Equipment suitable for detecting compressive strength of glass fiber plate

A compressive strength, glass fiber board technology, applied in the field of equipment for glass fiber board compressive strength testing, can solve the problems of glass fiber board crushing, wasting cost, wasting time, etc., to prevent displacement, not easily damaged, and prevent rupture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

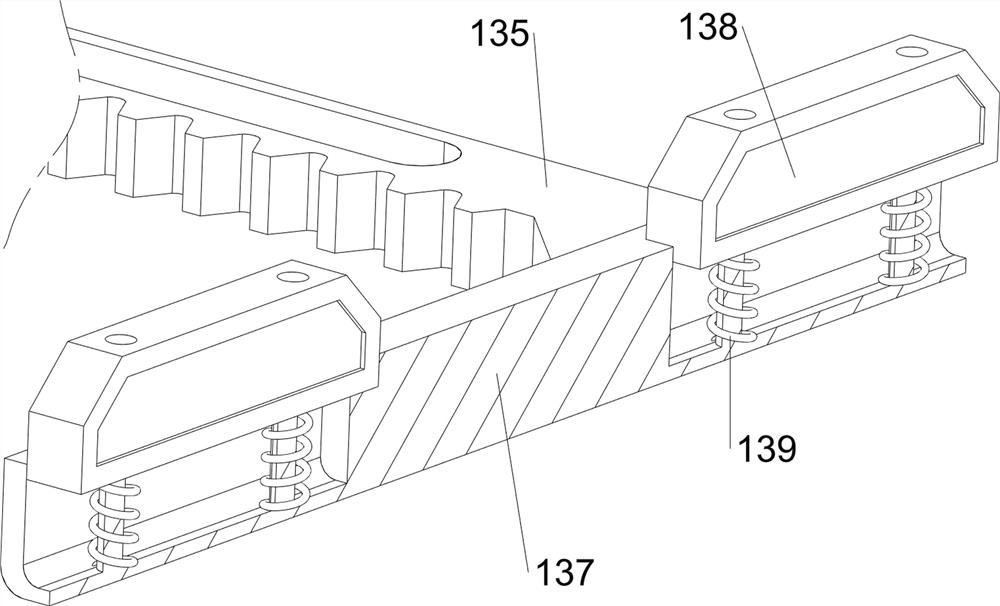

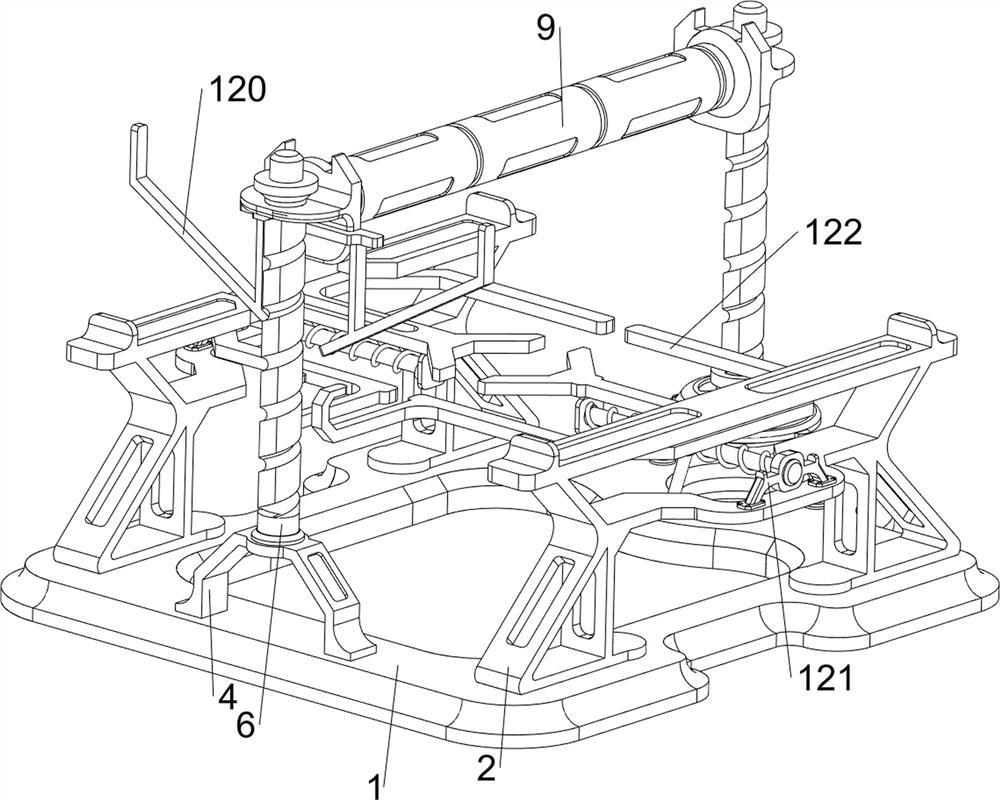

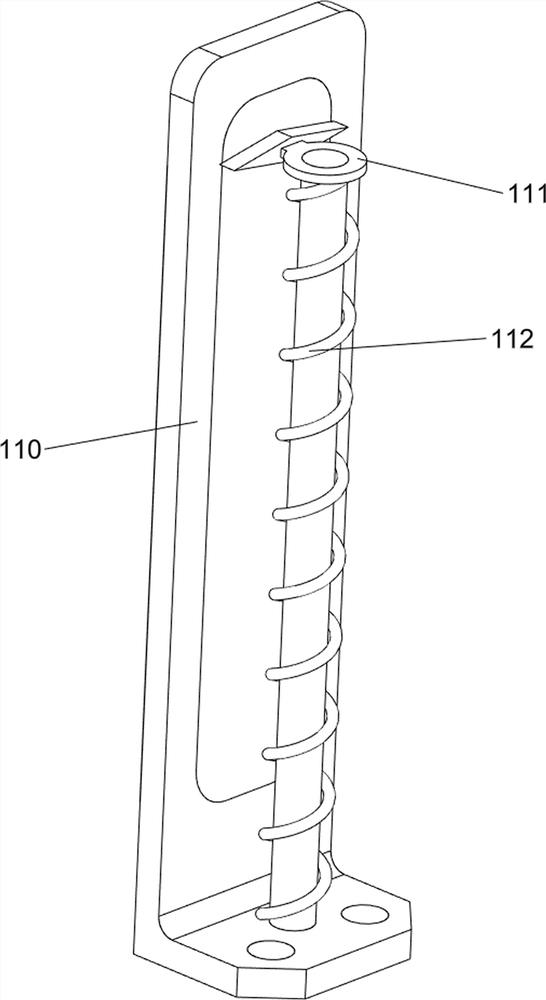

[0037] A device suitable for testing the compressive strength of glass fiber boards, such as Figure 1-6As shown, it includes a bottom plate 1, a storage frame 2, a first support frame 3, a motor 5, a first support block 4, a screw rod 6, a pulley 7, a flat belt 8, a lifting block 9, a prompt mechanism 10 and a detection mechanism 11 The top of the bottom plate 1 is symmetrically provided with a bearing frame 2 front and back, the right side of the top of the bottom plate 1 is provided with a first support frame 3, the left side of the top of the bottom plate 1 is provided with a first support block 4, and the top of the first support frame 3 is provided with a motor 5, The output shaft of the motor 5 is provided with a screw rod 6, and the top of the first support block 4 is also provided with a screw rod 6, and the top of the two screw rods 6 is provided with a pulley 7, and a flat belt 8 is set between the two pulleys 7. A lifting block 9 is connected between the upper part...

Embodiment 2

[0044] On the basis of Example 1, such as figure 1 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 and Figure 15 As shown, load-bearing mechanism 12 is also included, and load-bearing mechanism 12 includes special-shaped rod 120, the third support block 121, load-bearing plate 122 and compression spring 123, and lifting block 9 left sides are provided with special-shaped rod 120 symmetrically front and back, two bearings A third support block 121 is provided in the middle of the rack 2, and a load-bearing plate 122 is slidably arranged on the two third support blocks 121. A compression spring 123 is connected between the blocks 121 .

[0045] When people need to detect the compressive strength of the fiberglass board, the lifting block 9 moves downward to drive the special-shaped rod 120 to move downward, so that the special-shaped rod 120 contacts the load-bearing plate 122, drives the load-bearing plate 122 to mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com