Low-phosphorus low-boron high-pure anhydrous sodium carbonate and preparation method thereof

A technology of anhydrous sodium carbonate and sodium carbonate, applied in alkali metal carbonates, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as unsatisfactory needs, and achieve the effect of high product quality and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

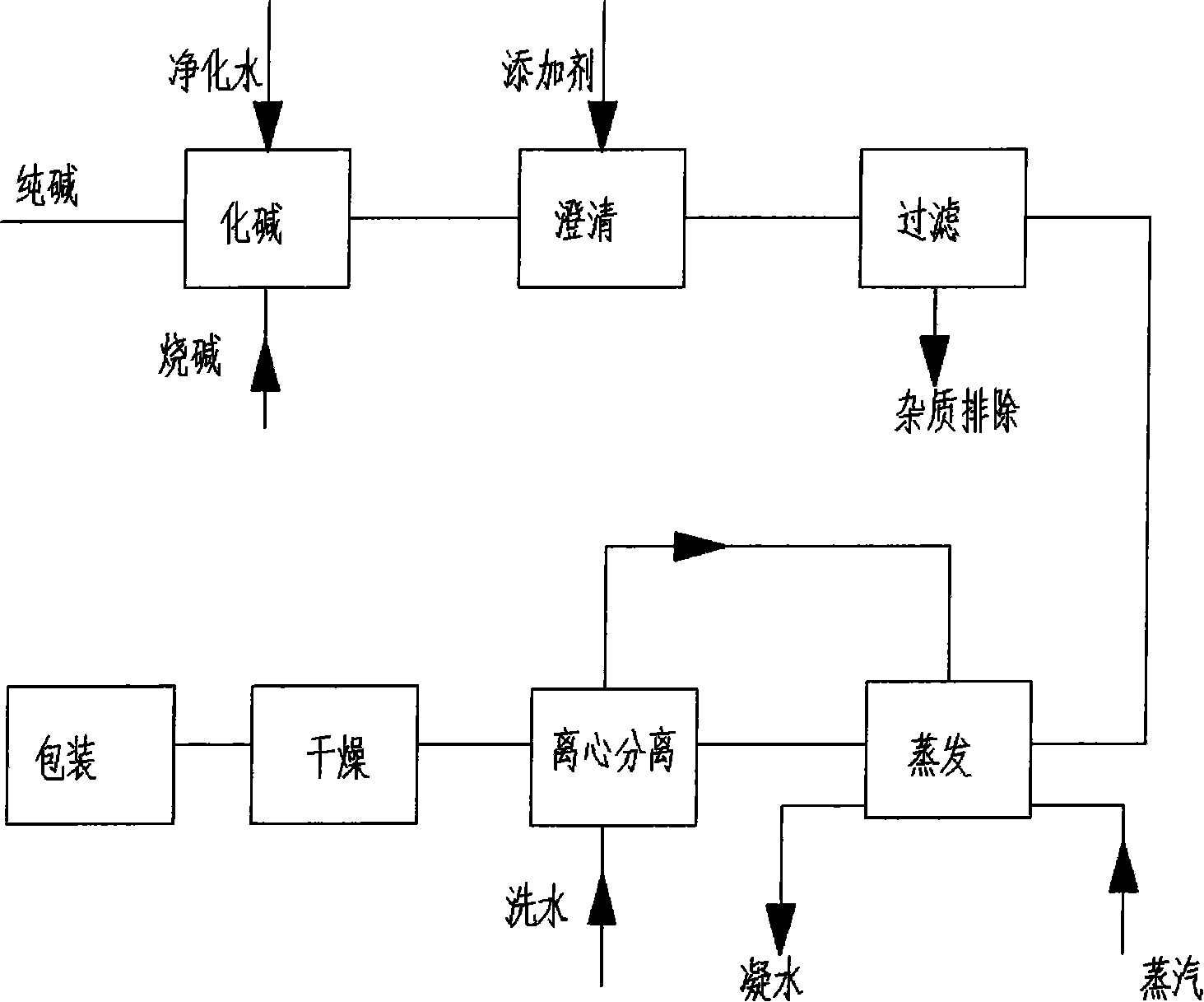

Image

Examples

preparation example Construction

[0017] A preparation method of low-phosphorus, boron high-purity anhydrous sodium carbonate, which comprises the following steps: (a) edible soda ash, purified water with an impurity mass percentage content below 0.01%, and purified water with a mass percentage content above 99% Caustic soda is added into the chemical material tank and fully reacted and stirred at a temperature of 80--105°C and normal pressure. The concentration of caustic soda in the edible soda ash is 360--400 grams per liter, and the addition amount of the caustic soda is 50-80 kg / ton of edible soda ash; (b) use a pump to send the reacted material to an insulated clarifier for further reaction, and the temperature of the clarifier is 60--80°C; (c) extract it from the clarifier The clear liquid enters the filter tank to filter, and the filtered filtrate flows into the filtrate tank by itself; (d) pump the clear liquid in the filtrate tank to the evaporator for evaporation, and the pressure of the evaporator i...

Embodiment 1

[0025] Add edible soda ash, purified water with an impurity mass percentage of 0.008-0.009%, and caustic soda with a mass percentage content of 99.01-99.5% into the chemical tank, fully react and stir at a temperature of 80°C and normal pressure , the alkali concentration of described edible soda ash is 380 grams / liter, and the add-on of described caustic soda is 60 kilograms / ton edible soda ash; The material after reaction is delivered to further reaction in the insulation clarifier tank with pump, described The temperature of the clarification tank is 70°C, and additives are added in the clarification tank, and the addition amount is 50ml / m 3 The clear liquid of the clarifier barrel enters the shower head filter tank to filter, and the filtered filtrate flows into the filtrate tank by itself; the filtrate in the filtrate tank is beaten to the evaporator with a pump to evaporate, and the pressure of the evaporator is controlled at 0.5MPa, The temperature of the evaporator is ...

Embodiment 2

[0027] Add edible soda ash, purified water with an impurity mass percentage of 0.01-0.009%, and caustic soda with a mass percentage content of 99.05-99.2% into the chemical tank, fully react and stir at a temperature of 90°C and normal pressure , the alkali concentration of described edible soda ash is 400 grams / liter, and the add-on of described caustic soda is 60 kilograms / ton edible soda ash; The material after reaction is delivered to further reaction in the insulation clarifier tank with pump, described The temperature of the clarification tank is 60°C, and additives are added in the clarification tank, and the addition amount is 100ml / m 3 The clear liquid of the clarifier enters the shower head filter tank and filters, and the filtered filtrate flows into the filtrate tank by itself; the filtrate in the filtrate tank is beaten to the evaporator with a pump to evaporate, and the pressure of the evaporator is controlled at 0.4MPa. The temperature of the evaporator is 105°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com