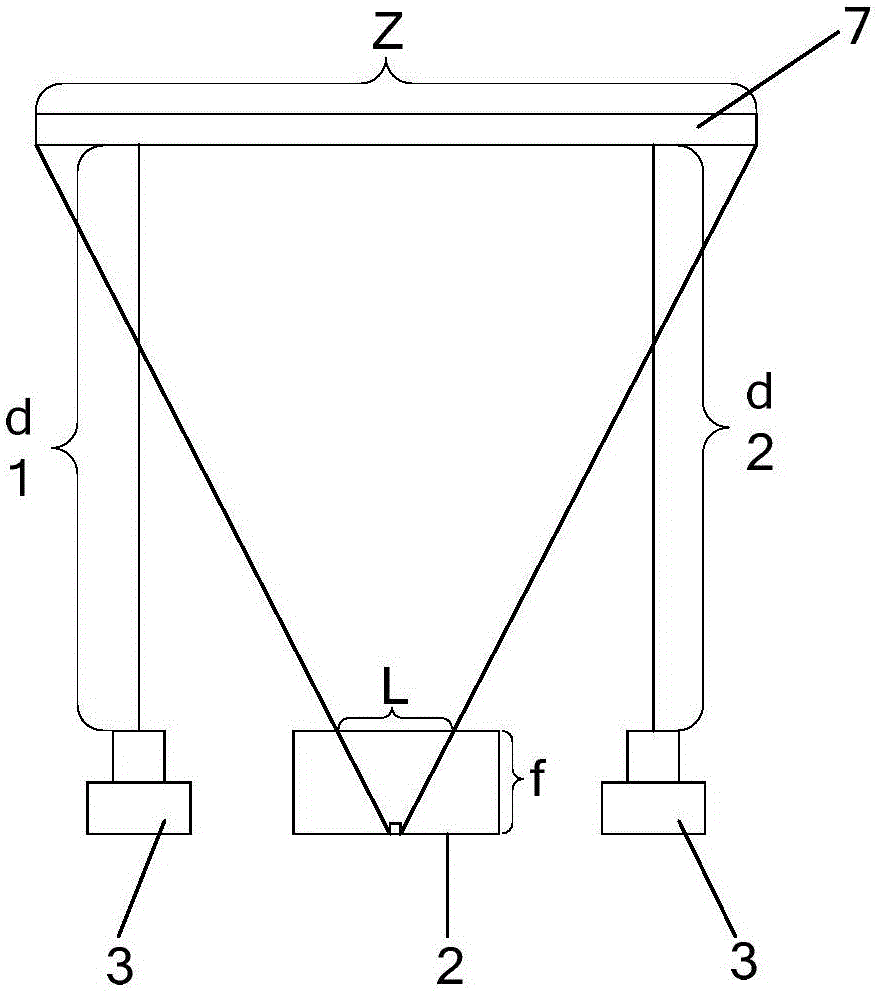

[0026] see figure 1 and figure 2 As shown, an intelligent auxiliary operation device for a stone mine forklift truck according to the present invention, the device is arranged on the forklift truck, and the device includes an ARM main controller 1, a camera 2, at least two radars 3, a The display screen 4 and a red laser emitting device 5; the camera 2, two radars 3, the display screen 4, and the red laser emitting device 5 are all connected to the ARM main controller 1, and the camera 2 is installed on a forklift The middle position of the two forks (not shown); the two radars 3 are symmetrically installed on both sides of the camera 2, while ensuring that the two radars 3 and the camera 2 are at the same height and the two radars 3 and the camera 2 are at the same height The central axis is parallel; the red laser emitting device 5 is installed directly below the camera 2, at the center of the forklift truck, and the laser emitted by the red laser emitting device 5 is para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com