Patents

Literature

35results about How to "Control adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

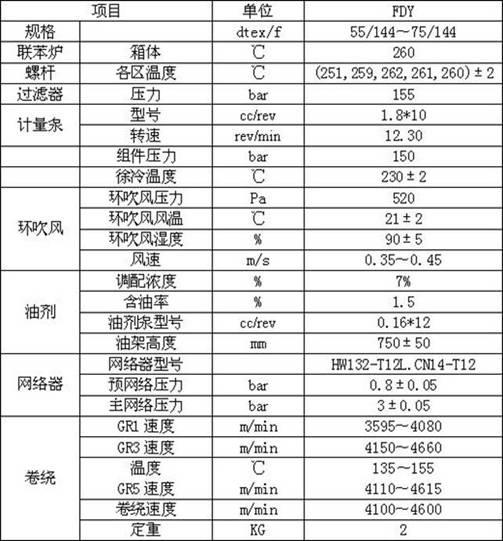

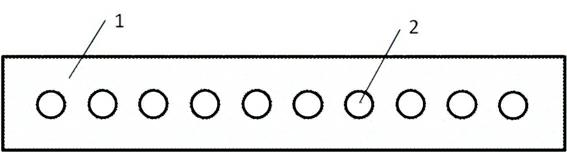

Porous superfine polyamide 6 fully-drawn yarn, preparation method thereof, and equipment thereof

InactiveCN102493016AImprove mixing uniformityImproved pressure stabilityFilament forming substance formingArtificial thread manufacturing machinesYarnAir velocity

The invention relates to a porous superfine polyamide 6 fully-drawn yarn, a preparation method thereof, and equipment thereof. According to the invention, existing FDY production equipment is adopted. A raw material polyamide 6 is sliced and dried; an additive is added on line; the material is subject to screw extrusion and melt extrusion; the material is then cured with a gradually cooling manner and a circular air blow cooling manner; with a reasonably selected spinning temperature of 259-262 DEG C, an air temperature in the circular air blowing process of 19-23 DEG C, a humidity of 85-95%, an air velocity of 0.35-0.45m / s, an oiling and clustering position of 700-800mm, and a winding speed of 4100-4600m / min, the porous superfine polyamide 6 fully-drawn yarn product with a specification of 55dtex / 144f-75dtex / 144f is prepared. Flexible operation is adopted in the preparation method. The preparation method is advantaged in simple technology and low production cost. The product is advantaged in stable performance, good yarn evenness, and good coloration property.

Owner:SUZHOU UNIV

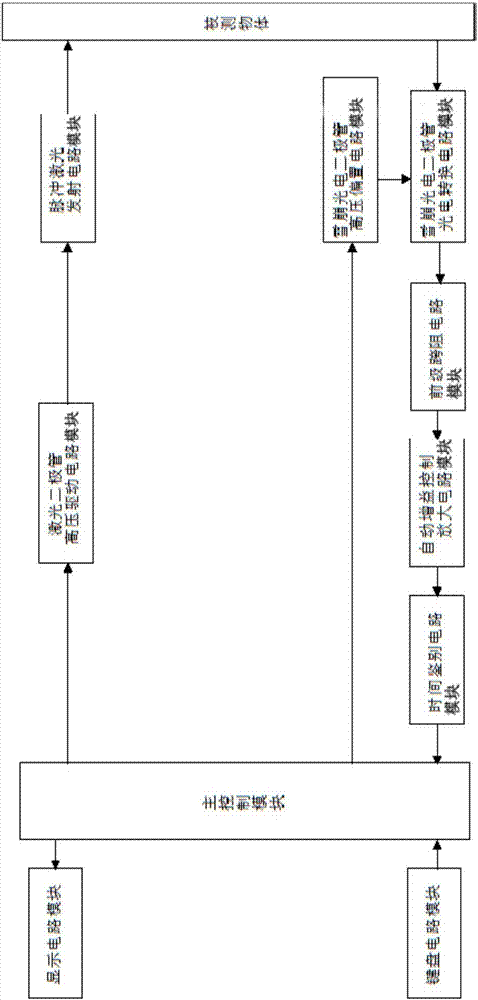

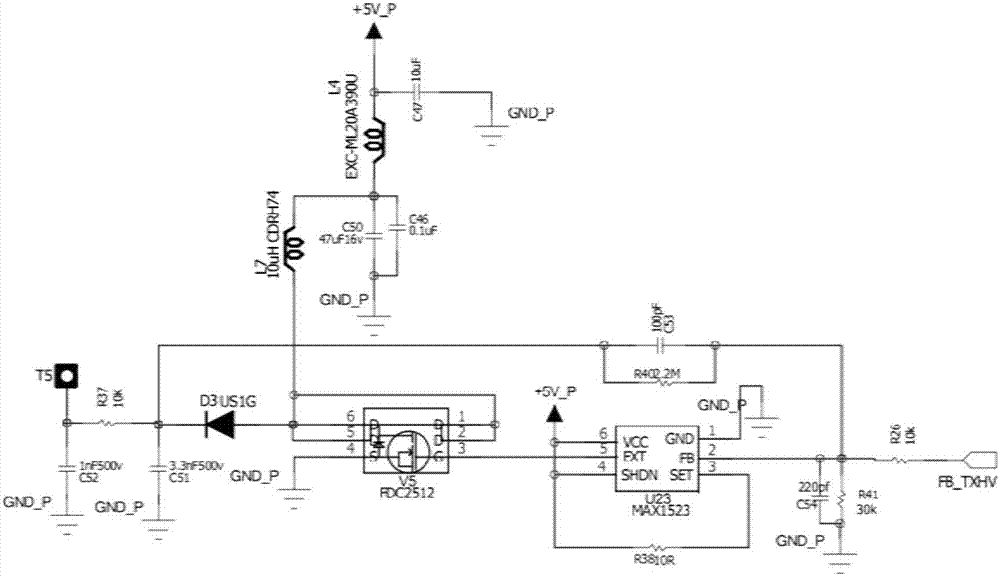

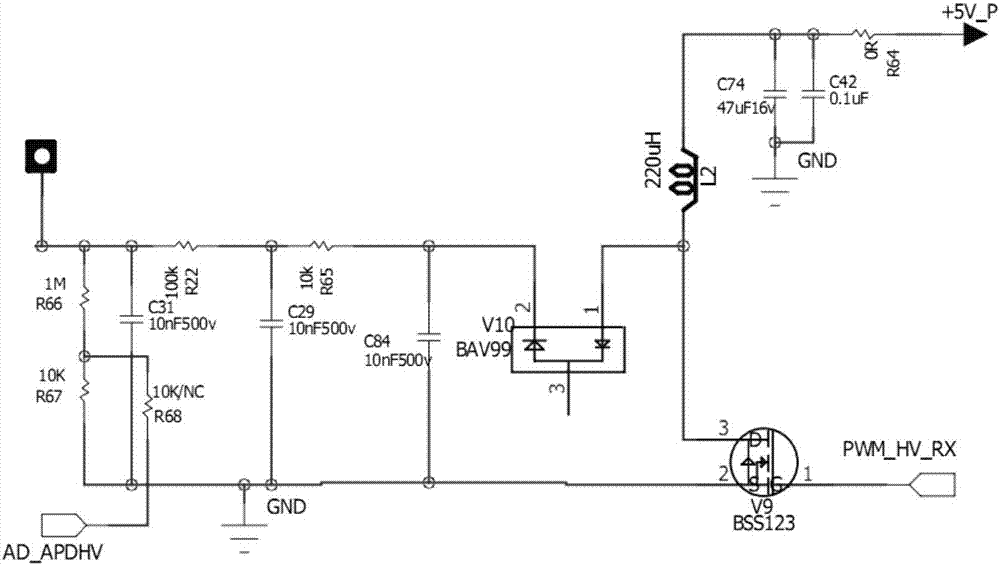

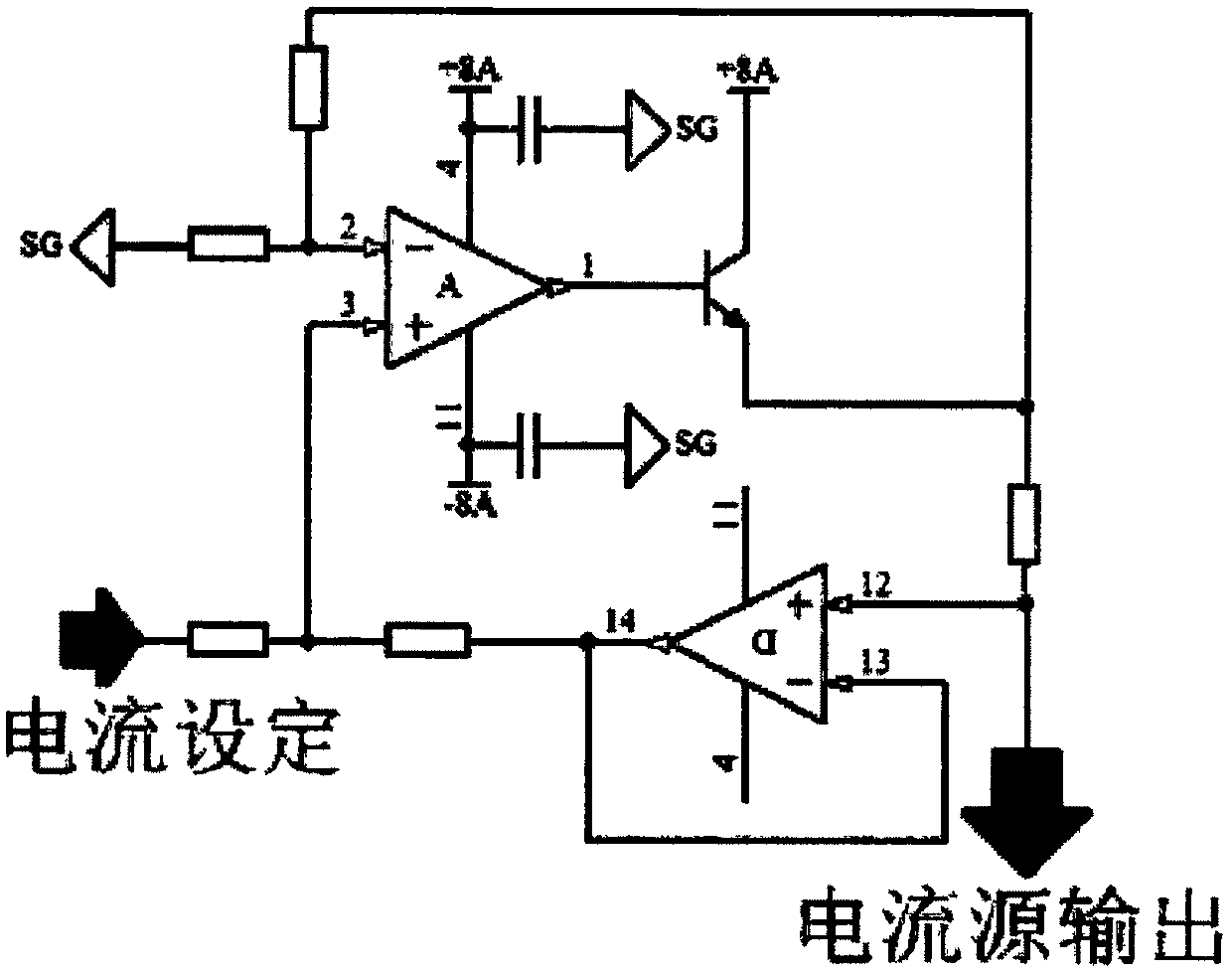

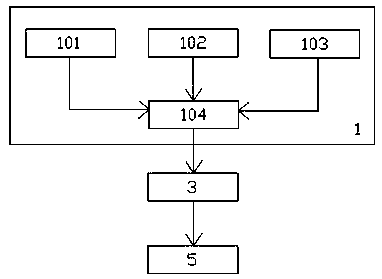

Wide-range high-speed high-precision laser range finding system

ActiveCN106932783AControl adjustmentHigh precisionElectromagnetic wave reradiationLaser rangingElectrical connection

A wide-range high-speed high-precision laser range finding system comprises a main control module, a display circuit module, a keyboard circuit module, a laser diode high-voltage driving circuit module, a pulse laser emission circuit module, an avalanche photodiode photoelectric switching circuit module, a pre-stage trans-impedance circuit module, an automatic gain control amplification circuit and a time discriminating circuit module, wherein the laser diode high-voltage driving circuit module is in electric control connection with the pulse laser emission circuit module and the main control module; the avalanche photodiode photoelectric switching circuit module, the pre-stage trans-impedance circuit module, the automatic gain control amplification circuit and the time discriminating circuit module are in electrical control connection successively and then in electrical connection with the main control module; the avalanche photodiode photoelectric switching circuit is also connected with an avalanche photodiode high voltage bias circuit module; and the avalanche photodiode high voltage bias circuit module is in electrical connection with the main control module.

Owner:SHENZHEN MILESEEY TECH

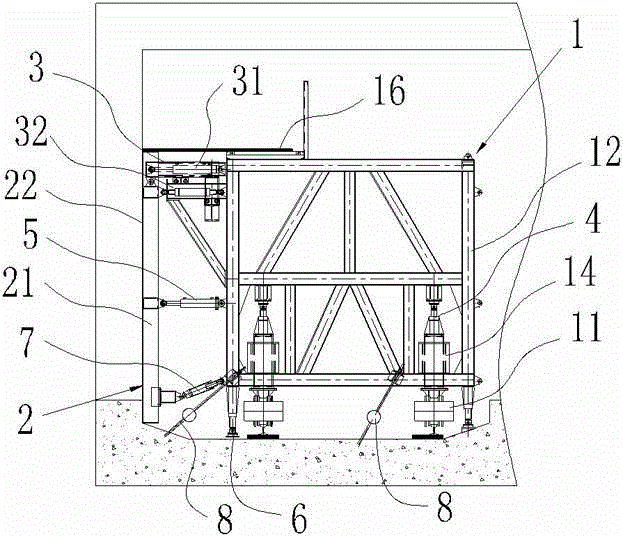

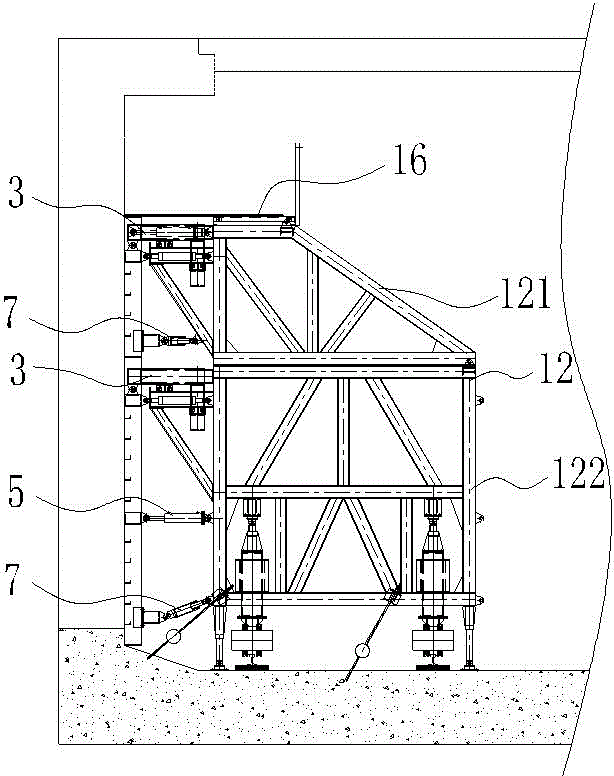

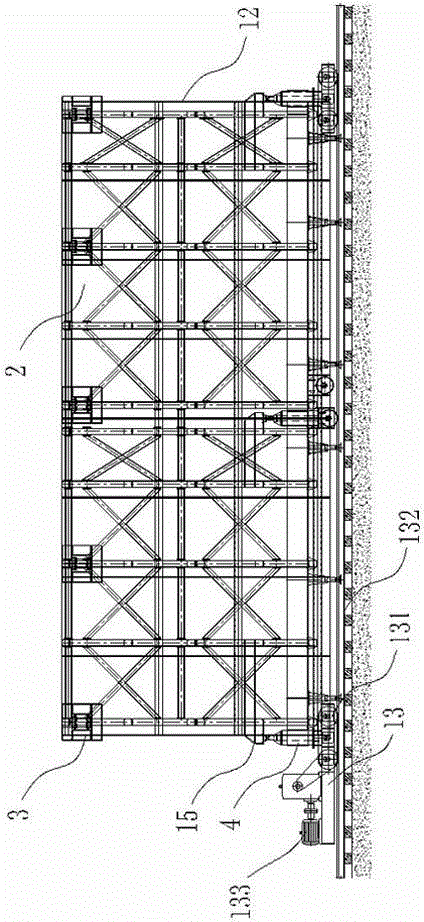

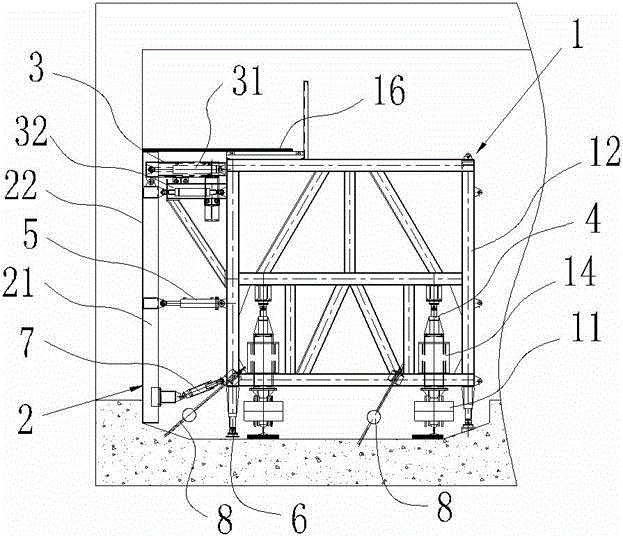

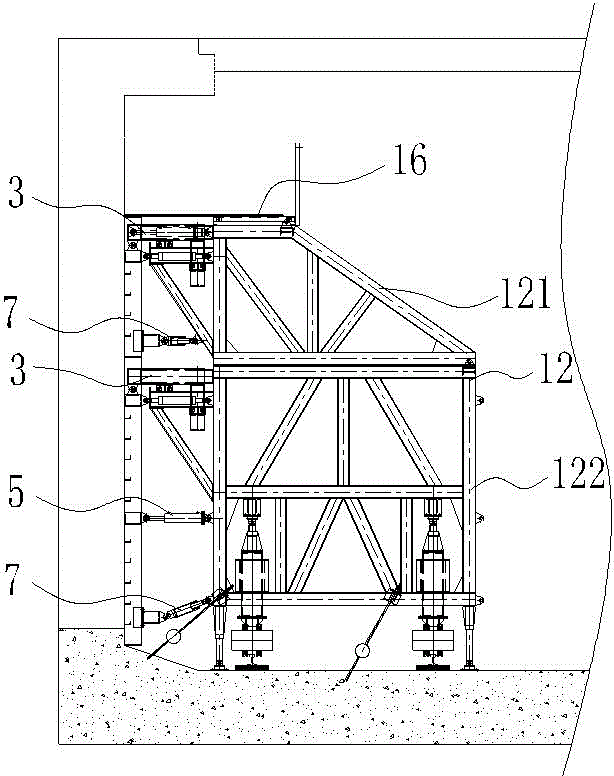

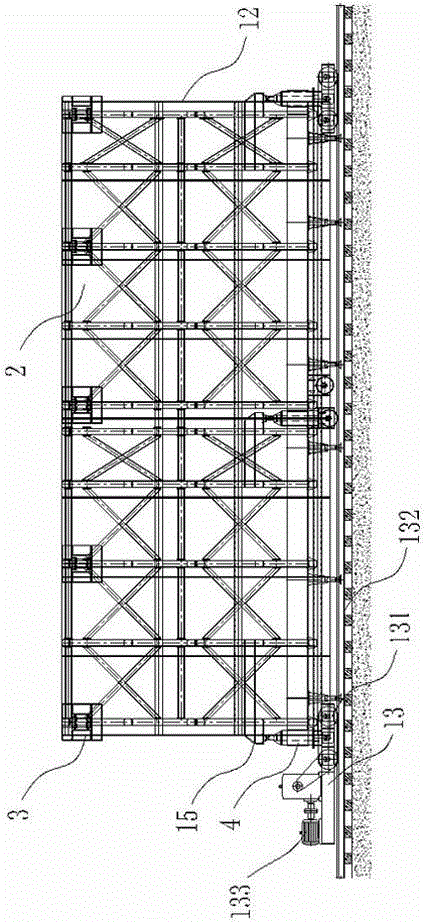

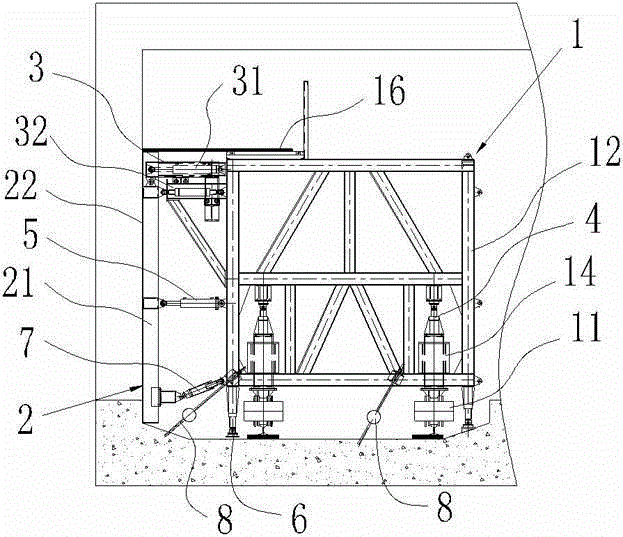

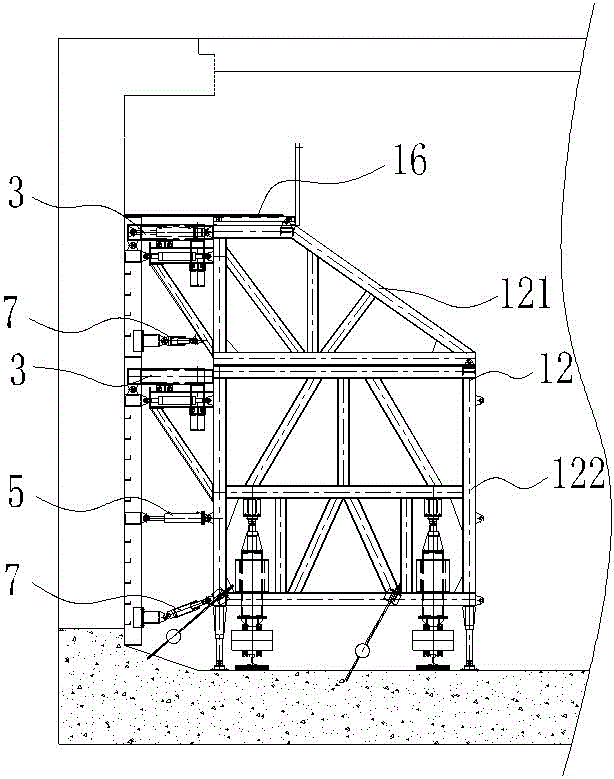

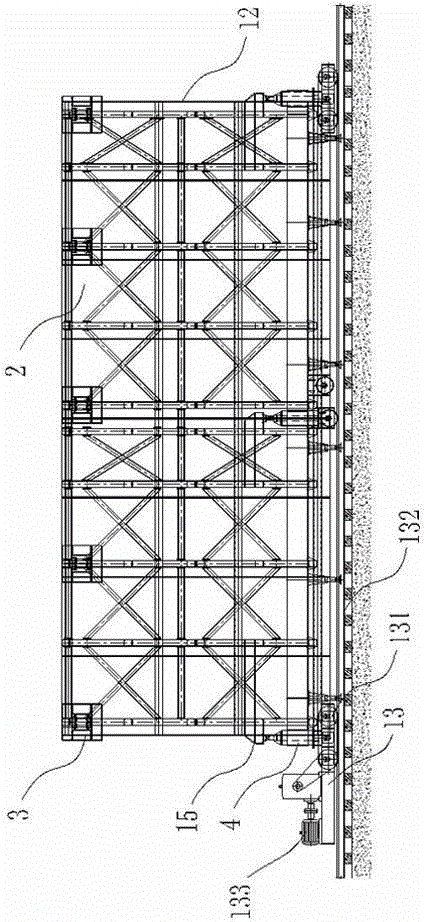

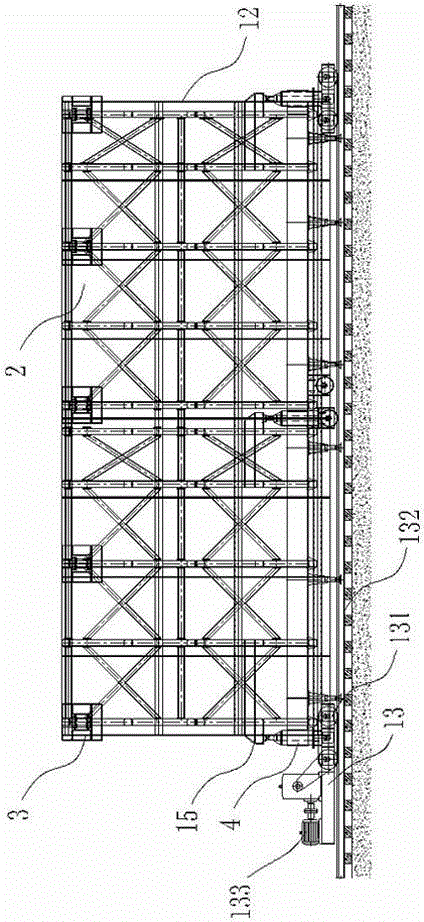

Side wall concrete construction method employing side wall trolley

ActiveCN103556817AImprove problems with heavy burdensImprove stabilityForms/shuttering/falseworksCantilevered beamPipe fitting

The invention discloses a side wall concrete construction method employing a side wall trolley. The employed side wall trolley is formed by a side wall trolley unit or longitudinal splicing of a plurality of side wall trolley units, the side wall trolley unit comprises a trolley moving and fixing system and a steel moulding plate connecting and positioning system; the construction steps are the followings in sequence: paving a walking track, precoating a release agent, enabling the trolley to move and take place, adjusting a screw jack, repeatedly adjusting an extension-type cantilever beam and a hydraulic jack, adjusting a bearing jack, mounting a lateral screw rod jack, mounting a foot margin inhaul cable, mounting an anti-floating screw rod jack, mounting an opposite-support pipe fitting, mounting a closing-up net and a water stop steel plate, casting concrete, stripping and the like, that building a steel pipe support and a spliced template is not required can be achieved, after the adoption of the invention, the mounting and the demounting speeds are fast, three-direction accurate adjustment can be achieved, the construction is stable and reliable, the concrete surface flatness is good, and joint deviation is small.

Owner:GUANGZHOU XINQIAO CONSTR SERVICE +1

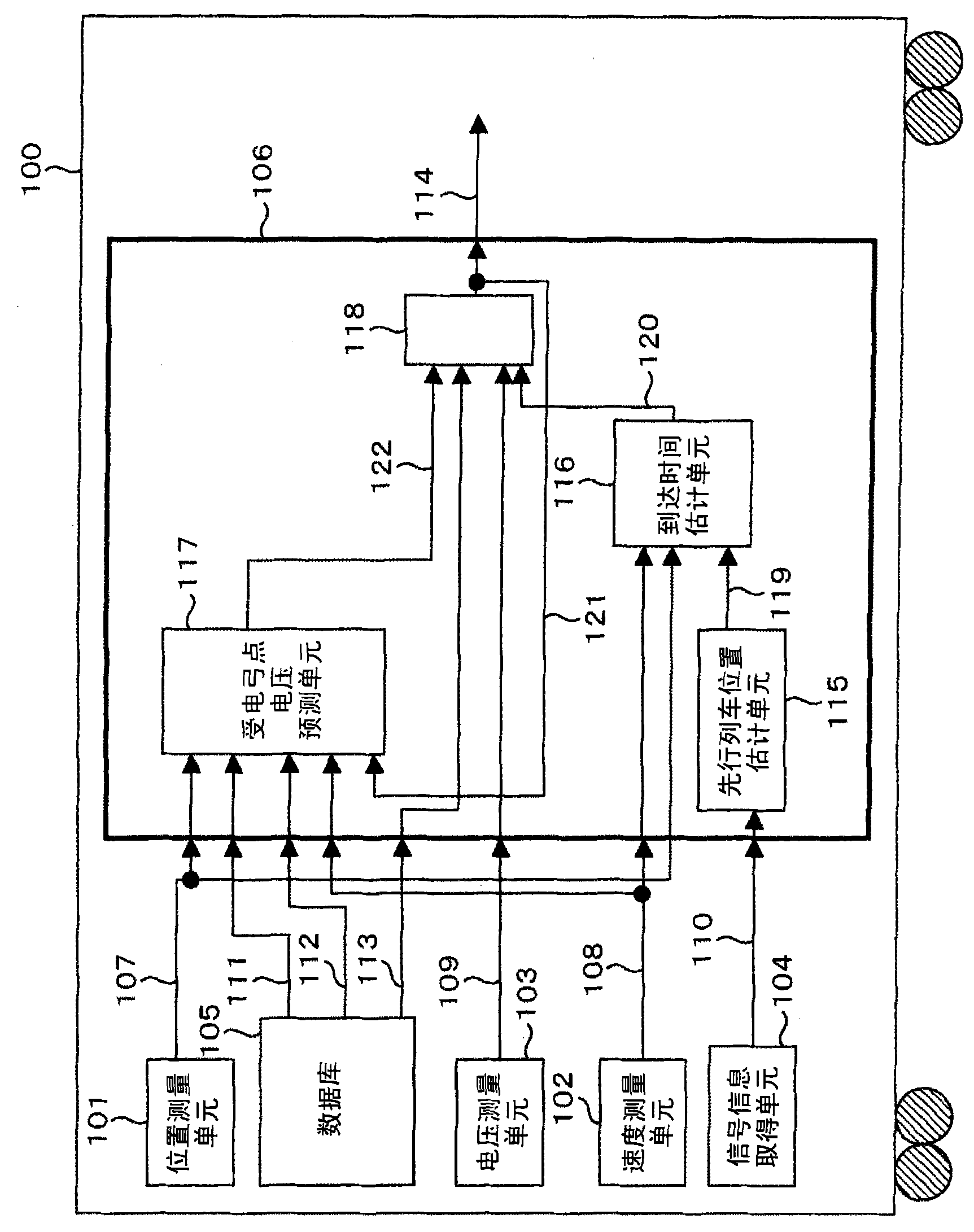

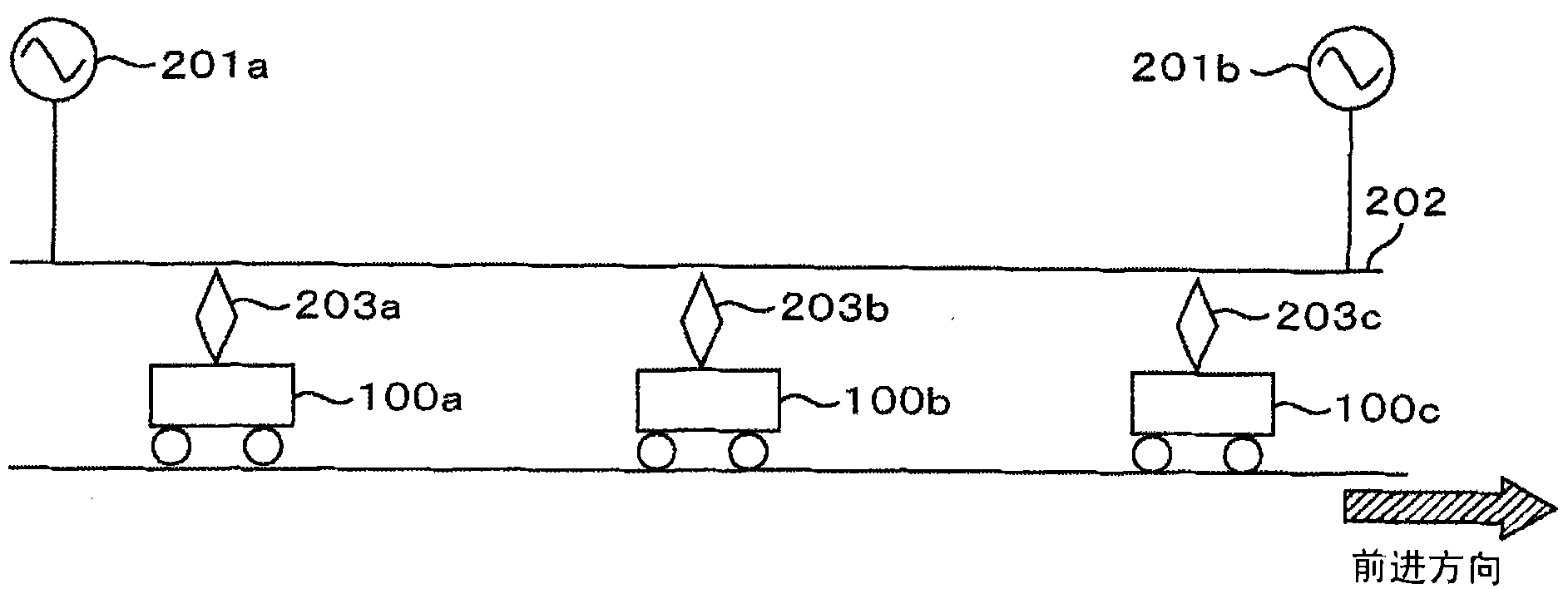

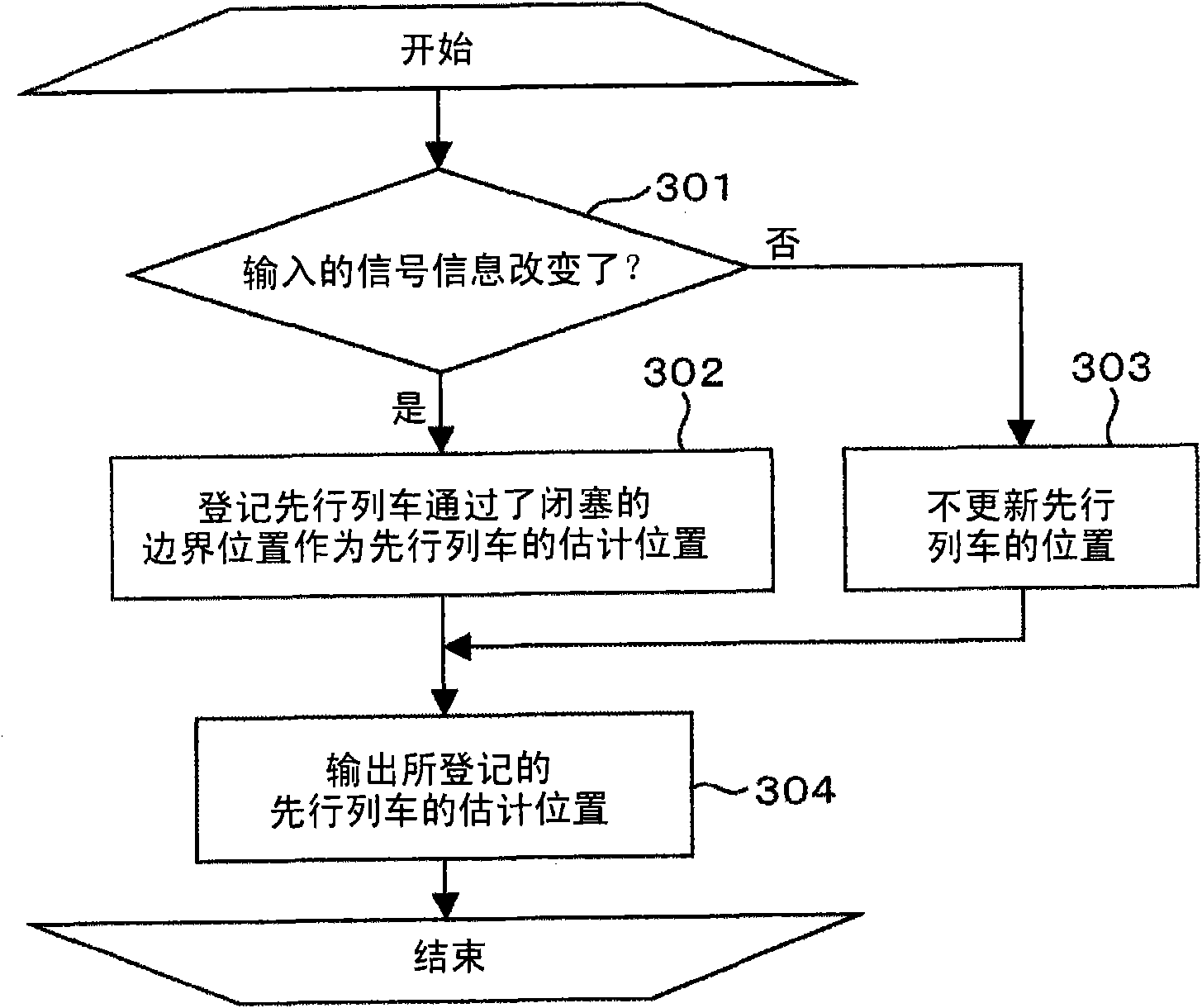

Train control system and railway control system

InactiveCN102085814AEliminate peak controlEliminate Interval ControlNon-enclosed substationsPower supply linesElectricityChair control unit

The invention provides a train control system. A driving control unit comprises a preceding train estimation unit which dynamically estimates the location of a preceding train according to signals obtained from a signal and information obtaining unit; an arrival time estimation unit which estimates the time when the present train arrives at the position of the preceding train according to the estimated position of the preceding train obtained from the preceding train estimation unit and the speed of the present train detected by a speed measuring unit; and a forecasting unit for pantograph point voltage, which forecasts the pantograph point voltage based on the location of the present train. Driving control commands are determined based on the time when the present train arriving at the position of the preceding train obtained from the arrival time estimation unit, the forecasting value of pantograph point voltage obtained from the forecasting unit for pantograph point voltage, and the actual pantograph point voltage obtained from a voltage measuring unit. In this way, the peak of a transformer station can be eliminated by actuating the driving control of the present train when influence on the signal mode of the following train is taken into consideration.

Owner:HITACHI LTD

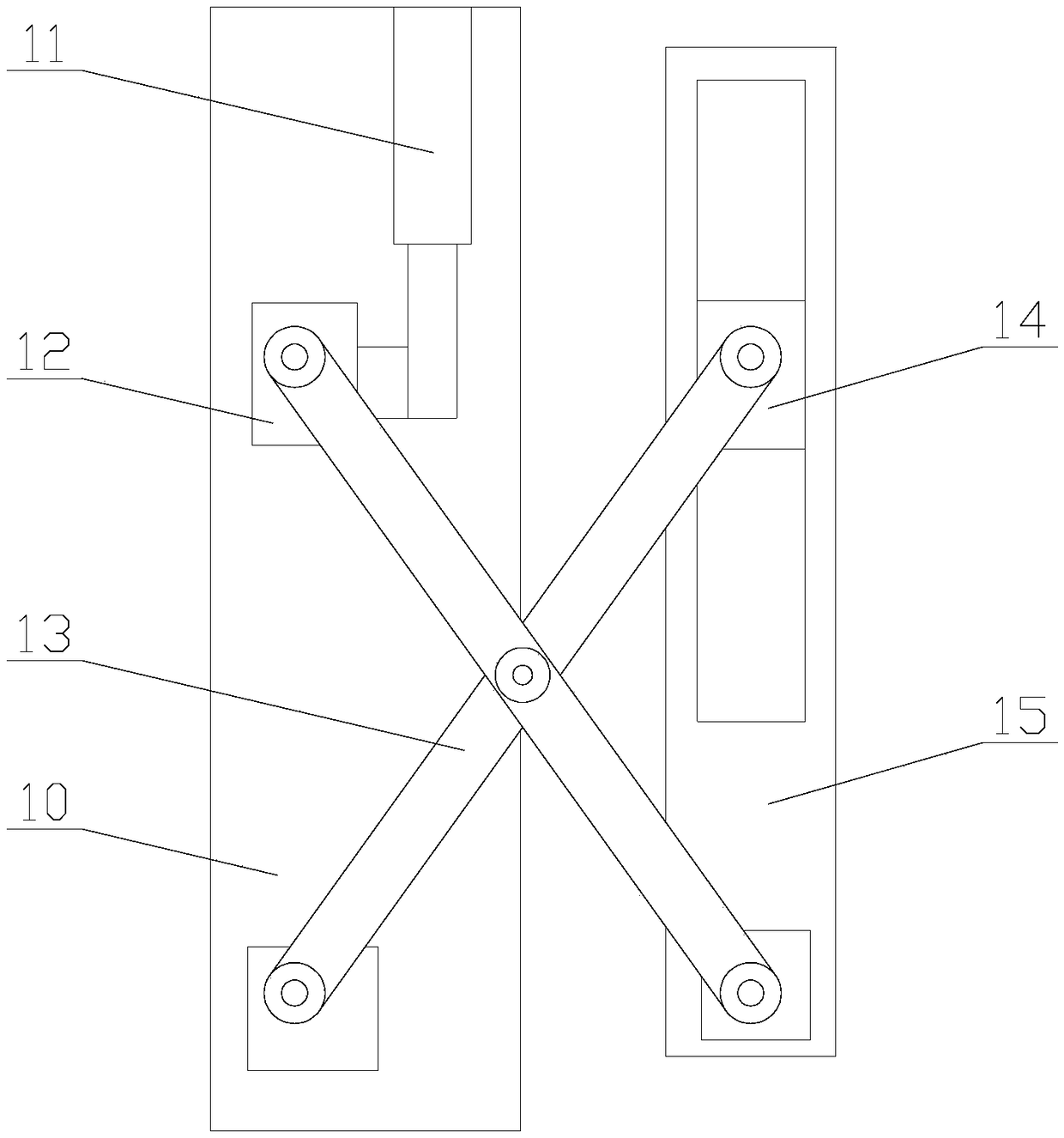

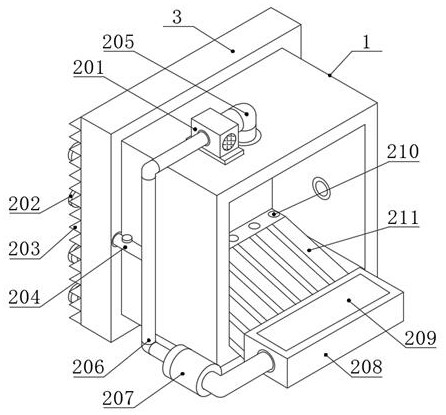

Intelligent parking device with wheel fixing function

InactiveCN108843084AImprove practicalityImprove reliabilityFire rescueParkingsParking spaceEngineering

The invention relates to an intelligent parking device with a wheel fixing function, which comprises a bracket and a lifting plate, and further comprising a fixing mechanism and a fire extinguishing mechanism, wherein the fixing mechanism comprises a turnover assembly and a fastening assembly; the turnover assembly comprises a first motor, a first gear, a second gear and two rotating units; the fastening assembly comprises a cylinder, a movable block, a telescopic frame, a slider and a clamp plate; the fire extinguishing mechanism comprises two fire extinguishing components. In the intelligentparking device with a wheel fixing function, vehicle wheels can be clamped and fixed by the fixing mechanism, so that the parking of the vehicle is stabler, the safety accidents of deviation, impactand high-altitude falling of the vehicle during lifting are avoided, and the parking safety and reliability are improved; through the fire extinguishing mechanism, the lifting and angle adjustment ofa nozzle can be controlled to achieve precise fire extinguishing against the fire point, thereby extinguishing the fire in time, preventing the fire from spreading and causing greater losses, and greatly improving the practicality and reliability of the parking device.

Owner:深圳市中科智诚科技有限公司

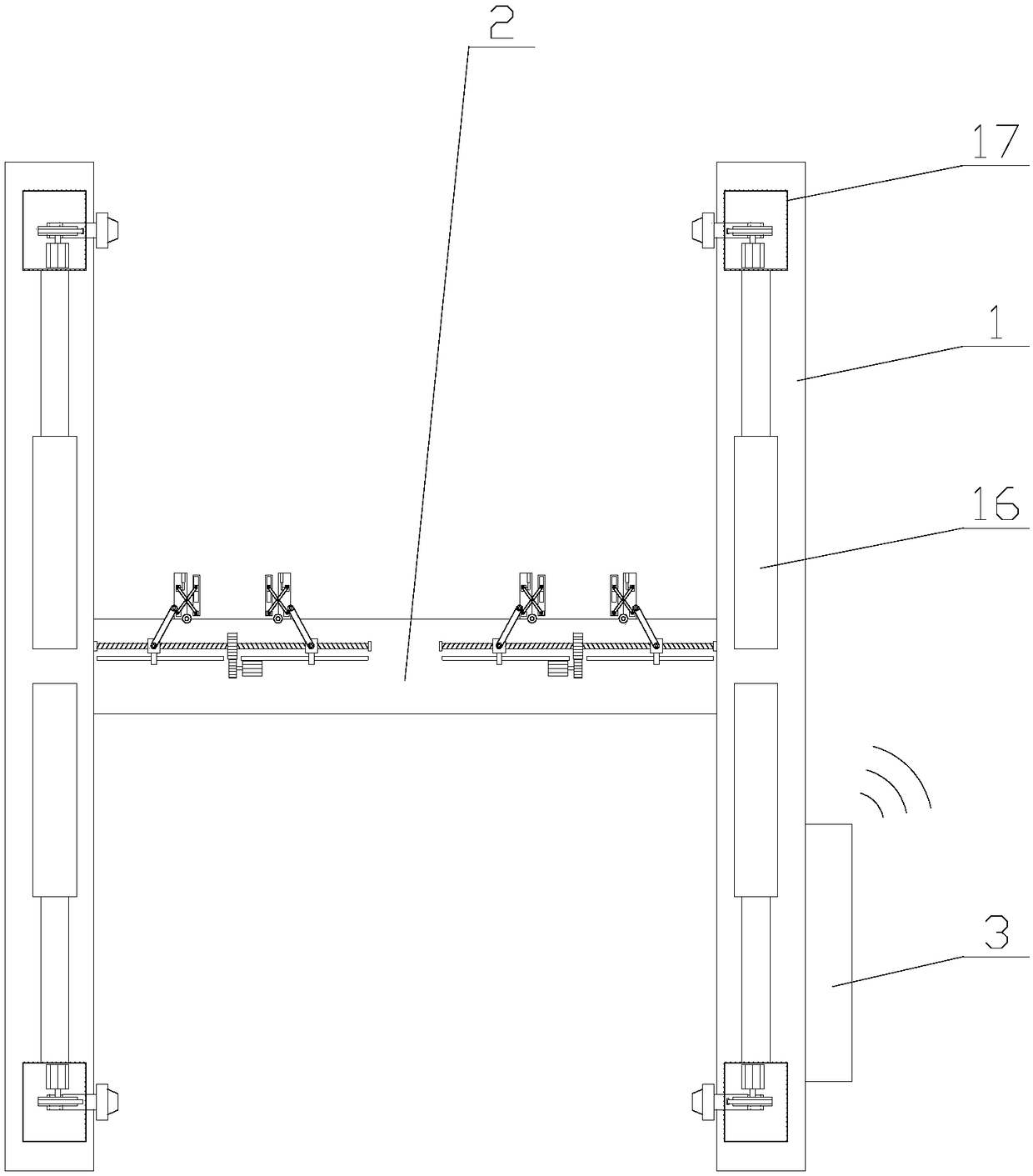

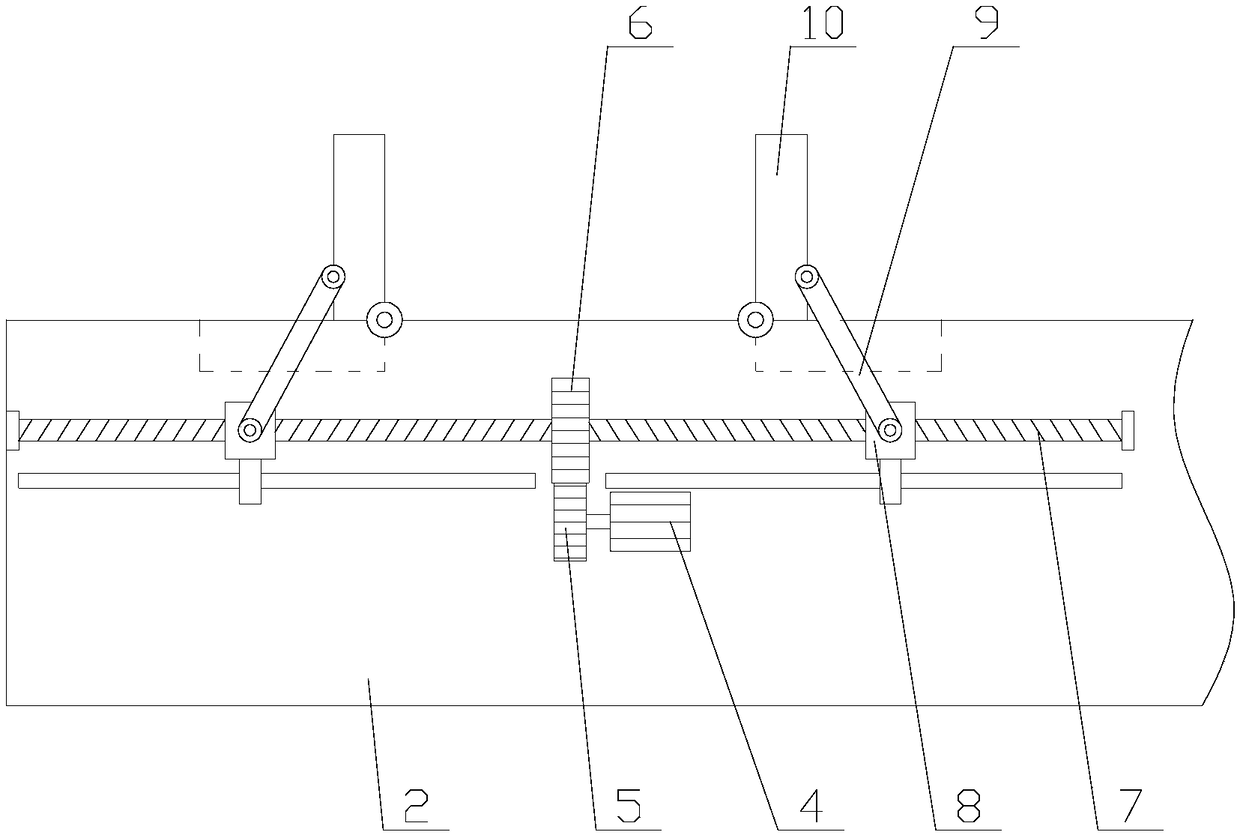

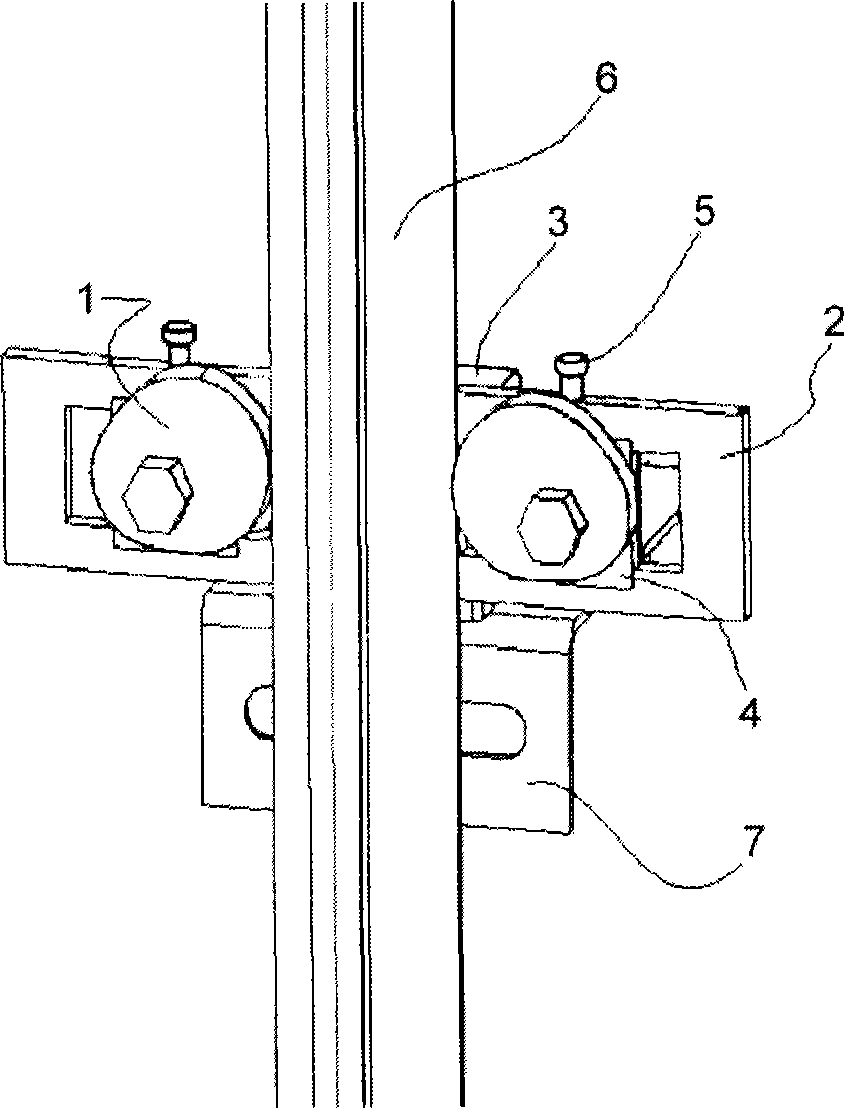

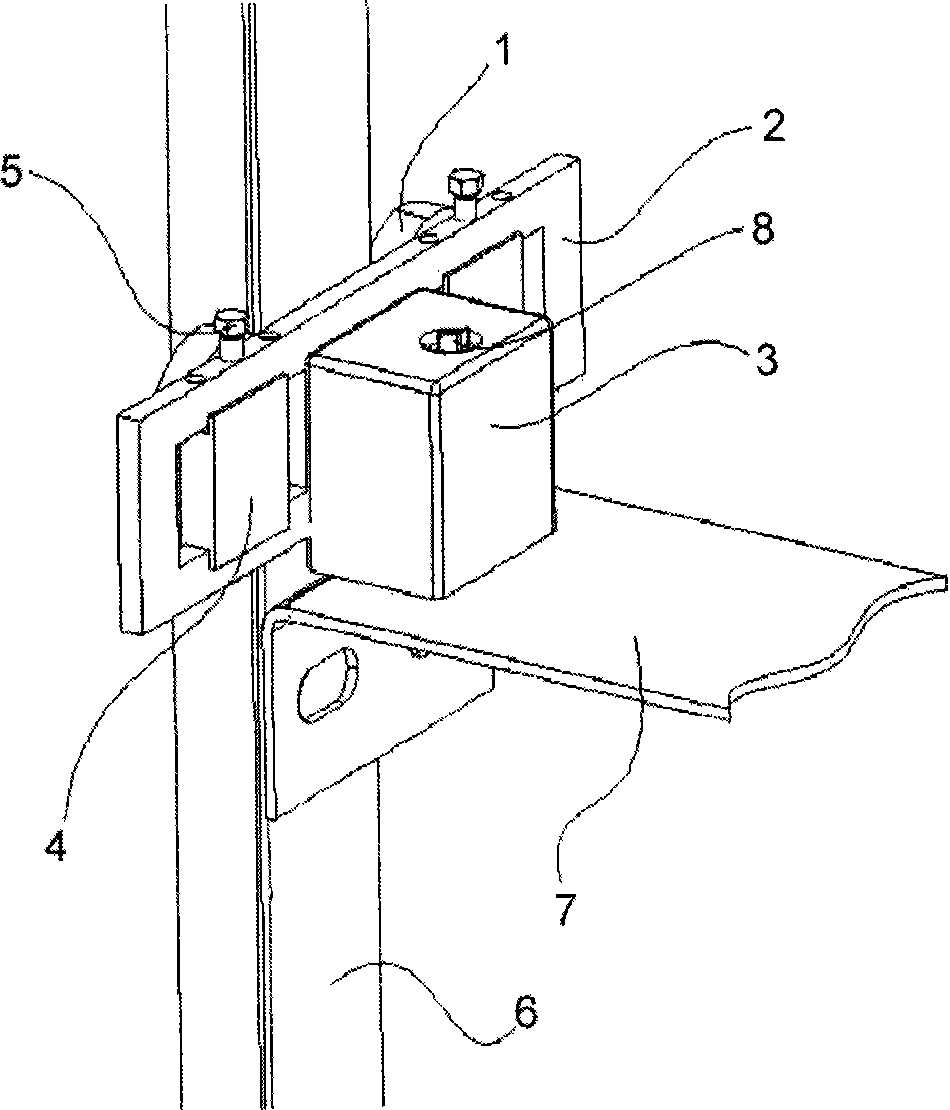

Guide rail straightness regulating device

InactiveCN101456526AHigh adjustment accuracyEasy to carryLifting devicesRailway track constructionSet screwEngineering

The invention discloses a straightness adjusting device for a guide rail, which comprises a cam or eccentric wheel adjusting mechanism capable of applying a stepless continuous controllable extrusion force to the guide rail or a beam, and a fixing device for fixing the adjusting mechanism. The adjusting mechanism comprises a cam (1), a sliding block (4), a sliding block moving guide rail (2), and a set screw (5) for fixing the sliding block (4) into the cam sliding block moving guide rail (2), wherein the cam (1) capable of rotating around the cam center thereof is movably arranged on the cam sliding block (4), and the sliding block (4) can move in the sliding block moving guide rail (2). The cam (1) is provided with a matched force application part convenient for a tool to apply a force to rotate the cam (1). The straightness adjusting device has the advantages of novel structure, convenient adjustment and time and labor conservation, can effectively control adjusting amount, is in particular suitable for fine adjustment, improves adjustment accuracy of the straightness of the guide rail greatly, has a simple structure, is convenient to carry, and can be widely applied to adjustment of straightness accuracy of elevator guide rails or other beams.

Owner:三六零安全科技股份有限公司 +1

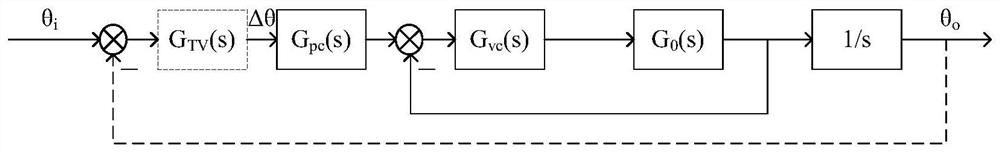

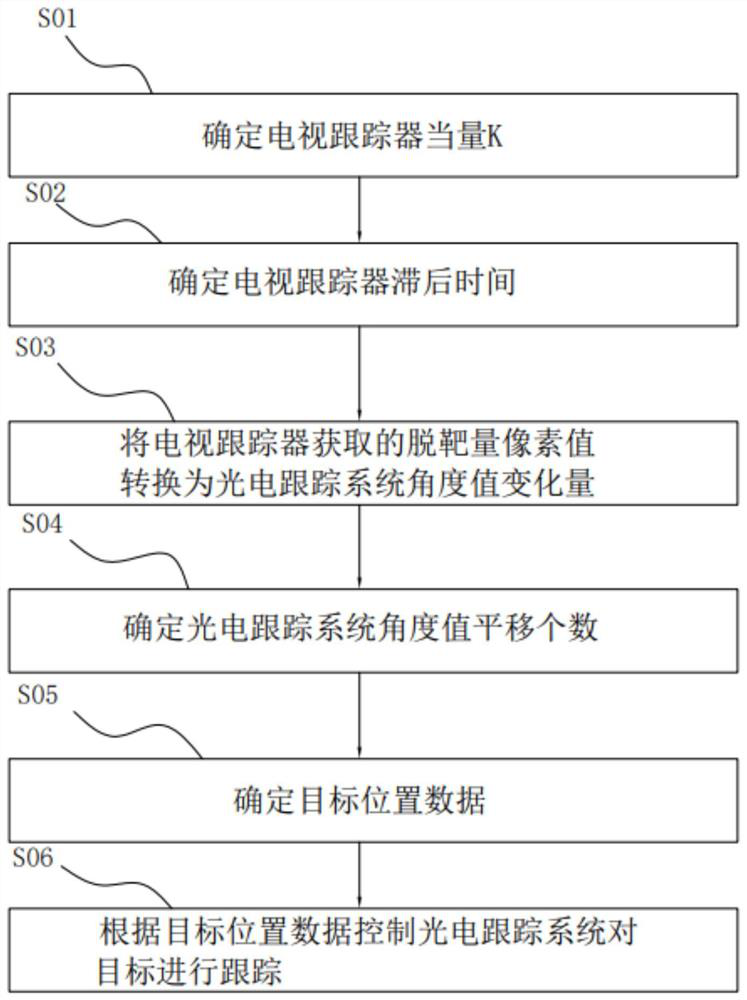

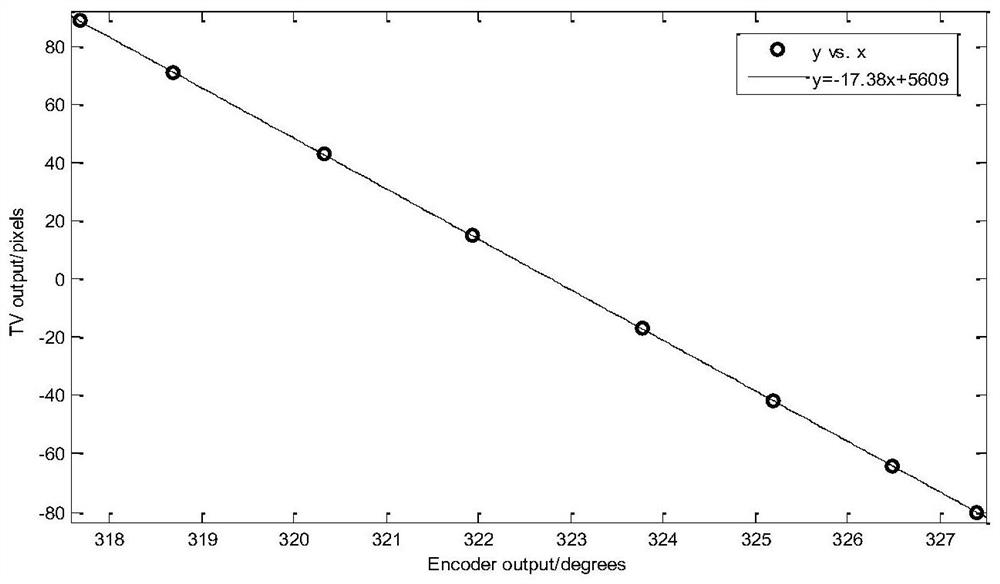

Method for improving tracking precision of photoelectric tracking system

ActiveCN112684817AEasy to controlControl adjustmentControl using feedbackEngineeringComputational physics

The invention discloses a method for improving the tracking precision of a photoelectric tracking system. According to the technical scheme, the method is characterized by comprising the following steps that S01, the equivalent K of a television tracker is determined; S02, lag time tau of the television tracker is determined; S03, the miss distance pixel value deltathetan obtained by the television tracker is converted into a miss distance angle value dthetan, dthetan=deltathetan / K,n=1, 2,..., and n is a positive integer; S04, an angle value thetao and an n translation number N of the photoelectric tracking system are determined, N=tau / T1, and T1 is an instrument data sampling interval; S05, target position data thetai, n-N, thetai, n-N=dthetan+thetao, n-N are determined; and S06, a photoelectric tracking system is controlled to track the target according to the target position data. The equivalent K of the television tracker and the lag time tau of the television tracker are determined, the miss distance data deltathetan are processed according to the two pieces of data, the precision of the obtained target position information is greatly improved, the target position information serves as feedforward of the photoelectric tracking system, and the tracking precision and stability of the photoelectric tracking system are greatly improved.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

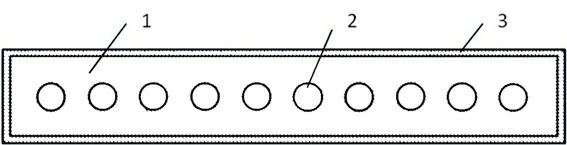

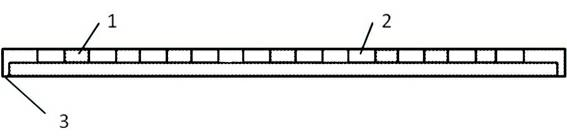

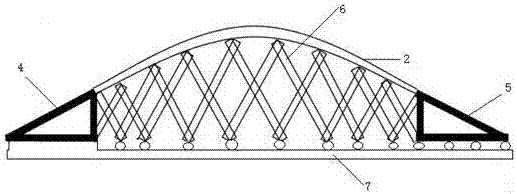

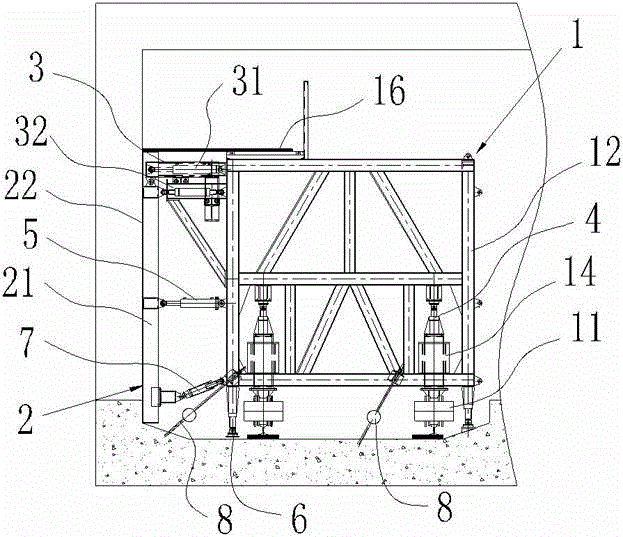

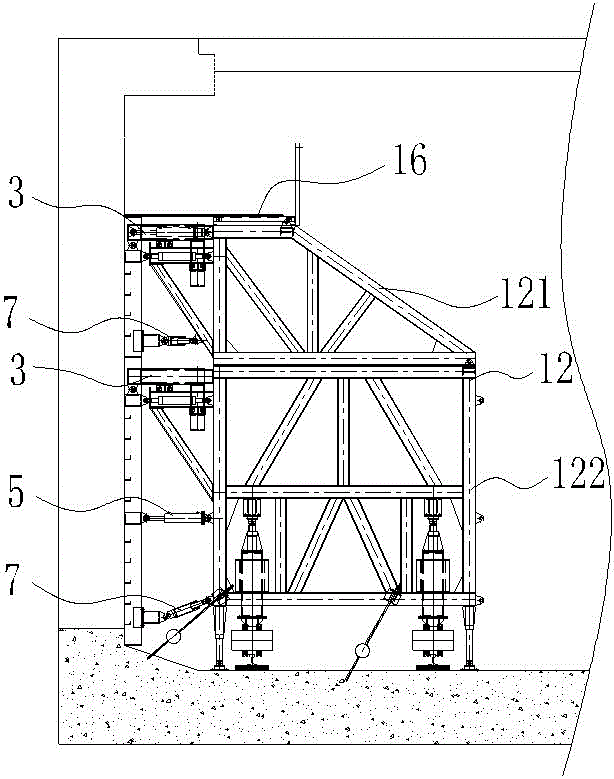

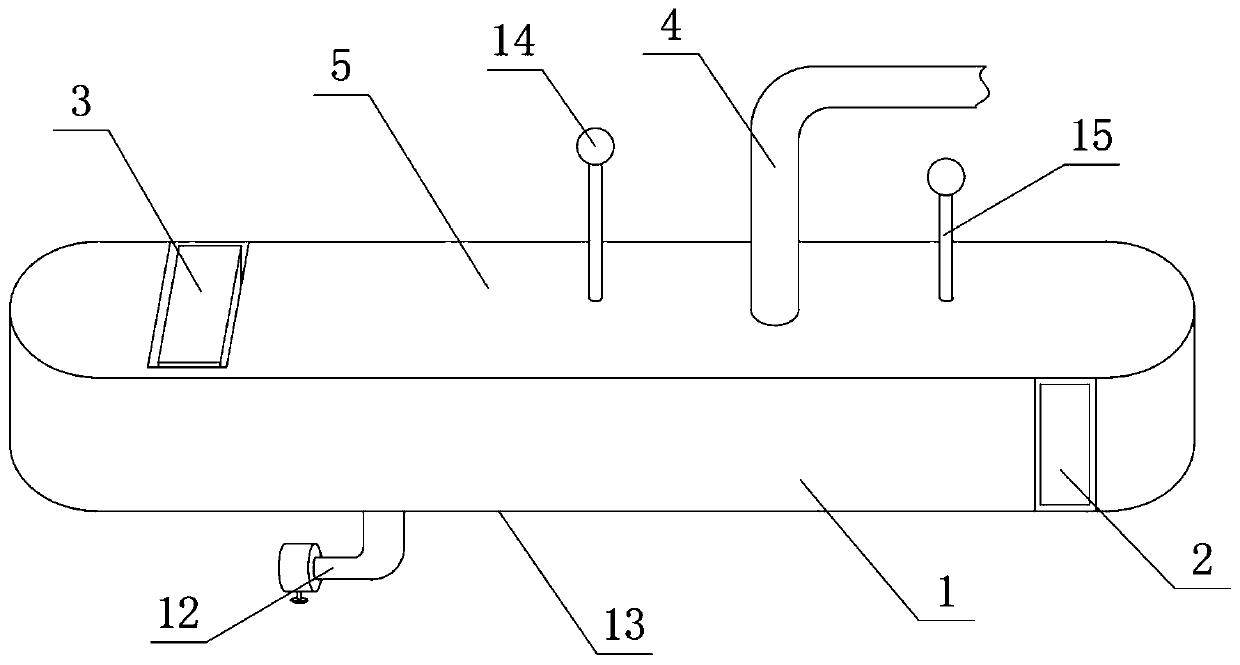

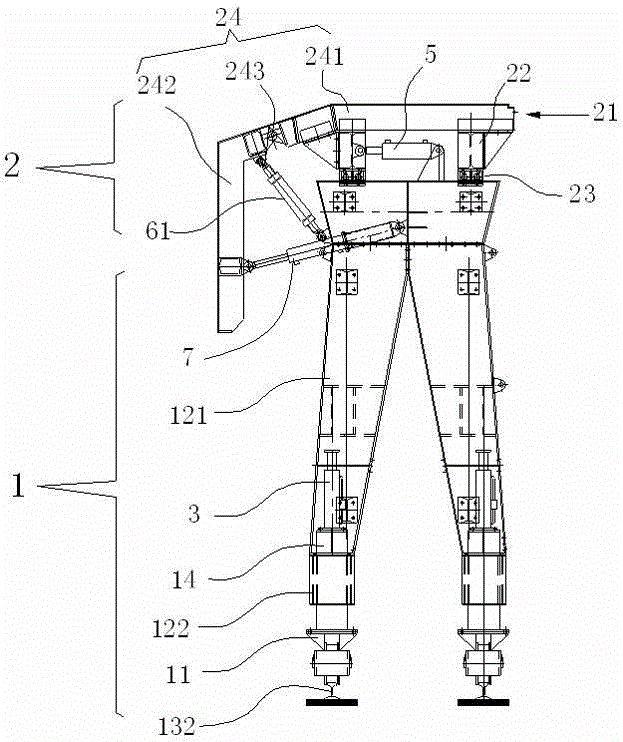

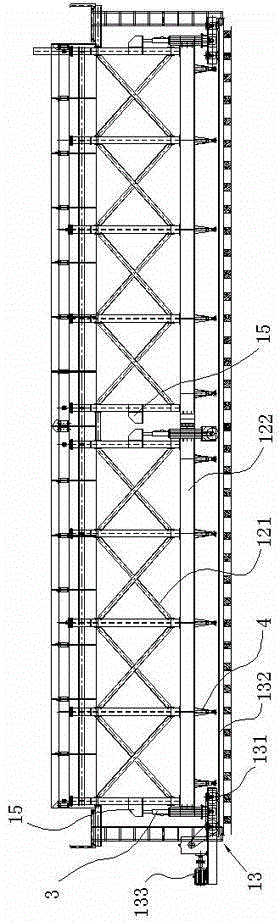

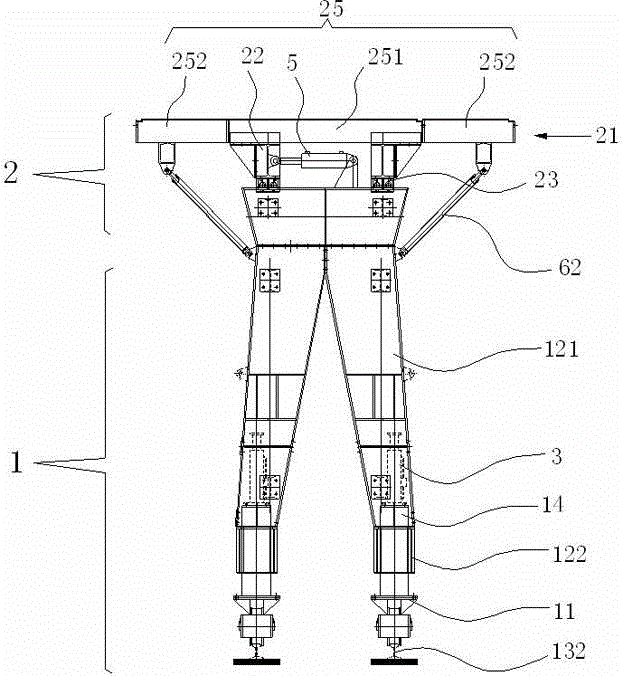

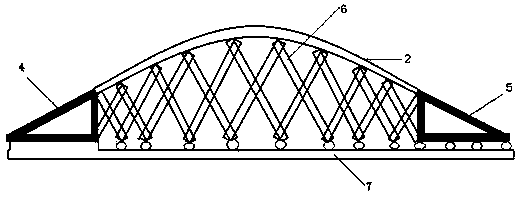

Side wall trolley

ActiveCN103557011AImprove problems with heavy burdensImprove stabilityUnderground chambersTunnel liningPipe fittingUltimate tensile strength

The invention discloses a side wall trolley which comprises a plurality of side wall trolley units spliced lengthways, wherein each side wall trolley unit comprises a trolley moving and fixing system and a steel moulding plate connecting and positioning system. The side wall trolley adopts the design of cantilever connection of a steel moulding plate and a trolley, combines hydraulic jacks, screw jacks and walking systems to realize three-position accurate adjustment, realizes bearing and transmission of load through components such as opposite supporting pipe fittings, lateral screw rod jacks, bearing jacks, tail margin guy cables and anti-floating screw rod jacks, and is stable and reliable in structure. Through the adoption of the side wall trolley, construction of a steel pipe bracket and assembly of moulding plates are not need, thus greatly simplifying construction procedures, improving the mounting speed and reliability of the moulding plates and the construction efficiency, meanwhile reducing labor intensity of workers, greatly saving manual labor, wood and steel pipe brackets and lowering the construction cost.

Owner:GUANGZHOU XINQIAO CONSTR SERVICE +1

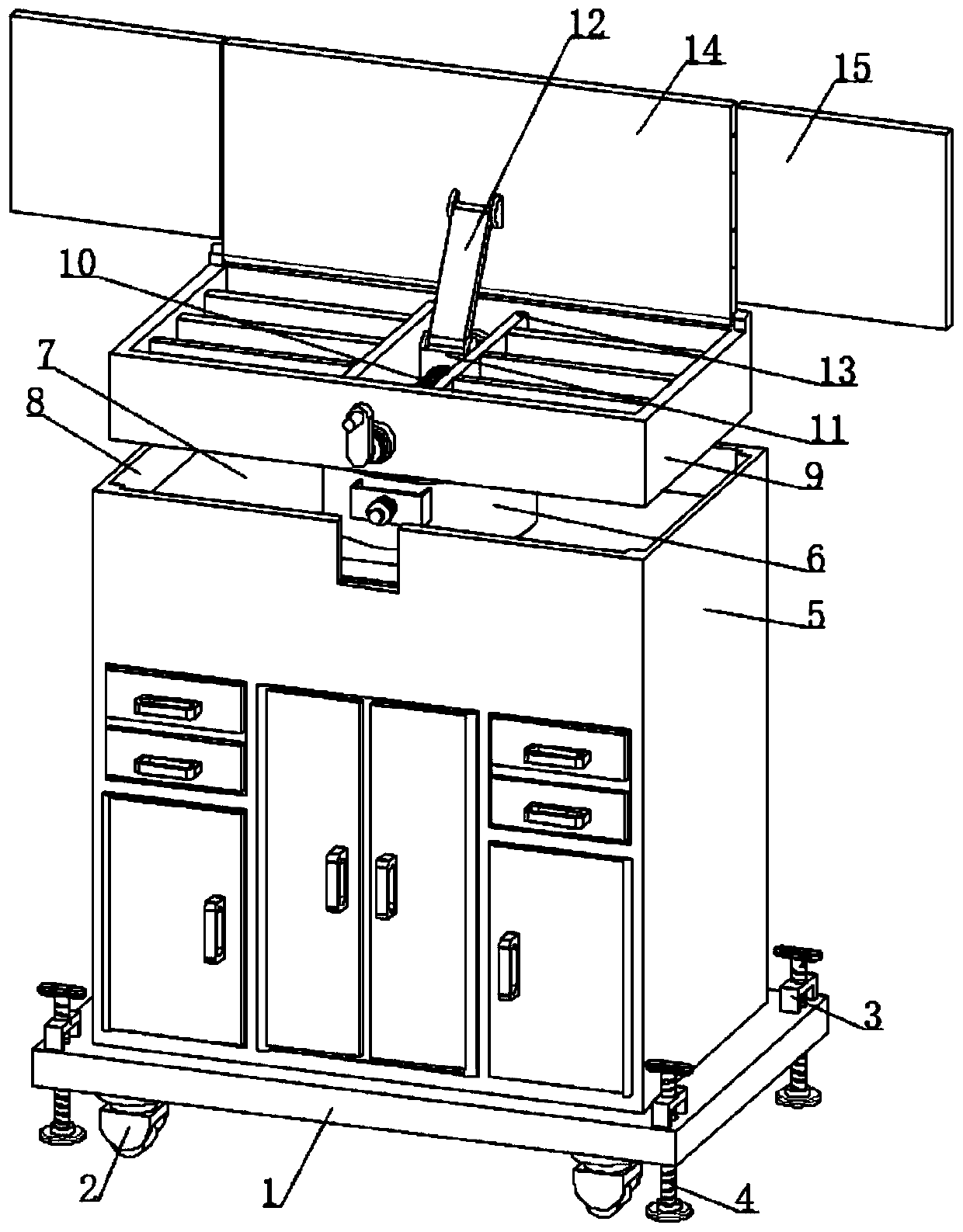

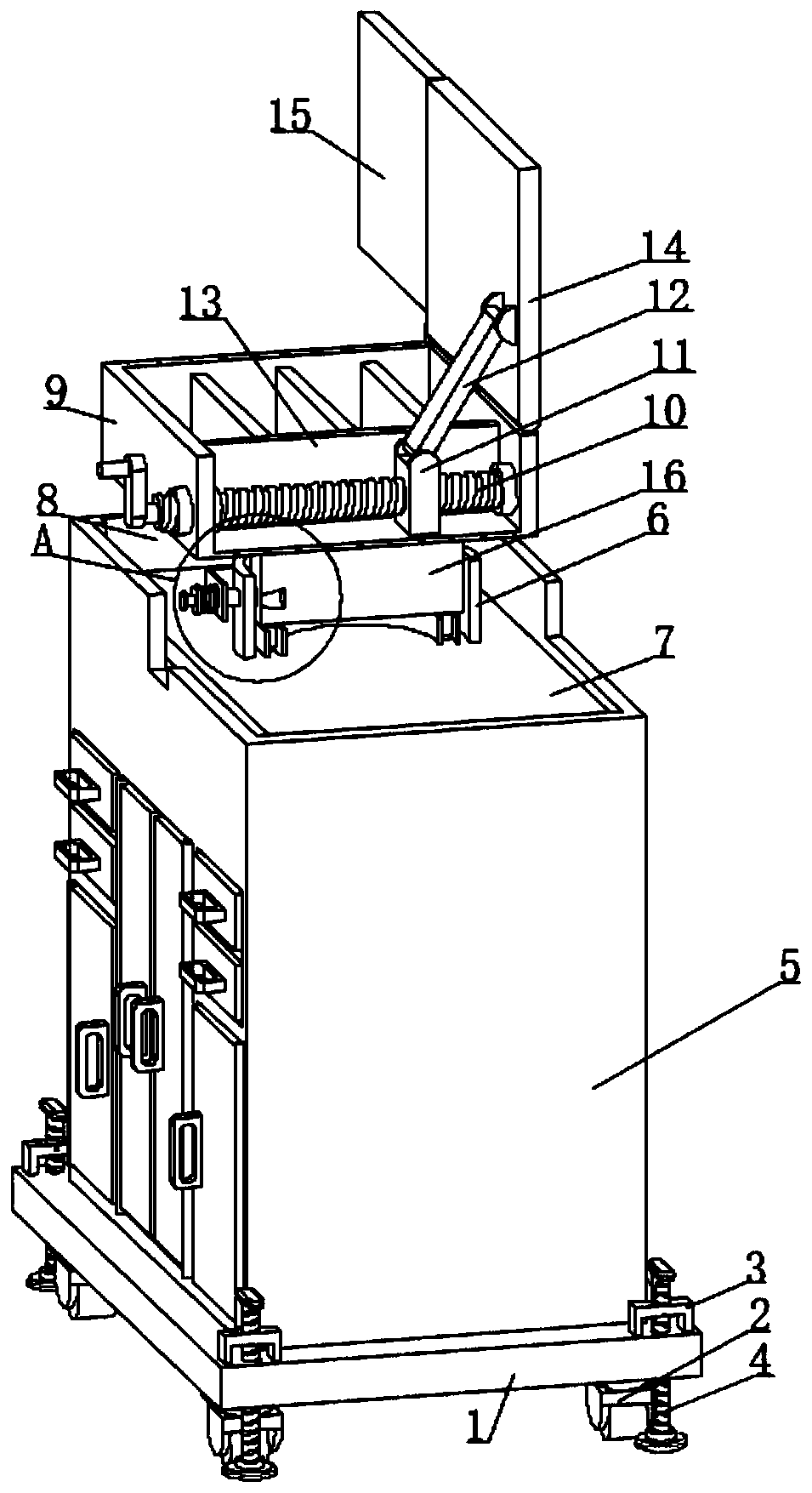

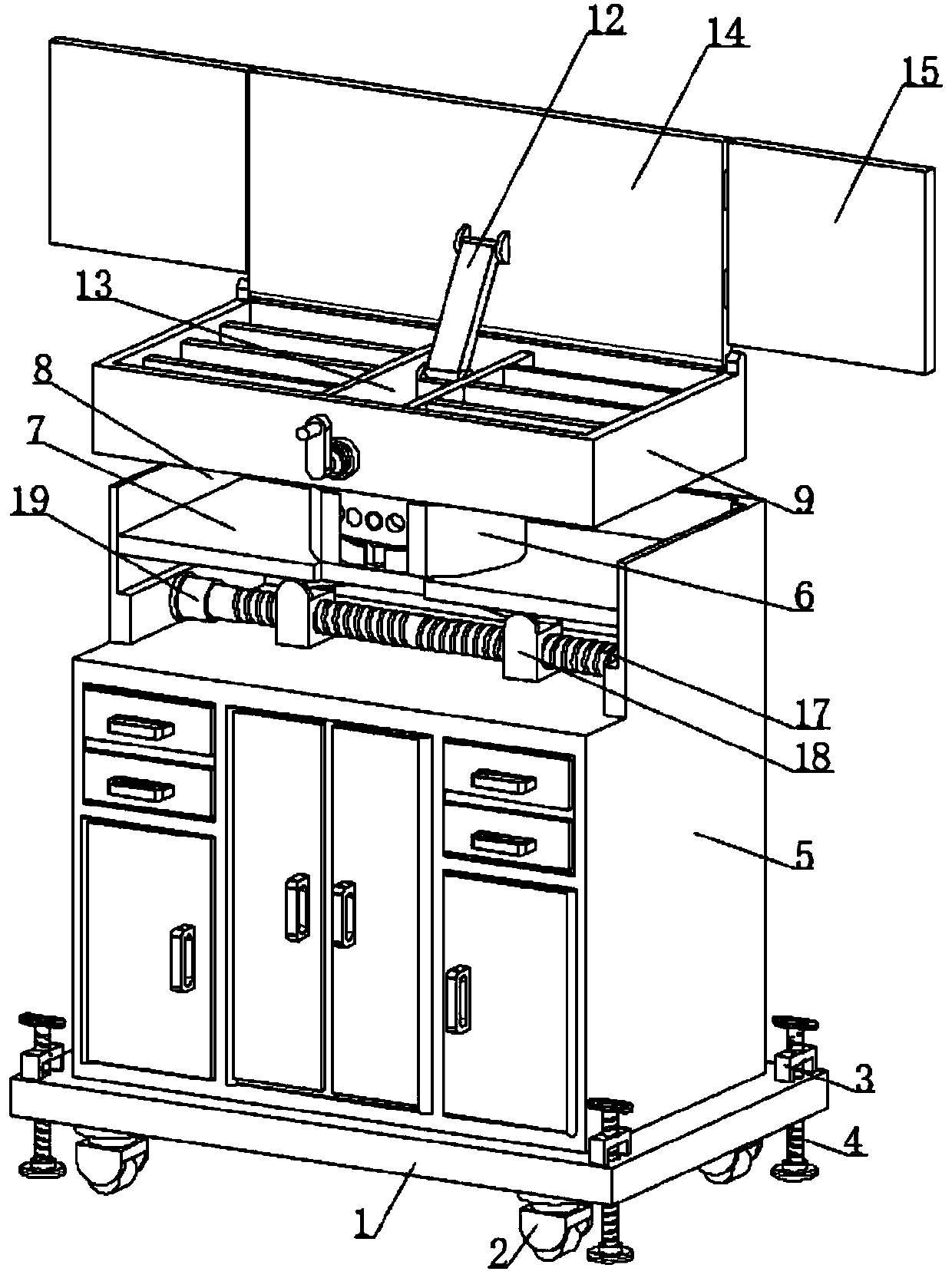

Special teaching auxiliary equipment for business administration

InactiveCN111276025AAvoid offsetEffective protectionTeaching apparatusPhysical medicine and rehabilitationDrive motor

Owner:山东经贸职业学院

Double-slag process for smelting ultralow-phosphorus and low-carbon steel in combined-blown converter

The invention relates to a double-slag process for smelting ultralow-phosphorus and low-carbon steel in a combined-blown converter. The double-slag process comprises the following steps: (1) molten iron and waste steel are put into the converter according to the molten iron ratio of 85% to 90%; (2) bottom blowing gas adopts nitrogen and argon in a switched manner, the nitrogen is adopted before the supply of 80% of oxygen, and the argon is automatically switched after the supply of 80%t of oxygen; (3) at the first stage of blowing, the flow rate of the oxygen adopts 20000-21000 Nm<3> / h within the first minute, and a normalized slag lance position of 1800-2000 mm is adopted; after the start of blowing for one minute, the flow rate of the oxygen is adjusted to be 13000 Nm<3> / h; (4) a de-slagging moment is set as 8-10 minutes after the start of blowing; (5) at the second stage of blowing, blowing is started when the high lance position is 1700-1800 mm, the flow rate of the oxygen is adjusted to be 18000 Nm<3> / h, and the converter end point control target is that carbon is less than 0.05%, and phosphorus is less than 0.004%. According to the double-slag process provided by the invention, the converter end point phosphorus can be stably controlled to be less than or equal to 0.004 percent, so that the target of smelting the ultralow-phosphorus and low-carbon steel by a single converter is stably realized.

Owner:NANJING IRON & STEEL CO LTD

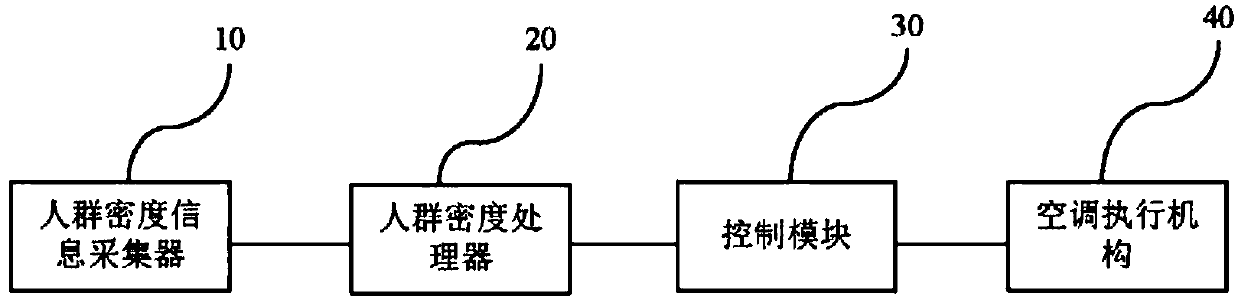

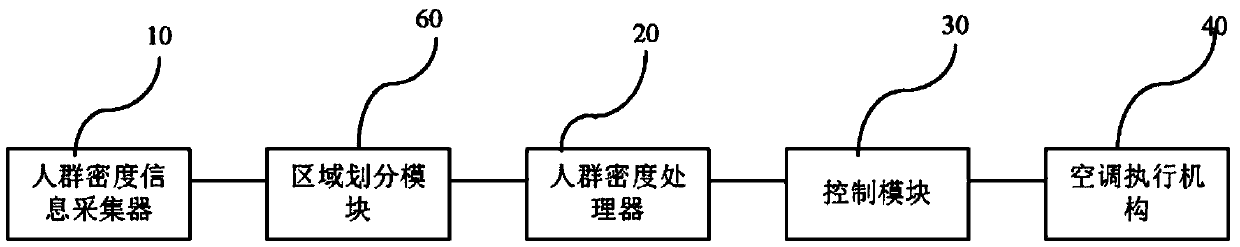

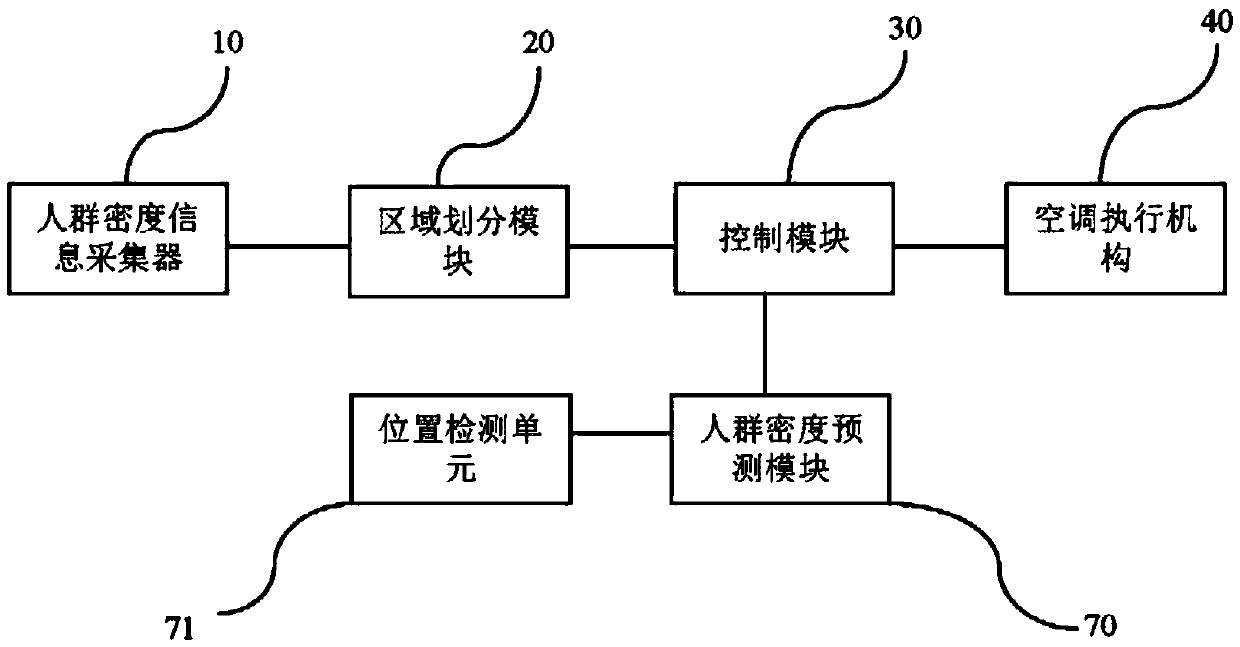

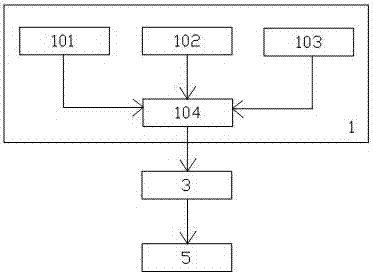

Central air conditioning control system and control method

PendingCN111023474AControl adjustmentFeel comfortableMechanical apparatusLighting and heating apparatusCollection analysisPublic place

The invention provides a central air conditioning control system and a control method. The control system comprises a crowd density information collector, a crowd density processor, a control module and an air conditioning execution mechanism. The crowd density information collector collects the information needed for analyzing the crowd density in one place, and transmits the information needed for analyzing the crowd density in the place to the crowd density processor. The crowd density processor obtains the crowd density in the place according to the information needed for analyzing the crowd density in the place, and transmits the crowd density in the place to the control module. The control module controls the air conditioning execution mechanism to adjust environmental parameters inthe place according to the data, stored inside, corresponding to the crowd density and the optimal environmental parameters and the crowd density in the place. The central air conditioning control system can automatically adjust the environment in the public place to provide the crowd more comfortable feelings in the public place.

Owner:SHANGHAI PATEO INTERNET TECH SERVICE CO LTD

Cache-on-board (COB) technology-based integrated light emitting diode (LED) packing method

InactiveCN102437271ALower working temperatureFlexible thickness controlSemiconductor devicesCooking & bakingHeat resistance

The invention relates to a cashe-on-board (COB) technology-based integrated light emitting diode (LED) packing method, which comprises the following steps that: 1. thickness of a mould and diameter of a reserved hole are adjusted; 2. the reserved hole on the mould is aligned to an LED chip which is well fixed on an aluminum circuit board, and the mould covers the aluminum circuit board; 3. after fluorescent glue is sprayed on the aluminum circuit board, the aluminum circuit board is baked, then the mould is removed after the baking so as to obtain an LED packing unit. The method has followinng beneficial effects that: the shape, position, thickness and quantity of the fluorescent flue can be adjusted by adjusting the thickness of a silicone board and the diameter of the reserved hole, so the LED integrated packing procedures can be simplified, the heat resistance and the working temperature of the LED chip can be reduced, the shape, position, thickness and quantity of the fluorescent glue can be flexible to control, the light emitting efficiency and the consistency, stability and service life of the product can be improved, the packing efficiency also can be improved, the waste can be reduced, and the product cost can be reduced. The baking temperature is set as 140 to 160 DEG C, so the packing effect is better.

Owner:秦会斌 +6

Hoisting television stand with retractable function

Owner:济宁呱牛信息技术有限公司

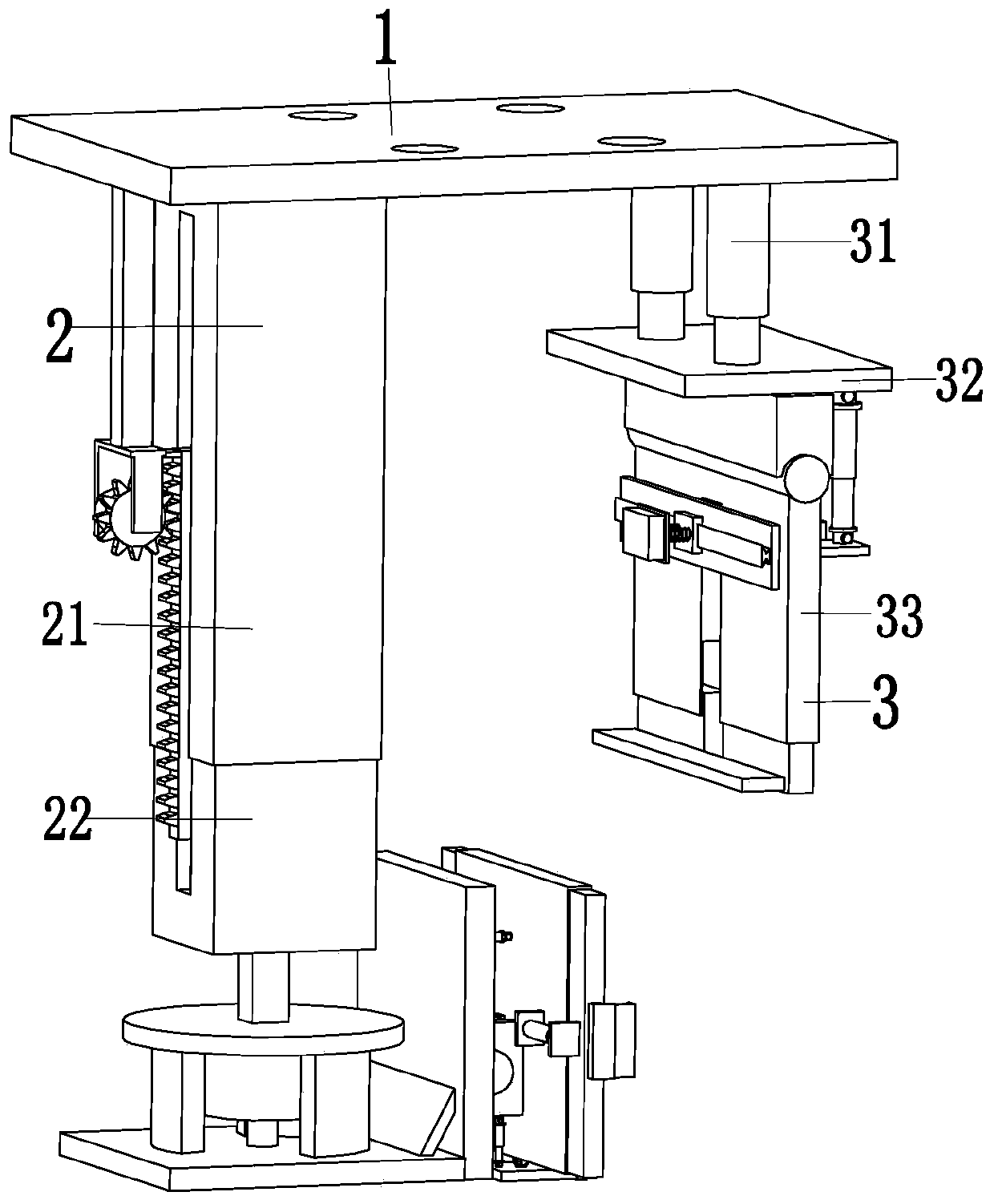

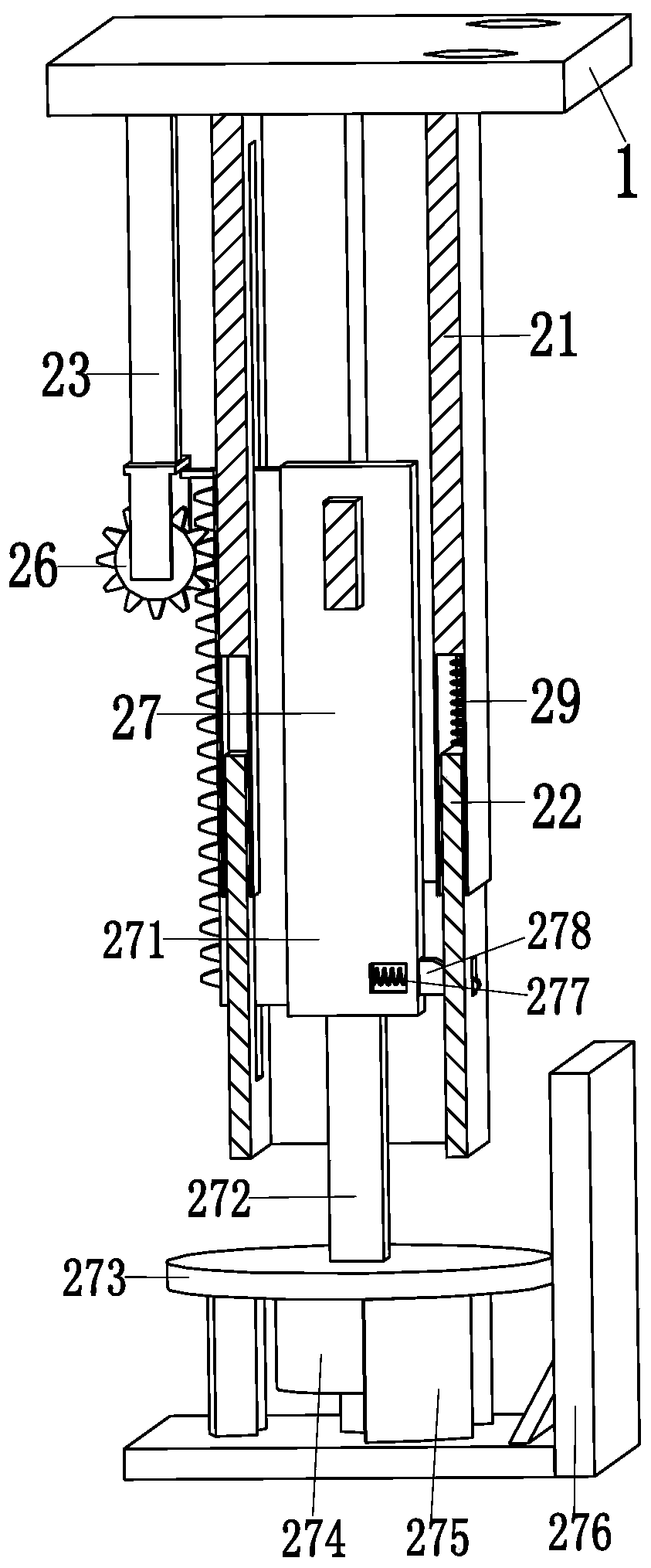

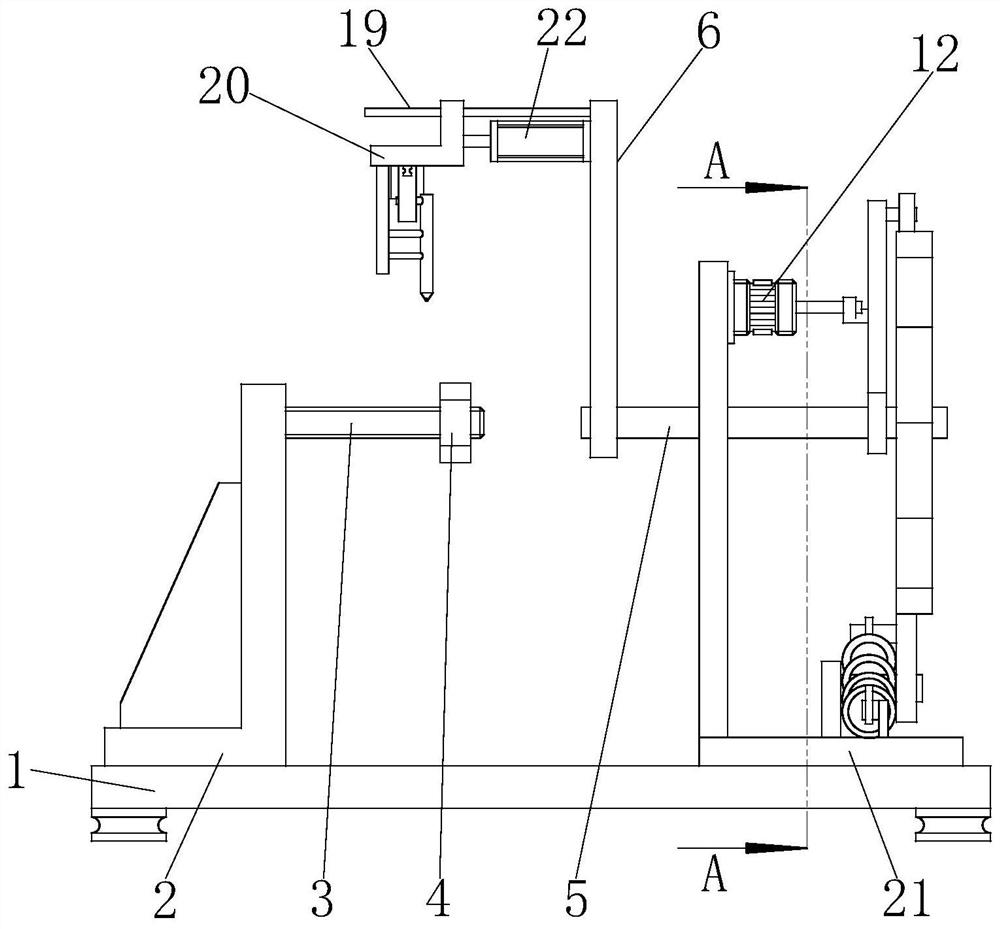

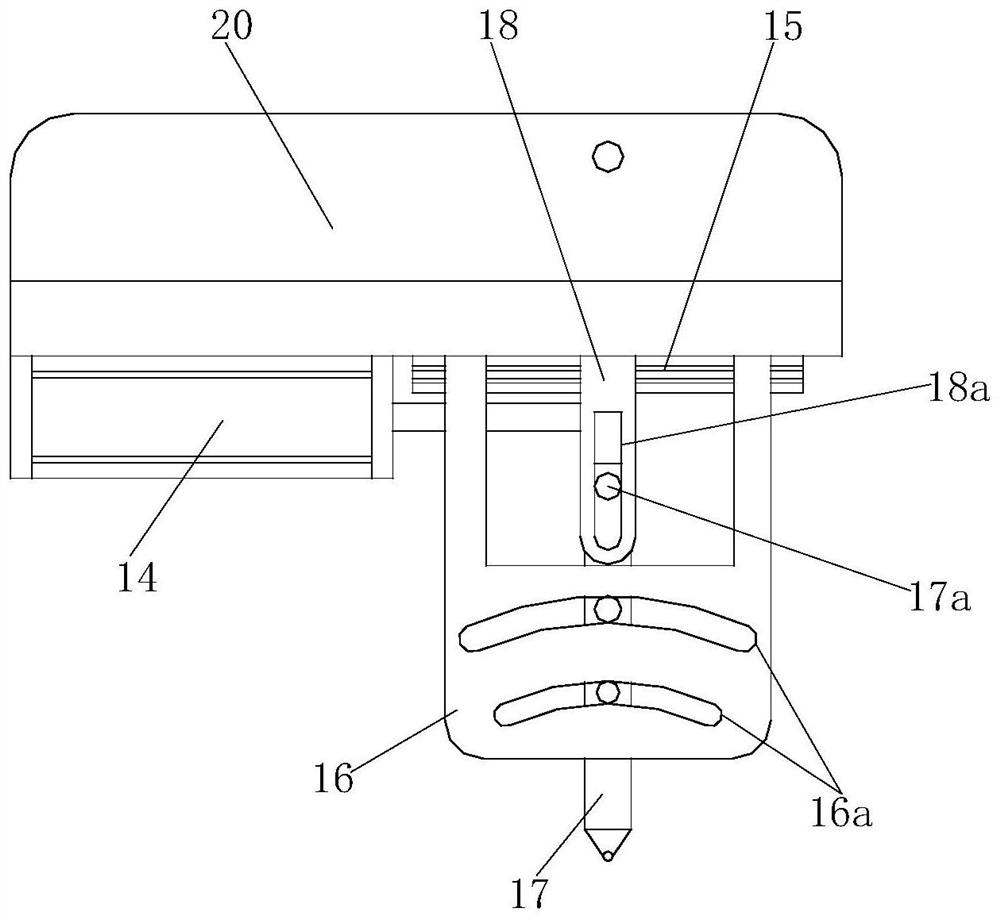

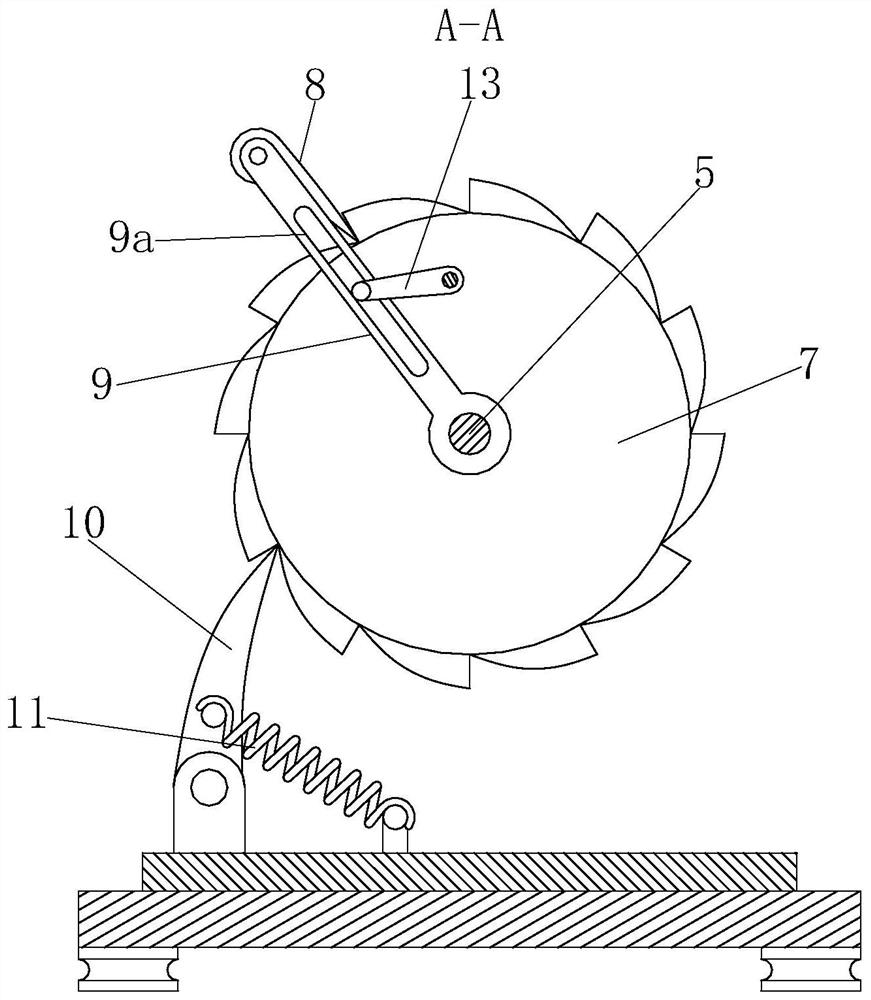

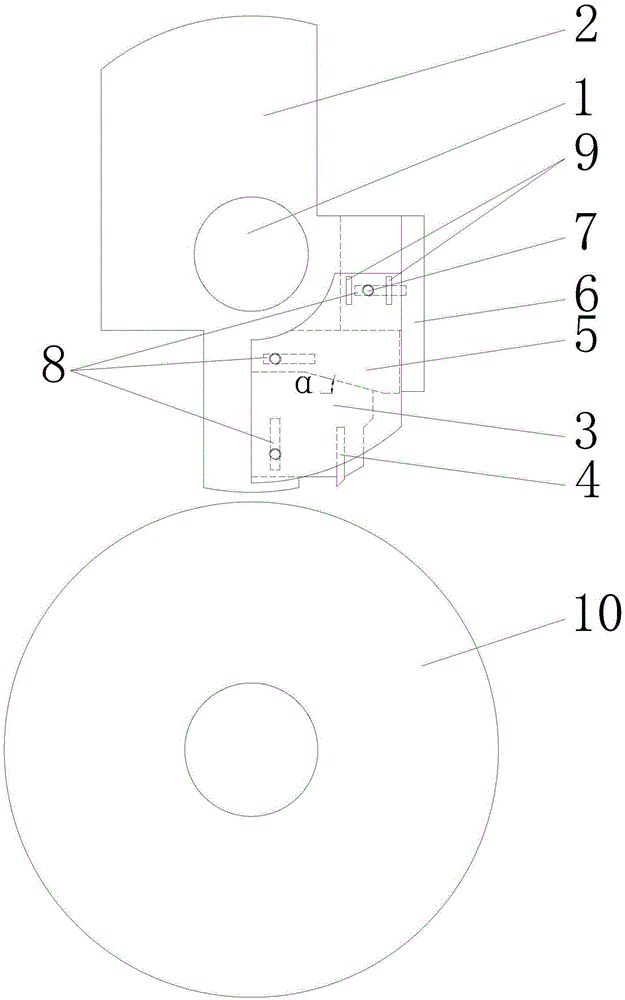

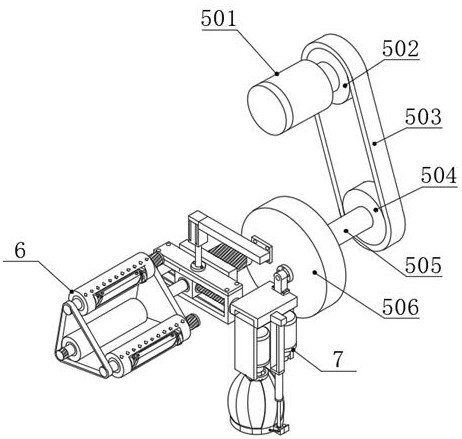

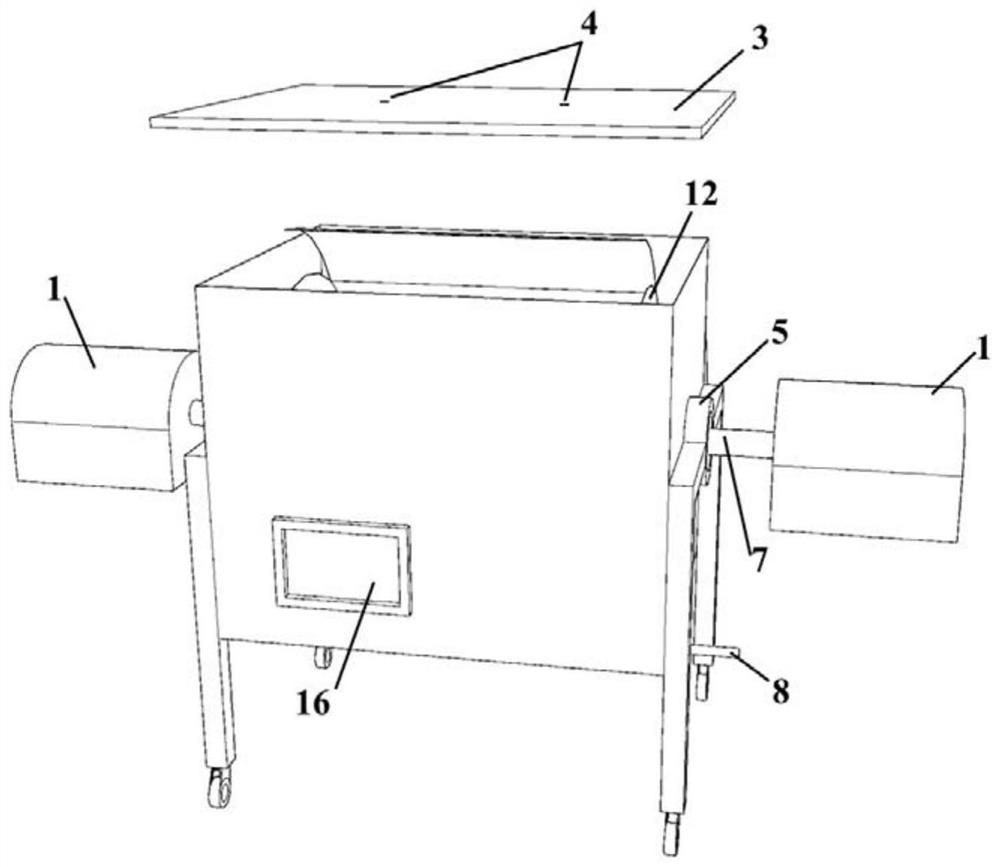

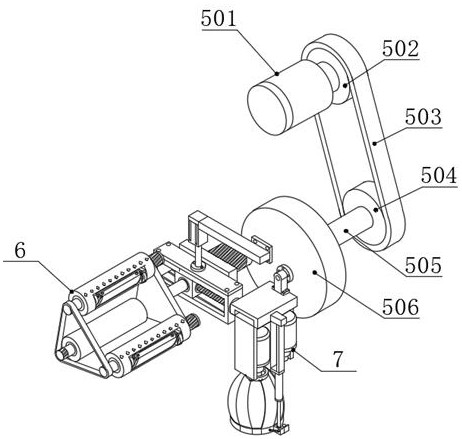

Cambered surface spraying type railway vehicle brake disc cambered surface repairing machine

InactiveCN112275498AControl automatic stop rotationControl horizontal slidingSpraying apparatusHydraulic cylinderEngineering

The invention relates to a cambered surface spraying type railway vehicle brake disc cambered surface repairing machine comprising a machine base. An installation base plate is installed on the left side of the machine base. A binding assembly is arranged on the installation base plate. A bearing pedestal is installed on the right side of the machine base. A center shaft is installed on the middleportion of the bearing pedestal in a rotating mode. The right end of the center shaft is connected with a corner limiting assembly. The left end of the central shaft is connected with a main body frame. A hydraulic cylinder and a guide rod are installed on the main body frame. The hydraulic cylinder and the guide rod are both connected with a spraying assembly. The cambered surface spraying typerailway vehicle brake disc cambered surface repairing machine is high in automation degree; on the basis that a brake disc is installed and clamped, a ratchet wheel and the spraying assembly can be controlled to automatically rotate in an intermittent mode, horizontal sliding and angle adjustment of a spraying gun can be controlled in the stop period, and therefore efficient and automatic sprayingand repairing of all arc-shaped blocks on the arc-shaped face of the brake disc can be completed.

Owner:ANHUI REMFG ENG DESIGN CENT

A side wall trolley

ActiveCN103557011BImprove problems with heavy burdensImprove stabilityUnderground chambersTunnel liningPipe fittingEngineering

The invention discloses a side wall trolley which comprises a plurality of side wall trolley units spliced lengthways, wherein each side wall trolley unit comprises a trolley moving and fixing system and a steel moulding plate connecting and positioning system. The side wall trolley adopts the design of cantilever connection of a steel moulding plate and a trolley, combines hydraulic jacks, screw jacks and walking systems to realize three-position accurate adjustment, realizes bearing and transmission of load through components such as opposite supporting pipe fittings, lateral screw rod jacks, bearing jacks, tail margin guy cables and anti-floating screw rod jacks, and is stable and reliable in structure. Through the adoption of the side wall trolley, construction of a steel pipe bracket and assembly of moulding plates are not need, thus greatly simplifying construction procedures, improving the mounting speed and reliability of the moulding plates and the construction efficiency, meanwhile reducing labor intensity of workers, greatly saving manual labor, wood and steel pipe brackets and lowering the construction cost.

Owner:GUANGZHOU XINQIAO CONSTR SERVICE +1

Non-embedded intelligent deceleration strip and working method thereof

ActiveCN106869045AControl adjustmentEasy to adjustTraffic signalsRoad signsElectric machineFixed frame

The invention discloses a non-embedded intelligent deceleration strip. The non-embedded intelligent deceleration strip comprises a control processing device, a crawler-type deceleration strip body, a driving motor, a fixing frame, a sliding frame, n fork type push-pull assemblies and a base; the deceleration strip body is located above the fork type push-pull assemblies, and the top ends of inclined rods of the fork type push-pull assemblies are rotatably connected with the deceleration strip body; and a first pulley is mounted at the bottom end of the inclined rod of each fork type push-pull assembly; the fixing frame and the sliding frame are located at the two ends of the deceleration strip body; the fixing frame is connected with one ends of the fork type push-pull assemblies rotatably, and the sliding frame is connected with the other ends of the fork type push-pull assemblies rotatably; second pulleys are mounted at the bottom end of the sliding frame, and the first pulleys and the second pulleys are embedded in a sliding rail; the driving motor is fixed to the base, and the driving motor is connected with the sliding frame; and the signal output end of the control processing device is connected with the signal input end of the driving motor. According to the non-embedded intelligent deceleration strip, excavation of the road surface for embedding is not needed, later maintenance is convenient, and a vehicle can be decelerated more accurately.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Side wall concrete construction method employing side wall trolley

ActiveCN103556817BImprove problems with heavy burdensImprove stabilityForms/shuttering/falseworksPipe fittingJoint deviation

The invention discloses a side wall concrete construction method employing a side wall trolley. The employed side wall trolley is formed by a side wall trolley unit or longitudinal splicing of a plurality of side wall trolley units, the side wall trolley unit comprises a trolley moving and fixing system and a steel moulding plate connecting and positioning system; the construction steps are the followings in sequence: paving a walking track, precoating a release agent, enabling the trolley to move and take place, adjusting a screw jack, repeatedly adjusting an extension-type cantilever beam and a hydraulic jack, adjusting a bearing jack, mounting a lateral screw rod jack, mounting a foot margin inhaul cable, mounting an anti-floating screw rod jack, mounting an opposite-support pipe fitting, mounting a closing-up net and a water stop steel plate, casting concrete, stripping and the like, that building a steel pipe support and a spliced template is not required can be achieved, after the adoption of the invention, the mounting and the demounting speeds are fast, three-direction accurate adjustment can be achieved, the construction is stable and reliable, the concrete surface flatness is good, and joint deviation is small.

Owner:GUANGZHOU XINQIAO CONSTR SERVICE +1

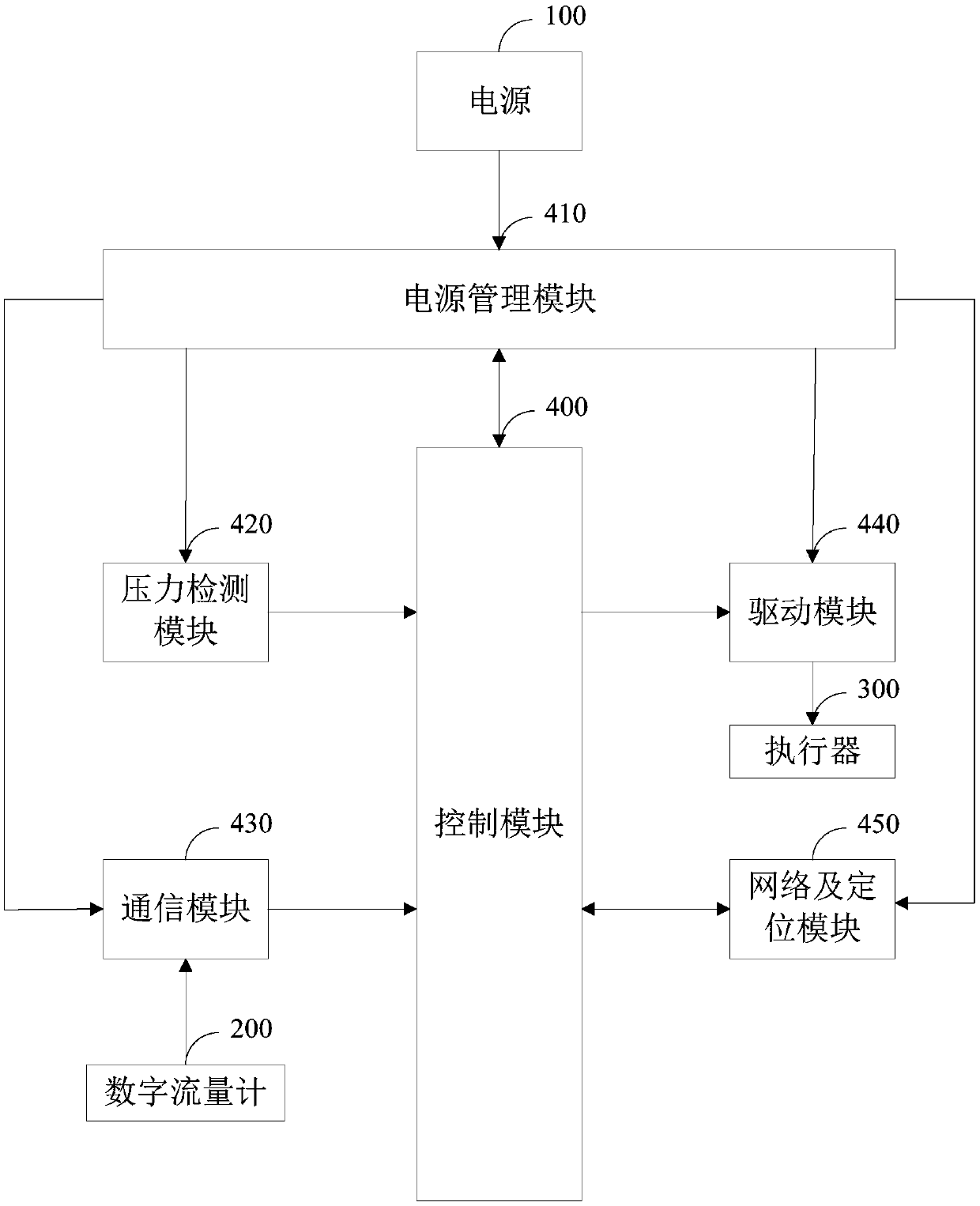

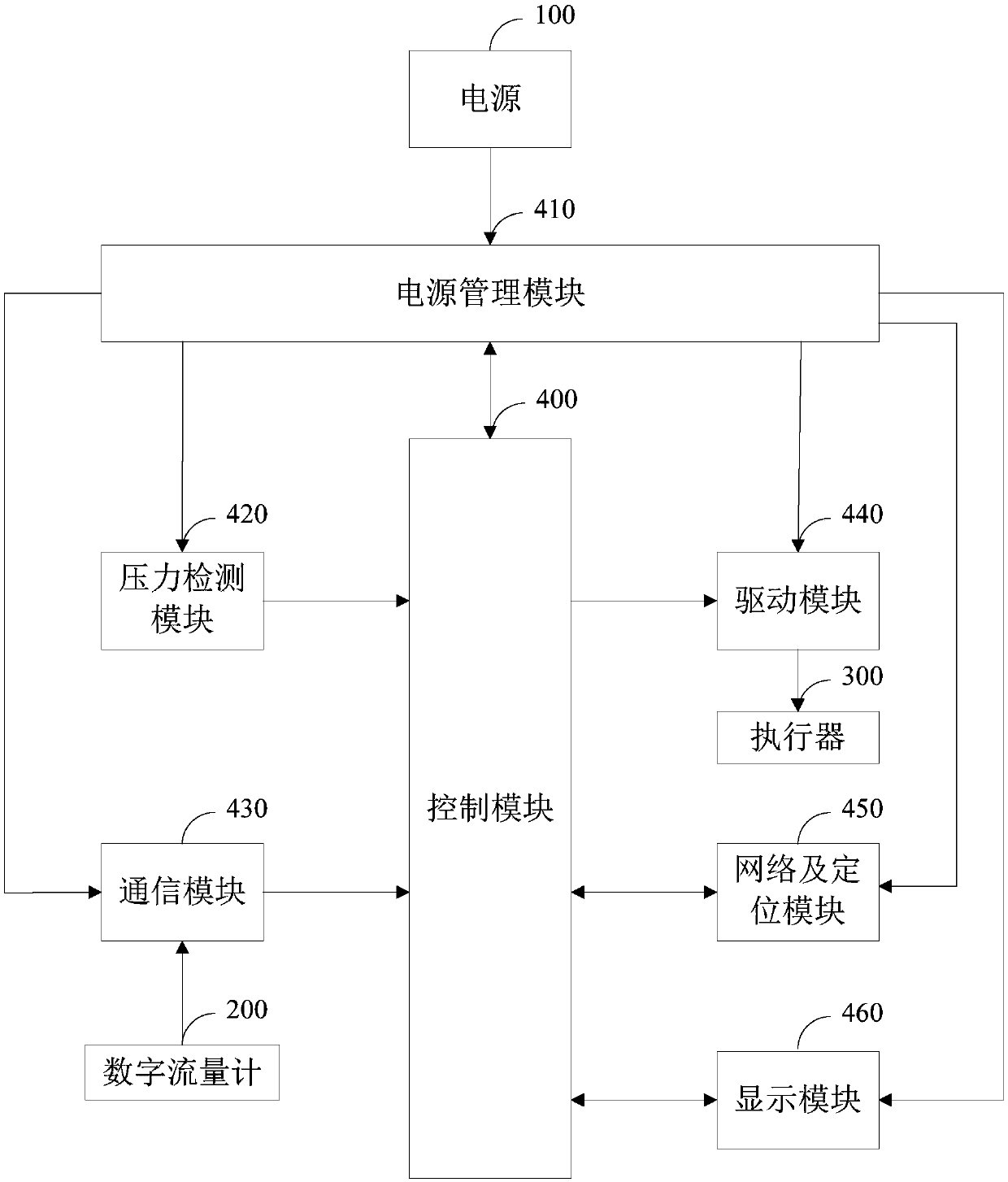

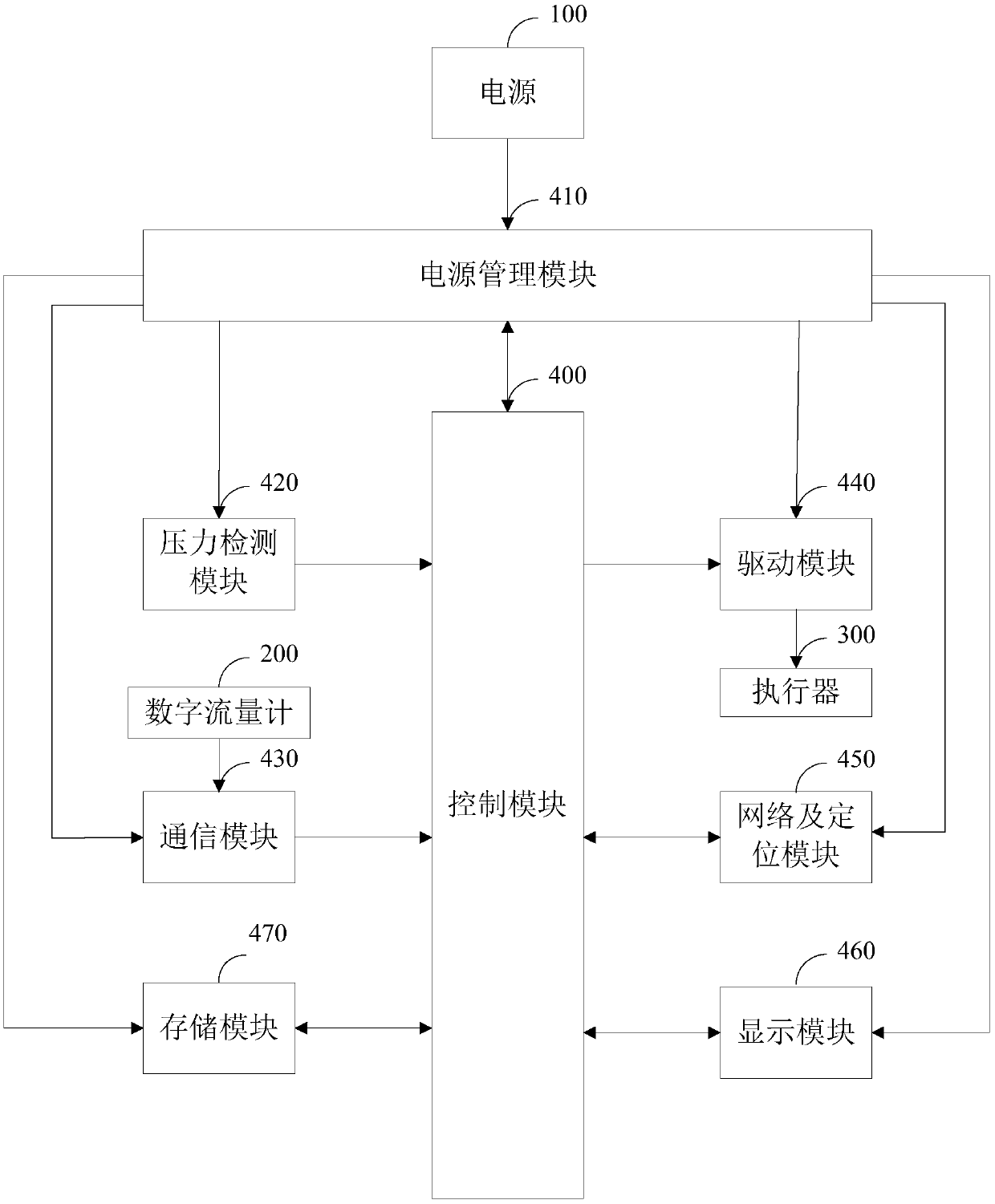

Pipe network pressure control circuit and system

PendingCN111434972ARegulating pressureControl adjustmentPipeline systemsControl engineeringCentralized management

The invention relates to a pipe network pressure control circuit. A control module, a pressure detection module, a communication module and a driving module are additionally arranged to control the adjusting process and the pressure precision, and the control module controls the driving module according to a pipe network actual pressure value obtained from the pressure detection module or data ofa digital flow meter from the communication module, so that pipe network pressure changes are obtained in real time to adjust the pipe network pressure; and low-energy-consumption management is achieved by additionally arranging a power management module, downstream pressure changes are obtained in real time by additionally arranging a pressure detection module and the driving module to then adjust the pipe network pressure, the problem that due to the fact that the downstream pressure is too large, a pipeline is exploded or water does not exist due to too low pressure is avoided, and the problems that according to a traditional technical scheme, manpower is consumed, the adjusting process and the pressure precision are difficult to control, the pressure of the downstream pipeline cannot be adjusted in real time according to the changes of downstream pressure requirements, and energy consumption waste is caused due to the fact that a power source cannot be managed in a centralized modeare solved.

Owner:深圳拓安信物联股份有限公司

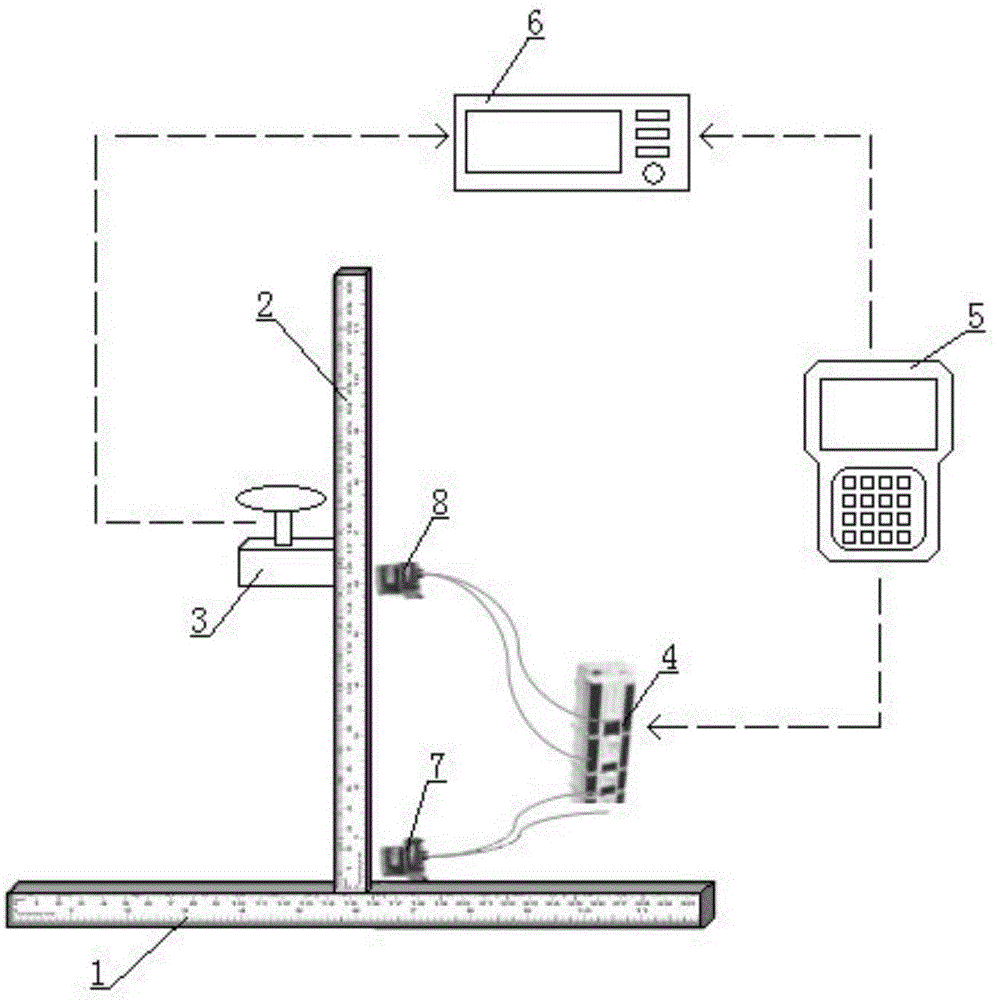

Apparatus and method for examining positioning precision of Bipolar positioning antenna

PendingCN106597486ASimple structureImprove performanceSatellite radio beaconingElectric machineryEngineering

The invention provides an apparatus for examining the positioning precision of a Bipolar positioning antenna. The apparatus includes a horizontal X-axis guide rail and a vertical Z-axis guide rail which are vertically disposed, a positioning module which is arranged on the vertical Z-axis guide rail or the horizontal X-axis guide rail, a displacement simulator, a PLC control module and a data processing backend. The apparatus fixes a to-be-examined Bipolar positioning antenna to the positioning module and inputs a displacement mode which is set manually to the displacement simulator. The apparatus then controls a servo motor through the PLC control module to drive the positioning module to move. Based on the coordinate data transmitted by the Bipolar positioning antenna and the displacement simulator, the apparatus obtains one monitoring displacement curve and one actual displacement curve after data processing. The apparatus then examines the positioning precision of the Bipolar positioning antenna by comparing the monitoring displacement curve and the actual displacement curve. The apparatus can directly simulate geological displacement and is advantaged by simple structure, easy operation and high measuring precision.

Owner:HUNAN LIANZHI BRIDGE & TUNNEL TECH

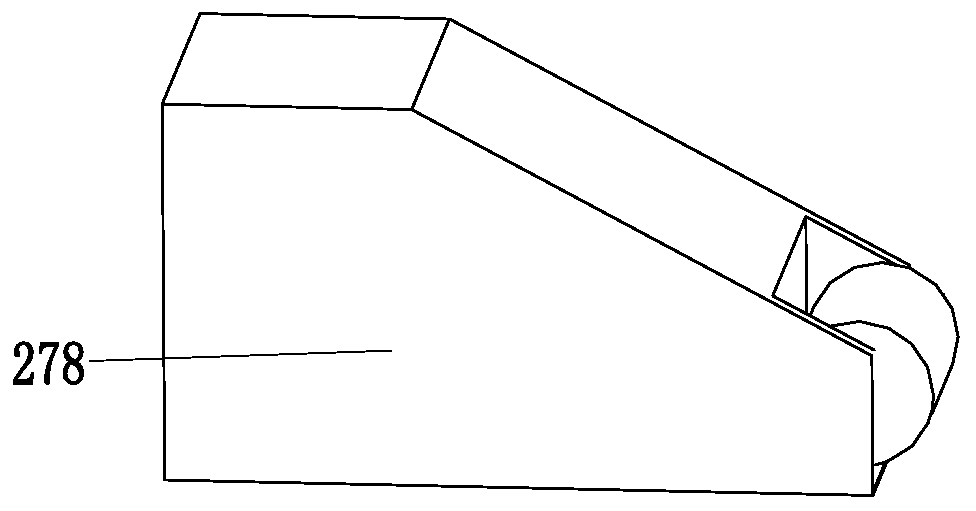

Adjustable die cutting cutter device

InactiveCN105291177AContinuously adjustable distance adjustmentAvoid wear and tearMetal working apparatusEngineeringSmall range

The invention discloses an adjustable die cutting cutter device which comprises a main shaft, a base, a fixing seat, a cutter, a wedge-shaped block and an adjusting supporting plate. The fixing seat is arranged below the inclined edge of the wedge-shaped block. The cutter faces a rotary cutter gasket and is fixed to the fixing seat. The fixing seat, the wedge-shaped block and the adjusting supporting plate are connected with the base. The adjusting supporting plate acts on the wedge-shaped block to horizontally move and push the wedge-shaped block. The adjustable die cutting cutter device has the beneficial effects that the die cutting cutter device is improved so that the distance between the cutter and the rotary cutter gasket can be continuously adjusted, in addition, the cutter can maintain the rigidity unchanged in the small-range distance change, the purpose of fine adjustment is achieved, the adjusting width is well controlled, and the cutter or the rotary cutter gasket is prevented from being abraded.

Owner:镇江市远兴包装机械有限公司

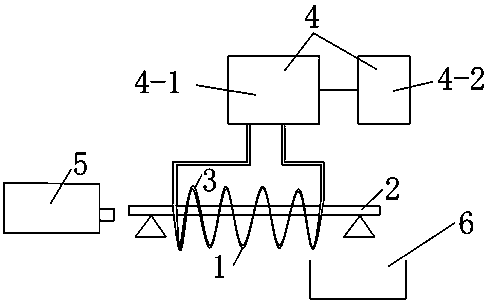

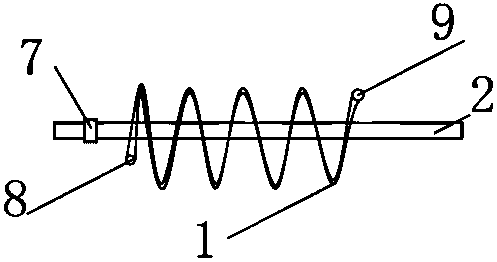

Quenching device

InactiveCN108676976ARealize continuous quenching treatmentChange the effect of heat treatmentFurnace typesIncreasing energy efficiencyQuenchingSpiral coil

The invention provides a quenching device. The quenching device includes a spiral coil quencher which is surrounded by a hollow copper pipe, wherein one end of the spiral coil quencher is a feeding end and the other end is a discharge end. A rail for workpiece running is arranged in the spiral coil quencher. A resistance wire is arranged in the hollow copper pipe, wherein two ends of the hollow copper pipe are connected with a heater. The spiral coil quencher is formed by the hollow copper pipe in a surrounded mode, a workpiece traveling in the spiral coil quencher is subjected to quenching treatment through the hollow copper pipe, the continuous quenching treatment of small parts can be realized, the effect of heat treatment to the processing workpiece can be changed, the adjustment of the heat treatment can be more precisely controlled, and not only is the work efficiency improved, but also the stability of the effect of the heat treatment is improved.

Owner:张家港市后塍热处理厂

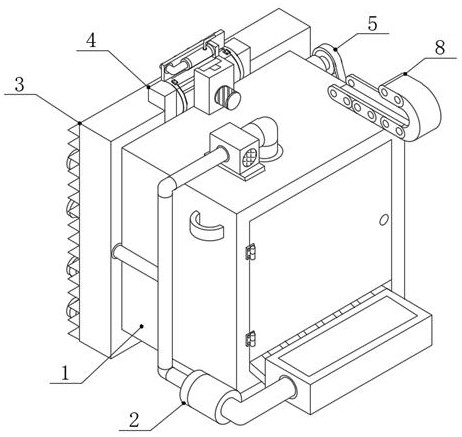

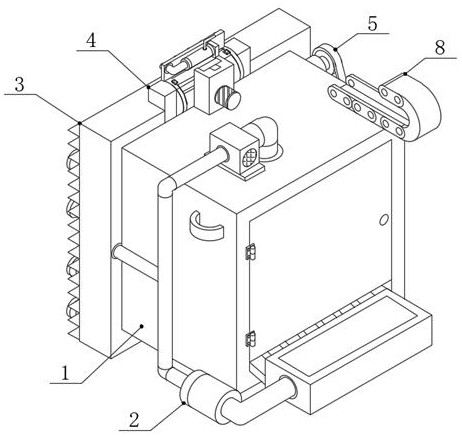

Automatic repairing equipment for damage of outer vertical face of sandwich board wall

ActiveCN113445780AAvoid secondary damageImprove handling fixesBuilding repairsLiquid spraying apparatusSandwich boardPutty

The invention discloses automatic repairing equipment for damage of the outer vertical face of a sandwich board wall, and belongs to the technical field of sandwich board metal face repairing. The automatic repairing equipment comprises a sealing cover provided with a hoisting ring, a fitting frame is fixedly connected to one side of the sealing cover, and a fitting mechanism is fixedly installed between the fitting frame and the corresponding position of one side of the sealing cover; and a driving mechanism is fixedly installed at one side of an inner cavity of the sealing cover, and a repairing mechanism and a spraying mechanism are installed at one side of the driving mechanism in a deflectable manner. According to the automatic repairing equipment, a scraping roller can fully scrape and smear scraping putty through a plurality of spliced scraping pieces, so that the color difference with the whole wall surface due to different aging degrees of finish paint after processing can be avoided, meanwhile, the curing degree of the finish paint is improved, manual treatment can be replaced by cooperation of multiple components, and the labor cost is reduced; and meanwhile, secondary damage to the wall is avoided through the flexible fitting mechanism, treatment and repair of damage of the outer vertical face of the wall in the transportation construction process are improved, and the good market application value is achieved.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

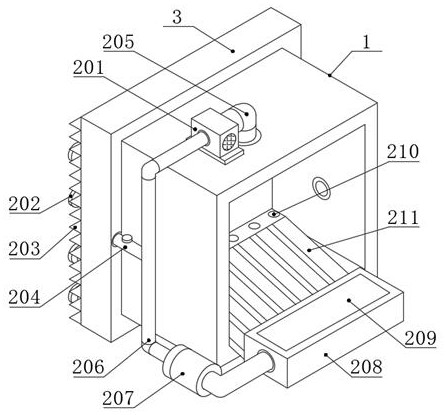

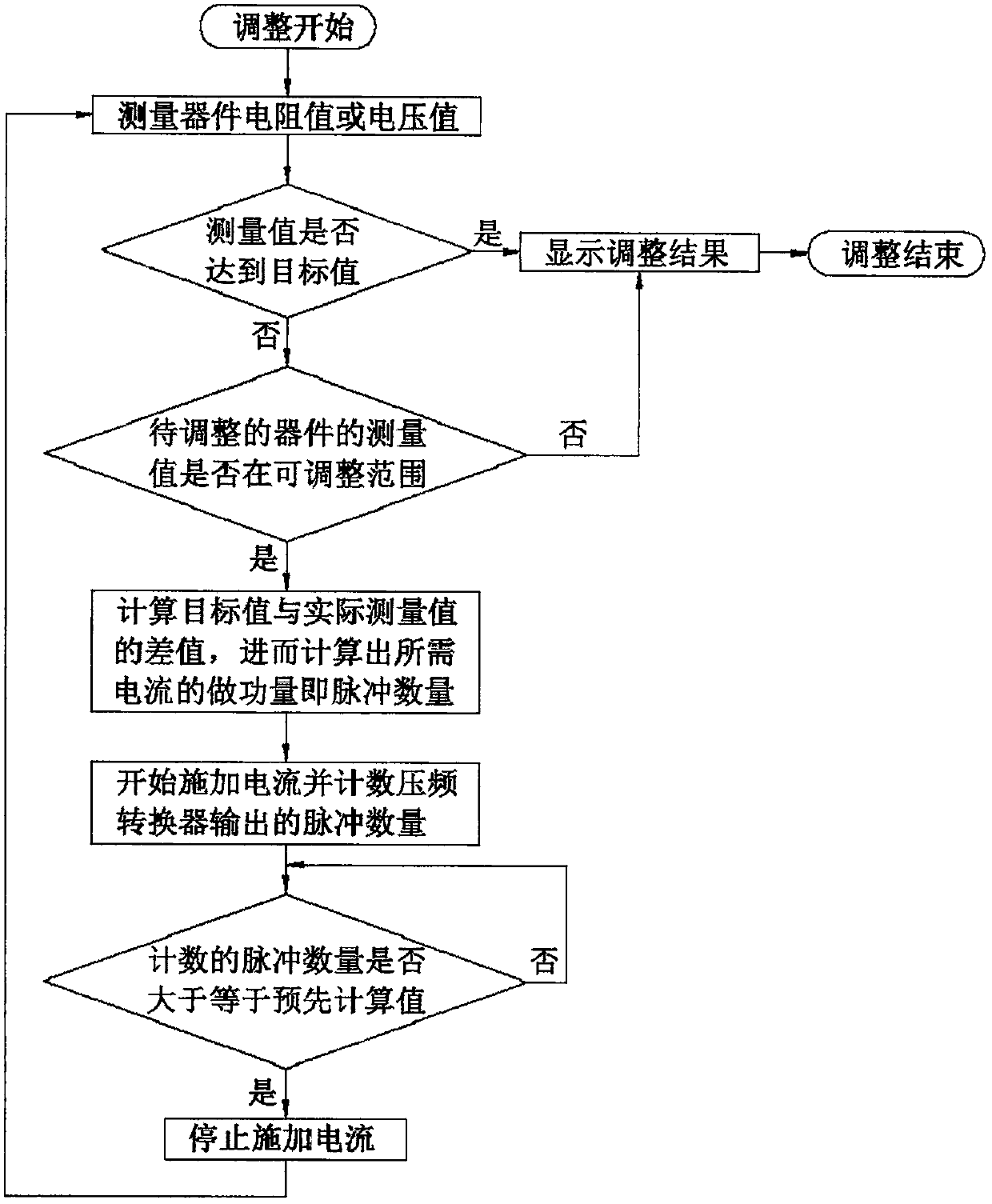

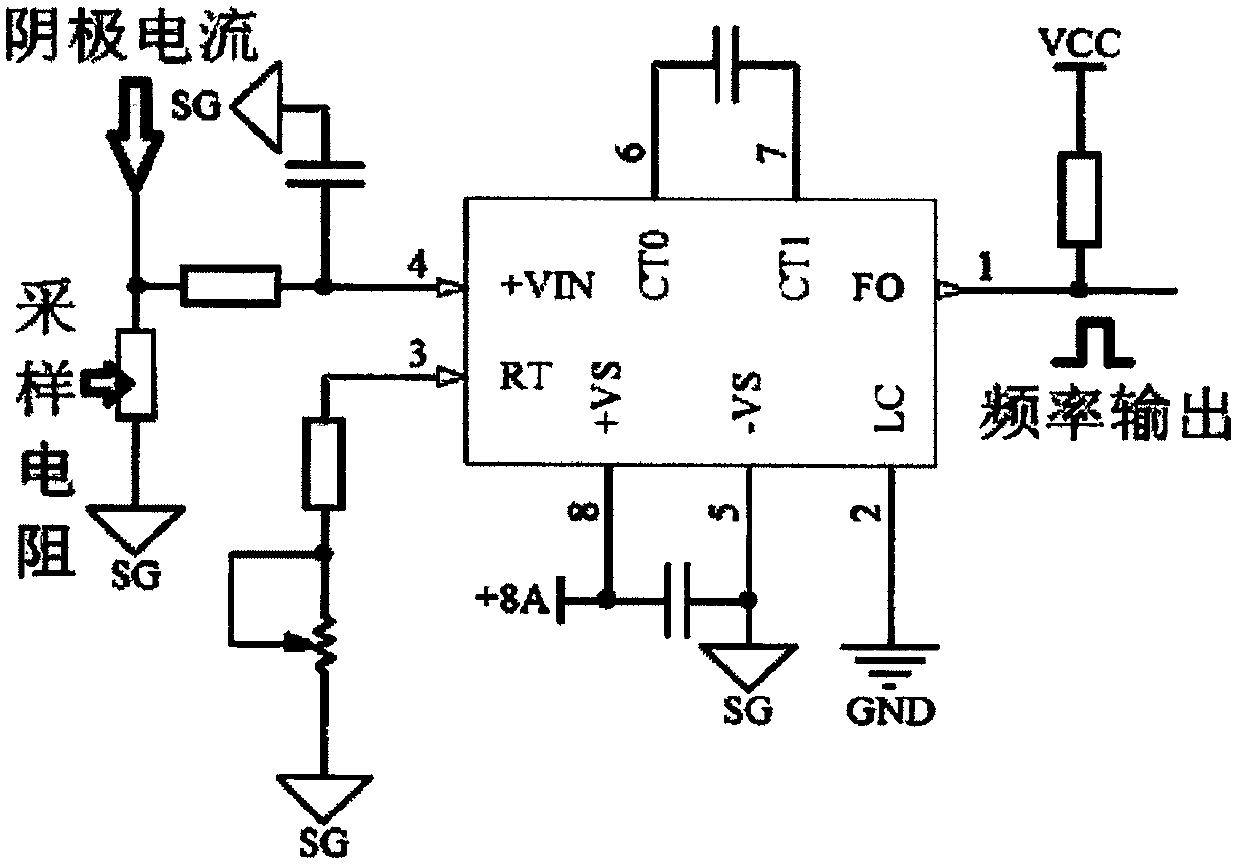

Automatic precise electrochemistry etching method and automatic precise electrochemistry etching equipment

InactiveCN111074329AStrong process adaptabilityThinning controlElectrolysis componentsEngineeringElectrochemistry

The invention discloses an automatic precise electrochemistry etching method. Precise etching process control is achieved mainly through parameter setting, automatic workpiece positioning, initial value collecting, etching current acting amount calculating, initial value adjusting and other steps, and accordingly precise etching is conducted on a to-be-treated workpiece. According to the automaticprecise electrochemistry etching method, through comparison of a pre-calculated current acting amount and a current actual acting amount in an actual etching process, the closed-loop control processof precise etching is conducted, and accordingly accurate control over electrochemistry etching is achieved, wherein a VCO conversion method is adopted for accurately obtaining the etching current actual acting amount in the etching process, and accordingly accurate control is conducted on the thinning amount of the workpiece. In addition, the invention further relates to automatic precise electrochemistry etching equipment implementing the automatic precise electrochemistry etching method. By means of the automatic precise electrochemistry etching method and the automatic precise electrochemistry etching equipment, the electrochemistry etching precision, electrochemistry etching process control stability and etching efficiency are greatly improved, and the etching cost is greatly reduced.

Owner:王晓冉

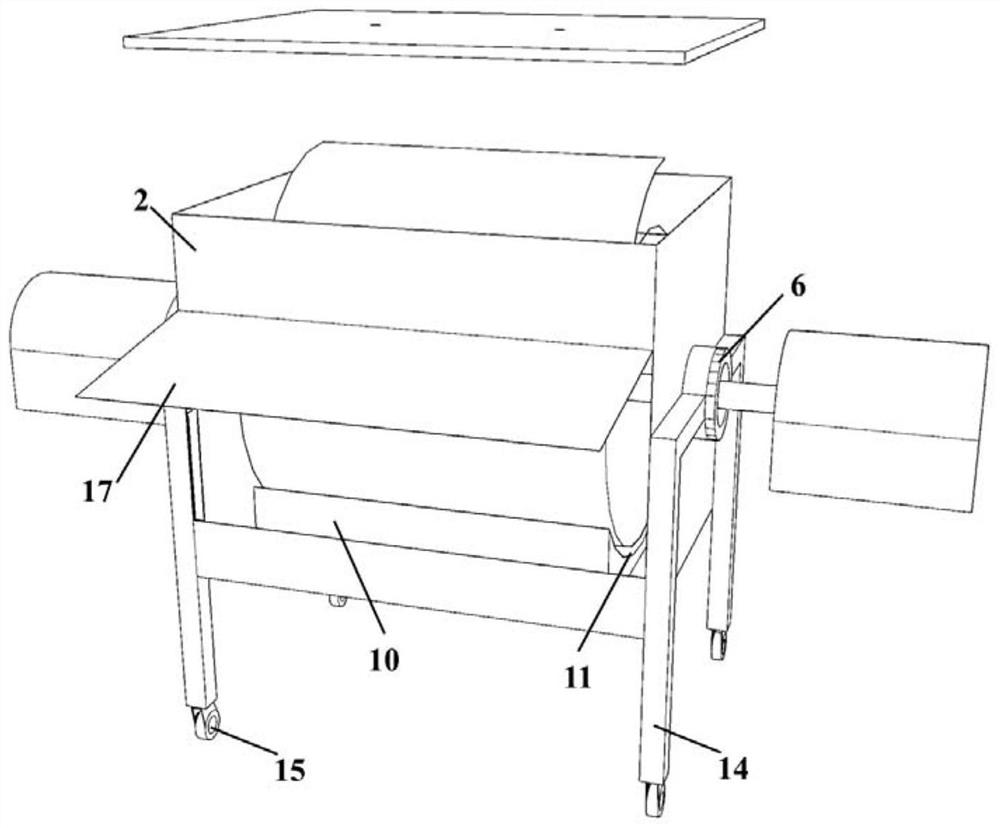

Environmentally-friendly and efficient organic fertilizer decomposing equipment

PendingCN109776123AProtect healthProtect environmentOrganic fertiliser preparationEnvironmental resistancePush and pull

The invention discloses environment-friendly and efficient organic fertilizer decomposing equipment. The equipment comprises a side body and a partition plate, the lower end position of the side bodyis provided with a bottom plate, a drainage channel is arranged at the middle of the left side of the bottom plate, the inside of the right side of the front end of the side body is provided with a discharge door, an upper cover is arranged at the upper end of the side body, for more environment protection and full sealing, an odor is discharged by an exhaust channel, and sewage is discharged by the drainage channel, thereby protecting health and environment of production personnel; in order to be more decomposed and even, and a chain drives a scraper to push and pull, which has less dead angle and sinking than traditional material turning, thereby increasing the fertilizer efficiency; for being more efficient, through temperature and pressure control, a motor can be effectively controlledto adjust the rotation speed of a main rotating wheel to adjust the turning speed, the feeding and discharging are quick and convenient, which is more efficient than traditional pushing and shoveling, and comprehensive mechanical feeding and discharging is achieved.

Owner:北京清大元农生物科技有限公司

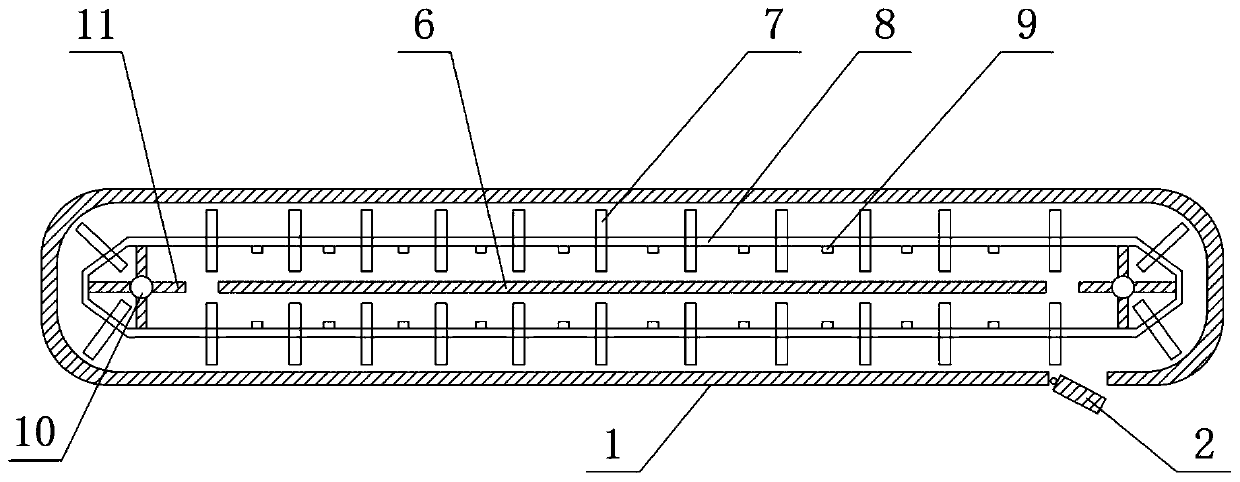

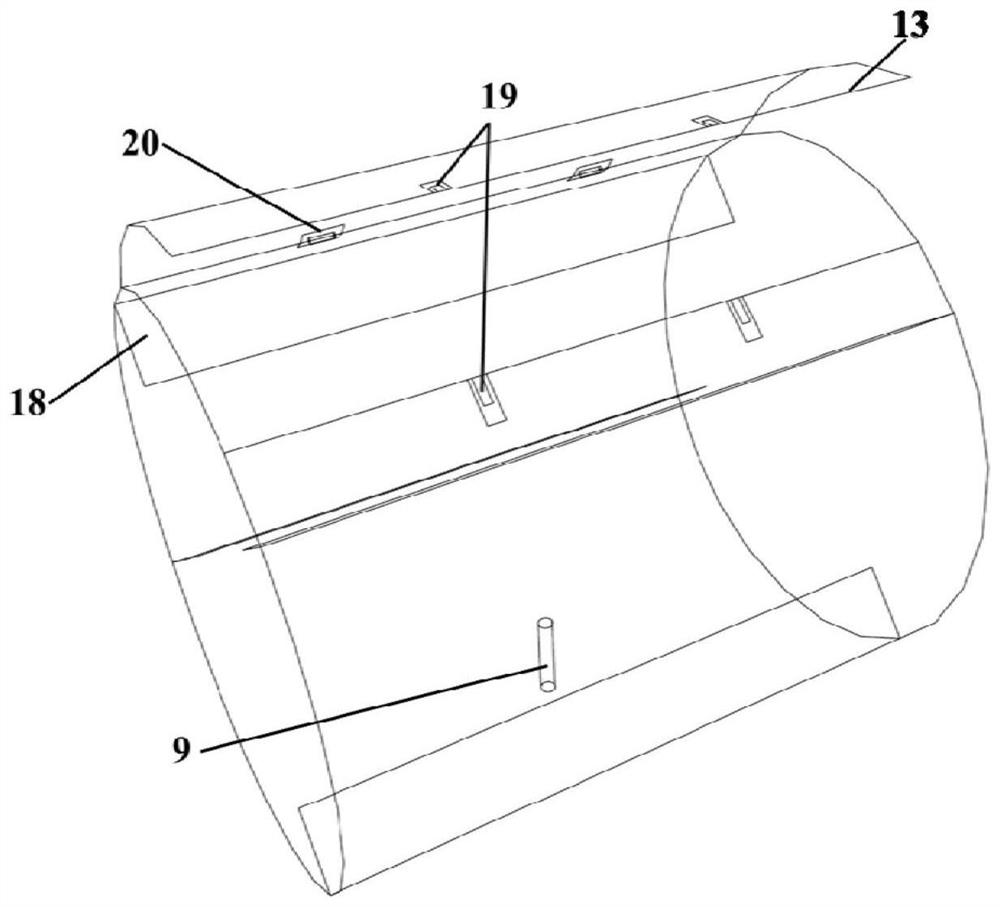

Dewatered sludge bio-drying apparatus

ActiveCN113735398AOptimizing the Biodrying ProcessRealize intelligent operationSludge treatment by de-watering/drying/thickeningBiological sludge treatmentMicroorganismProcess engineering

The present invention relates to a dewatered sludge bio-drying apparatus, the apparatus comprises a reactor main body. The reactor main body comprises a drum inner shell (12) for filling dewatered sludge to be dried; and a reactor outer shell (2). the reactor outer shell (2) is internally provided with an air distribution cavity (10) for aerating the roller inner shell (12), and the air distribution cavity (10) is connected with a ventilation pipe (8); a feeding hole is formed in the roller inner shell (12); a discharging hole is formed in the side surface of the reactor outer shell (2); and the dewatered sludge bio-drying apparatus further comprises a rotating mechanism used for controlling the roller inner shell (12) to rotate. Compared with the prior art, thedewatered sludge bio-drying apparatus has the advantages that a good growth environment can be provided for microorganisms, moisture in materials can be rapidly removed, and therefore the drying efficiency is improved.

Owner:SHANGHAI UNIV OF ENG SCI

Floor slab concrete construction method applying floor slab trolley

ActiveCN103603490BControl adjustmentImprove carrying capacityForms/shuttering/falseworksFloor slabEngineering

Owner:GUANGZHOU XINQIAO CONSTR SERVICE +1

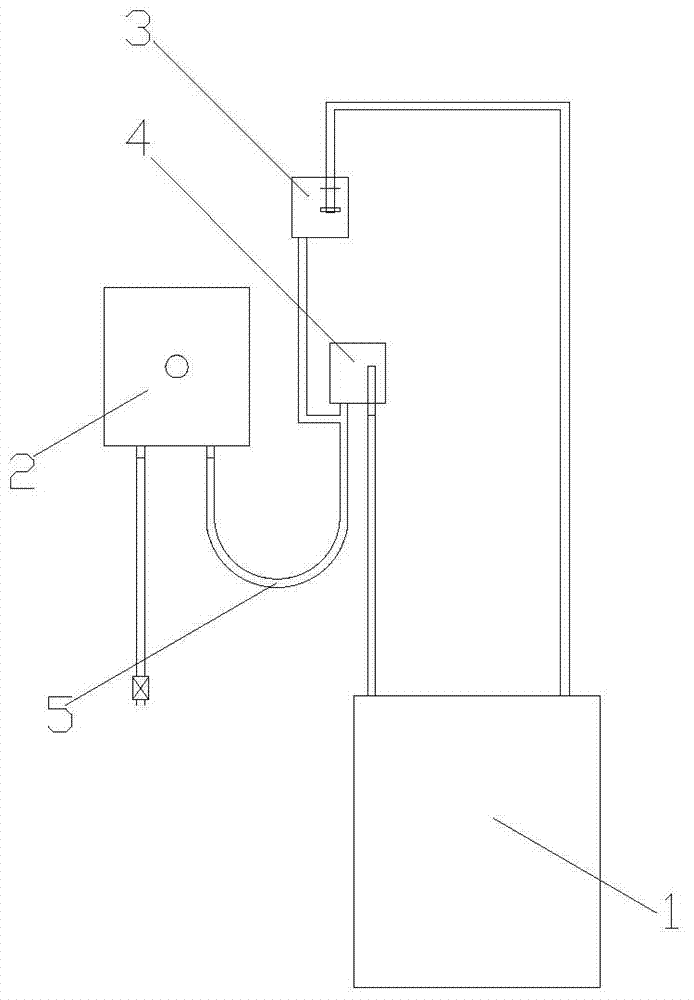

Humidity balance device

InactiveCN104503500AAchieve balance adjustmentControl adjustmentHumidity controlWater flowEngineering

The invention discloses a humidity balance device which comprises a main water tank, a moisturizing water tank, a water flow control box and a water level control box, wherein the water level control box is positioned above the main water tank; the water flow control box is positioned above the water level control box; the water flow control box, the water level control box and the main water tank are connected in series in sequence through pipelines to form water path circulation; the pipeline between the water flow control box and the water level control box is also communicated with a U-shaped pipeline; the other end of the U-shaped pipeline is connected with the moisturizing water tank; the height of the moisturizing water tank is equal to the water level control box. Due to the mode, the moisture balance device which is simple in structure and convenient to use is provided, so that moisture balance adjustment can be quickly realized; furthermore, the humidity adjustment value can be precisely controlled, and the aim of fine adjustment is fulfilled.

Owner:SUZHOU DONGHUA TESTING INSTR

A dual-slag process for smelting ultra-low phosphorus and low-carbon steel in a double-blown converter

The invention relates to a double-slag process for smelting ultralow-phosphorus and low-carbon steel in a combined-blown converter. The double-slag process comprises the following steps: (1) molten iron and waste steel are put into the converter according to the molten iron ratio of 85% to 90%; (2) bottom blowing gas adopts nitrogen and argon in a switched manner, the nitrogen is adopted before the supply of 80% of oxygen, and the argon is automatically switched after the supply of 80%t of oxygen; (3) at the first stage of blowing, the flow rate of the oxygen adopts 20000-21000 Nm<3> / h within the first minute, and a normalized slag lance position of 1800-2000 mm is adopted; after the start of blowing for one minute, the flow rate of the oxygen is adjusted to be 13000 Nm<3> / h; (4) a de-slagging moment is set as 8-10 minutes after the start of blowing; (5) at the second stage of blowing, blowing is started when the high lance position is 1700-1800 mm, the flow rate of the oxygen is adjusted to be 18000 Nm<3> / h, and the converter end point control target is that carbon is less than 0.05%, and phosphorus is less than 0.004%. According to the double-slag process provided by the invention, the converter end point phosphorus can be stably controlled to be less than or equal to 0.004 percent, so that the target of smelting the ultralow-phosphorus and low-carbon steel by a single converter is stably realized.

Owner:NANJING IRON & STEEL CO LTD

A kind of automatic repair equipment for damaged external facade of sandwich panel wall

ActiveCN113445780BAvoid secondary damageImprove handling fixesBuilding repairsLiquid spraying apparatusMechanical engineeringSandwich panel

The invention discloses an automatic repair device for the damage of the exterior facade of a sandwich panel wall, which belongs to the technical field of repairing the metal surface of the sandwich panel, and comprises a closed cover provided with a hoisting ring, one side of the closed cover is fixedly connected with a fitting frame A fitting mechanism is fixedly installed between the fitting frame and the corresponding position on one side of the closure cover, a drive mechanism is fixedly installed on one side of the inner cavity of the closure cover, and a repair mechanism and a spraying mechanism are installed deflectably on one side of the drive mechanism. mechanism. In the present invention, a plurality of spliced scraping sheets are used to fully scrape the scraping putty by the scraping roller, which can avoid the color difference with the wall as a whole due to the aging degree of the topcoat after processing, and at the same time improve the curing degree of the topcoat , can replace manual processing through multi-component cooperation, reduce labor costs, and at the same time avoid secondary damage to the wall through the flexible bonding mechanism, and improve the processing and repair of damage to the external facade of the wall during transportation and construction. It has a good market Value.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

A non-embedded intelligent speed bump and its working method

ActiveCN106869045BControl adjustmentEasy to adjustTraffic signalsRoad signsSpeed bumpControl engineering

The invention discloses a non-embedded intelligent deceleration strip. The non-embedded intelligent deceleration strip comprises a control processing device, a crawler-type deceleration strip body, a driving motor, a fixing frame, a sliding frame, n fork type push-pull assemblies and a base; the deceleration strip body is located above the fork type push-pull assemblies, and the top ends of inclined rods of the fork type push-pull assemblies are rotatably connected with the deceleration strip body; and a first pulley is mounted at the bottom end of the inclined rod of each fork type push-pull assembly; the fixing frame and the sliding frame are located at the two ends of the deceleration strip body; the fixing frame is connected with one ends of the fork type push-pull assemblies rotatably, and the sliding frame is connected with the other ends of the fork type push-pull assemblies rotatably; second pulleys are mounted at the bottom end of the sliding frame, and the first pulleys and the second pulleys are embedded in a sliding rail; the driving motor is fixed to the base, and the driving motor is connected with the sliding frame; and the signal output end of the control processing device is connected with the signal input end of the driving motor. According to the non-embedded intelligent deceleration strip, excavation of the road surface for embedding is not needed, later maintenance is convenient, and a vehicle can be decelerated more accurately.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com