LED phase-change heat radiating substrate and preparation method thereof

A heat-dissipating substrate and phase change technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing luminous efficiency, small heat dissipation space, affecting service life, etc., to achieve excellent heat transfer performance, ensure heat dissipation performance, and ensure stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing an LED phase-change heat dissipation substrate, comprising the steps of:

[0048] (1) Preparation of plates: Firstly, use a punching machine to punch the copper sheet according to the shape of the mold of the required upper cover plate 1 and lower cover plate 3 and cut out the upper cover plate 1 and lower cover plate 3, then place the upper cover plate Put 1 and lower cover 3 into 10 times diluted HF-223 metal cleaner for ultrasonic cleaning for 5 minutes to remove surface oil and edge burrs, and finally rinse with clean water to remove residual cleaning on the surface of upper cover 1 and lower cover 3 liquid to obtain upper cover plate 1 and lower cover plate 3;

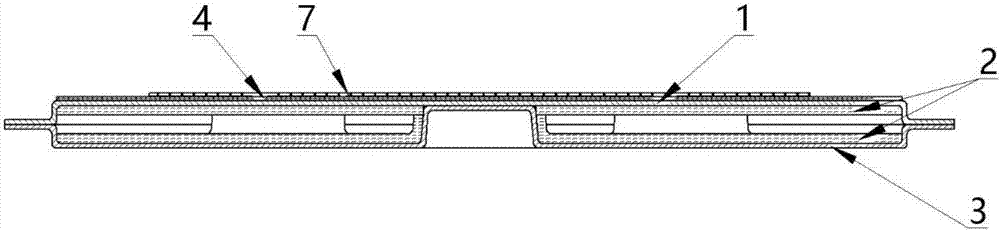

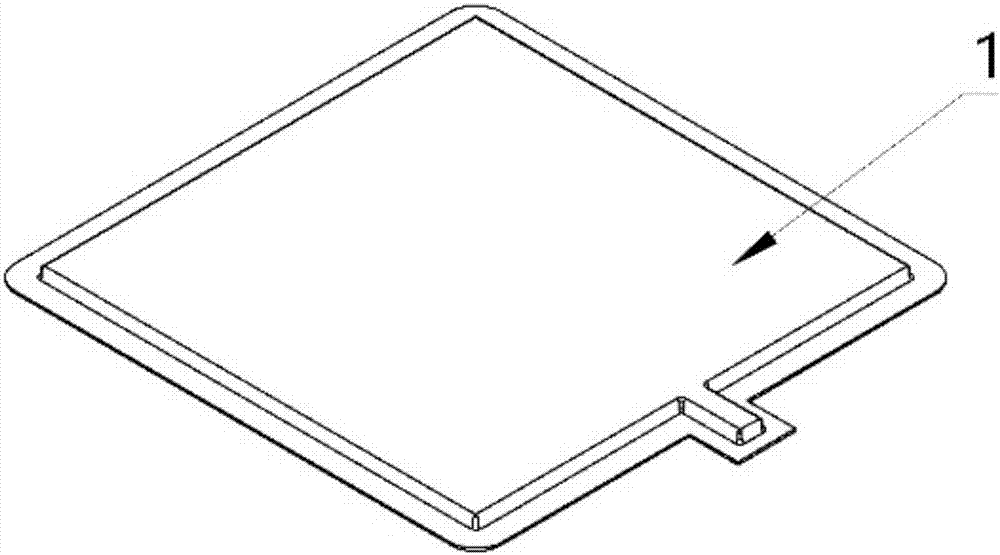

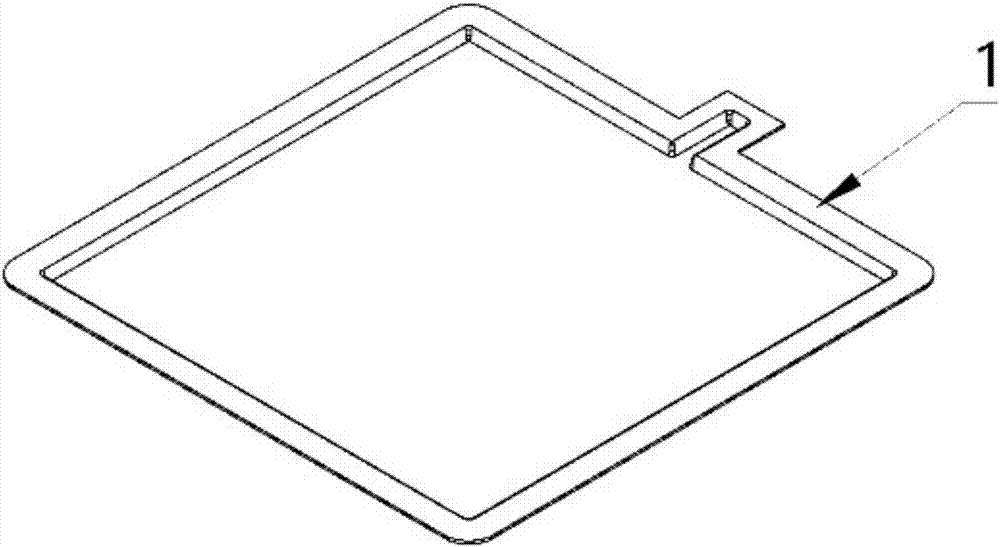

[0049] The axonometric view of the outer surface and the axonometric view of the inner surface of the upper cover plate 1 are respectively as follows figure 2 and image 3 Shown; The outer side axonometric view and the inner side axonal view of the lower cover plate 3 are respectiv...

Embodiment 2

[0055] A method for preparing an LED phase-change heat dissipation substrate, comprising the steps of:

[0056] (1) Preparation of plates: Firstly, use a punching machine to punch the copper sheet according to the shape of the mold of the required upper cover plate 1 and lower cover plate 3 and cut out the upper cover plate 1 and lower cover plate 3, then place the upper cover plate Put 1 and lower cover 3 into 10 times diluted HF-223 cleaning solution for ultrasonic cleaning for 7 minutes to remove surface oil and edge burrs, and finally rinse with clean water to remove residual cleaning solution on the surface of upper cover 1 and lower cover 3 , to obtain the upper cover plate 1 and the lower cover plate 3; then apply the insulating material nano-scale zirconia on the outer surface of the upper cover plate to form a layer of insulating adhesive layer 4 with a thickness of 0.02mm, and on the insulating adhesive layer 4 The upper cover plate finished product 1 is made on the ...

Embodiment 3

[0061] A method for preparing an LED phase-change heat dissipation substrate, comprising the steps of:

[0062] (1) Preparation of plates: Firstly, use a punching machine to punch the copper sheet according to the shape of the mold of the required upper cover plate 1 and lower cover plate 3 and cut out the upper cover plate 1 and lower cover plate 3, then place the upper cover plate Put 1 and lower cover 3 into 10 times diluted HF-223 cleaning solution for ultrasonic cleaning for 3 minutes to remove surface oil and edge burrs, and finally rinse with clean water to remove residual cleaning solution on the surface of upper cover 1 and lower cover 3 , to obtain the upper cover plate 1 and the lower cover plate 3; then apply the insulating material nano-scale zirconia on the outer surface of the upper cover plate to form a layer of insulating adhesive layer 4 with a thickness of 0.02mm, and on the insulating adhesive layer 4 The upper cover plate finished product 1 is made on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com