Intermediate frequency furnace, application thereof, and method for smelting silicon iron by utilizing crystalline silicon scraps

An intermediate frequency furnace and crystalline silicon technology, applied in the field of crystalline silicon waste treatment, to reduce energy consumption, solve the problem of landfill pollution, and achieve the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

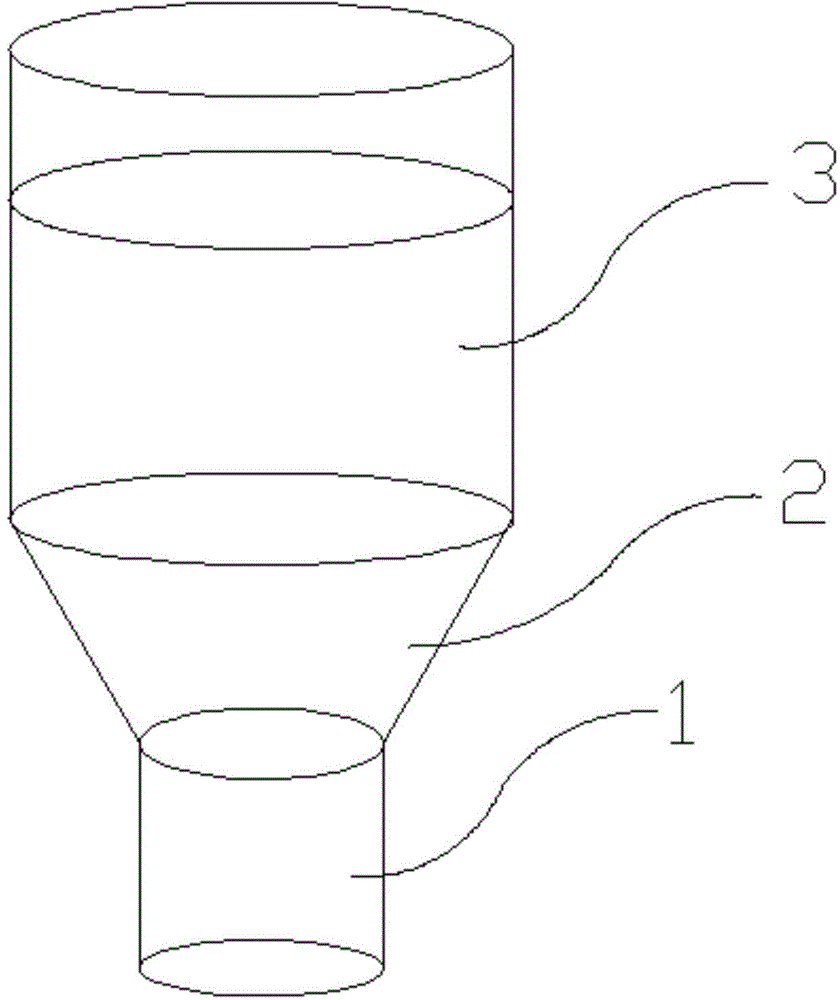

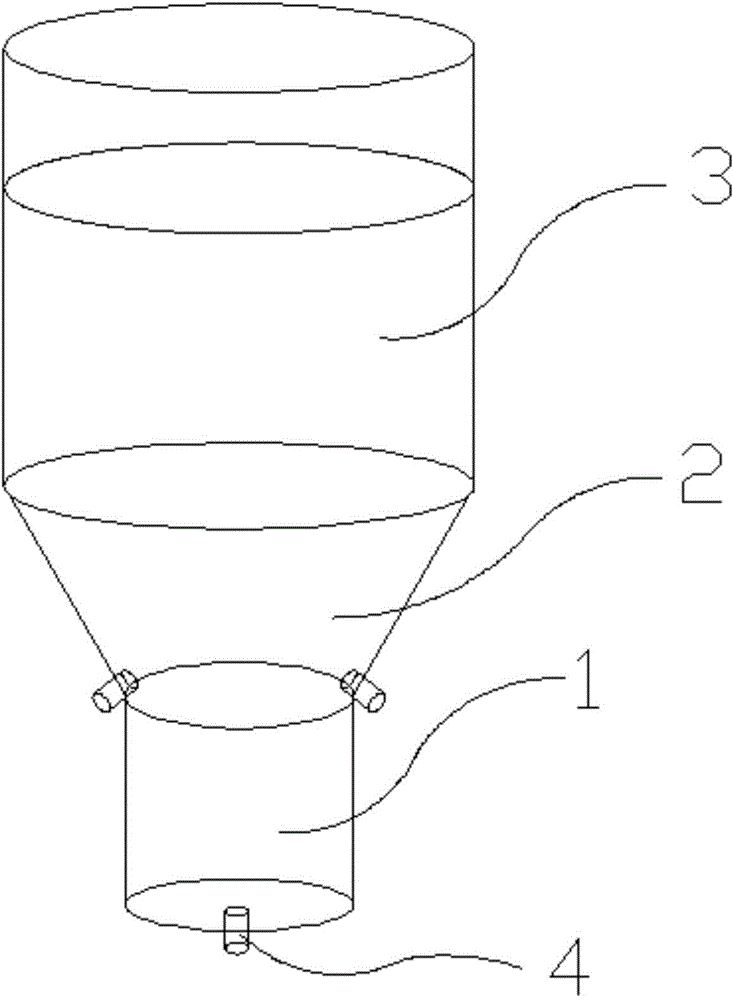

[0088] Such as figure 2As shown, an intermediate frequency furnace includes a furnace body, and the furnace body is divided into three sections: the lower section 1 of the furnace body, the middle section 2 of the furnace body, and the upper section 3 of the furnace body from bottom to top; the diameter of the lower section 1 of the furnace body is 764 mm, and the height is 700 mm. The shape of the longitudinal section of the middle section 2 of the furnace body is an internally hollow rounded table shape, and the diameter of the lower end of the middle section 2 of the furnace body is equal to the diameter of the lower section 1 of the furnace body; the height of the middle section 2 of the furnace body is 700mm, and the angle between the side surface and the horizontal plane is 60° , the height of the upper section 3 of the furnace body is 1462mm, and the diameter of the upper end of the middle section 2 of the furnace body is equal to the diameter of the upper section 3 of ...

Embodiment 2

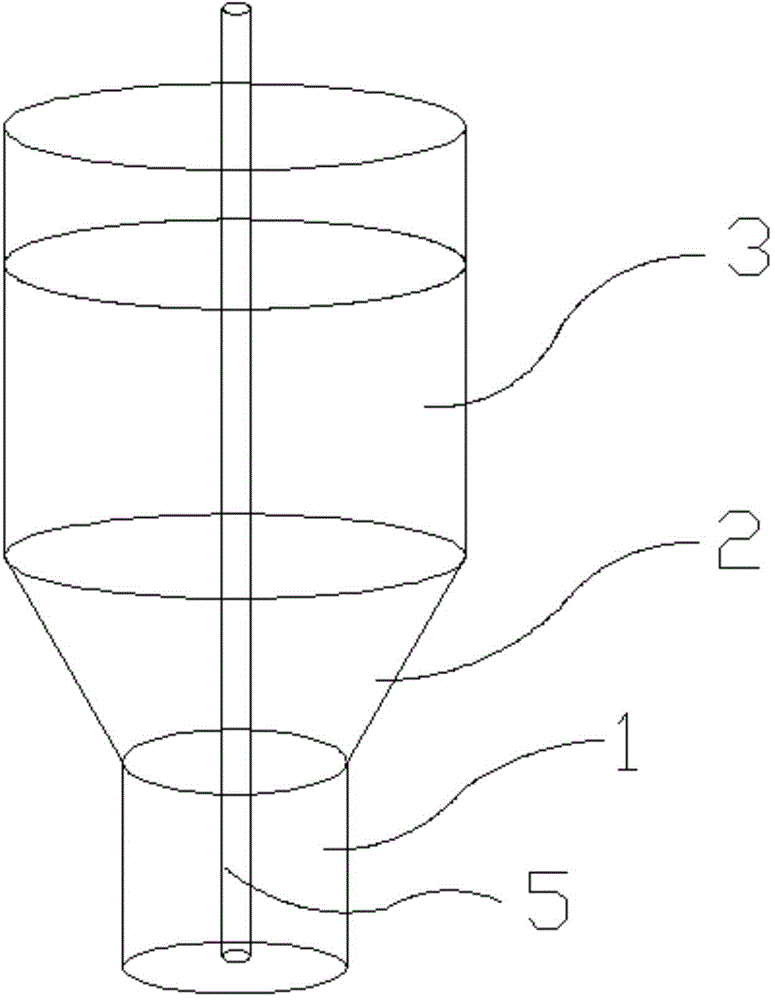

[0096] Such as image 3 As shown, an intermediate frequency furnace is the same as Example 1, the difference is that the height of the lower section 1 of the furnace body is 600mm, and the volume of the lower section 1 of the furnace body accounts for 40% of the working section of the furnace body; it also includes a blowing gun 5, and the feed passes through The spray gun 5 is inserted downwards into the bottom of the lower section 1 of the furnace body through the top of the furnace body. Silicon powder waste is added using a blow gun 5 .

[0097] (A) 2500kg of low-carbon scrap steel required for smelting ferrosilicon alloy is loaded into the furnace, the heating coils in the lower section 1 of the furnace body and the middle section 2 of the furnace body are energized to melt the scrap steel into molten iron, and continue to heat the molten iron to within the range of 1590°C to 1630°C; The composition of silicon powder waste is: Si: 72%, Si-C: 16%, Fe: 2%, and the rest is ...

Embodiment 3

[0103] Such as figure 2 As shown, an intermediate frequency furnace includes a furnace body, and the furnace body is divided into three sections: the lower section 1 of the furnace body, the middle section 2 of the furnace body, and the upper section 3 of the furnace body from bottom to top; the diameter of the lower section 1 of the furnace body is 874 mm, and the height is 800 mm. The shape of the longitudinal section of the middle section 2 of the furnace body is an internally hollow rounded table shape, and the diameter of the lower end of the middle section 2 of the furnace body is equal to the diameter of the lower section 1 of the furnace body; the height of the middle section 2 of the furnace body is 700mm, and the angle between the side surface and the horizontal plane is 60° , the height of the upper section 3 of the furnace body is 2024mm, the diameter of the upper end of the middle section 2 of the furnace body is equal to the diameter of the upper section 3 of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com