Wire rod performance quality detection system and detection method

A detection system and performance technology, applied in the field of wire rod performance and quality detection system, can solve the problems of low degree of automation, insufficient intelligence, inconvenient disassembly and assembly of fixtures, etc., and achieve the effect of high degree of automation, saving detection cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

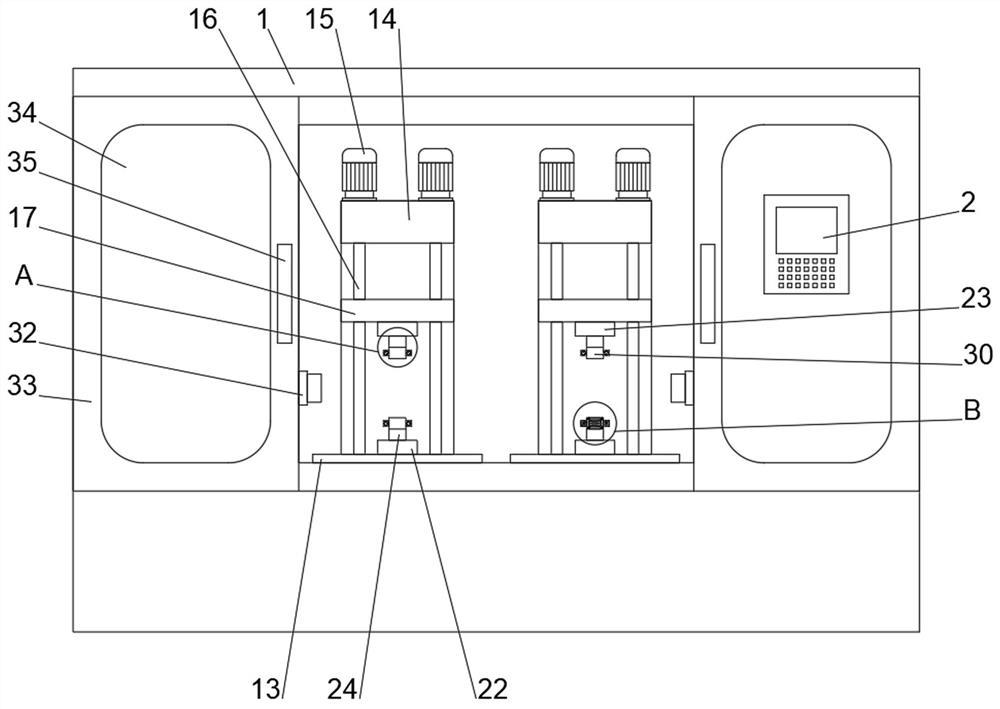

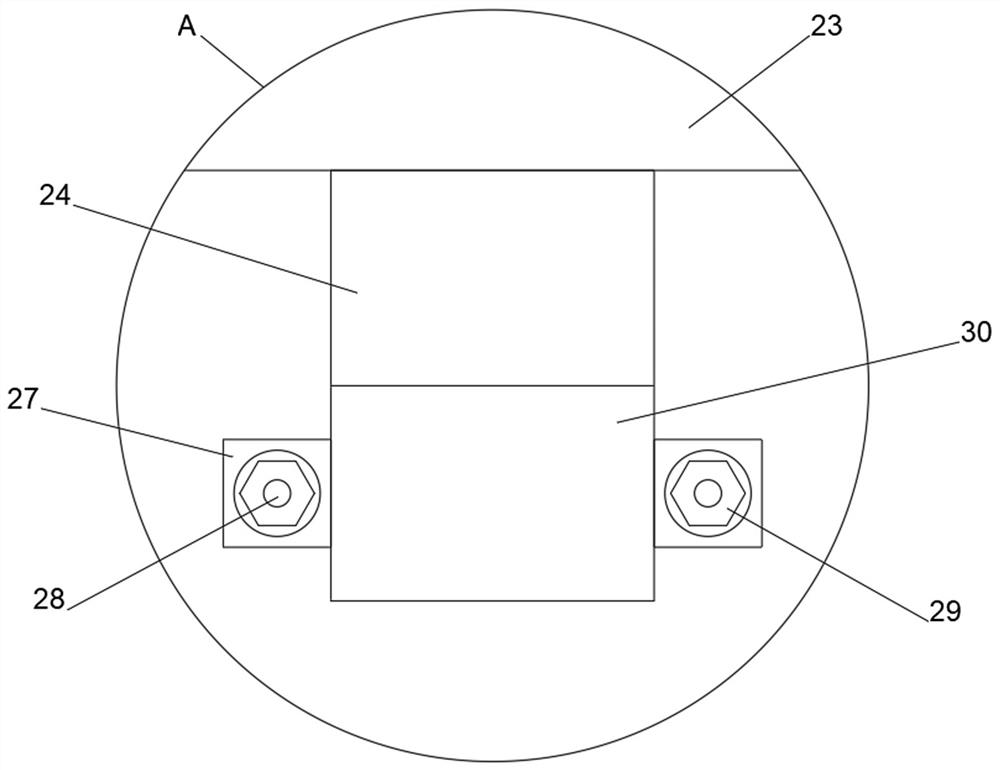

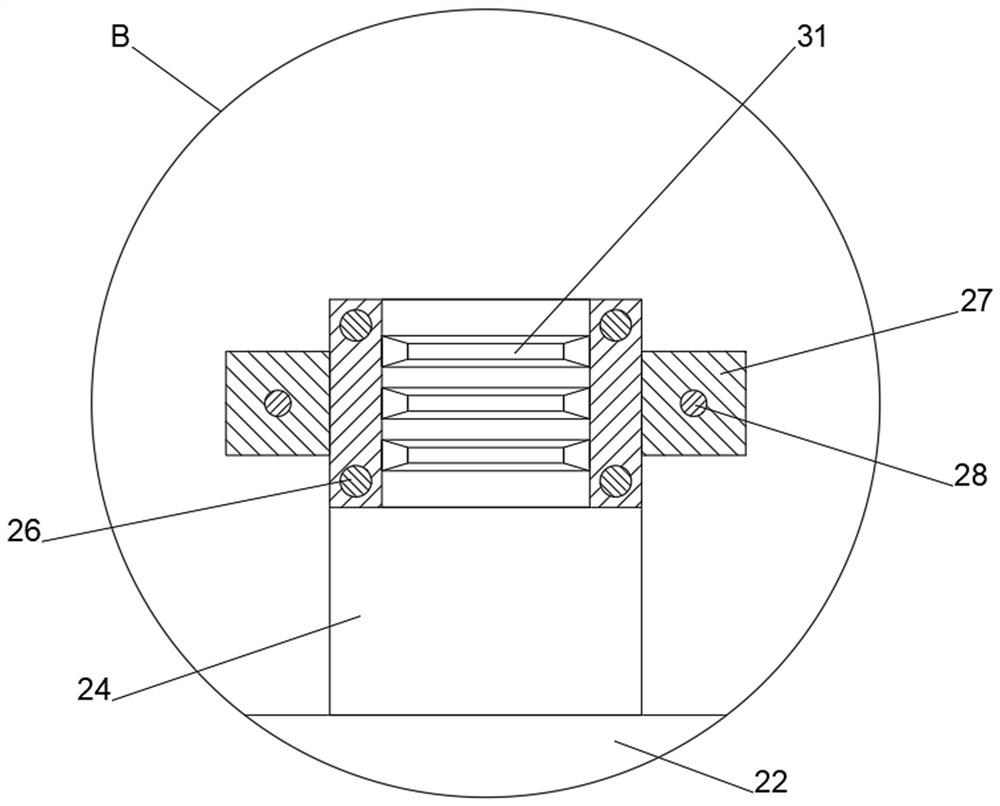

[0038] See Figure 1-8One embodiment of the present invention is: a wire performance quality detection system, including machine tool 1, a number of control panels 2, a station plate 13, a cantilever 14, a stretch plate 17, a connecting groove 18, a connection screw hole 20, a limit The hole 25, the ear plate 27 and the visual camera 32, the bottom end of the upper side of the machine 1 is configured with visual cameras 32, and the two sides of the front side of the machine tool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com