A control module and system capable of realizing domino-style automation of photovoltaic modules

A technology for photovoltaic modules and control modules, applied in photovoltaic modules, photovoltaic power generation, electric vehicles, etc., can solve the problems of high cost, hidden safety hazards in roof operations, and reduced use efficiency of roof photovoltaic power generation systems, etc. The effect of improving the efficiency of snow melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

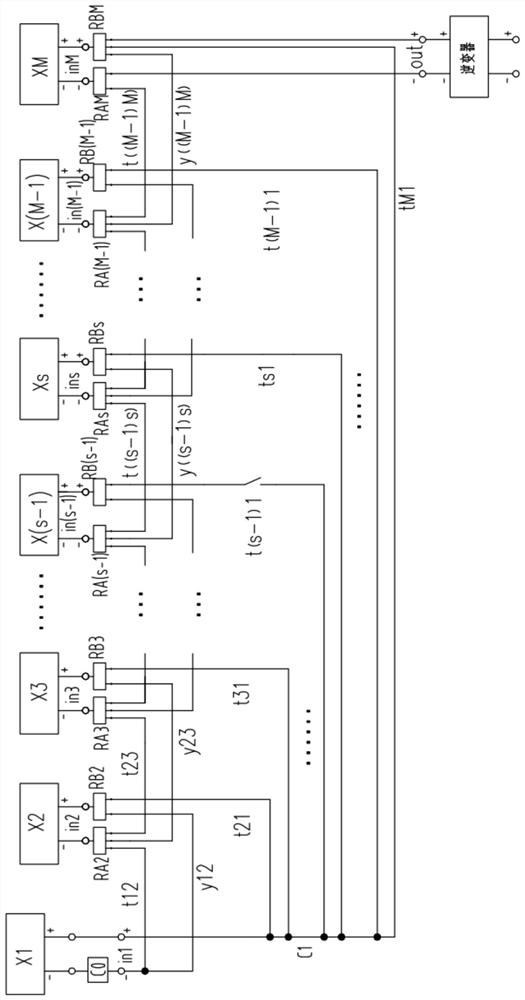

[0053] A photovoltaic power supply control module proposed in this embodiment includes: M photovoltaic interfaces, each photovoltaic interface is used to connect to a photovoltaic module;

[0054] The photovoltaic power supply control module includes at least a first working state and a second working state:

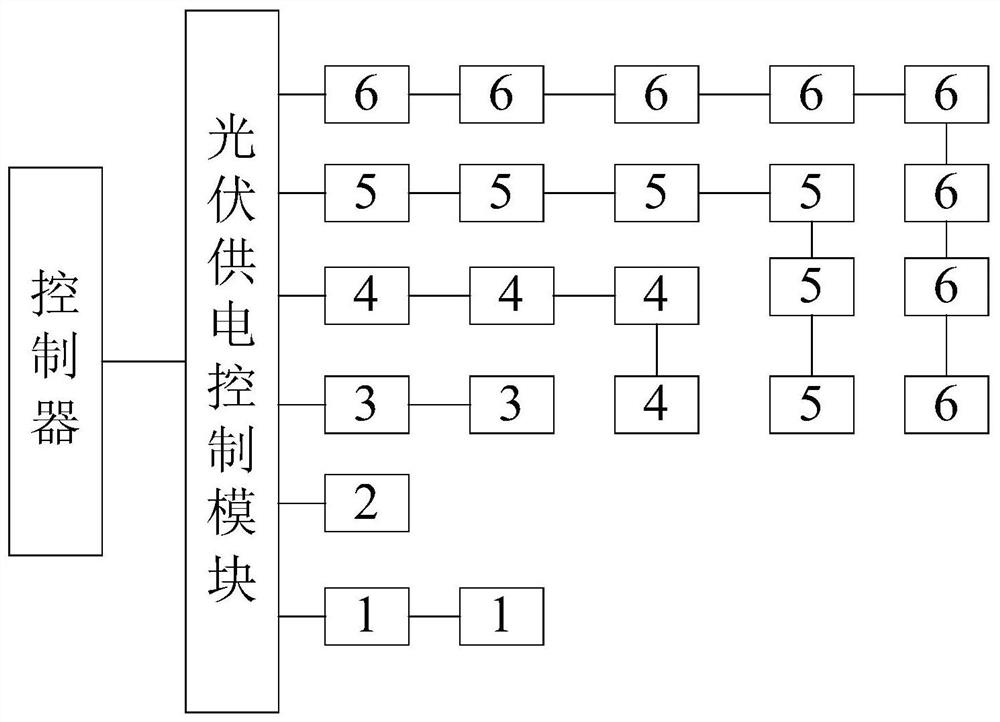

[0055] In the first working state, the photovoltaic modules connected to the first to the Mth photovoltaic interfaces are all in the power supply mode and supply power to the external load;

[0056] In the second working state, when the photovoltaic components connected to the kth photovoltaic interface are in load mode, the photovoltaic components connected to the first to k-1 photovoltaic interfaces are all in power supply mode, and the first to k-1 photovoltaic The photovoltaic module connected to the interface supplies power to the photovoltaic module connected to the kth photovoltaic interface, 2≤k≤M.

[0057] Specifically, in this embodiment, in the second working...

Embodiment 2

[0060] Compared with Embodiment 1, in this embodiment, the photovoltaic power supply control module further includes a power interface for connecting to a power supply. In the second working state, when the photovoltaic component connected to the first photovoltaic interface is in the load mode, the power supply connected to the power supply interface supplies power to the photovoltaic component connected to the first photovoltaic interface. In this way, the automation of the photovoltaic modules connected to the first photovoltaic interface is further guaranteed.

[0061] Specifically, in this embodiment, in the second working state, when the photovoltaic module connected to the kth photovoltaic interface is in the load mode, the power supply connected to the power supply interface, the power supply connected to the first to k-1th photovoltaic interfaces The photovoltaic modules are powered by the photovoltaic modules connected to the kth photovoltaic interface, 2≤k≤M. In th...

Embodiment 3

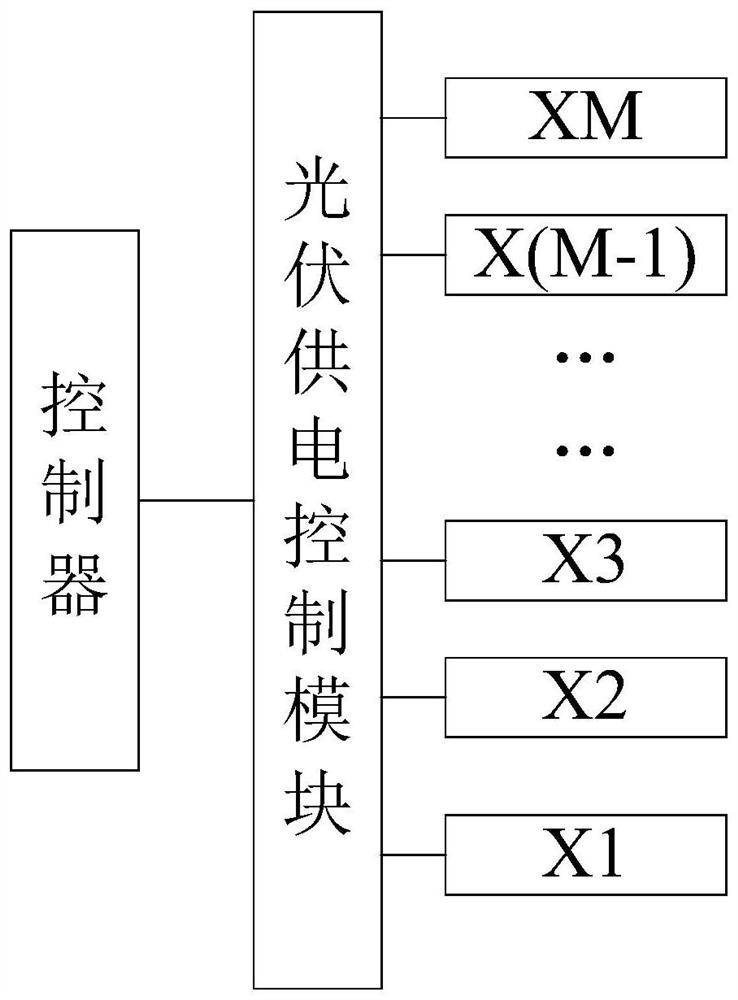

[0064] refer to figure 1 , the present invention proposes a system capable of realizing Domino-style automation of photovoltaic modules, including the photovoltaic power supply control module provided in Embodiment 1, and also includes a controller and M photovoltaic modules.

[0065] The M photovoltaic modules correspond to the M photovoltaic interfaces of the photovoltaic power supply control module, and each photovoltaic interface is connected to the corresponding photovoltaic module, that is, the first photovoltaic interface is connected to the first photovoltaic module X1, and the second photovoltaic interface is connected to the second photovoltaic module X2. By analogy, the Mth photovoltaic interface is connected to the Mth photovoltaic module.

[0066] The controller is connected with the photovoltaic power supply control module, and is used to control the photovoltaic power supply control module to switch the working state, and is used to control the photovoltaic pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com