Cylindrical object verticality noncontact detection device and method

A non-contact detection device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems that manual detection methods are incompetent, and achieve the effects of adjustable parameters, simple operation, simple and direct calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

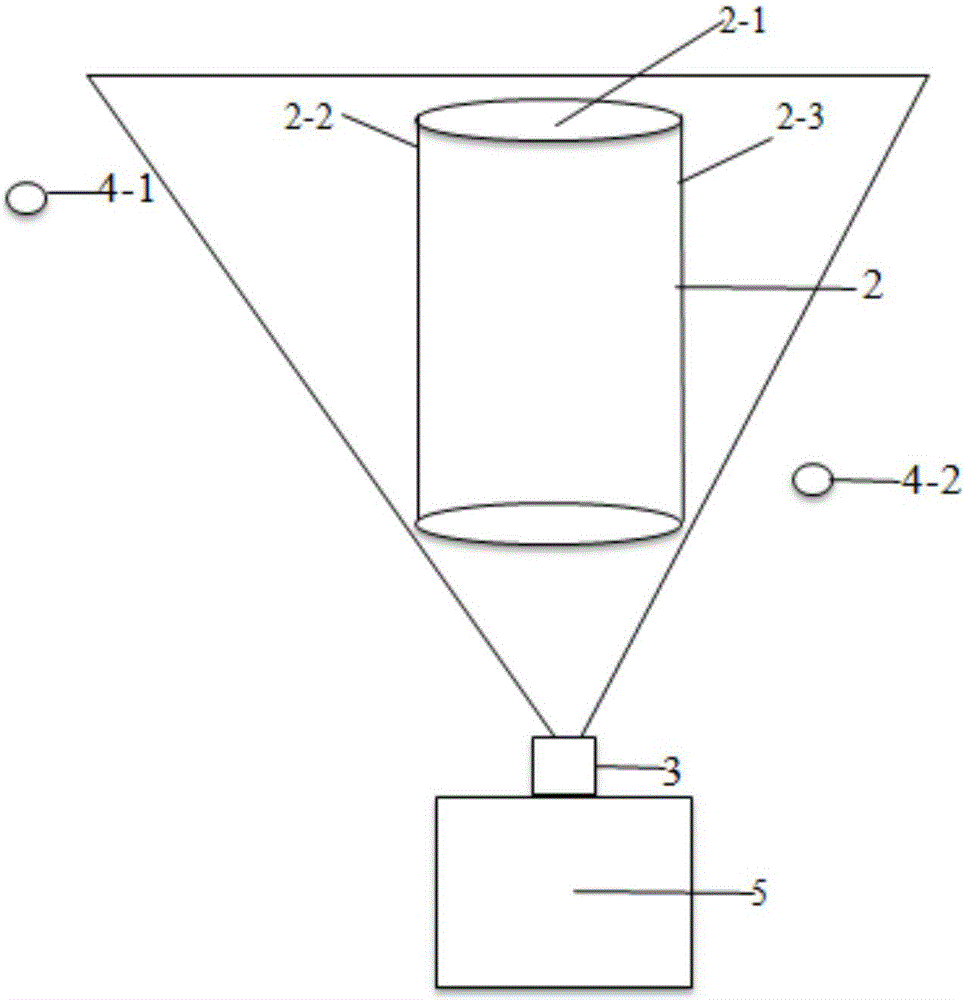

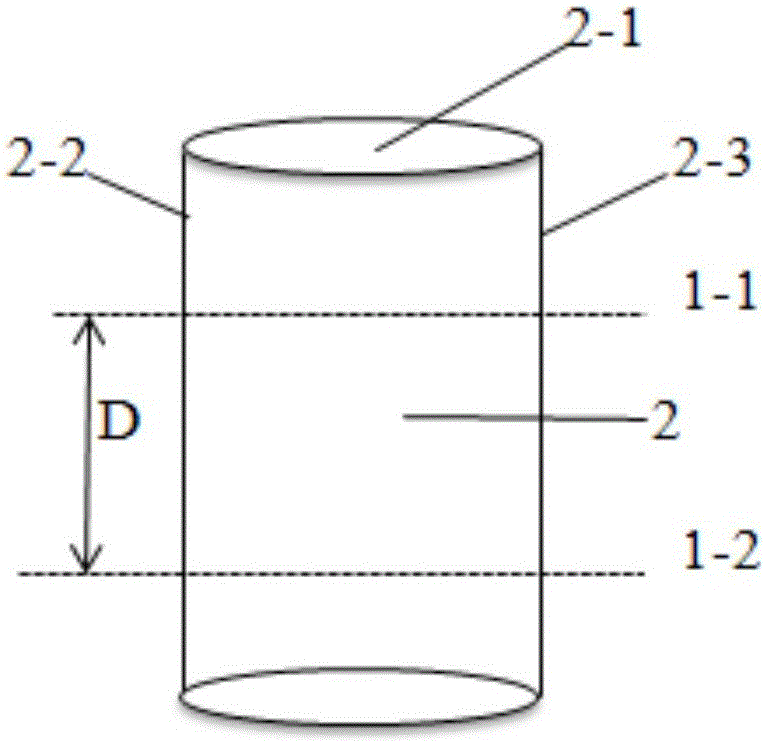

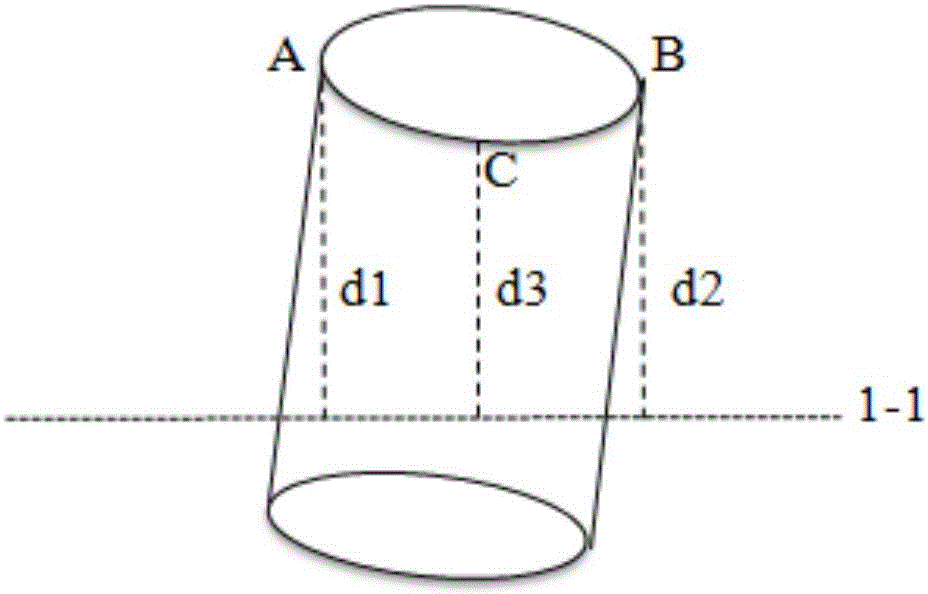

[0028] Aiming at the needs of industrial testing, a device is designed to realize real-time verticality testing of cylindrical metal parts and guide the installation. The detection requirements include: the height of cylindrical metal parts is 1000~2300mm, the diameter of cylindrical metal parts is 350~1200mm, and the detection accuracy is 0.05°~0.1°. Design parameters such as figure 2 Middle D = 800mm, camera field of view θ = 60°, and the actual engineering measurement accuracy is 0.05°, which meets the design requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com