A non-embedded intelligent speed bump and its working method

A speed bump, non-embedded technology, applied in the field of non-embedded intelligent speed bump, can solve the problems of difficult maintenance, inconvenient use and popularization of intelligent speed bump, etc., achieves accurate adjustment, is conducive to controlling vehicle speed, and ensures safe driving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

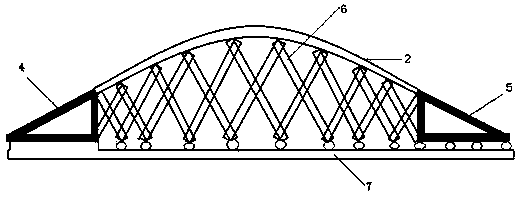

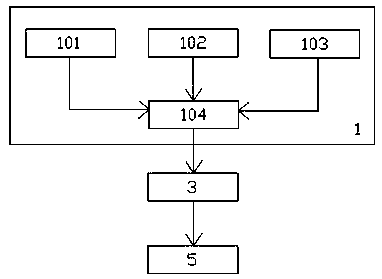

[0033] like figure 1 As shown, a non-embedded intelligent deceleration belt according to the embodiment of the present invention includes: a control processing device 1, a crawler type deceleration belt body 2, a driving motor 3, a fixed frame 4, a sliding frame 5, and n groups of fork-type push-pull components 6 , The top surface is provided with the base 7 of slide rail. Wherein, n is an integer greater than 3, such as 5, 7 or 10. The selection of the n value can be determined according to the length of the crawler type deceleration belt body 2 .

[0034] N sets of fork-shaped push-pull assemblies 6 are arranged parallel to each other. like figure 1 As shown, the fork-type push-pull assembly 6 includes multiple sets of slanting rods, and each set of slanting rods includes two slanting rods. Two oblique rods are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com