Multi-step printed circuit board differential through hole processing method and printed circuit board thereof

A technology for printed circuit boards and processing methods, applied in the directions of printed circuit manufacturing, printed circuits, printed circuits, etc., can solve the problem of difficult to process multi-level printed circuit boards, etc., achieve flexible control of surface copper thickness, and reduce surface copper. Influence of unevenness, effect of improving process reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The method for processing differentiated through-holes of multi-level printed circuit boards provided by Embodiment 1 of the present invention can be used to process three-level printed circuit boards having three kinds of differentiated through-holes with different hole copper thicknesses.

[0052] In this embodiment, the lamination process can be used to process the laminated board in advance, and the laminated board can include two outer metal layers (that is, the surface copper foil layer, referred to as the surface copper layer) on both sides and at least one inner layer in the middle. Layer circuit layers, and an insulating dielectric layer between the inner circuit layers of each layer, and between the inner circuit layer and the outer metal layer. The method of this embodiment is applicable to circuit boards whose final surface copper thickness is 2 ounces (OZ, 1 OZ is approximately equal to 35 μm) or above 2 OZ.

[0053] In this embodiment, when initially press...

Embodiment 2

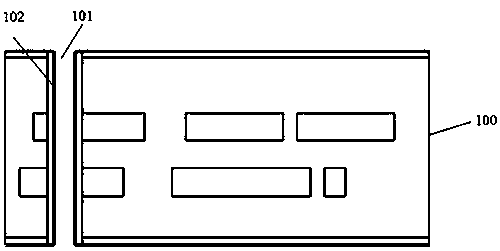

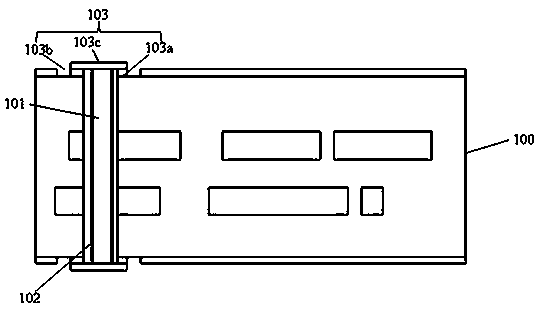

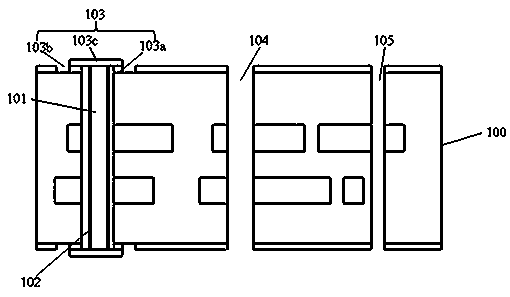

[0083] refer to Figure 9 , the embodiment of the present invention provides a printed circuit board, the initial thickness of the surface copper of the circuit board is F 0 Oz, after the first copper immersion electroplating, surface copper minus copper, second copper immersion electroplating, first electroplating, and third copper immersion electroplating, the surface copper (F) of the laminate is thickened to greater than 2OZ and less than Equal to 3OZ; where F= F 0 +ΔF 1 -ΔF 2 +ΔF 3 +ΔF 4 +ΔF 5 ; The circuit board is provided with three kinds of differentiated through holes: the first large through hole 101, the second middle through hole 104 and the third small through hole 105 along the direction vertical to the board surface; the aperture of the first large through hole 101 is larger than the Describe the aperture of the second middle through hole 104; The aperture of the second middle through hole 104 is greater than the aperture of the third small through hole 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com