Converter smelting method for low-phosphorus low-oxygen steel

A converter smelting, low-oxygen steel technology, applied in the manufacture of converters, etc., to achieve the effect of small deoxidizer consumption, simple process, and reduced phosphorus and oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

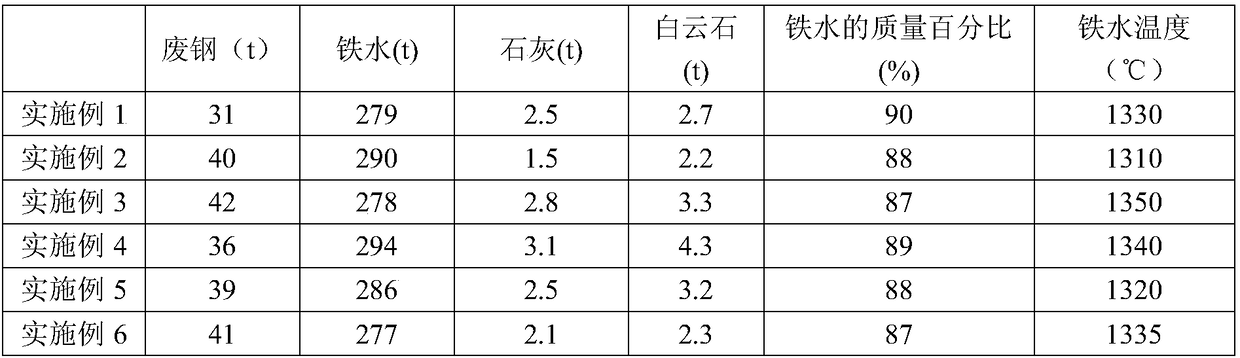

[0036] Embodiment 1-6 adopts following steps to carry out converter smelting:

[0037] (1) In a 300t converter, add raw materials to make slagging according to Table 1, and control the contents of P, C and Si in the molten iron to be 0.08-0.12wt% for P, 4.3-4.7wt% for C, and 0.3-0.6wt% for Si wt%, the temperature of molten iron is 1300-1350°C;

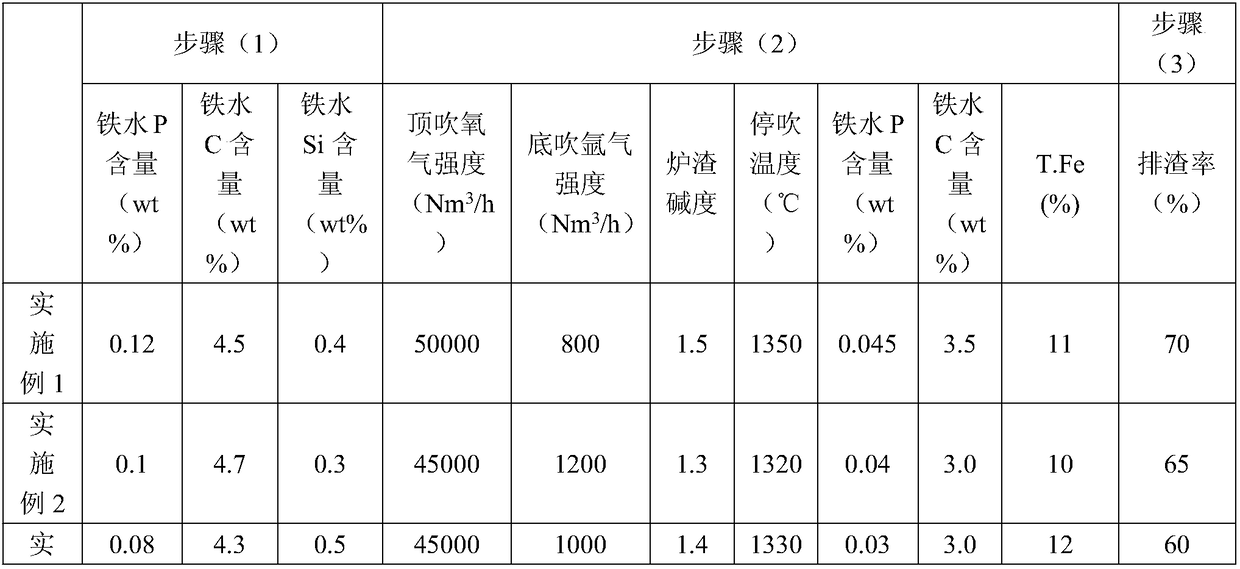

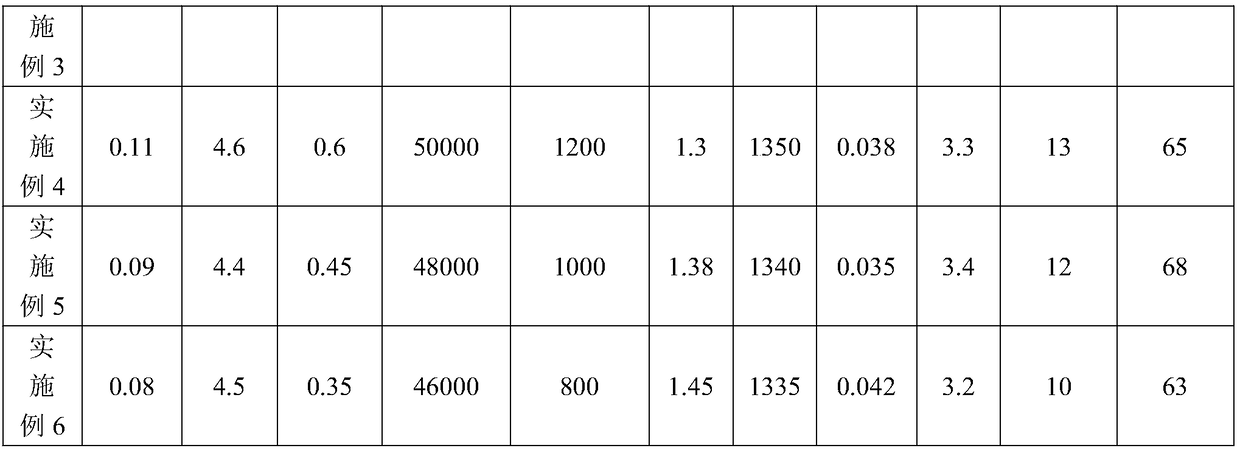

[0038] (2) Blowing: Blow oxygen at the top of the converter, blow argon at the bottom of the converter, stop blowing when the slag basicity is 1.2-1.5, and the intensity of blowing oxygen is 45000-50000Nm 3 / h, the intensity of argon blowing is 800~1200Nm 3 / h; when the blowing is stopped, the P content in the molten iron is 0.03-0.05wt%, the C content is 3.0-3.5wt%, and the blowing stop temperature is 1300-1350°C;

[0039] (3) Slag discharge: pour out 50-70% of dephosphorization slag;

[0040] (4) Continue slagging and blowing: add lime, lightly burned dolomite and soft silica to make slag, blow oxygen at the top of the converter, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com