Thermoelectric refrigeration liquid cooling device

A technology of liquid cooling and thermoelectric refrigeration, which is applied in the direction of electric solid devices, cooling/ventilation/heating transformation, circuits, etc., can solve the problems of difficult chip heat dissipation control limit temperature, lower chip operating temperature, etc., and achieve compact size and high heat exchange efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

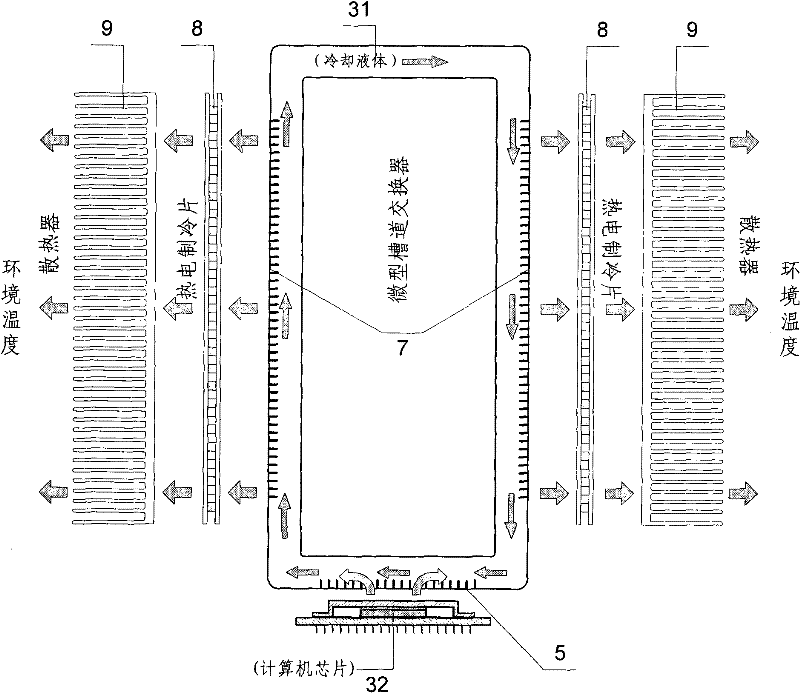

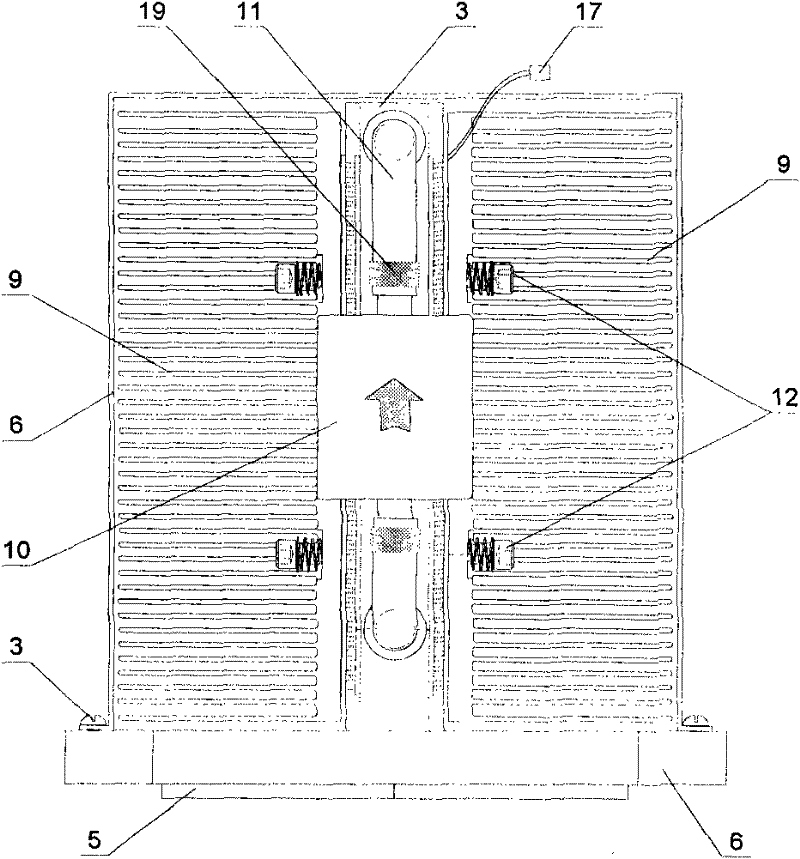

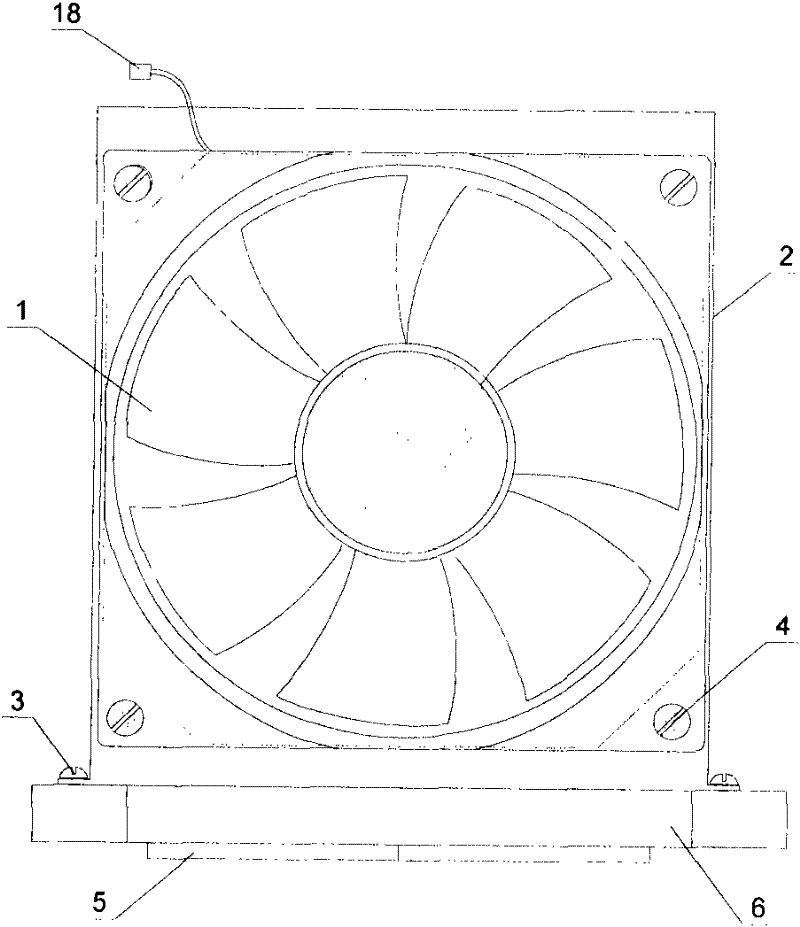

[0040]The thermoelectric refrigeration-liquid electronic cooler of the present invention is mainly composed of seven parts: a fan 1 for air circulation and a fan cover 2; a micro-channel refrigeration exchanger 7, a thermoelectric refrigeration module 8, a radiator 9, a hollow substrate 6 and a micro-channel Cooling plate 5. The fan 1 of the present invention is fixedly installed on the fan cover 2 by the screw 4, the fan 1 has a power cord 18, the screw 3 passes through the hole 15 on the hollow base plate 6 to fix the fan cover 2 on the hollow base plate 6, and the top of the hollow base plate 6 is fixed vertically A micro-channel refrigeration exchanger 7 is installed, and the two sides of the micro-channel refrigeration exchanger 7 are respectively symmetrically provided with a thermoelectric cooling module 8 and a radiator 9, a micro-channel refrigeration exchanger 7, a thermoelectric cooling module 8, and a radiator 9 is placed in the fan cover 2; the thermoelectric refr...

Embodiment 2

[0055] The thermoelectric refrigeration-liquid electronic cooler of the present invention is mainly composed of seven parts: a fan 1 for air circulation and a fan cover 2; a micro-channel refrigeration exchanger 7, a thermoelectric refrigeration module 8, a radiator 9, a hollow substrate 6 and a micro-channel Cooling plate 5. The fan 1 of the present invention is fixedly installed on the fan cover 2 by the screw 4. There is a power cord 18 on the fan 1. The screw 3 passes the hole 15 on the hollow base plate 6 to fix the fan cover 2 on the hollow base plate 6. The top of the hollow base plate 6 is fixedly installed. There is a micro-channel refrigeration exchanger 7, and the two sides of the micro-channel refrigeration exchanger 7 are respectively symmetrically provided with a thermoelectric cooling module 8 and a radiator 9, a micro-channel refrigeration exchanger 7, a thermoelectric cooling module 8, and a radiator 9 Placed in the fan cover 2; the thermoelectric cooling modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com