A method for smelting low-sulfur, low-phosphorus, low-silicon cr-mo steel ingots

A smelting method and steel ingot technology, which is applied in the field of smelting low-sulfur, low-phosphorus, low-silicon Cr-Mo steel ingots, can solve problems such as difficult slag floating up, flaw detection of steel plates, etc., and achieve the effects of low cost, strong versatility, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

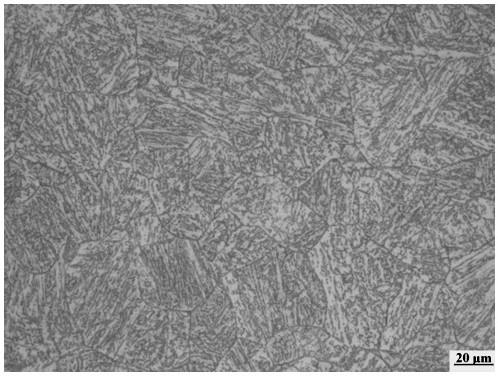

Image

Examples

Embodiment 1

[0019] One furnace of 12Cr2Mo1VR is smelted, with a single furnace of 117 tons and a single steel ingot of 53 tons. The finished rolled steel plate has a thickness of 137mm and a length of 13,500mm. The chemical composition of the steel ingot and its mass percentage content are: C: 0.14%, Si: 0.06%, Mn: 0.57%, Cr: 2.34%, Mo: 1.02%, V: 0.304%, Ni: 0.14%, Ca: 0.001 %, P: 0.005%, S: 0.003%, As: 0.004%, Sn: 0.001%, Sb: 0.001%, the balance is Fe and unavoidable impurities.

[0020] The low-sulfur, low-phosphorus and low-silicon Cr-Mo steel ingot smelting method of this embodiment includes electric furnace steelmaking process control, refining furnace refining process control, VOD process control, and casting process control procedures. The specific process steps are as follows:

[0021] (1) Electric furnace steelmaking process control procedure: In the electric furnace steelmaking process, add 38kg / t steel active quicklime, 23kg / t steel fluorite, when the electric furnace tapping, S: 0....

Embodiment 2

[0028] Smelting one furnace of 12Cr2Mo1R, a single furnace of 105 tons, a single ingot of 47 tons, the thickness of the finished rolled steel plate is 134mm, and the length is 12800mm. The chemical composition of the steel ingot and its mass percentage content are: C: 0.12%, Si: 0.07%, Mn: 0.54%, Cr: 2.41%, Mo: 1.03%, V: 0.02%, Ni: 0.17%, Ca: 0.001 %, P: 0.004%, S: 0.002%, As: 0.003%, Sn: 0.001%, Sb: 0.001%, the balance is Fe and unavoidable impurities.

[0029] (1) Electric furnace steelmaking process control procedure: In the electric furnace steelmaking process, add 43kg / t steel active quicklime, 23kg / t steel fluorite, when the electric furnace tapping, S: 0.029%, P: 0.008%;

[0030] (2) Refining process control procedure of the refining furnace: During the refining process of the refining furnace, add active quicklime 5kg / t steel, 3kg / t steel fluorite, smelting 35min; before adding alloy, add 2.2kg / t steel of Al wire at one time; add alloy Then add 500kg of metal Cr, after the...

Embodiment 3

[0035] Smelting a furnace of 2.25Cr1Mo0.25V, a single furnace of 112 tons, a single steel ingot 52 tons, the thickness of the finished rolled steel plate is 142mm, and the length is 11870mm. The chemical composition of the steel ingot and its mass percentage content are: C: 0.13%, Si: 0.10%, Mn: 0.53%, Cr: 2.39%, Mo: 1.01%, V: 0.31%, Ni: 0.18%, Ca: 0.001 %, P: 0.007%, S: 0.005%, As: 0.002%, Sn: 0.001%, Sb: 0.001%, the balance is Fe and unavoidable impurities.

[0036] (1) Electric furnace steelmaking process control procedure: In the electric furnace steelmaking process, 40kg / t steel active quicklime and 26kg / t steel fluorite are added during electric furnace steelmaking, S: 0.03%, P: 0.009%;

[0037] (2) Refining furnace refining process control procedure: In the refining process of the refining furnace, add active quicklime 4kg / t steel and 2.6kg / t steel fluorite for 20 minutes; add 2.1kg / t steel of Al wire at one time before adding alloy; After alloying, add 500kg of metallic Cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com