Multifunctional lithium-sulfur battery diaphragm as well as preparation method and application thereof

A lithium-sulfur battery, multi-functional technology, applied in battery pack parts, circuits, electrical components and other directions, can solve the problems of affecting the performance of battery separators, adverse coating uniformity, not very ideal, etc., to improve cycle safety, Achieve mass production and reduce wastage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention also discloses a preparation method of a multifunctional lithium-sulfur battery diaphragm, which includes the following steps:

[0036] S1: Prepare the main material aqueous solution with a concentration of 2.0mg / ml~6.0mg / ml and the graphene oxide aqueous solution with a concentration of 2.0mg / ml~11.5mg / ml respectively, filter the main material aqueous solution into a slurry, and mix with the graphene oxide aqueous solution Mixing, using auxiliary methods such as manual grinding, magnetic stirring or homogenizer to mix the two evenly to obtain a stable and dispersed functional slurry; the content of graphene oxide is 20wt.% ~ 60wt.%; the content of the main material is 40wt. .%~80wt.%, the sum of the content of graphene oxide and the content of the host material is 100%.

[0037] S2: Use a 30-90-micron thick doctor blade to evenly coat the functional slurry in step S1 on the surface of the basic diaphragm, and dry it for 6-10 hours at a temperature of 60°C-8...

Embodiment 1

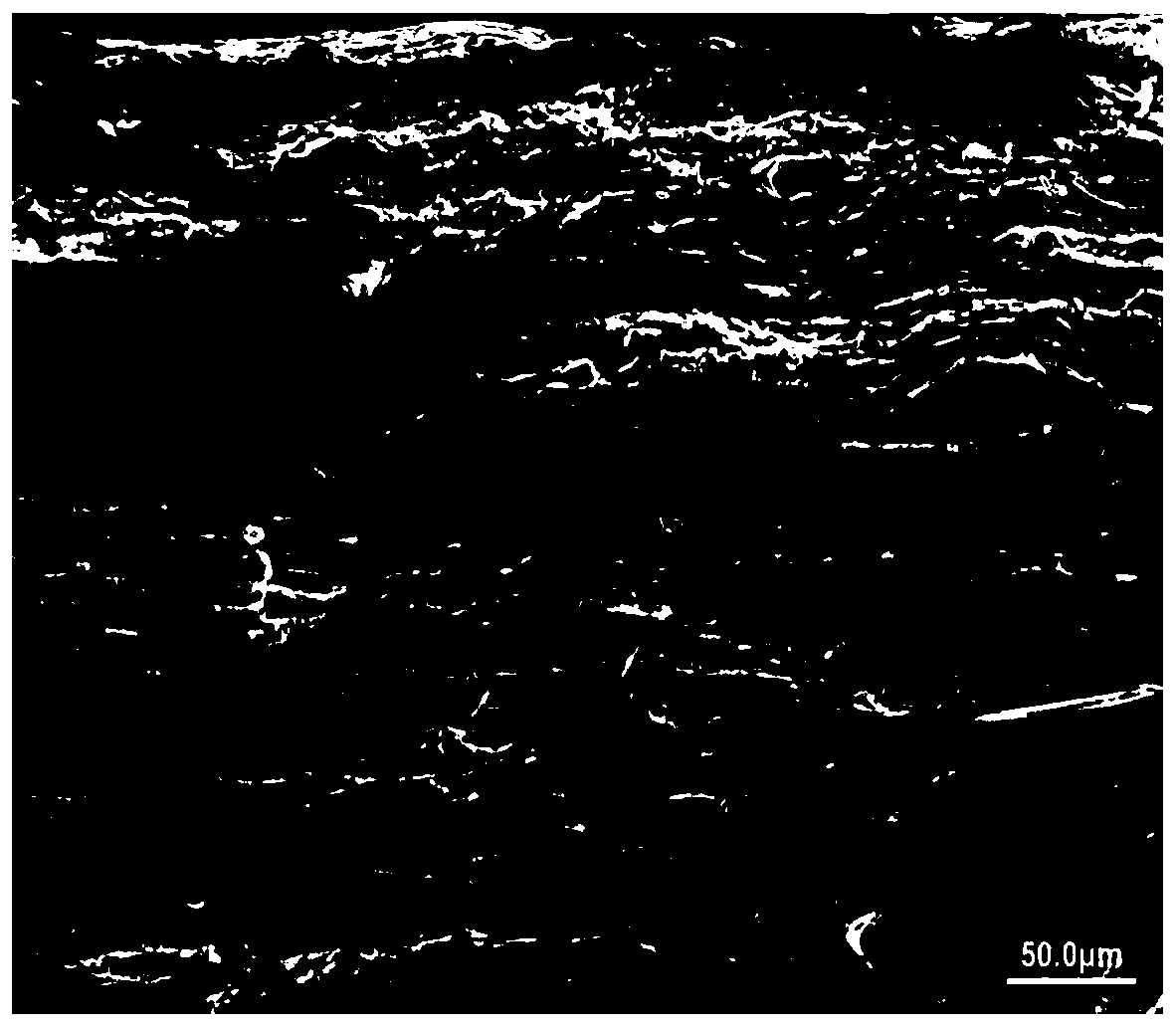

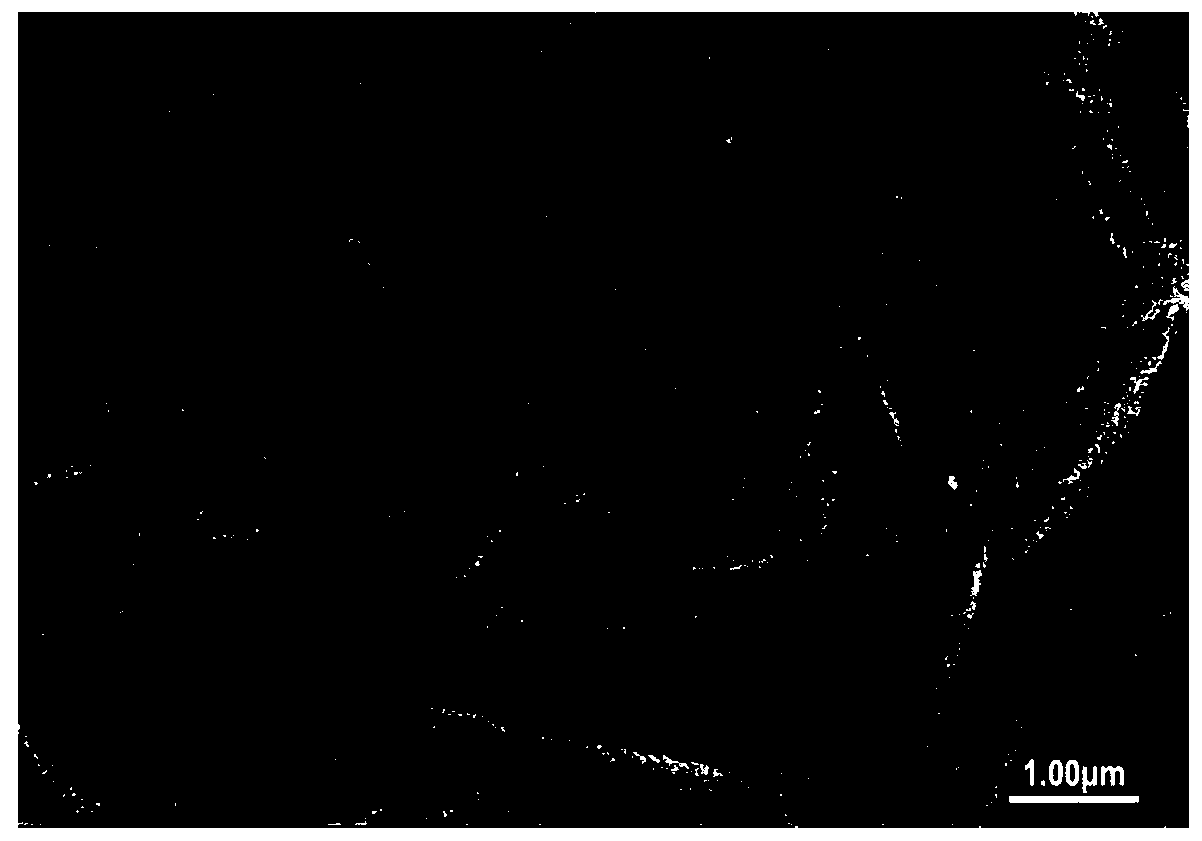

[0050] A multifunctional lithium-sulfur battery separator, specifically, graphene oxide is used as an inductive material, and the concentration is controlled in the range where it has strong liquid crystallinity; another 2D nanomaterial, boron nitride nanosheet, is used as the main material, after many times After screening, it is stored in aqueous solution. As an inductive material, graphene oxide mainly plays the role of inducing orientation of liquid crystals, and its content is 60wt.%. Another nano-sheet material, boron nitride, is used as the main material, and its content is controlled at 40wt.%. The thickness of the functional coating is 5 microns. The base diaphragm was a commercial diaphragm polyethylene diaphragm (JSM-16).

[0051] The specific preparation method is:

[0052] (1) Weigh 9.7935g of boron nitride nanosheet aqueous solution (the solute mass is 0.0391g), and vacuum filter until the filter membrane only contains a small amount of solvent and the boron ni...

Embodiment 2

[0056] A multifunctional lithium-sulfur battery separator, specifically, graphene oxide is used as an inductive material, and the concentration is controlled in the range where it has strong liquid crystallinity; another 2D nanomaterial, boron nitride nanosheet, is used as the main material, after many times After screening, it is stored in aqueous solution. Graphene oxide, as an inductive material, mainly plays the role of inducing orientation of liquid crystals, and its content is 40wt.%. Another nanosheet material, boron nitride, is used as the main material, and its content is controlled at 60wt.%. The thickness of the functional coating is 5 microns. The base diaphragm was a commercial diaphragm polyethylene diaphragm (JSM-16).

[0057] The specific preparation method is:

[0058] (1) Weigh 35.4283g of an aqueous solution of boron nitride nanosheets (the solute mass is 0.2183g), and vacuum filter until the filter membrane only contains a small amount of solvent and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com