Patents

Literature

32 results about "Phosphorus low" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A low phosphorus has many possible causes, including hypercalcemia related to hyperparathyroidism, alcoholism, malnutrition, hypothyroidism, overuse of diuretics, rickets or osteomalacia. Low blood phosphorus is also associated with liver disease and kidney failure.

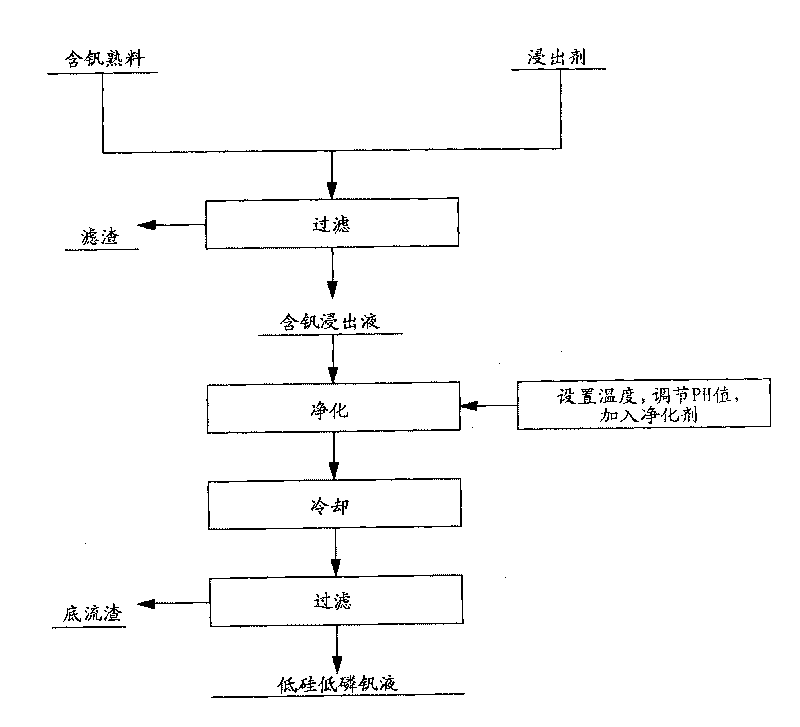

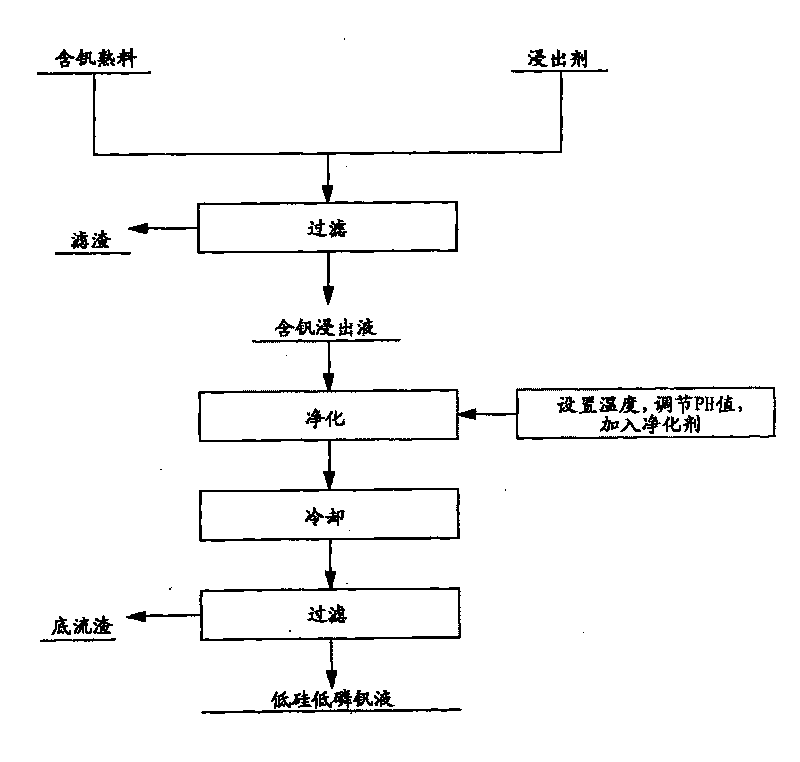

Phosphorus and silicon removing method of vanadium-contained clinker leaching liquor

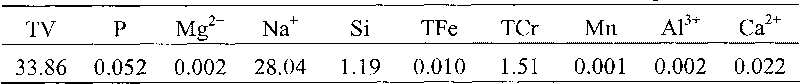

The invention discloses a phosphorus and silicon removing method of a vanadium-contained clinker. A vanadium-contained clinker leaching liquor is obtained by leaching the vanadium-contained clinker by using the method comprising the following steps of: setting the temperature of the vanadium-contained clinker leaching liquor within a temperature range of 60 DEG C to boiling; regulating the pH value of the vanadium-contained clinker leaching liquor; regulating the pH value of the vanadium-contained clinker leaching liquor by utilizing an acid and an alkali according to the varieties of purifying agents to be added; adding the purifying agent and determining the addition of the purifying agent according to the detected contents of phosphorus and silicon in the vanadium-contained clinker leaching liquor and the reaction formula of the phosphorus and the silicon in the vanadium-contained clinker leaching liquor and the purifying agent; and cooling and filtering the obtained vanadium-contained clinker leaching liquor to obtain a low-phosphorus low-silicon vanadium liquor. The phosphorus and silicon removing method of the vanadium-contained clinker has a loose requirement for vanadium liquor components and can simultaneously effectively remove the phosphorus and the silicon as impurities.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

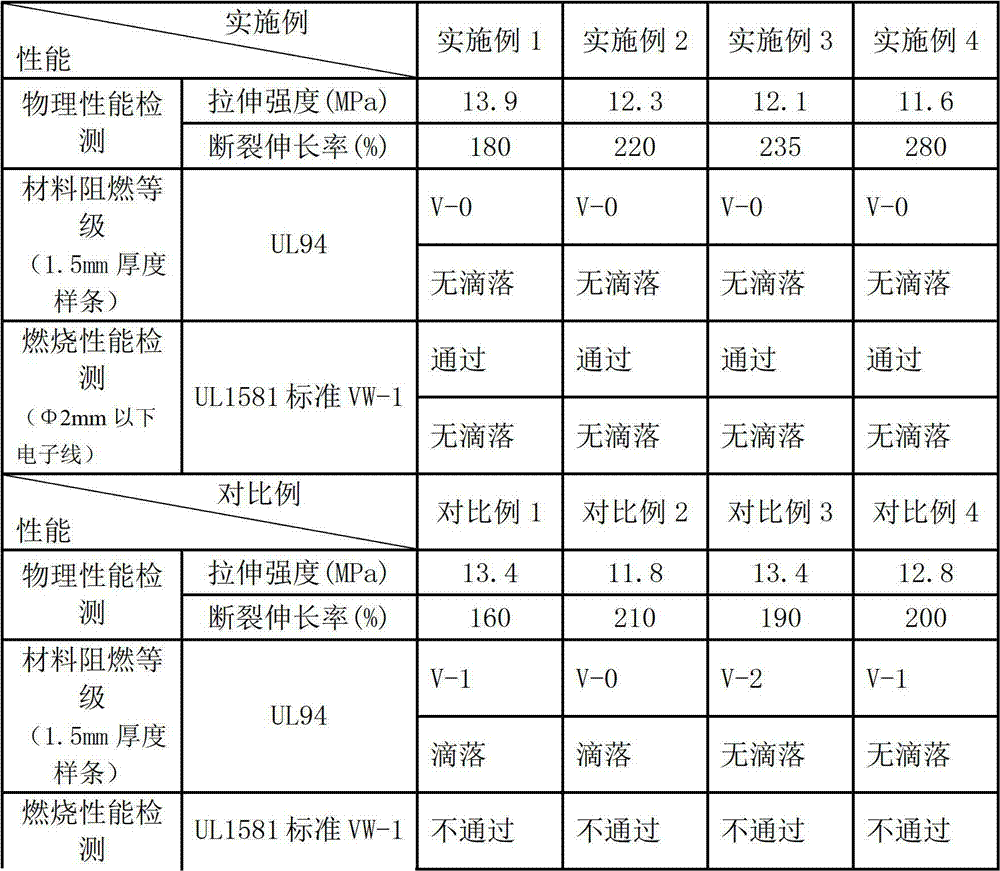

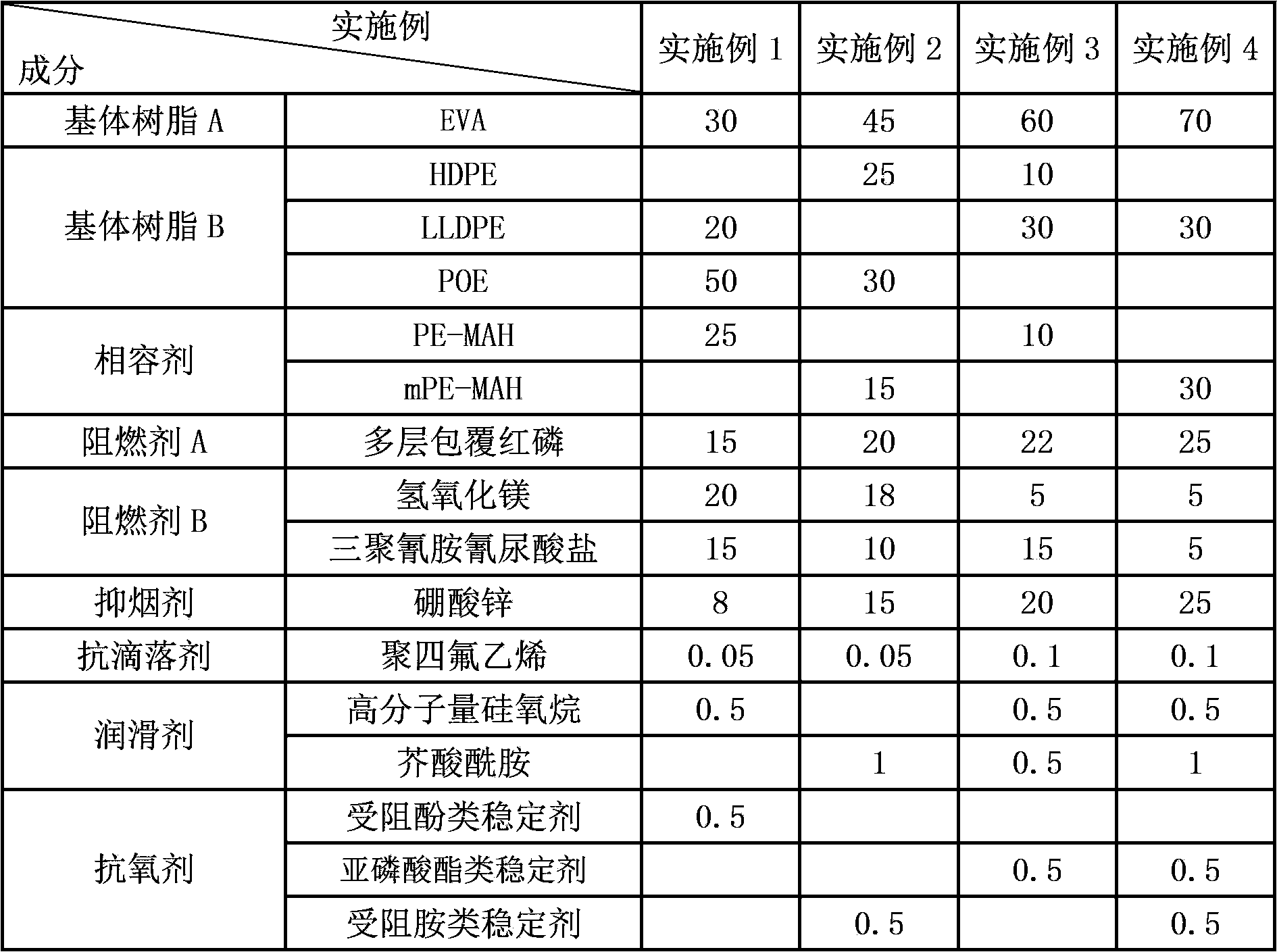

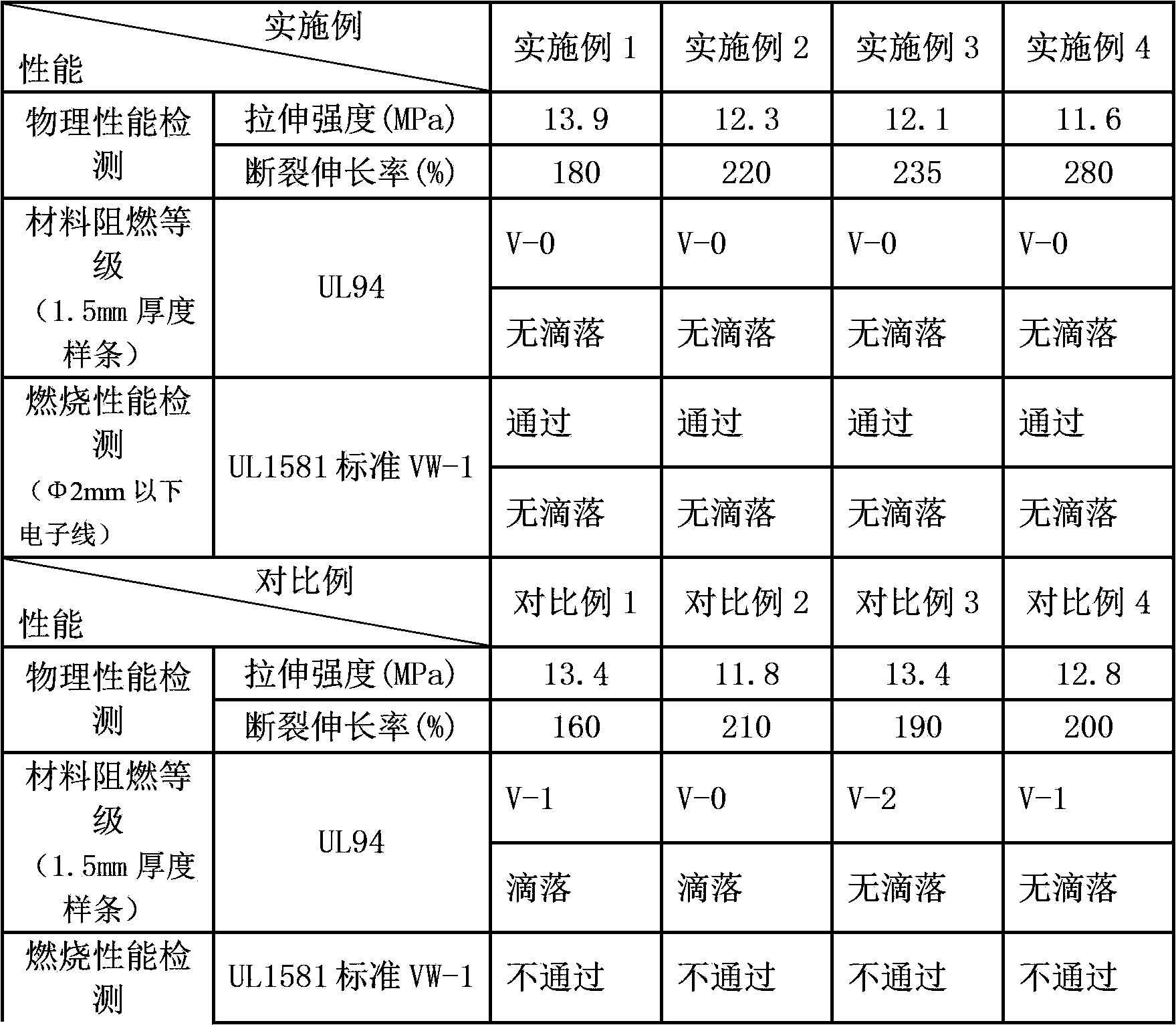

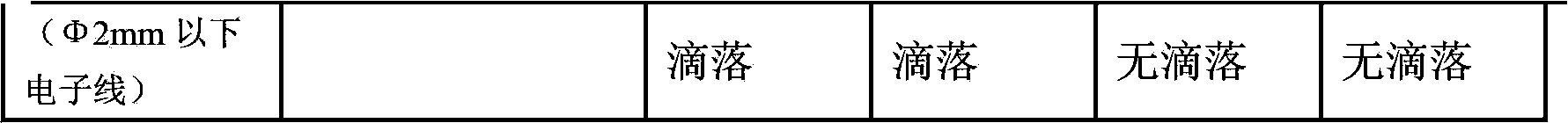

Multilayer coated red phosphorus low smoke halogen-free flame retardant polyolefin cable sheath material and preparation method thereof

ActiveCN102731888AGood halogen freeImprove flame retardant performanceInsulated cablesInsulated conductorsElastomerPolymer science

The present invention belongs to the technical field of a new material, and provides a multilayer coated red phosphorus low smoke halogen-free flame retardant polyolefin cable sheath material and a preparation method thereof. The sheath material comprises the following components, by weight, 30-70 parts of a matrix resin A, 30-70 parts of a matrix resin B, 5-30 parts of a compatibilizer, 5-40 parts of a flame retardant agent A, 10-40 parts of a flame retardant agent B, 0.1-2 parts of a lubricant, and 0.1-1 part of an antioxidant. The preparation method comprises the following steps: A, extruding; and B, carrying out granulation on the extruded material by a granulator to obtain the sheath material finished product. Advantages of the material of the present invention are that: the sheath material is prepared by matching the flame retardant agent A and the flame retardant agent B with the polyolefin elastomer raw material, such that characteristics of halogen-free property and good low smoke flame retardation effect are provided, and advantages of good physical property, good water resistance and less dripping are provided; and the preparation method has a simple preparation process, and is suitable for large-scale industrial production.

Owner:ZHEJIANG SHIP ELECTRONICS TECH

Environment friendly metal surface treatment agent and application thereof

ActiveCN108193202AReduce corrosionPrevent penetrationMetallic material coating processesPhosphorus lowNitrogen

The invention discloses an environment friendly metal surface treatment agent and application thereof. The environment friendly metal surface treatment agent uses water as a solvent and contains 10 ppm-50000 ppm of a zirconium / titanium compound, 200 ppm-10000 ppm of an organic material, 20 ppm-1000 ppm of a complexing agent, 20 ppm-1000 ppm of a wetting assistant, 1 ppm-10000 ppm of a film formation accelerant and 1 ppm-200 ppm of an antirust agent. The non-phosphorus low-nitrogen before-coating environment friendly metal surface treatment agent is provided, main ingredients of the agent do not contain nitrogen, and meanwhile, a composite conversion film capable of improving the film corrosion resistance and the coating bonding capacity can be formed on the metal surface.

Owner:NANJING KERUN LUBRICANTS +2

80 kilogram grade low welding crack sensibility high-strength steel plate special-purpose welding wire

InactiveCN101157166AAchieve microalloyingPrevent cold crackingWelding/cutting media/materialsSoldering mediaForeign matterNiobium

The invention belongs to the welding wire technical field, and discloses a special welding wire for 80 Kg level steel plate with low welding crack sensibility and high strength. The invention has the technical proposal that the welding wire includes the elements in the following weight percentage: 0.06 to 0.12 percent of carbon, 0.40 to 1.00 percent of silicon, 1.40 to 2.10 percent of manganese, 0.02 to 0.20 percent of titanium, 0.001 to 0.01 percent of boron, 0.05 to 1.50 percent of nickel, 0.05 to 1.20 percent of chromium, niobium b lower than or equal to 0.10 percent, vanadium lower than or equal to 0.10 percent, sulfur lower than or equal to 0.10 percent, phosphorus lower than or equal to 0.10 percent, the rest comprises iron and other unavoidable foreign matters. Through the experiment, the ambient temperature of the welding joint for welding crack sensibility and high strength steel plate is subzero 20 DEG C to 50 DEG C by utilizing the welding wire without preheat, and the occurrence of cold cracks can be prevented.

Owner:金秋生

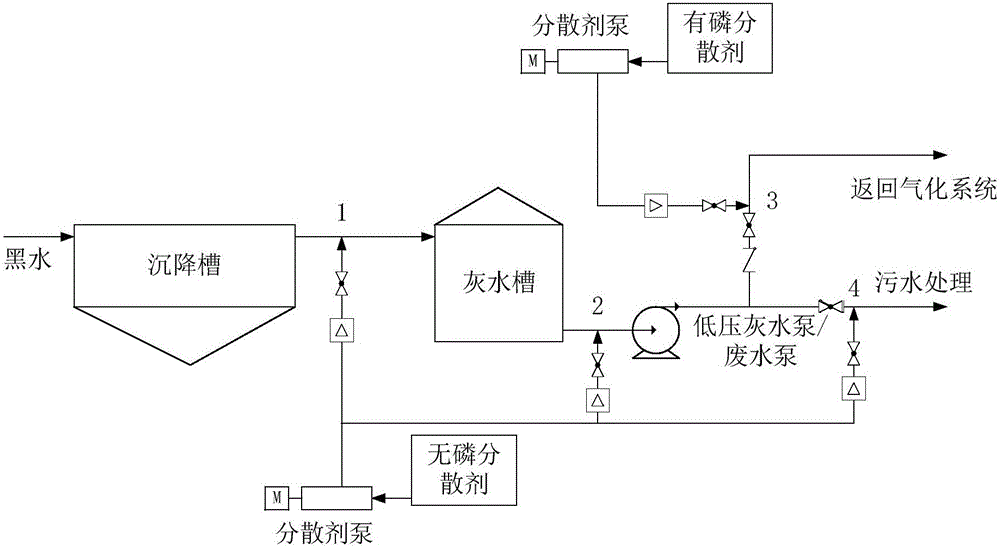

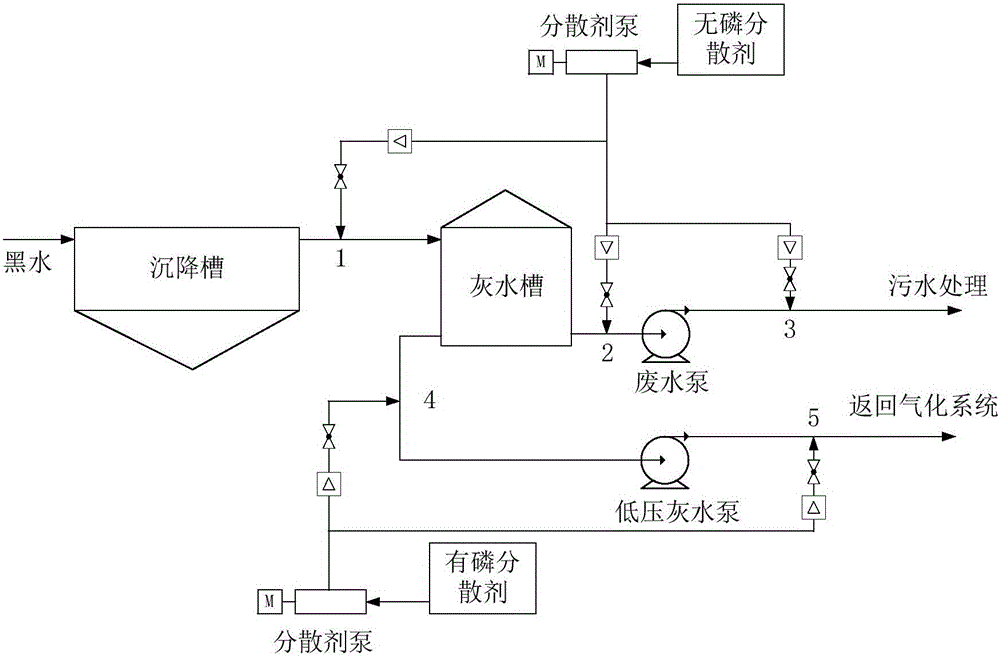

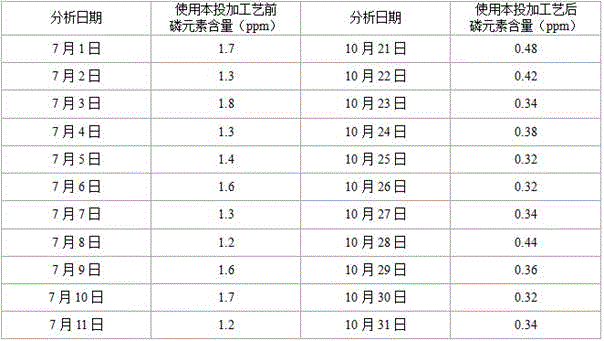

Addition technology of zero-phosphorus-low-phosphorus grey water scale inhibition and dispersion agent

ActiveCN105776591AReduce phosphorus contentGood anti-scaling and dispersing effectSpecific water treatment objectivesScale removal and water softeningPhosphorus lowWastewater

The invention discloses an addition technology of a zero-phosphorus-low-phosphorus grey water scale inhibition and dispersion agent, and belongs to the technical field of gasification water treatment. A formula and an addition technology of a scale inhibition and dispersion agent are improved, a low-phosphorus dispersion agent is added at a high-temperature part, a zero-phosphorus dispersion agent is added at a low-temperature part, and the low-phosphorus dispersion agent and the zero-phosphorus dispersion agent are combined and added at different sections, so that the content of phosphorus elements in externally discharged waste water of gasification enterprises is greatly reduced, the discharged waste water reaches the first-level industrial water discharge standard of China, environment-friendly discharge is realized, and besides, good grey waste scale inhibition and dispersion effects are achieved.

Owner:TAIZHOU JIUYUN CHEM TECH CO LTD

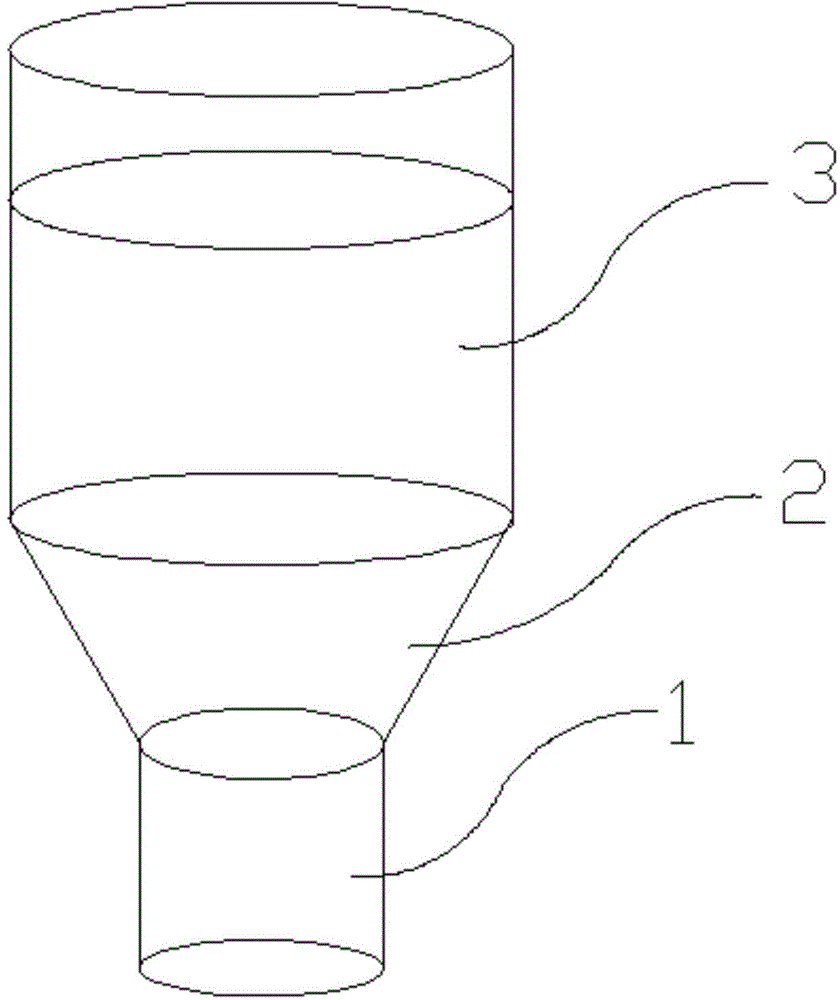

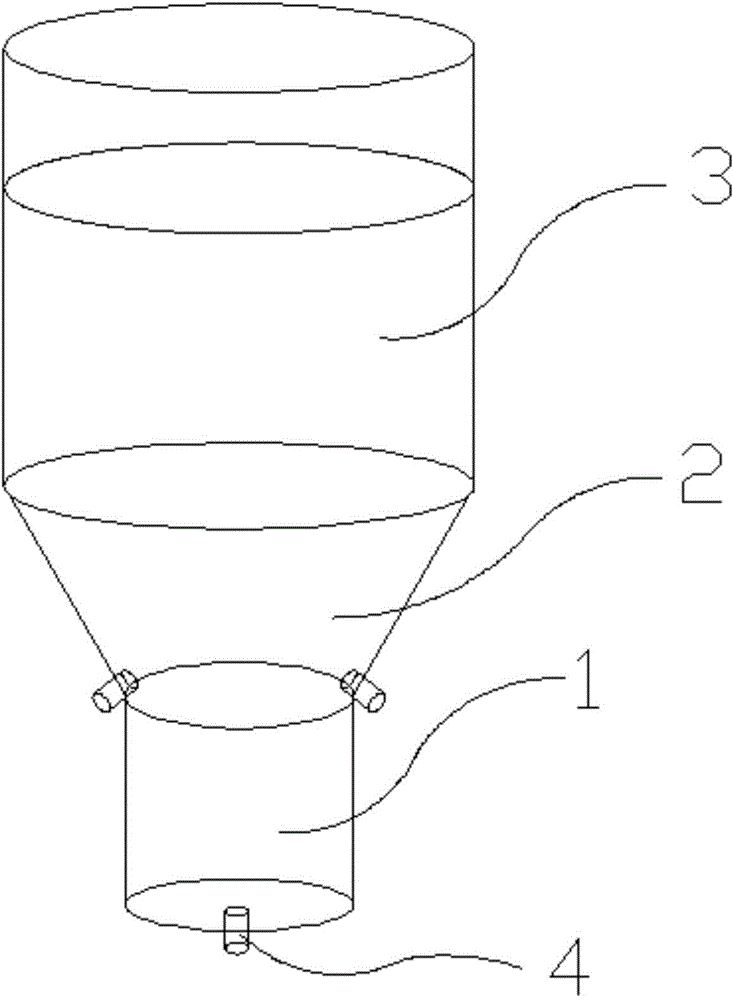

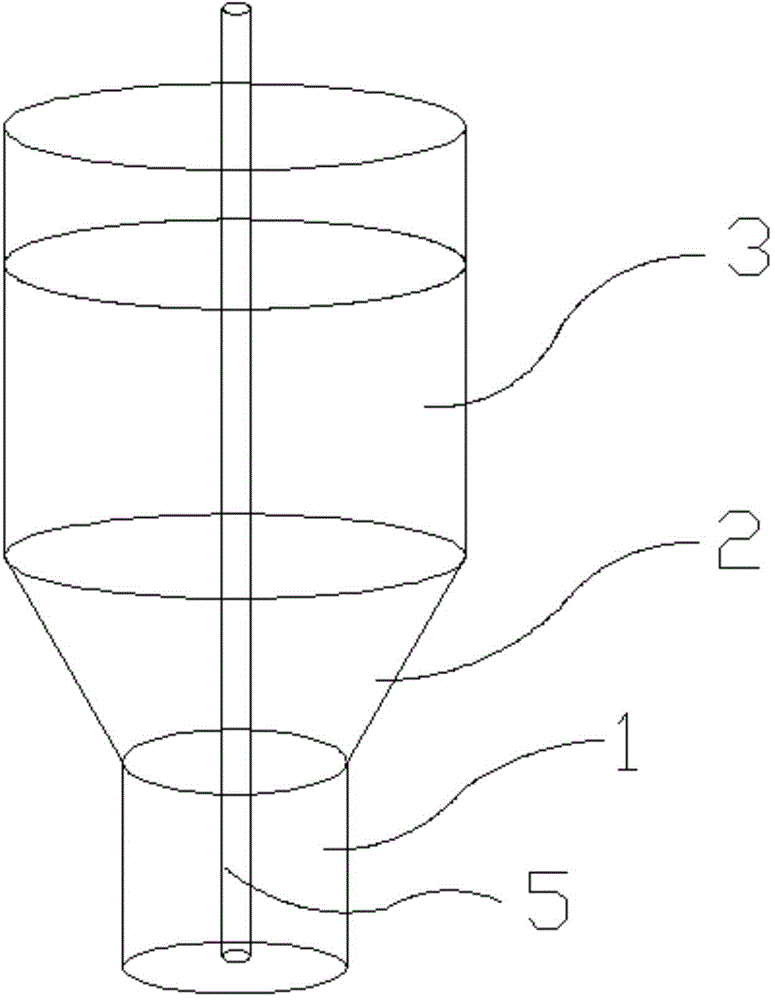

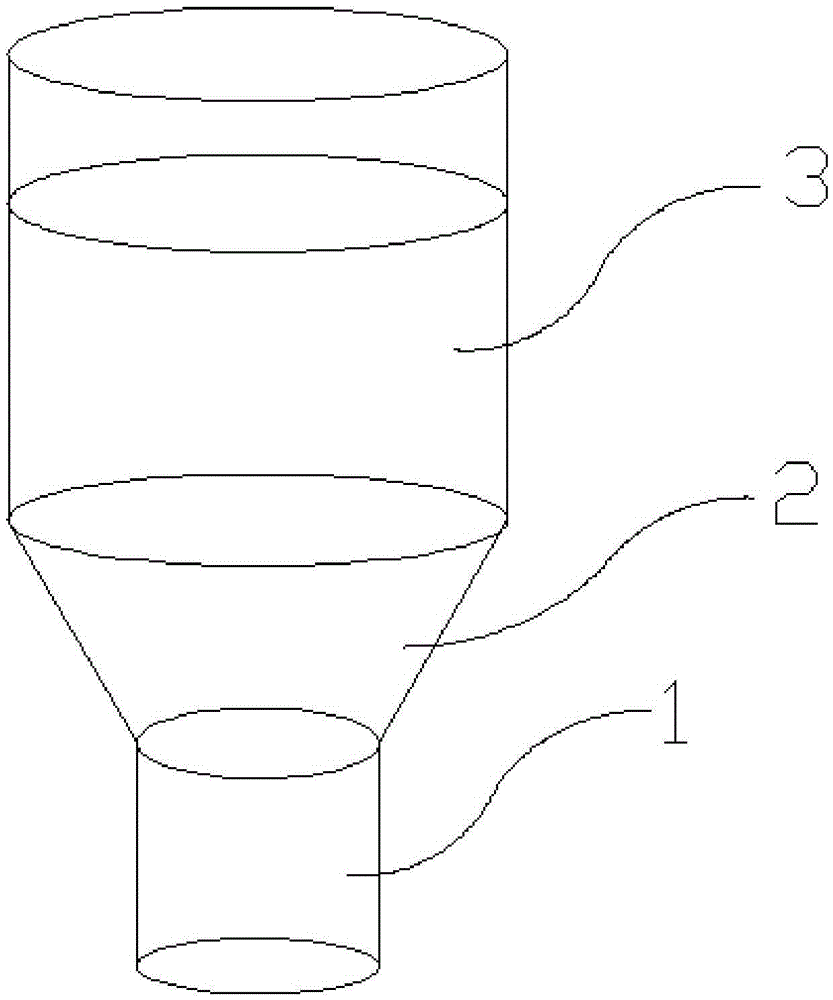

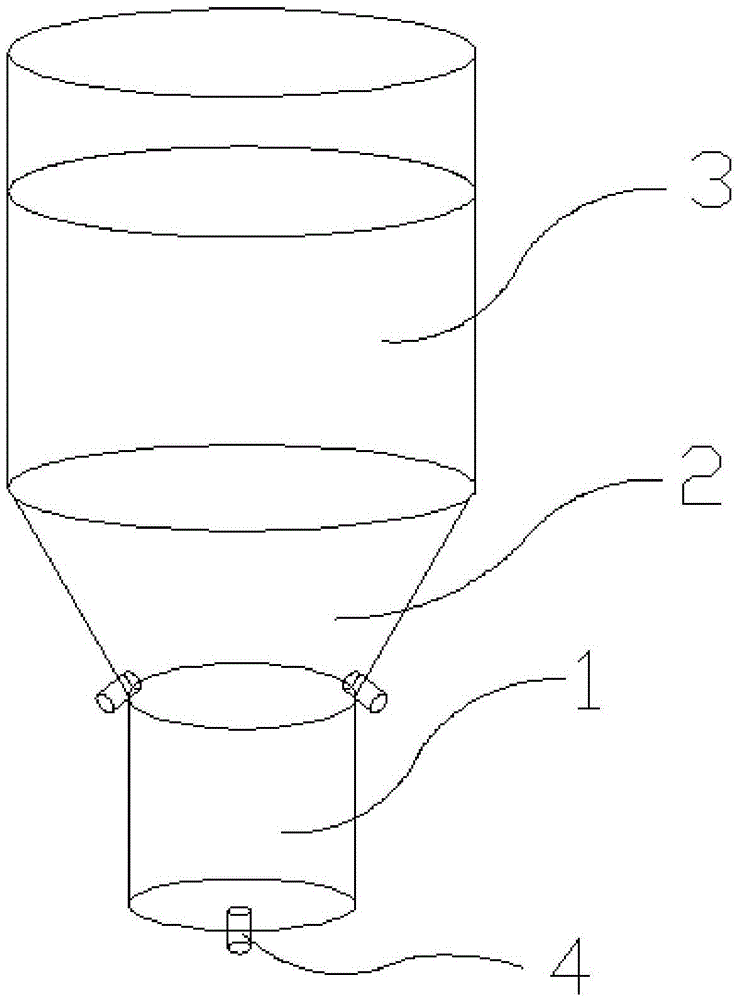

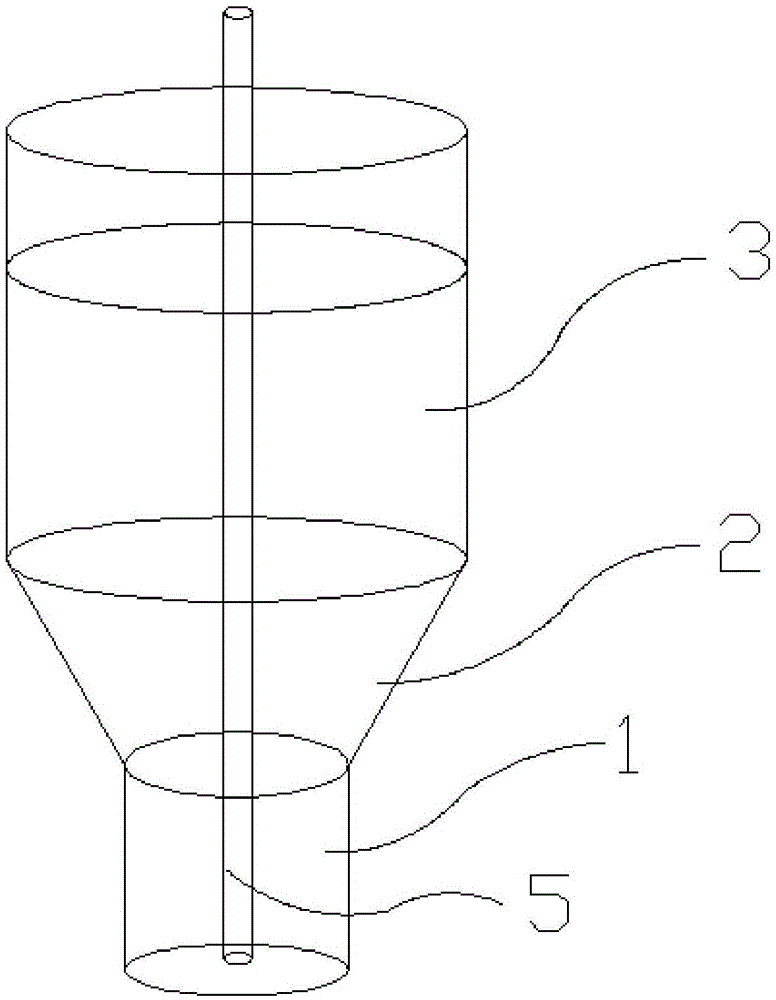

Intermediate frequency furnace, application thereof, and method for smelting silicon iron by utilizing crystalline silicon scraps

InactiveCN104482761AHigh purityReduce consumptionCrucible furnacesPhosphorus lowIntermediate frequency

The invention discloses an intermediate frequency furnace, application thereof, and a method for smelting silicon iron by utilizing crystalline silicon scraps, which belong to the field of crystalline silicon scraps disposal. The intermediate frequency furnace comprises a furnace body, wherein the furnace body is divided into a furnace body lower section, a furnace body middle section and a furnace body upper section from bottom to top; the diameter of the furnace body lower section is smaller than the diameter of the furnace body upper section; the shape of the longitudinal section of the furnace body middle section is in an inverted truncated cone shape with a hollow interior; the diameter of the lower end of the furnace body middle section is equal to the diameter of the furnace body lower section; the diameter of the upper end of the furnace body middle section is equal to the diameter of the furnace body upper section. The method for smelting the silicon iron by utilizing the crystalline silicon scraps comprises the following steps of charging steel scraps required for smelting the silicon iron alloy into the furnace, blowing silicon powder scraps into the furnace, finally discharging silicon iron alloy liquid, vacuum decarbonizing, casting cooling, and finishing the smelting process. According to the intermediate frequency furnace and the method, carbon elements in silicon carbide are utilized to reduce silicon dioxide, so that the energy consumption is reduced; in addition, carbon coke does not need to be added, so that the impact of element phosphorus and element sulphur is reduced; the product silicon iron is low-phosphorus low-sulphur low-carbon silicon iron, which has high value.

Owner:王先玉

Non-phosphorus low-foaming washing powder preparation method

InactiveCN103122279ASuitable for useIncrease the fragranceInorganic/elemental detergent compounding agentsAnionic surface-active compoundsSodium bicarbonateLaundry

The invention relates to the field of laundry supplies, in particular to a non-phosphorous low-foaming washing powder method. The non-phosphorous low-foaming washing powder method includes: filling 50-60 parts of sodium bicarbonate and 2-3 parts of hydroxymethyl cellulose into a mixer to uniformly mix, then adding 1-12 parts of sodium dodecyl benzene sulfonate and 6-10 parts of sodium silicate after mixing, adding 6-8 parts of fatty acid after reaction, adding 4-6 parts of 10% sodium perborate after 24 hours to uniformly mix and adding proper essence and fluorescent brightener. Production equipment for non-phosphorous low-foaming washing powder is simple. The non-phosphorous low-foaming washing powder is low in foaming and applicable to washing machines, utilizes natural plant and animal oil as active matters, is compounded with various high-efficient surfactants and alkalescence builders and is capable of efficiently cleaning, pollution-free and harmless for human bodies. The fluorescent brightener has functions of whitening and brightening, and the essence can make detergents aromatic. The non-phosphorous low-foaming washing powder can be used to wash off gentian violet, ball pen oil, stains of oil, blood, milk, juice and the like which are hard to remove, and is veritable in cleaning.

Owner:DALIAN DEDA TECH DEV

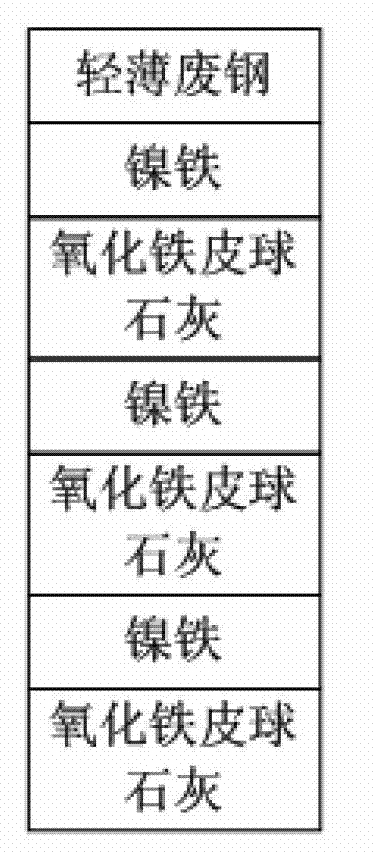

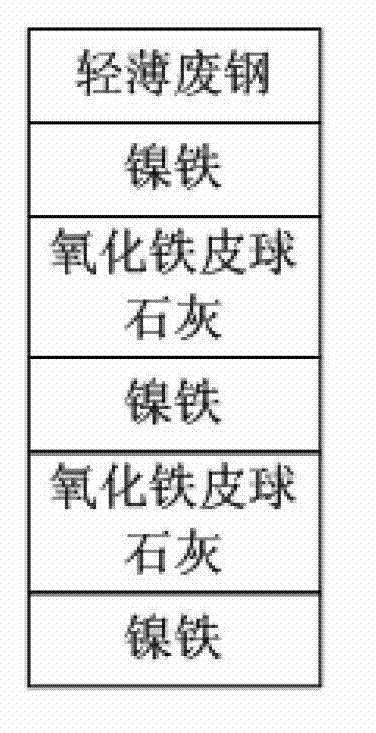

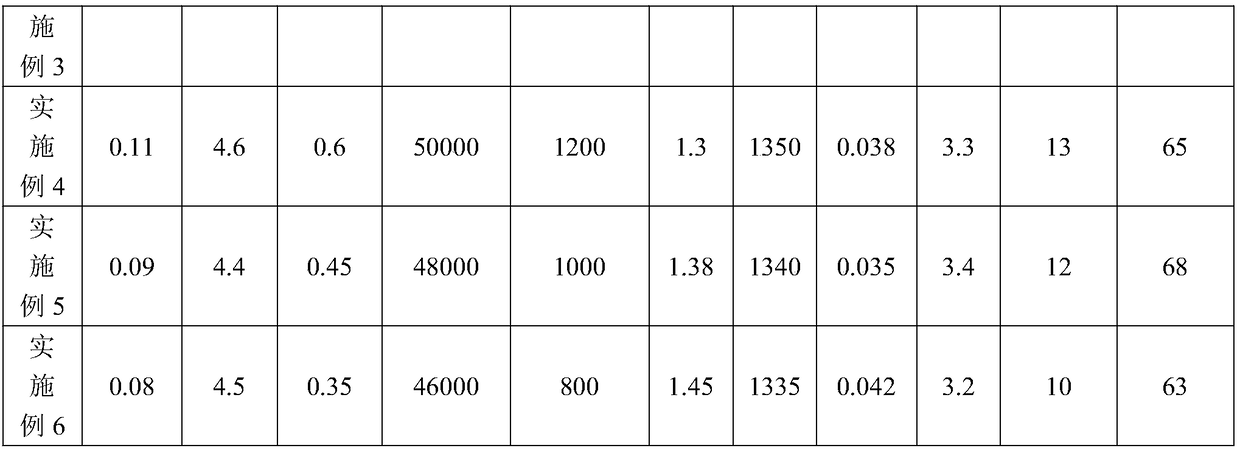

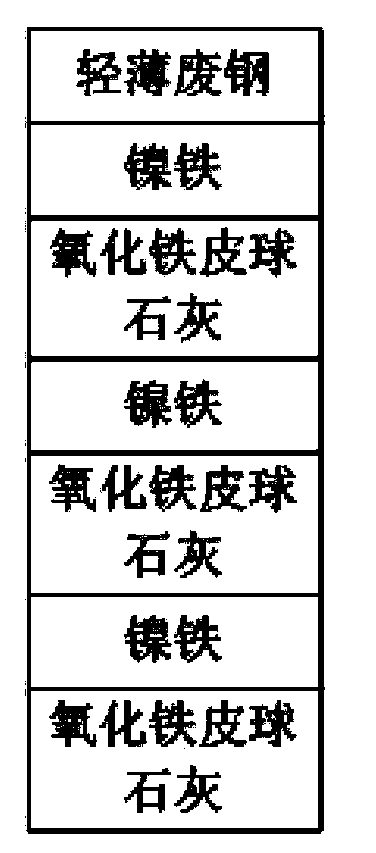

Low-cost efficient dephosphorization smelting process for electric arc furnace

InactiveCN102965467AOvercoming the problem of low dephosphorization efficiencyFlexible structureProcess efficiency improvementElectric furnacePhosphorus lowAlkalinity

A low-cost efficient dephosphorization smelting process for electric arc furnace belongs to the field of electric arc furnace smelting. According to the invention, reasonable blending process is carried out in a charging stage of the electric arc furnace; accessories in a traditional electric arc furnace smelting process is moved to a charging stage; through reasonable distribution of the cold raw materials and accessories in the electric arc furnace, problems of contradiction of theoretical demands of the dephosphorization oxygen potential, alkalinity and temperature during melting process of the cold raw materials and accessories is solved; and smelting dephosphorization process of the electric arc furnace runs through the whole process from starting to the end of the melting, so as to achieve the goal of efficient dephosphorization. The invention has the following advantages: the difficulty in dephosphorization of electric arc furnace traditional smelting process is solved; dephosphorization is basically realized when the melting down of the cold materials; and the process realizes dephosphorization rate of 75%-90%, rephosphorization rate after deslagging less than 5%, and end point phosphorus lower than 0.01%.

Owner:德龙钢铁有限公司

Calcification roasting method of vanadium/phosphorus-containing material

The invention discloses a calcification roasting method of a vanadium / phosphorus-containing material. The method is implemented by carrying out calcification roasting on a roasting material, wherein the roasting material comprises a vanadium / phosphorus-containing material, a calcium-containing material, a saccharide compound, a magnesium-containing compound and an aluminum-containing compound; the calcification roasting comprises first roasting and second roasting; in the first roasting process, the temperature is increased from 15-100 DEG C to 300-600 DEG C at the speed of 8-15 DEG C / minute; and in the second roasting process, the temperature is 820-900 DEG C, and the time is 80-180 minutes. Under the synergetic effects of the saccharide compound, magnesium-containing compound and aluminum-containing compound under roasting conditions, the materials can not be easily sintered; and the roasted materials can be leached to directly obtain the low-phosphorus low-silicon high-vanadium-content vanadium-containing leach solution.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

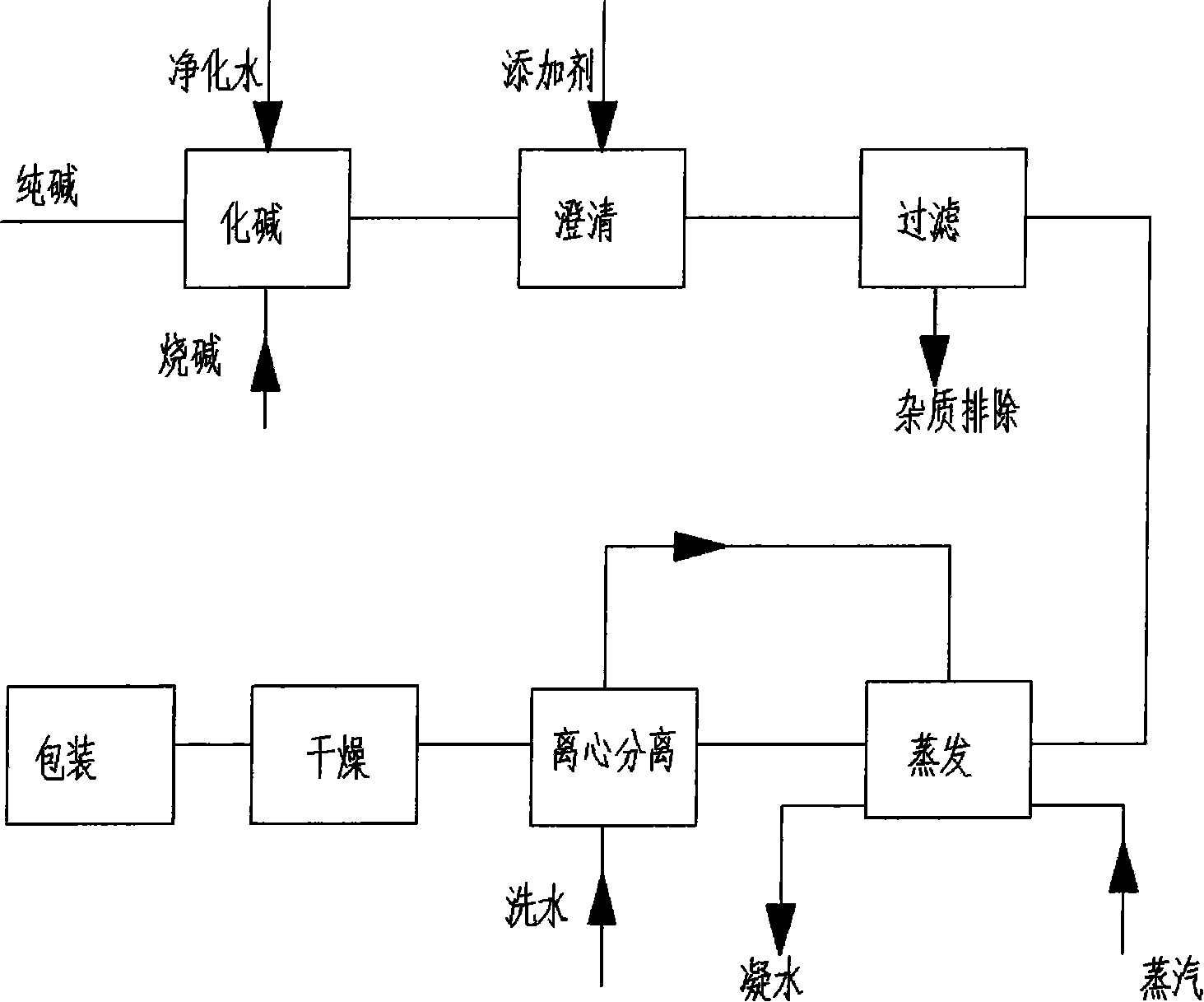

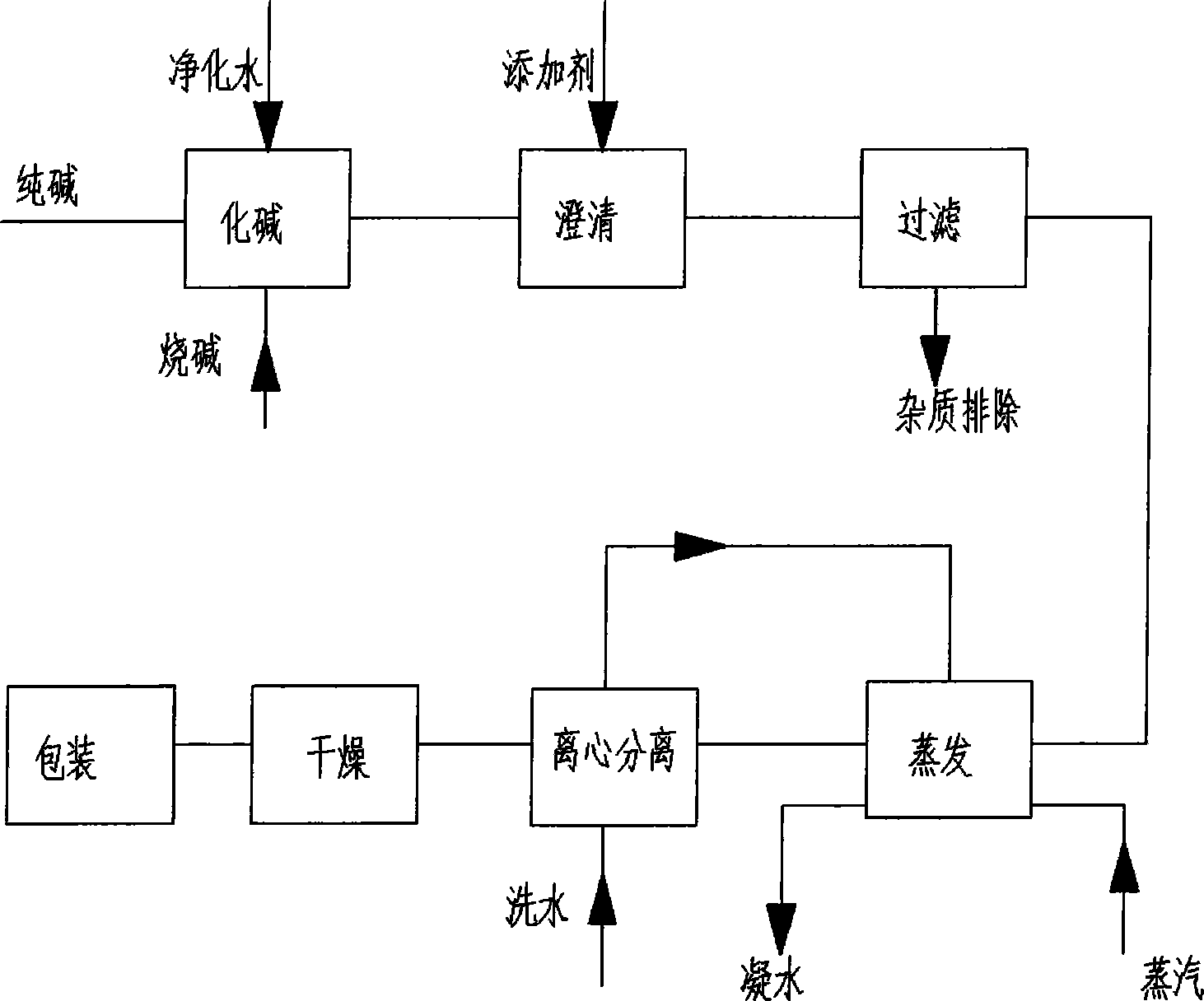

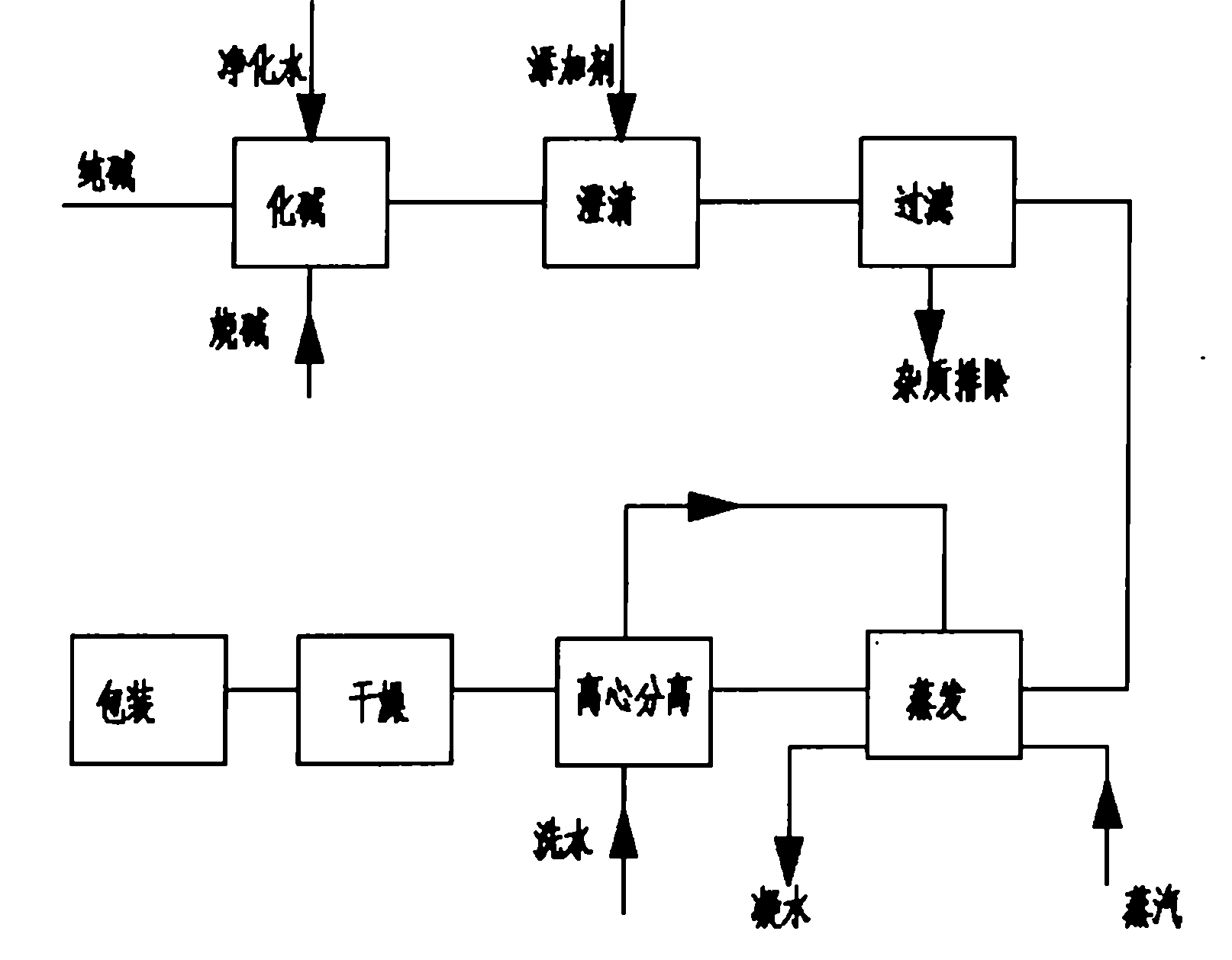

Low-phosphorus low-boron high-pure anhydrous sodium carbonate and preparation method thereof

ActiveCN101148261ASimple processMeet the use requirementsAlkali metal carbonatesAlkali metal sulfites/sulfatesPhosphorus lowPhysical chemistry

The present invention discloses one kind of high purity anhydrous sodium carbonate product with low P and B content and its preparation process. The preparation process includes the following steps: 1. reaction of sodium carbonate, pure water and sodium hydroxide in a reactor; 2. further reaction of the materials in a heat insulating and setting tank; 3. filtering to obtain filtrate; 4. evaporating the filtrate in an evaporator to crystallize; 5. washing the crystallized material in a centrifuge and solid-liquid separating; and 6. drying in a drying bed. The preparation process is simple and the prepared anhydrous sodium carbonate product has high quality and P and B content lower than 5 ppm.

Owner:TIANJIN BOHUA YONGLI CHEM IND

Low welding crack sensibility high-strength steel plate special-purpose welding wire

InactiveCN101157167AAchieve microalloyingPrevent cold crackingWelding/cutting media/materialsSoldering mediaForeign matterNiobium

The invention belongs to the welding wire technical field, which discloses a special welding wire for a steel plate with low welding crack sensibility and high strength. The technical proposal is that the welding wire contains elements in the following weight percentage: 0.06 to 0.12 percent of carbon, 0.40 to 1.00 percent of silicon, 1.40 to 2.10 percent of manganese, 0.02 to 0.20 percent of titanium, 0.001 to 0.01 percent of boron, 0.20 to 0.60 percent of molybdenum, 0.05 to 1.20 percent of chromium, niobium b lower than or equal to 0.10 percent , vanadium lower than or equal to 0.10 percent, sulfur lower than or equal to 0.10 percent, phosphorus lower than or equal to 0.10 percent, the rest comprises iron and other unavoidable foreign matters. Through the experiment, the ambient temperature of the welding joint for welding crack sensibility and high strength steel plate is subzero 20 DEG C by utilizing the welding wire without preheat, and the creation of cold cracks can be prevented.

Owner:金秋生

LF refining dephosphorization production process for low-phosphorus low-carbon steel

InactiveCN103938069AReduce steelmaking costsImprove product qualityProcess efficiency improvementSteelmakingPhosphorus low

Belonging to the technical field of smelting processes in the metallurgical industry, the invention relates to an LF refining dephosphorization production process for low-phosphorus low-carbon steel. According to a technical scheme adopted by the invention, the product comprises the following chemical components by mass: 0.01-0.03% of C, 0.15-0.25% of Mn, less than or equal to 0.015% of S, less than or equal to 0.015% of P, less than or equal to 0.03% of Si, 0.02-0.04% of AlS, and the balance Fe and inevitable impurities. The smelting process control is as the following that: during LF refining, lime is added in two batches in terms of 400-600kg / furnace, the argon flow rate is 200-300NL / min; the LF output molten steel temperature is 1610-1630DEG C; the RH vacuum treatment cycle is 17-22min; the output molten steel temperature is 1585-1600DEG C; and the tundish molten steel temperature is 1550-1570DEG C. The production process provided by the invention effectively reduces the steelmaking cost, and improves the subsequent stamping and other deep processing performance of the product.

Owner:TANGSHAN GUOFENG IRON & STEEL

Method for smelting ferrosilicon by utilizing crystalline silicon scraps

The data of application of the invention is 2014-12-17, the application number is 2014107883956, and the original application name is: divisional application of a patent including an intermediate frequency furnace and application thereof as well as a method for smelting ferrosilicon by utilizing crystalline silicon scraps. The invention discloses a method for smelting ferrosilicon by utilizing crystalline silicon scraps and belongs to the field of crystalline silicon scrap treatment. The method for smelting ferrosilicon by utilizing crystalline silicon scraps comprises the steps of feeding steel scrap needed for smelting ferrosilicon into a furnace, then blowing silicon powder scrap, finally delivering a ferro-silicon alloy solution out of the furnace, carrying out vacuum decarburization and casting cooling, and then finishing the smelting process. According to the invention, carbon element in silicon carbide is used for reducing silicon dioxide, so that energy consumption is reduced; coke does not need to be added, so that influences of phosphorus element and sulfur element are reduced; and the product, namely, the ferrosilicon, is low-phosphorus low-sulfur low-carbon ferrosilicon and is high in value.

Owner:王先玉

Desulfurization method of low-phosphorus low-silicon molten iron

InactiveCN110578030AOptimizing componentsImprove desulfurization efficiencyPhosphorus lowThermal insulation

The invention relates to a desulfurization method of low-phosphorus low-silicon molten iron. The method comprises the following steps that after tapping is finished, a ladle car runs to a wire feedingposition, the temperature is controlled at 1450 DEG C-1550 DEG C, a bottom blowing nitrogen system is turned on, the nitrogen flow is 60-100 NL per minute, lime particles are added to the liquid level of the molten iron, and the addition amount is 1.5-4 Kg per ton of molten iron, the ladle bottom blowing nitrogen system is closed after lime melting, and a thermal insulation agent is added, then the passivated packed wire of magnesium is fed at the wire feeding speed of 35-40m per minute, the wire feeding amount is 0.3-0.6 Kg per ton of iron, the wire feeding needs to be finished once, after the wire feeding is finished, the ladle bottom blowing nitrogen system is started, and the bottom blowing flow is 60-100 NL per minute, and the bottom blowing is stopped after 3-5 min. According to themethod, the desulfurization effect is better, and the desulfurization rate can reach up to 92% or above.

Owner:内蒙古赛思普科技有限公司

Low-phosphorus low-sulphur nickel-containing pig iron and its preparation method

The invention provides low phosphorus low-sulphur nickel-containing pig iron comprising less than 4.5% of C, 4.0-9.0% of Ni, less than 0.05% of S, less than 0.05% of P, less than 0.2% of impurity elements and the balance of Fe. The invention also provides a preparation method of the low phosphorus low-sulphur nickel-containing pig iron by use of a low grade nickel ore, and the method includes ore separation, crushing and sintering of the nickel ore, crude smelting in a blast furnace, refining in an electric arc furnace and other steps.

Owner:CHAOYANG HONGXIANG ADVANCED MATERIALS

Method for on-line producing low radiation film glass by floating process

The invention relates to a method for online production of low-emissivity film glass by float method. The method utilizes chemical vapor deposition method to deposit silicon oxide, boron oxide doped with carbon shielding layer and tin oxide, antimony oxide doped with fluorine and phosphorus on the hot glass surface. Composite film layer for low emissivity layer. Compared with the existing technology, the film layer prepared by this method has higher deposition rate at the same temperature, uniform film layer, small surface resistance, high conductivity, low emissivity, good wear resistance, strong alkali resistance, and has It has the advantages of stable production, high production efficiency, and is suitable for manufacturing large-scale low-e glass.

Owner:HANGZHOU BLUSR NEW MATERIALS TECH

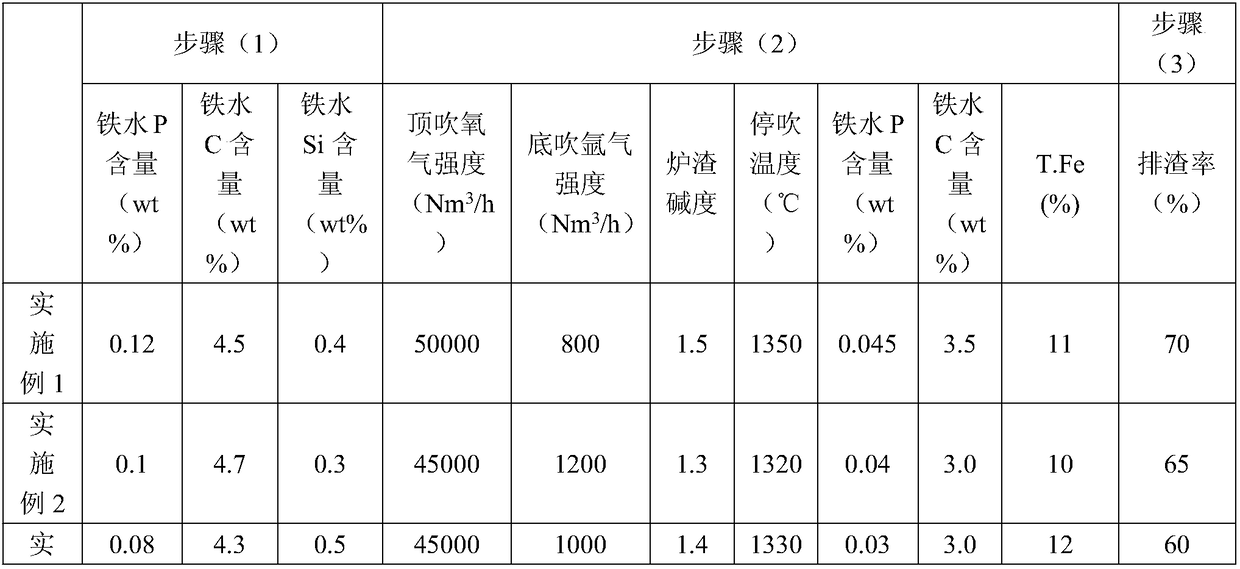

Converter smelting method for low-phosphorus low-oxygen steel

The invention discloses a converter smelting method for low-phosphorus low-oxygen steel. The converter smelting method comprises: (1) adding raw materials, and slagging; (2) carrying out blowing smelting, wherein oxygen is blown at the top of a converter, argon is blown at the bottom of the converter, and blowing smelting is stopped when the alkalinity of the slag is 1.2-1.5; (3) discharging the slag; (4) continuously carrying out slagging and blowing smelting, wherein oxygen is blown at the top of the converter, argon is blown at the bottom of the converter, and blowing smelting is stopped when the alkalinity of the slag is 3.5-4.5; and (5) simultaneously carrying out bottom blowing at unequal flow rates on the bottom of the converter after lifting the gun so as to finally obtain the molten steel with the P content of less than 0.01 wt% and the O content of less than 0.06 wt%, wherein the bottom blowing comprises high-flow rate bottom blowing and low-flow rate bottom blowing, the flowrate of the high-flow rate bottom blowing is 800-1200 Nm<3> / h, the flow rate of the low-flow rate bottom blowing is 400-800 Nm<3> / h, and the bottom blowing time is 2-5 min. According to the present invention, the converter smelting method is suitable for the bottom blowing with different flow rates to promote mass transfer, such that the phosphorus content and the oxygen content in the steel areeffectively reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

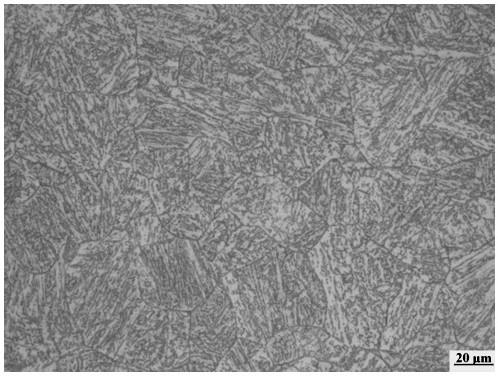

Low-phosphorus low-sulfur rare-earth alloy material for roller and preparation method thereof

The invention discloses a low-phosphorus low-sulfur rare-earth alloy material for a roller and a preparation method thereof. The alloy material is composed of the following elements of, by weight, 1.5%-1.58% of C, 5.3%-5.7% of Cr, 0.5%-0.6% of Si, 0.6%-0.8% of Mn, 2.0%-2.2% of W, 3.6%-3.8% of Mo, 2.9%-3.1% of V, 0.80%-1.00% of Co, 0.3%-0.4% of Ni, 0.08%-0.12% of Cu, 0.01%-0.03% of Nb, 0.15%-0.25%of Al, 0.10%-0.20% of Ti, less than or equal to 0.015% of P, less than or equal to 0.008% of S, 80.197%-82.141% of Fe and the balance of other inevitable impurity elements. The rare-earth alloy material for the roller has the advantages of being high in hardness, high in wear resistance, high in toughness and the like, being excellent in comprehensive performances and low production cost.

Owner:JIANGSU YULI NEW MATERIAL TECH

Low-cost efficient dephosphorization smelting process for electric arc furnace

InactiveCN102965467BOvercoming the problem of low dephosphorization efficiencyFlexible structureElectric furnaceProcess efficiency improvementPhosphorus lowAlkalinity

A low-cost efficient dephosphorization smelting process for electric arc furnace belongs to the field of electric arc furnace smelting. According to the invention, reasonable blending process is carried out in a charging stage of the electric arc furnace; accessories in a traditional electric arc furnace smelting process is moved to a charging stage; through reasonable distribution of the cold raw materials and accessories in the electric arc furnace, problems of contradiction of theoretical demands of the dephosphorization oxygen potential, alkalinity and temperature during melting process of the cold raw materials and accessories is solved; and smelting dephosphorization process of the electric arc furnace runs through the whole process from starting to the end of the melting, so as to achieve the goal of efficient dephosphorization. The invention has the following advantages: the difficulty in dephosphorization of electric arc furnace traditional smelting process is solved; dephosphorization is basically realized when the melting down of the cold materials; and the process realizes dephosphorization rate of 75%-90%, rephosphorization rate after deslagging less than 5%, and end point phosphorus lower than 0.01%.

Owner:德龙钢铁有限公司

Low-phosphorus low-sulfur high-alloy thick plate blank smelting process

InactiveCN108384920AMeet production requirementsQuality improvementManufacturing convertersProcess efficiency improvementPhosphorus lowThick plate

The invention provides a low-phosphorus low-sulfur high-alloy thick plate blank smelting process, and belongs to the technical field of steel making. As for the steps and parameter control, a double slag method is adopted in a converter, the catch carbon temperature is controlled to be 1600-1620 DEG C, and the phosphorus content at the endpoint is controlled to be no more than 0.008 wt%; the content of [S] in pretreated molten iron is no more than 0.0050 wt%; as for slag oxidation controlled by LF refining control, the sum of FeO and MnO is equal to 1.0-1.5 wt%, and the slag adding amount is 8-12 kg per ton of steel; a thick plate blank is adopted for production, and the maximum thickness specification is 400 mm; and the superheat degree is controlled to be 15-25 DEG C in the continuous casting process. The low-phosphorus low-sulfur high-alloy thick plate blank smelting process has the advantages that a production method of a high-alloy steel blank with the alloy amount being 5-12 wt%,the content of finished phosphorus is controlled to be no more than 0.015 wt%, the content of sulfur is controlled to be no more than 0.0025 wt%, and the maximum alloy amount of high-alloy steel canreach to 12 wt%.

Owner:SHOUGANG CORPORATION

A kind of microbial self-assembly nanomaterial and its preparation method and application

ActiveCN105779356BImprove adaptabilityEfficient removalMaterial nanotechnologyBacteriaPhosphorus lowWastewater

The invention discloses a microbial self-assembled nanometer material, its preparation method and application. Specifically, the present invention utilizes a bacterium Shewanella sp. that can efficiently remove phosphorus in high-salt wastewater under aerobic conditions, and simultaneously utilize raw materials in wastewater to synthesize calcium and phosphorus nanoparticles. CF8‑6 synthesized calcium-phosphorus nanomaterials while removing phosphorus from wastewater, especially calcium-phosphorus nanoparticles were synthesized under the condition of low phosphorus saturation. The method and the nanometer material prepared by it play an important role in the fields of removing environmental pollution, biomedicine and the like.

Owner:SHANDONG UNIV

Low-phosphorus low-protein instant rice for people with chronic kidney diseases to eat

InactiveCN110973477AImprove hydrolysis efficiencyIncrease vitalityFood ingredient as antioxidantSeed preservation by coatingBiotechnologyPhosphorus low

The invention relates to low-phosphorus low-protein instant rice suitable for people with chronic kidney diseases to eat. The preparation steps comprises raw material pretreatment, burdening, composite strain fermentation, high-temperature and high-pressure airflow jet powder mixing, twin-screw extrusion curing, ultrahigh-pressure full-speed fresh-keeping cold air knife rotary cutting, cooling, secondary microwave puffing, electromagnetic vibration enhanced vacuum freeze drying, polishing, back-pressure sterilization, packaging and finished product obtaining. With the high-temperature high-pressure airflow jet powder mixing technology, the instant rice can be eaten instantly after being brewed with boiled water, so that complete curing needs to be guaranteed in the processing process. According to the invention, the high pressure (3-4Mpa) is adopted to generate high-speed airflow, so that the rice flour is sprayed and impacted without dead angles and the water content of the mixed material added with water is uniform. The high temperature (90-120 DEG C) enables the rice flour to be primarily cured before extrusion, so that complete curing after extrusion is ensured; protein denaturation occurs at the same time, so that the content of non-high-quality protein is reduced. Aspergillus oryzae strains remaining in the rice flour can be killed under high temperature and high pressure.

Owner:长融汇通(天津)食品科技研发有限公司

Multilayer coated red phosphorus low smoke halogen-free flame retardant polyolefin cable sheath material and preparation method thereof

ActiveCN102731888BImprove physical performanceImprove water resistanceInsulated cablesInsulated conductorsElastomerPolymer science

The present invention belongs to the technical field of a new material, and provides a multilayer coated red phosphorus low smoke halogen-free flame retardant polyolefin cable sheath material and a preparation method thereof. The sheath material comprises the following components, by weight, 30-70 parts of a matrix resin A, 30-70 parts of a matrix resin B, 5-30 parts of a compatibilizer, 5-40 parts of a flame retardant agent A, 10-40 parts of a flame retardant agent B, 0.1-2 parts of a lubricant, and 0.1-1 part of an antioxidant. The preparation method comprises the following steps: A, extruding; and B, carrying out granulation on the extruded material by a granulator to obtain the sheath material finished product. Advantages of the material of the present invention are that: the sheath material is prepared by matching the flame retardant agent A and the flame retardant agent B with the polyolefin elastomer raw material, such that characteristics of halogen-free property and good low smoke flame retardation effect are provided, and advantages of good physical property, good water resistance and less dripping are provided; and the preparation method has a simple preparation process, and is suitable for large-scale industrial production.

Owner:ZHEJIANG SHIP ELECTRONICS TECH

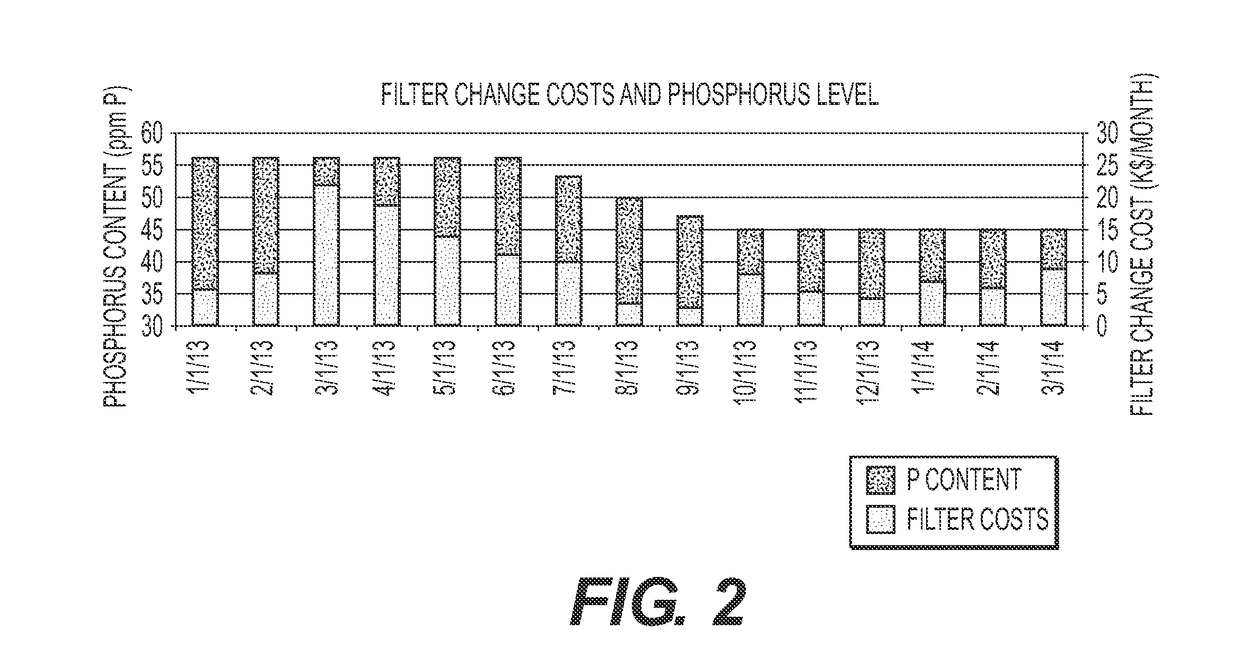

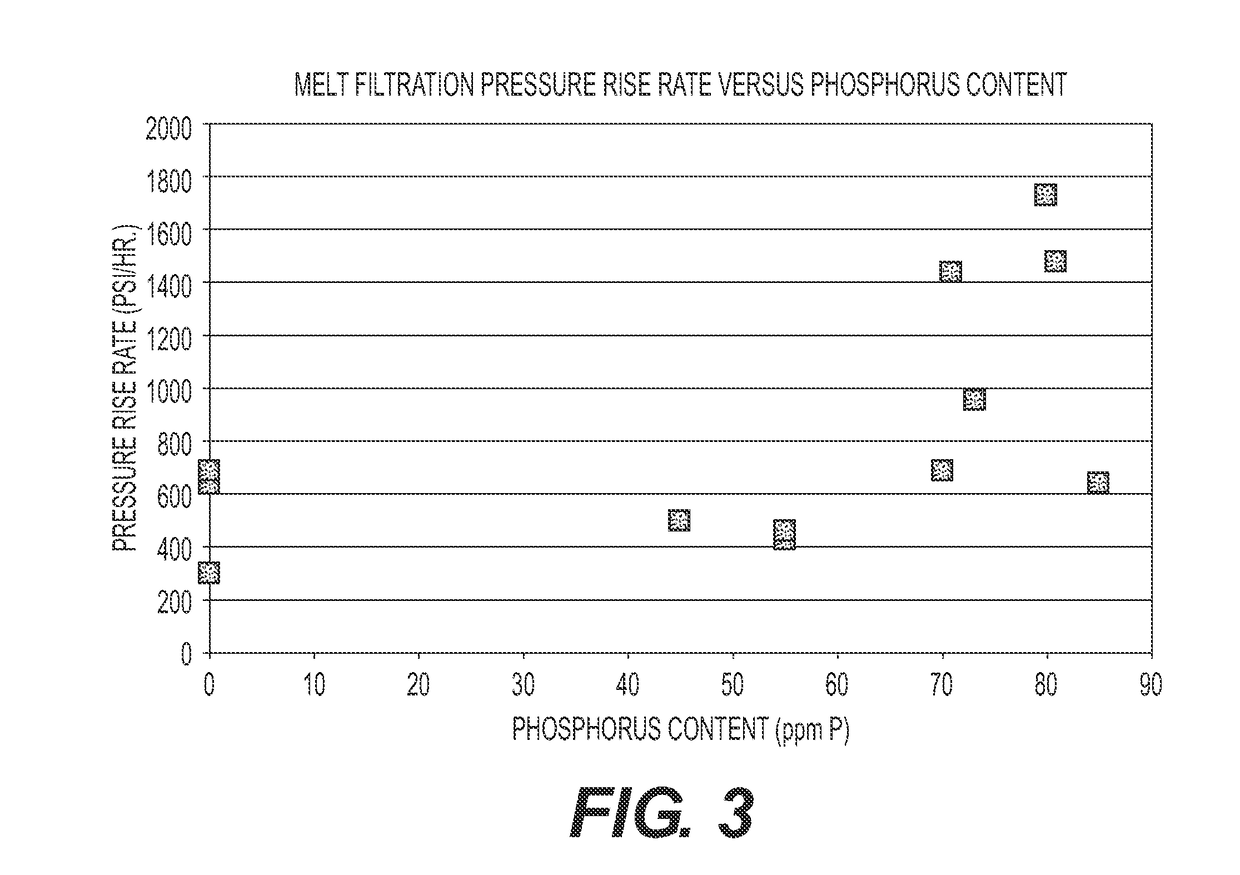

Low Phosphorus Low Color Polyamides

The present invention provides a low-phosphorus polyamide compound and a process for preparing such a polyamide.

Owner:ASCEND PERFORMACE MATERIALS OPERATIONS LLC

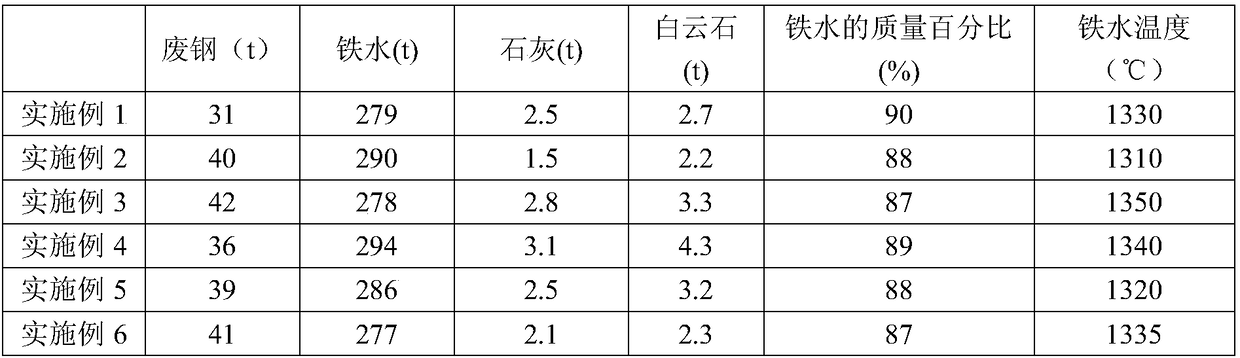

A dual-slag process for smelting ultra-low phosphorus and low-carbon steel in a double-blown converter

The invention relates to a double-slag process for smelting ultralow-phosphorus and low-carbon steel in a combined-blown converter. The double-slag process comprises the following steps: (1) molten iron and waste steel are put into the converter according to the molten iron ratio of 85% to 90%; (2) bottom blowing gas adopts nitrogen and argon in a switched manner, the nitrogen is adopted before the supply of 80% of oxygen, and the argon is automatically switched after the supply of 80%t of oxygen; (3) at the first stage of blowing, the flow rate of the oxygen adopts 20000-21000 Nm<3> / h within the first minute, and a normalized slag lance position of 1800-2000 mm is adopted; after the start of blowing for one minute, the flow rate of the oxygen is adjusted to be 13000 Nm<3> / h; (4) a de-slagging moment is set as 8-10 minutes after the start of blowing; (5) at the second stage of blowing, blowing is started when the high lance position is 1700-1800 mm, the flow rate of the oxygen is adjusted to be 18000 Nm<3> / h, and the converter end point control target is that carbon is less than 0.05%, and phosphorus is less than 0.004%. According to the double-slag process provided by the invention, the converter end point phosphorus can be stably controlled to be less than or equal to 0.004 percent, so that the target of smelting the ultralow-phosphorus and low-carbon steel by a single converter is stably realized.

Owner:NANJING IRON & STEEL CO LTD

A method for smelting low-sulfur, low-phosphorus, low-silicon cr-mo steel ingots

ActiveCN107746908BNo obvious lamination defectsSimple processProcess efficiency improvementElectric furnaceSteelmakingForeign matter

The invention discloses a smelting process of a Cr-Mo steel ingot being low in sulfur, phosphorus and silicon. The smelting process includes the steps of: electric furnace steelmaking process control,refining process control in a refining furnace, VOD process control and casting process control, wherein in the casting process control step, casting is carried out via a bottom casting method. The steel ingot of the Cr-Mo steel is not more than 0.005% in sulfur content, not more than 0.007% in phosphorus content, and not more than 0.1% in silicon content. A largest produced steel ingot can reach53 tons in weight. After the steel ingot is processed, NB / T47013.3 first-class flaw detection qualification rate of the steel board is not less than 96%; the steel board is free of obvious layering defect and is free of large granular foreign matters. The smelting process is simple and low-cost, employs regular steelmaking equipment, has simple operations and good university and can save energy.

Owner:WUYANG IRON & STEEL

Low-phosphorus low-boron high-pure anhydrous sodium carbonate and preparation method thereof

ActiveCN101148261BSimple processMeet the use requirementsAlkali metal carbonatesAlkali metal sulfites/sulfatesPhosphorus lowPhysical chemistry

Owner:TIANJIN BOHUA YONGLI CHEM IND

A method for calcification and roasting of vanadium-phosphorus-containing materials

The invention discloses a calcification roasting method of a vanadium / phosphorus-containing material. The method is implemented by carrying out calcification roasting on a roasting material, wherein the roasting material comprises a vanadium / phosphorus-containing material, a calcium-containing material, a saccharide compound, a magnesium-containing compound and an aluminum-containing compound; the calcification roasting comprises first roasting and second roasting; in the first roasting process, the temperature is increased from 15-100 DEG C to 300-600 DEG C at the speed of 8-15 DEG C / minute; and in the second roasting process, the temperature is 820-900 DEG C, and the time is 80-180 minutes. Under the synergetic effects of the saccharide compound, magnesium-containing compound and aluminum-containing compound under roasting conditions, the materials can not be easily sintered; and the roasted materials can be leached to directly obtain the low-phosphorus low-silicon high-vanadium-content vanadium-containing leach solution.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Novel low-phosphorus low-sulfur steel smelting process

InactiveCN113584250AReduce the difficulty of smeltingReduce blow damageManufacturing convertersProcess efficiency improvementPhosphorus lowSmelting process

The invention provides a novel low-phosphorus low-sulfur steel smelting process. The novel low-phosphorus low-sulfur steel smelting process comprises the following steps: 1, carrying out furnace washing and steel ladle washing operations before converter smelting; 2, carrying out a desulfurization process, specifically, carrying out deep desulfurization by using high-temperature molten iron and adopting a KR desulfurization method, wherein the sulfur content in the molten iron is less than or equal to 0.001%; 3, carrying out a converter process, specifically, carrying out smelting by using a top-bottom combined blowing converter, adding self-produced first-class waste steel by adopting a single-slag remaining method, using low-phosphorus low-sulfur lime, dolomite and iron-containing oxide, carrying out converter end point control, specifically, controlling the tapping carbon content to be less than or equal to 0.04%, the phosphorus content to be less than or equal to 0.009%, the sulfur content to be less than or equal to 0.004% and the temperature to be greater than or equal to 1620 DEG C, adding a dephosphorization agent and lime in the tapping process for slag washing, adding part of lime for slag thickening treatment after tapping is finished, then carrying out slagging-off operation, and carrying out alloying after slagging-off is finished; 4, carrying out a refining process, specifically, carrying out fine adjustment on components, slagging, removing impurities and increasing the temperature; and 5, carrying out a continuous casting process, specifically, carrying out continuous casting, and finally ensuring that the content of phosphorus and sulfur in a casting blank smelting finished product is less than or equal to 100 ppm.

Owner:QINGDAO SPECIAL STEEL CO LTD

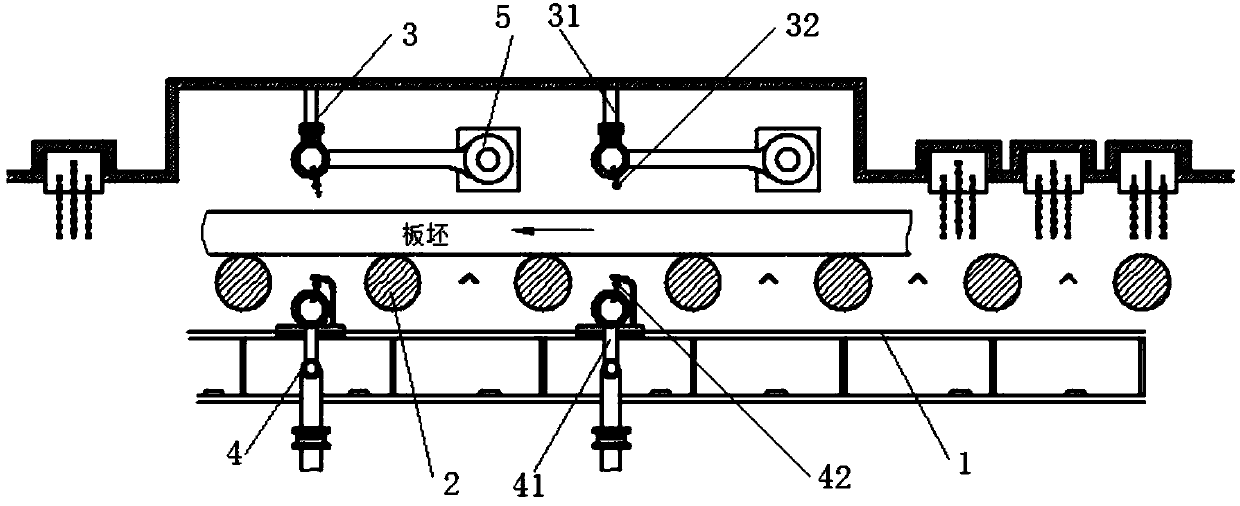

Jetting face widened dephosphorizing machine

PendingCN107900119AImprove working conditionImprove phosphorus removal efficiencyWork treatment devicesMetal rolling arrangementsPhosphorus lowPulp and paper industry

The invention provides a jetting face widened dephosphorizing machine which can effectively monitor the working states of nozzle headers. The jetting face widened dephosphorizing machine comprises a roller table base arranged in a box body, a roller table used for conveying plate blanks, an upper dephosphorizing header, a lower dephosphorizing header and an adjusting device used for adjusting theupper dephosphorizing header. The roller table is arranged on the roller table base. The upper dephosphorizing header and the lower dephosphorizing header are symmetrically distributed above and belowthe roller table. The upper dephosphorizing header and the lower dephosphorizing header both comprise bases and nozzles. The bases are arranged on the roller table base, the nozzles are arranged at the top ends of the corresponding bases, the included angle between the axis extension direction of each nozzle and the height direction of the corresponding base ranges from 12 degrees to 15 degrees,and the openings of the included angles face the feeding directions of the plate blanks. The nozzles are provided with detection sensors, a monitoring terminal is arranged on the background and used for receiving detection signals sent by the detection sensors and regulating the water jet capacity of the nozzles, and the monitoring terminal is in communication connection with the detection sensors.

Owner:河北新金轧材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com