A kind of automatic repair equipment for damaged external facade of sandwich panel wall

A façade, sandwich panel technology, applied in metal processing equipment, grinding/polishing equipment, building maintenance, etc., can solve the lack of wall surface adaptability, manual repair is prone to accidental collision, and the cost of artificial materials is high. problems, achieve good market application value, avoid secondary damage, and reduce labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

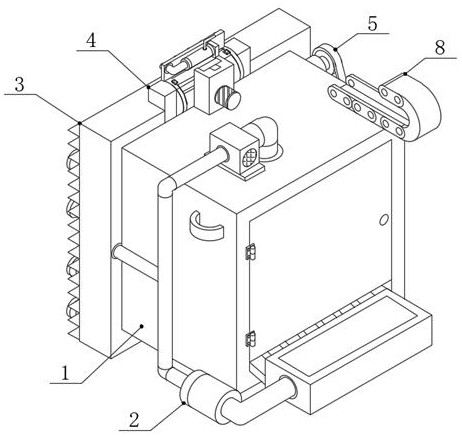

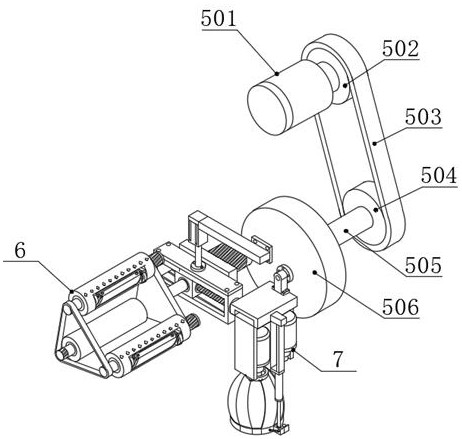

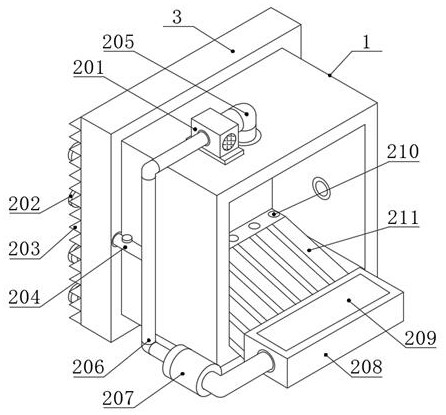

[0046] The specific embodiment is as follows: the closure cover 1 is a closed heat insulation mechanism, and the hoisting rings on both sides of the closure cover 1 can be facilitated to be hoisted to the damaged position of the wall for processing, and the cross-sectional shape of the fitting pad 203 is conical, and the The pad 203 can be fully attached to the corner of the metal surface through the taper, and at the same time, the adsorption strength can be enhanced and modified through a plurality of separate vacuum suction cups 202. At the same time, the attachment pad 203 and the attachment frame 3 are accommodated to avoid grinding, spraying and repairing. For the damage to the external environment, the installation of the drive mechanism 5 can realize the integrated accommodation of the repair mechanism 6 and the spray mechanism 7, reduce the difficulty of hoisting, improve the degree of equipment integration, and meet the stability and safety of the wall repair.

[0047...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com