Cache-on-board (COB) technology-based integrated light emitting diode (LED) packing method

A technology of LED packaging and LED chips, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of uncontrollable shape, position, quantity, and thickness of fluorescent glue, low packaging efficiency, poor product consistency, etc., to simplify LED The effects of integrated packaging procedures, lower product costs, and reduced waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An integrated LED packaging method based on COB technology, comprising the following steps:

[0028] 1) Adjust the thickness of the mold and the diameter of the reserved hole;

[0029] 2) Align the reserved hole on the mold with the LED chip on the aluminum-based circuit board that has been solidified, and cover the mold on the aluminum-based circuit board;

[0030] 3) Baking is performed after applying fluorescent glue, and the mold is removed after baking to obtain an LED packaging unit.

[0031] The mold in step 1 includes a substrate and reserved holes, the substrate is provided with a number of reserved holes, and flanges for positioning and fixing are provided around the back of the substrate.

[0032] The mold in step 1 is prepared from silicone rubber.

[0033] The upper and lower surfaces of the mold in step 1 are polygonal, circular or oval.

[0034] The baking temperature in step 3 is 140-160°C.

Embodiment 2

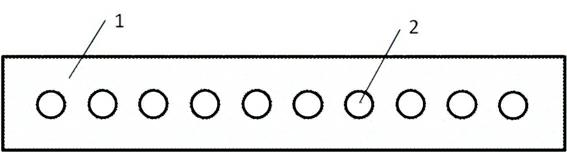

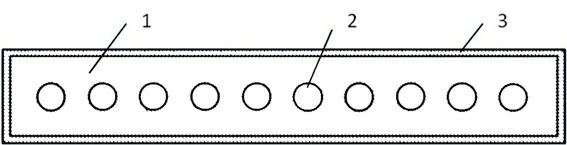

[0036] like figure 1 , 2 , 3, is a kind of dot fluorescent rubber mold, which is made of a silicone rubber plate 1 as a base material, and a flange 3 is processed during molding, and then a reserved hole 2 is processed on it according to the size of the LED package. The shape, position, thickness and quantity of the fluorescent glue can be adjusted by adjusting the thickness of the silicone rubber plate 1 and the diameter of the reserved hole 2, and the height of the flange 3 can be adjusted by the thickness of the aluminum-based circuit board

Embodiment 3

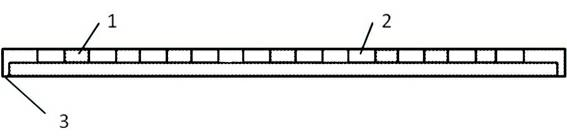

[0038] like Figure 4 As shown, the schematic diagram after direct bonding 5 on the aluminum-based circuit board 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com