Ultrasonic sensor, piezoelectric composite ceramic chip and preparation method of blank of piezoelectric composite ceramic chip

A piezoelectric ceramic sheet, piezoelectric composite technology, applied in the field of sensors, can solve the problems of composite materials that cannot thin piezoelectric phase, complex process, large mechanical impact, etc., and achieve the effects of low cost, simple process and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

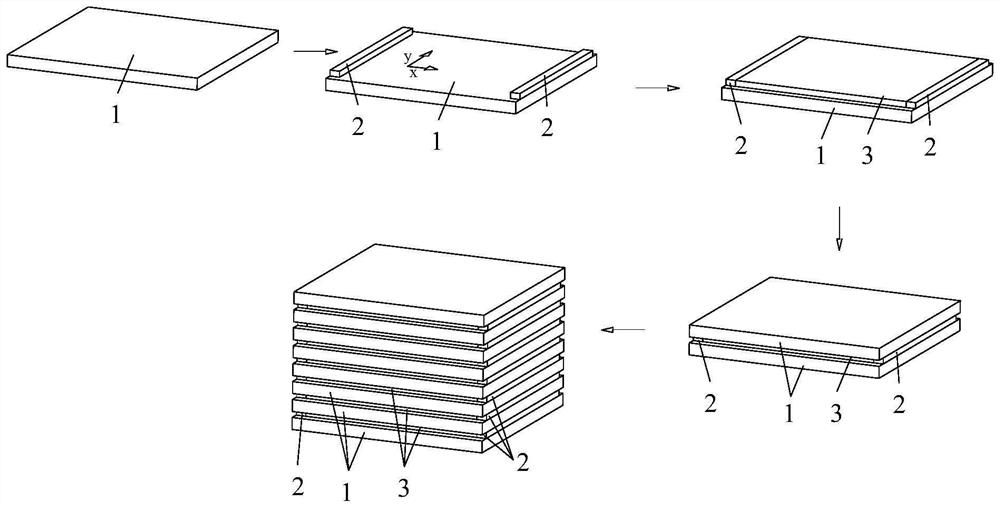

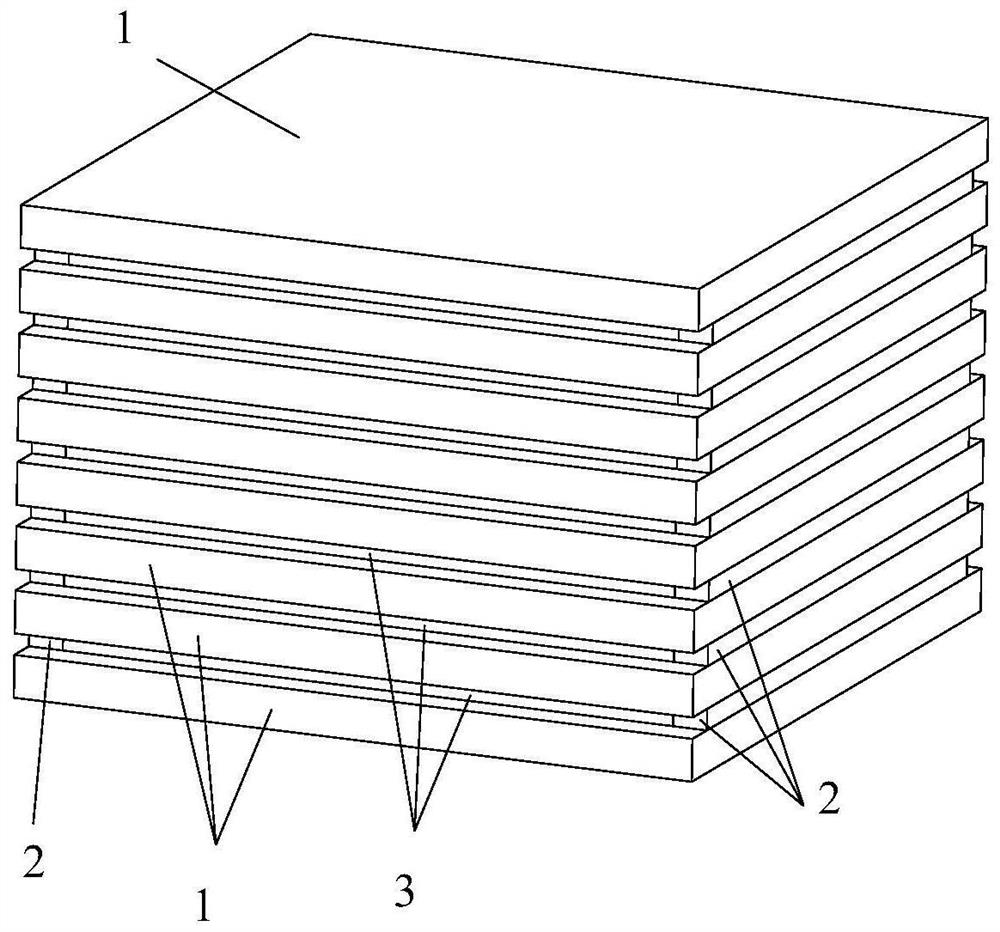

[0059] Such as figure 1 and 2 As shown, the preparation method of a piezoelectric composite ceramic sheet blank described in this embodiment comprises the following steps:

[0060] S1. Two spacers 2 are arranged on one side of the piezoelectric ceramic sheet 1, and the two spacers 2 are arranged at intervals;

[0061] S2. filling the area between the two spacers 2 with a polymer to form a polymer phase 3, and the polymer phase 3 is flush with the top of the spacer 2;

[0062] S3. Paste another piezoelectric ceramic sheet 1 on the top of the polymer phase 3, and the spacer 2 is located between corresponding two adjacent piezoelectric ceramic sheets 1;

[0063] S4. Repeating S1 to S3, stacking the piezoelectric ceramic sheets 1 layer by layer to form a piezoelectric composite ceramic sheet blank.

[0064] The preparation method of a piezoelectric composite ceramic sheet blank described in this application is based on piezoelectric ceramic sheets 1, by setting spacers 2 betwee...

Embodiment 2

[0071] Such as Figure 1-4 As shown, the preparation method of a piezoelectric composite ceramic sheet described in this embodiment comprises the following steps:

[0072] A1. The piezoelectric composite ceramic sheet blank is made based on the preparation method of the piezoelectric composite ceramic sheet blank described in Example 1;

[0073] A2: reducing the air bubbles in the piezoelectric composite ceramic sheet blank, and solidifying the polymer;

[0074] A3: cutting the piezoelectric composite ceramic sheet blank solidified in step A2 to form a piezoelectric composite ceramic sheet.

[0075] Specifically, vacuuming is used to reduce air bubbles in the piezoelectric composite ceramic sheet blank.

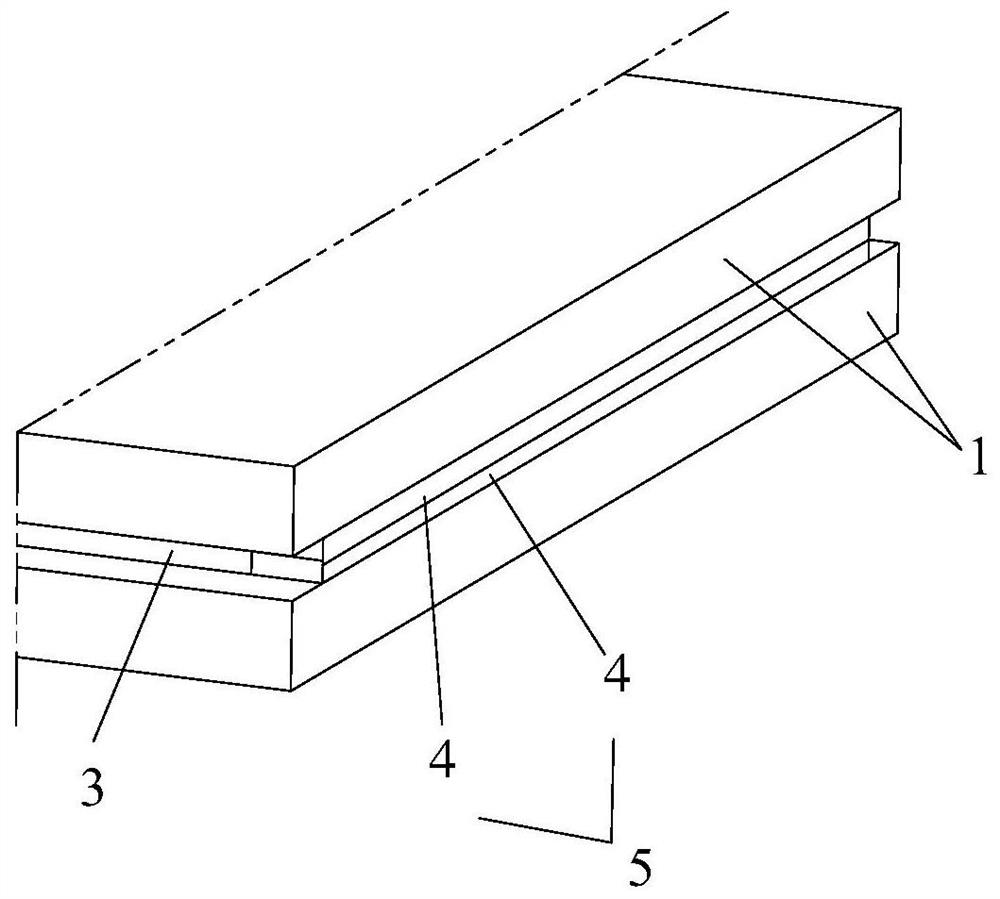

[0076] Such as Figure 4 As shown, on the basis of the above, in a further preferred manner, when the piezoelectric composite ceramic sheet blank is cut, all the spacers 2 are cut off.

[0077] Beneficial effects of this embodiment: the preparation method of a piezoelectr...

Embodiment 3

[0079] Such as Figure 4 As shown, a preparation method for an ultrasonic sensor described in this embodiment comprises the following steps:

[0080] B1. based on the preparation method of the piezoelectric composite ceramic sheet described in embodiment 2, the piezoelectric composite ceramic sheet is made;

[0081] B2: Electrodes are installed and polarized on the opposite two surfaces of the piezoelectric composite ceramic sheet perpendicular to the polymer phase 3 to form a piezoelectric composite ceramic sheet assembly, wherein one electrode is the first electrode 5 and the other electrode is the first electrode 5 The second electrode 6, the first electrode 5 is a negative pole, and the second electrode 6 is a positive pole;

[0082] B3. draw the first electrode lead 7 on the side of the first electrode 5 away from the piezoelectric composite ceramic sheet, and draw the second electrode lead on the side of the second electrode 6 away from the piezoelectric composite ceram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com