Automobile valve tappet surface runout detection device

A detection device and runout technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems of poor result accuracy, slow detection speed, low work efficiency, etc., and achieve high work efficiency, high accuracy, The effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

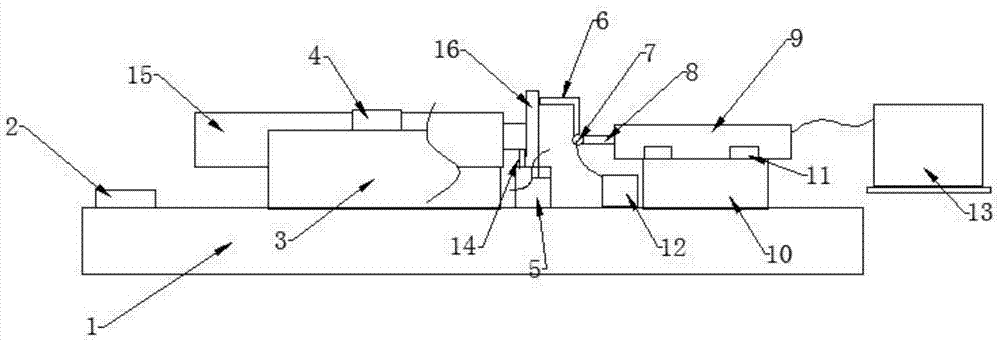

[0017] Such as figure 1 As shown, a kind of detection device of the runout amount of the end face of the automobile valve lifter of the present invention comprises a base 1, a leveler 2, a V-shaped iron 3, a fixing clip 4, a U-shaped iron 5, a detection probe 6, a rotating shaft 7, a connecting Rod 8, dial indicator 9, detection platform 10, fastening clip 11, motor 12, numerical control instrument 13, positioning plate 14, valve tappet 15, end face 16.

[0018] The left end of the base 1 is provided with a leveler 2 for ensuring the level of the base 1 .

[0019] The right side of the leveler 2 is provided with a V-shaped iron 3 for placing the main body of the valve tappet 15, the V-shaped iron 3 is provided with a fixing clip 4, and the right side of the V-shaped iron 3 is provided with a U-shaped iron 5 for placing the end face 16, A positioning plate 14 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com