Patents

Literature

167results about How to "Fast decomposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Teeth whitening composition and method

InactiveUS20050048444A1Fast decompositionAccelerate effectCosmetic preparationsTeeth fillingIonCompound (substance)

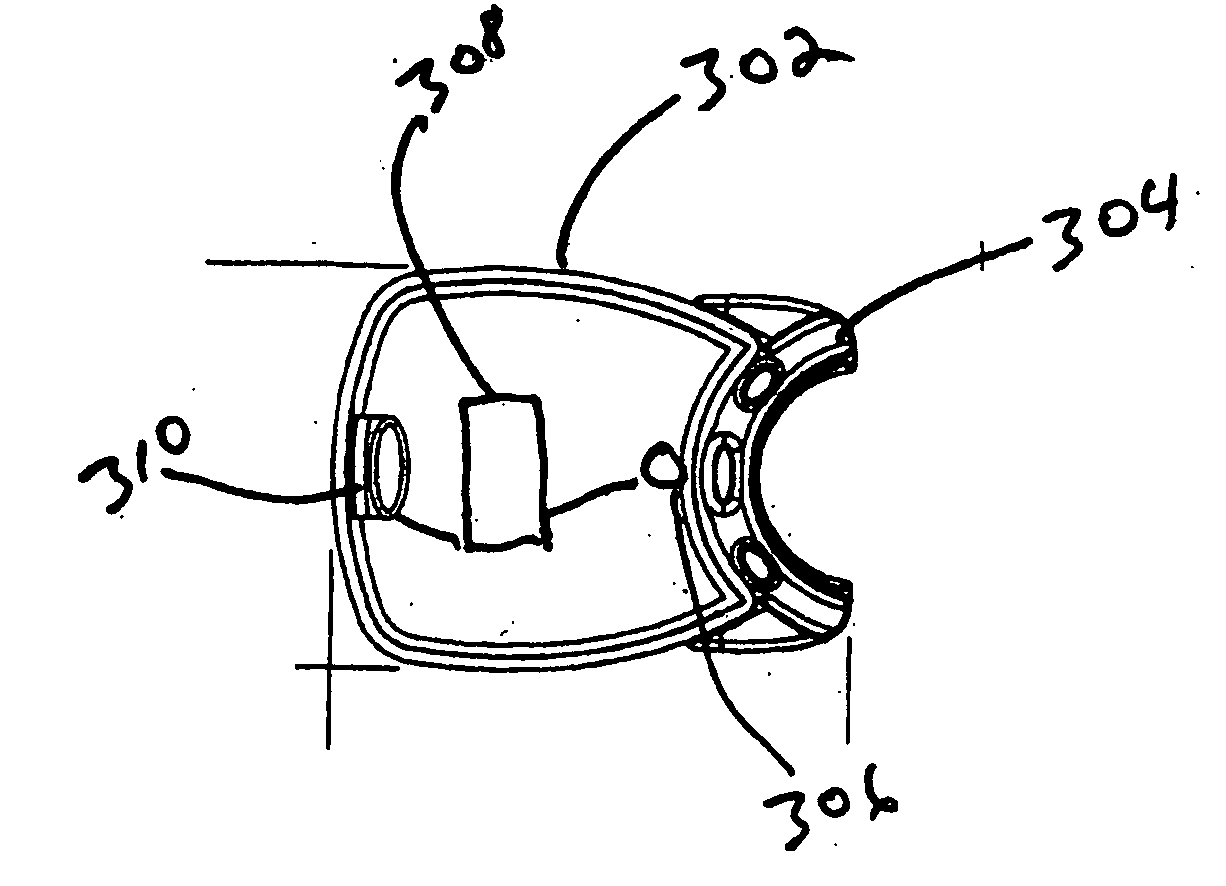

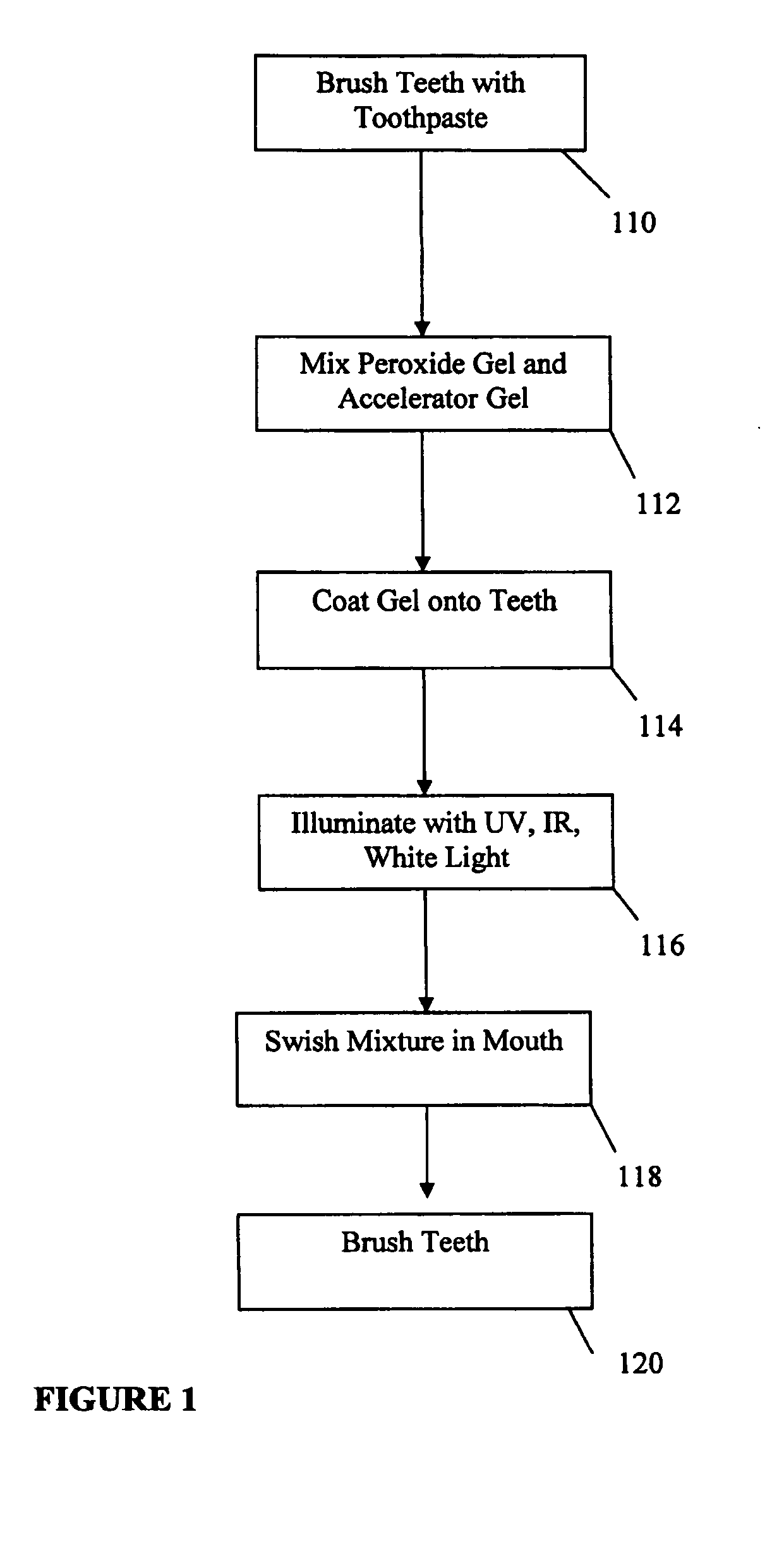

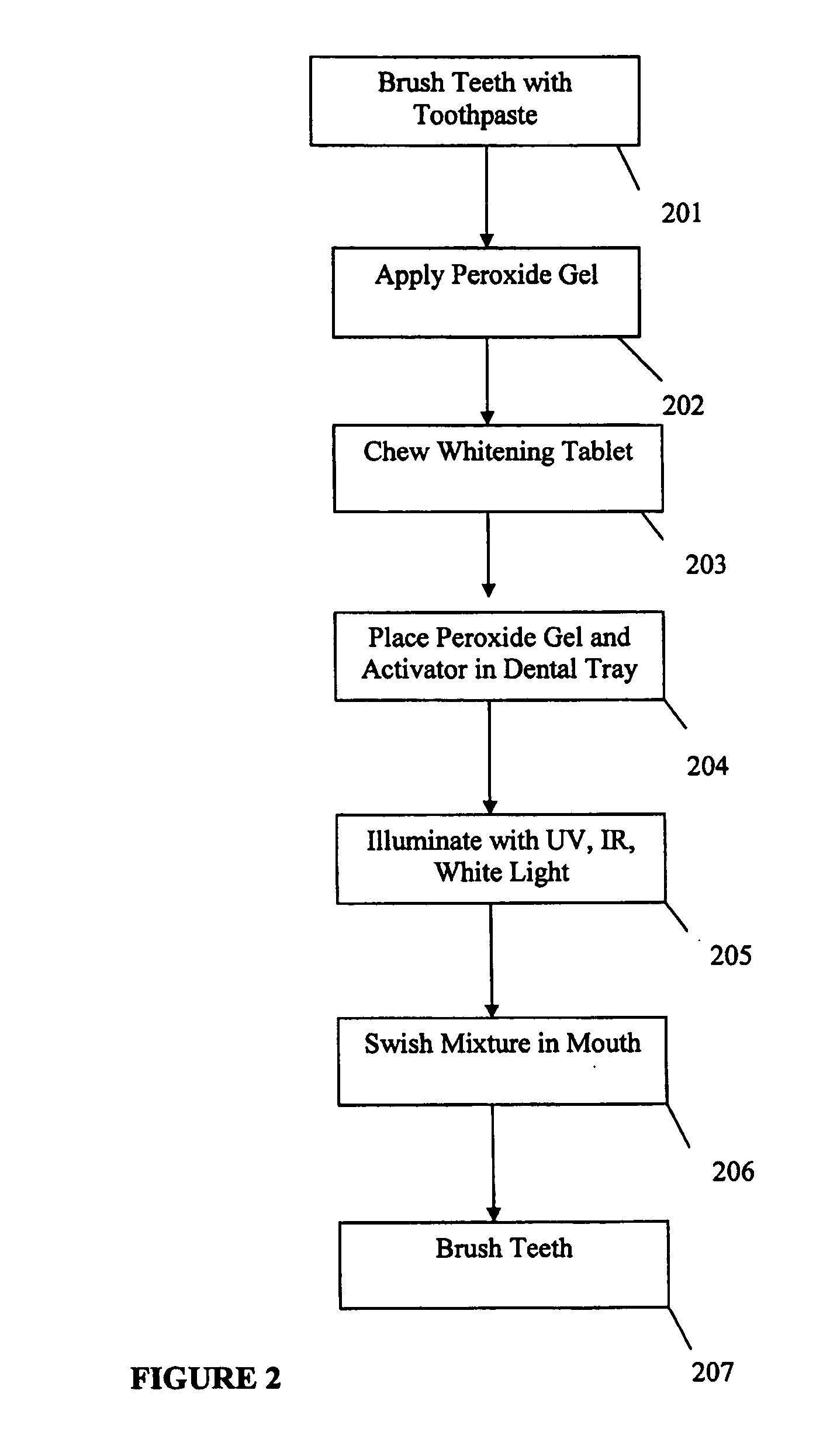

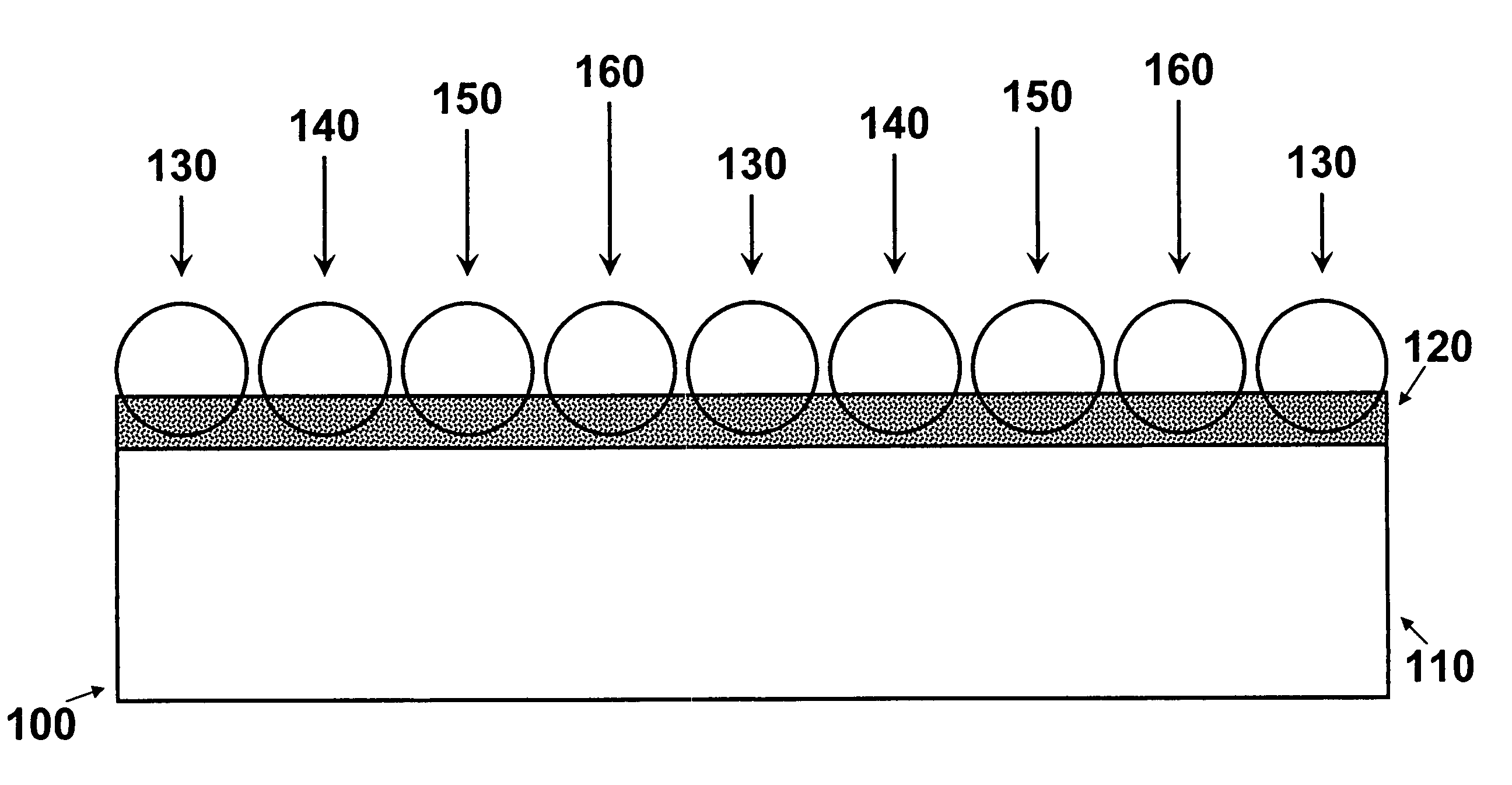

A dental whitening composition is formed from tablet formulation containing a metal ion catalyst and an alkaline pH raising compound and a peroxide solution having a concentration of about 1 percent to about 15 percent peroxide. The combination of the tablet formulation containing the metal ion within an alkaline composition along with the peroxide rinse forms a dental composition having foam like consistency, which whitens the surface of teeth. The tablet formulation can also be in the form of a gel or solution. The process of whitening teeth is accelerated by using a light emitting device producing a selected wavelength range. The light emitting device can be incorporated into a dental tray having a dental receiving area formed from a polymer having optical properties.

Owner:MILESTONE SCIENTIFIC INC

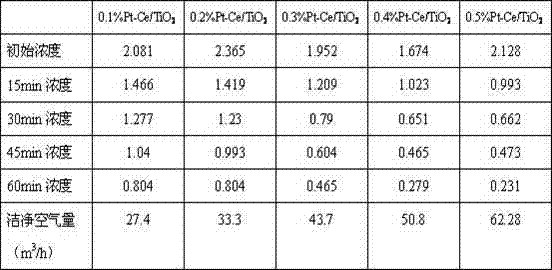

Metal alloy catalyst for formaldehyde purification and preparation method thereof

ActiveCN104646029AReduce dosageSpeed up decompositionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCatalytic oxidationBULK ACTIVE INGREDIENT

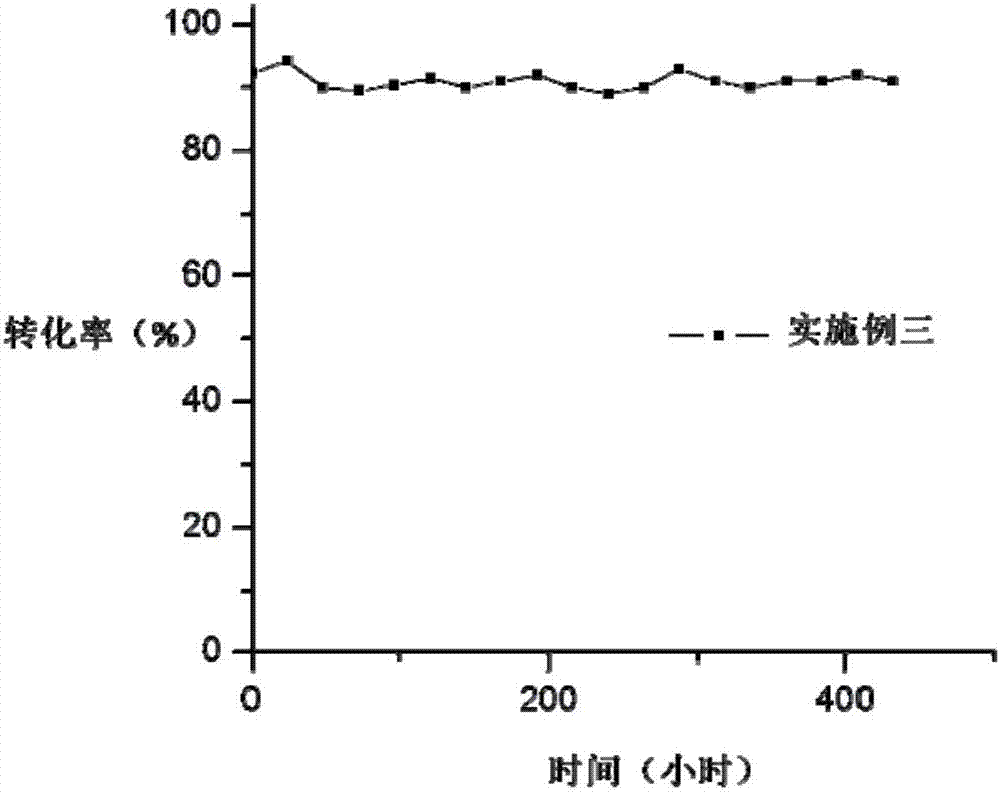

The invention discloses a metal alloy catalyst for formaldehyde purification and a preparation method thereof. The catalyst takes a metal alloy as an active center and takes a metal oxide as a carrier; the metal alloy is formed by compounding a precious metal A and a transition metal B; the precious metal A refers to any one of Pt, Ru, Rh, Pd and Ag; and the transition metal B refers to any one or a mixture of at least two out of Fe, Ni, Mn and Co. The preparation method comprises the following steps: synthesizing composite precious metal alloy nanoparticles by taking a precursor solution of the precious metal and the transition metal as a raw material under the CO atmosphere; loading the nanoparticles serving as active ingredients onto the carrier, reducing by virtue of hydrogen or a reducing solution to obtain the metal alloy catalyst. According to the catalyst disclosed by the invention, the indoor low-concentration harmful gas such as formaldehyde can be subjected to catalytic oxidation so as to prepare nontoxic and harmless CO2 and H2O under the room temperature conditions without light, electricity and other external auxiliary equipment, so that green purification of the formaldehyde is realized, and the catalyst has high stability.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

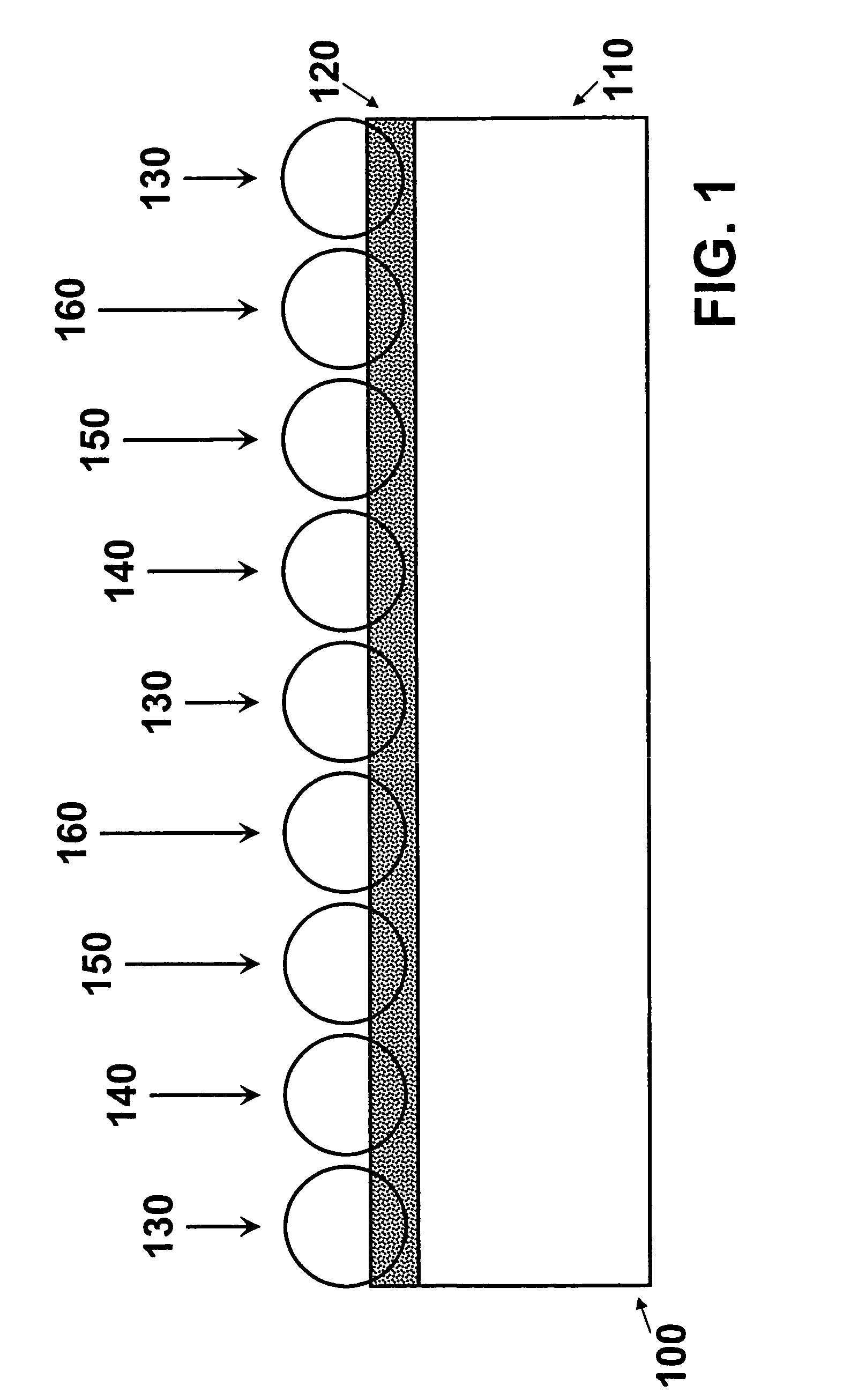

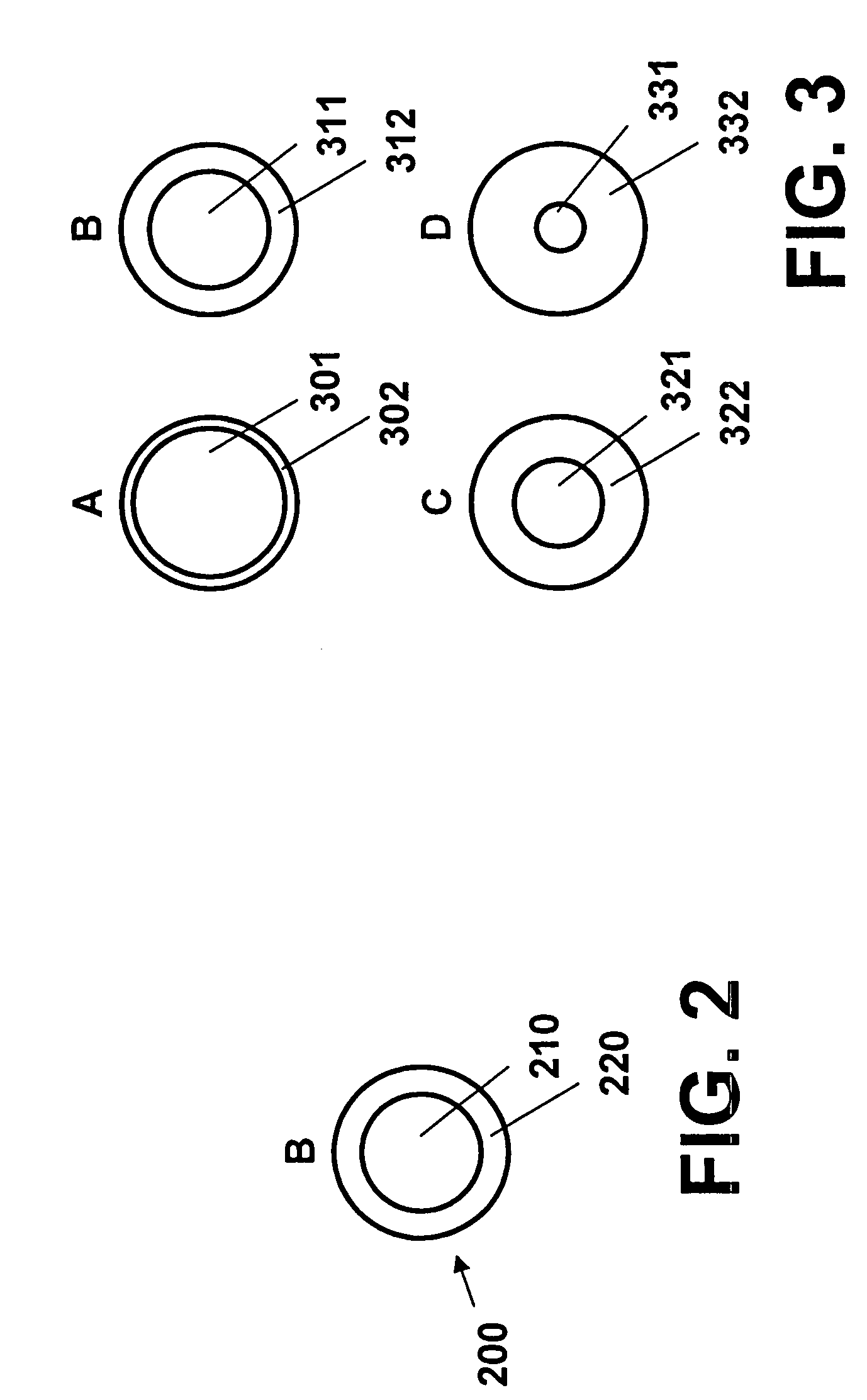

Method and apparatus for controlled delivery of active substance

InactiveUS7435256B2Fast decompositionFaster rateSurgeryAlcoholic beverage preparationInsertion stentEngineering

The invention relates to a method and device for coating a device with time-release drugs by providing a plurality of micro coated pellets having different release rates on the surface of the medical device structure, e.g., a stent. Organizing the micro pellets with different release rates on the structure can result in the structure having a plurality of release regions with varying release profiles.

Owner:BOSTON SCI SCIMED INC

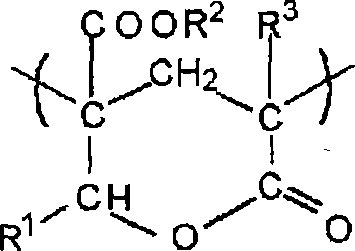

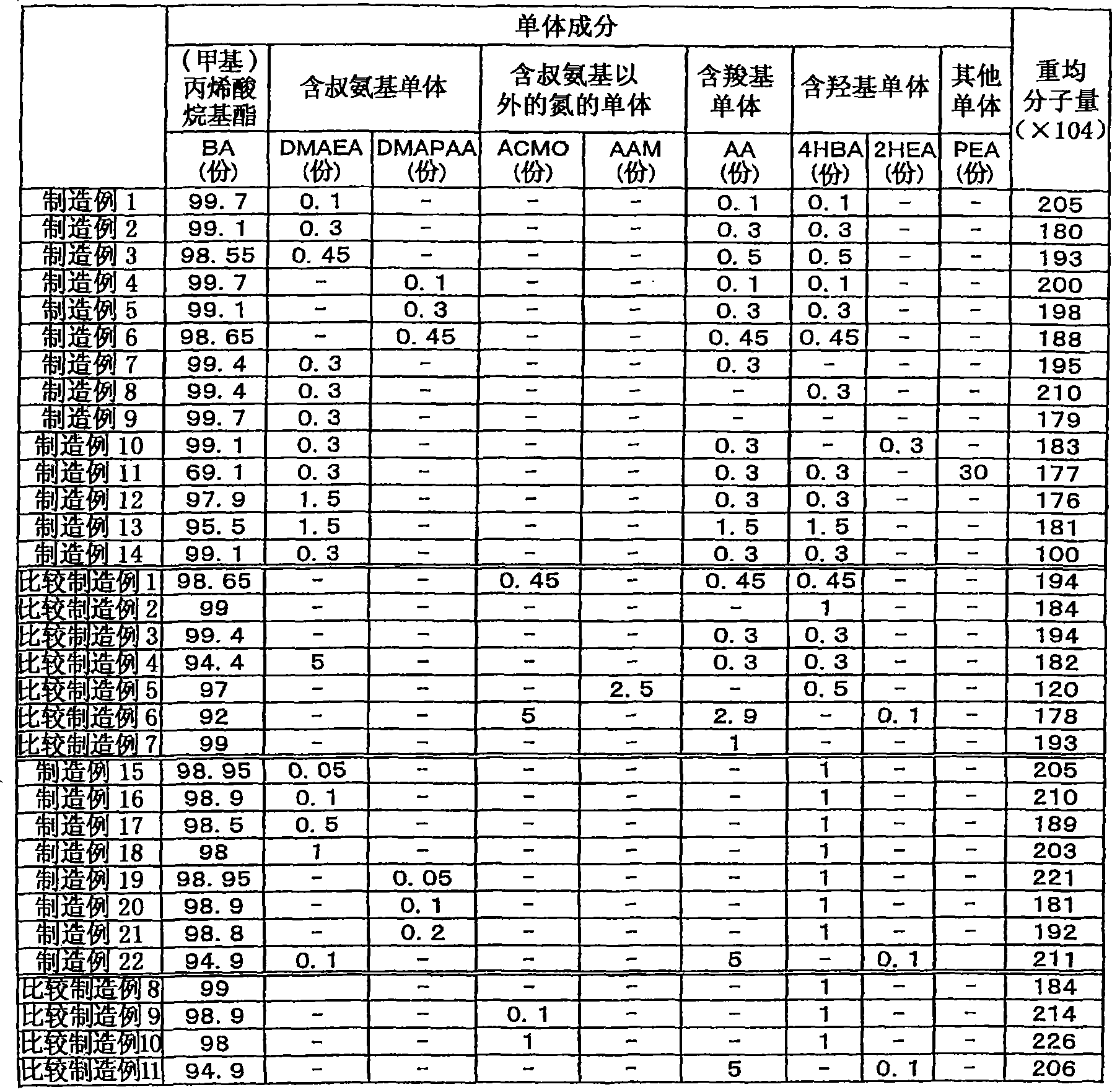

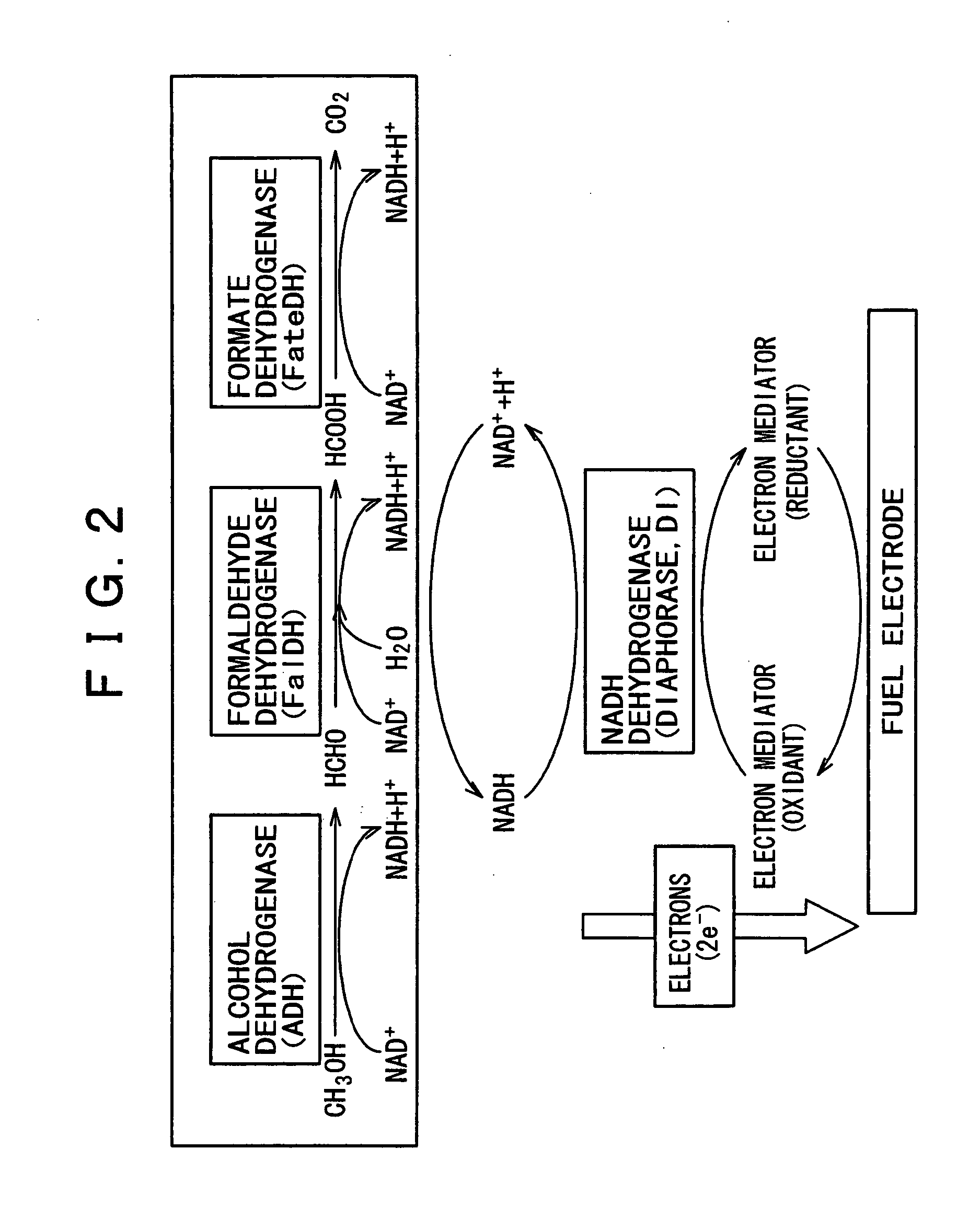

Pressure-sensitive adhesive composition for optical film, pressure-sensitive adhesive layer for optical film, production method thereof, pressure-sensitive adhesive optical film and image display

ActiveCN101418198AExcellent productivityImprove machinabilityFilm/foil adhesivesPolarising elementsMeth-Optical thin film

A pressure-sensitive adhesive composition can form an pressure-sensitive adhesive layer that has satisfactory reworkability such that optical films can be easily peeled from liquid crystal panels with no adhesive residue and also has satisfactory processability such that it can be worked without pressure-sensitive adhesive fouling or dropout. The pressure-sensitive adhesive composition for an optical film of the present invention comprises 100 parts by weight of a (meth)acrylic polymer comprising 45 to 99.99% by weight of an alkyl (meth)acrylate monomer unit and 0.01 to 2% by weight of a tertiary amino group-containing monomer unit; and 0.01 to 2 parts by weight of a peroxide as a crosslinking agent.

Owner:NITTO DENKO CORP

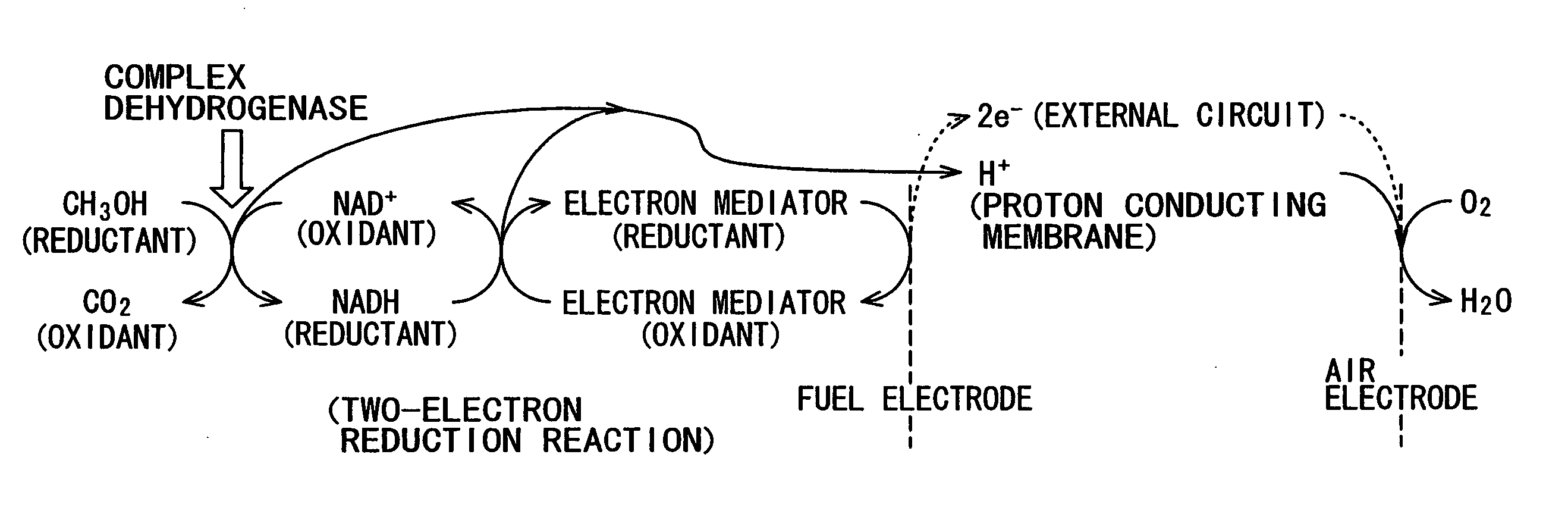

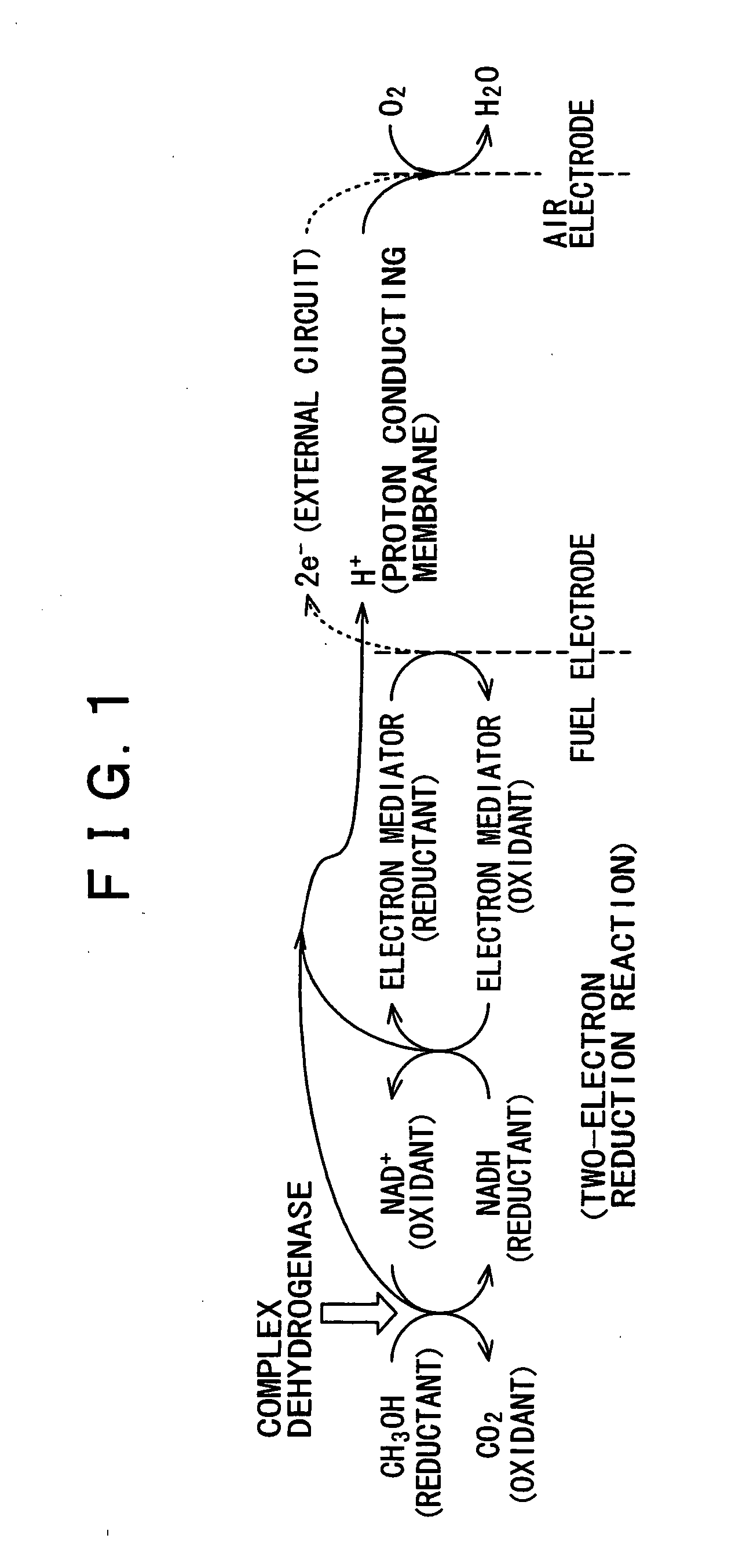

Fuel battery

ActiveUS20050053825A1Evenly decomposedFast formingImmobilised enzymesBioreactor/fermenter combinationsHigh current densityFuel cells

A fuel cell which utilizes the biogenic metabolism to produce a high current density is provided. The fuel cell generates electric power in such a way that the fuel is decomposed stepwise by a plurality of enzymes and those electrons formed by oxidation are transferred to the electrode. The enzymes work such that the enzyme activity of the enzyme involved in decomposition in the early stage is smaller than the sum of the enzyme activities of the enzymes involved in decomposition in the later stage. In the case where a coenzyme is involved, the enzyme activity of the oxidase that oxidizes the coenzyme is greater than the sum of the enzyme activities of the enzymes involved in the formation of the reductant of the coenzyme, out of the enzymes involved in the stepwise decomposition of the fuel.

Owner:MURATA MFG CO LTD

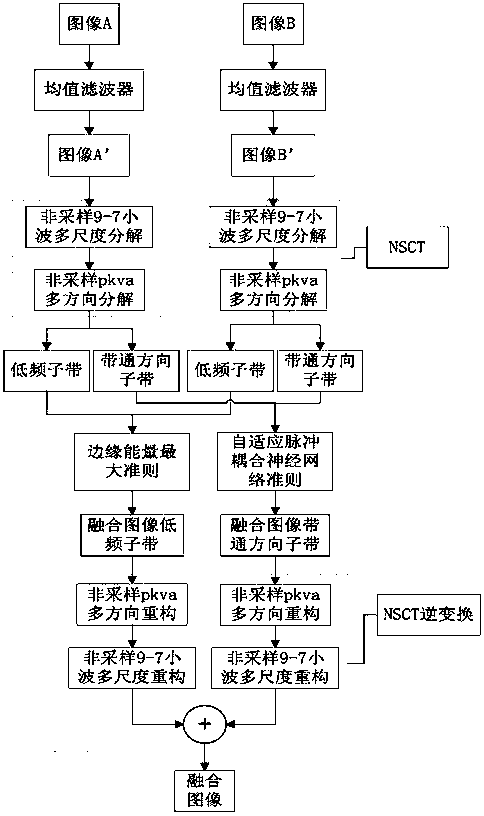

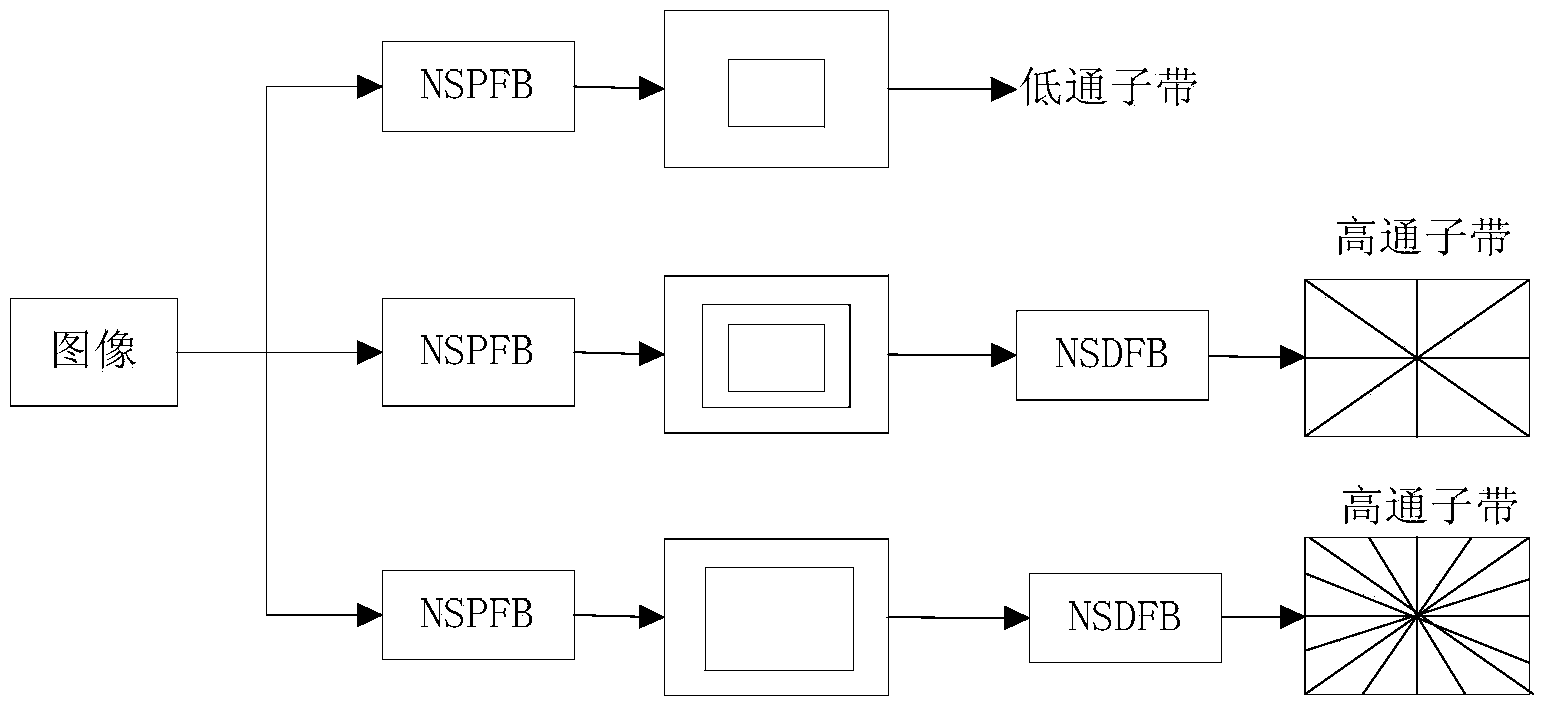

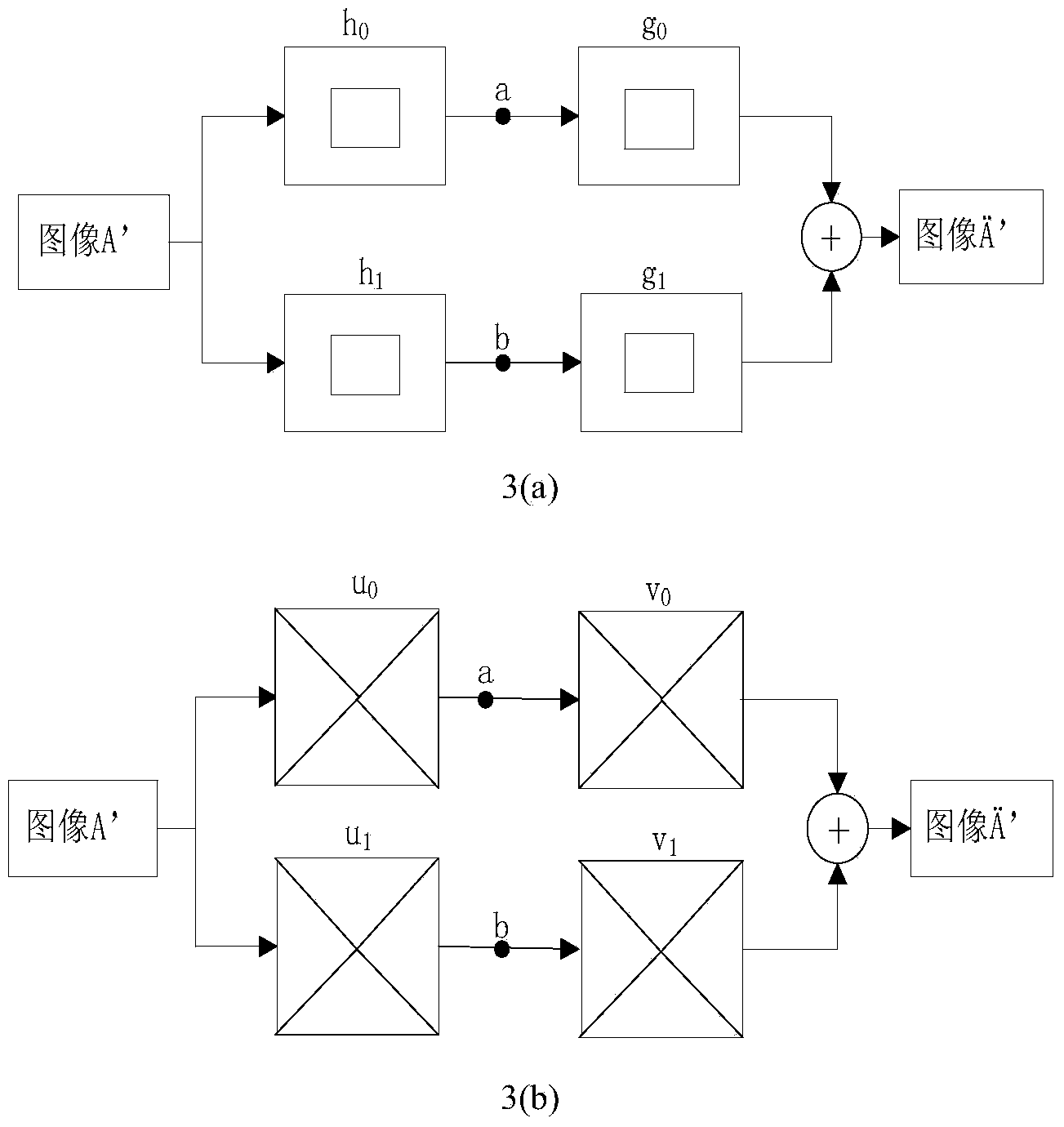

Contourlet transformation-adaptive medical image fusion method based on non-sampling

InactiveCN104282007ALimited universalityFast decompositionImage enhancementGeometric image transformationImaging processingContourlet

The invention relates to a contourlet transformation-adaptive medical image fusion method based on non-sampling and belongs to the field of image processing. The method comprises the steps that firstly, a source image is subjected to arithmetic average filtering and then is decomposed through an orthogonal 9-7 wavelet filter and a pkva filter during non-sampling to obtain low-frequency sub-band coefficients and all band-pass direction sub-band coefficients; secondly, the low-frequency sub-band coefficients are selected and fused according to the edge information maximum criterion, all the band-pass sub-band coefficients are selected and fused through an adaptive PCNN model based on a visual neuron model; lastly, a final fused image is obtained by means of inverse transformation of NSCT. According to the contourlet transformation-adaptive medical image fusion method based on non-sampling, the algorithm is very effective and correct, the edge and space texture information of the fused image is clear, color distortion is low, the false contour phenomenon does not exist, and feature information of the source image is well reserved.

Owner:CHANGCHUN UNIV OF SCI & TECH

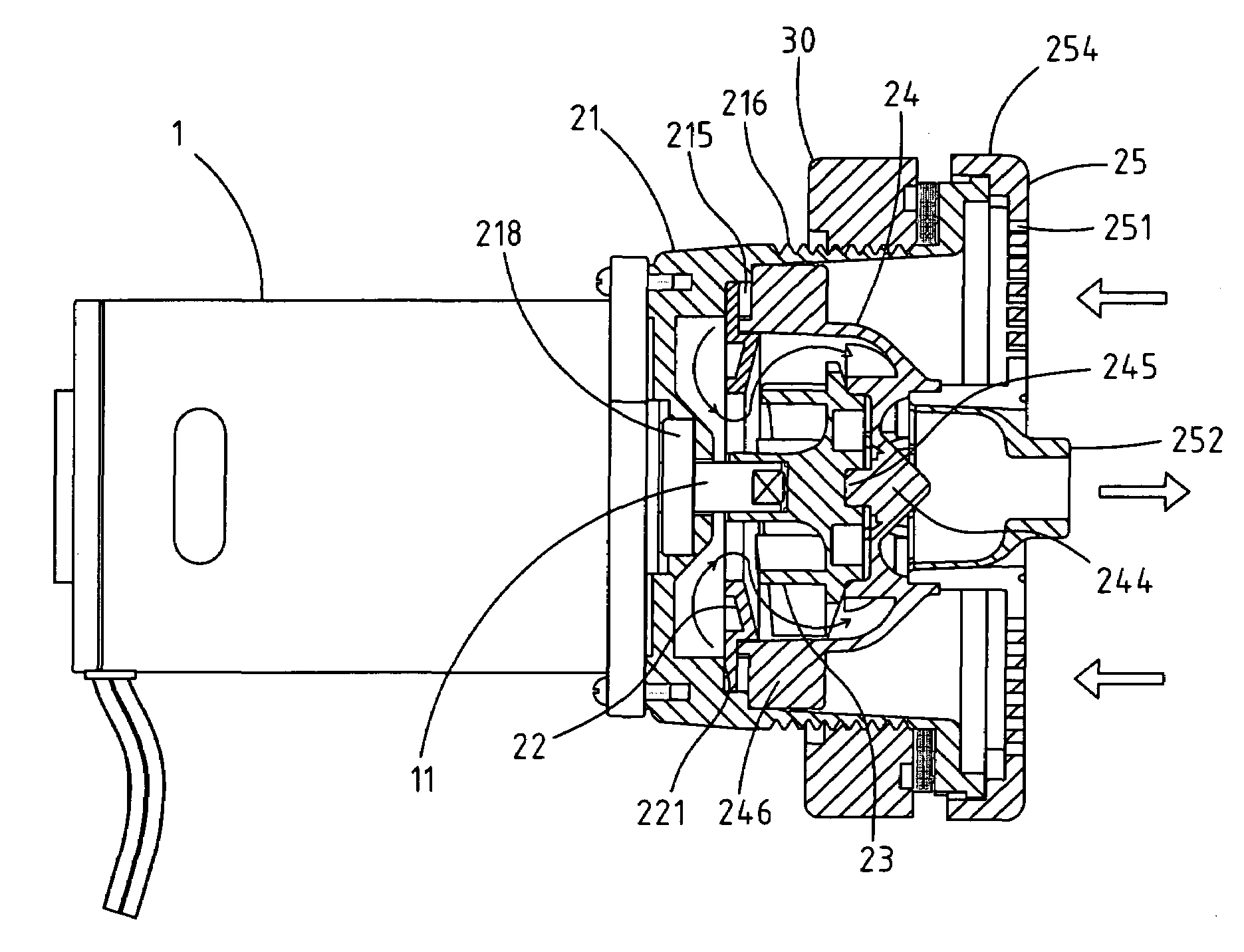

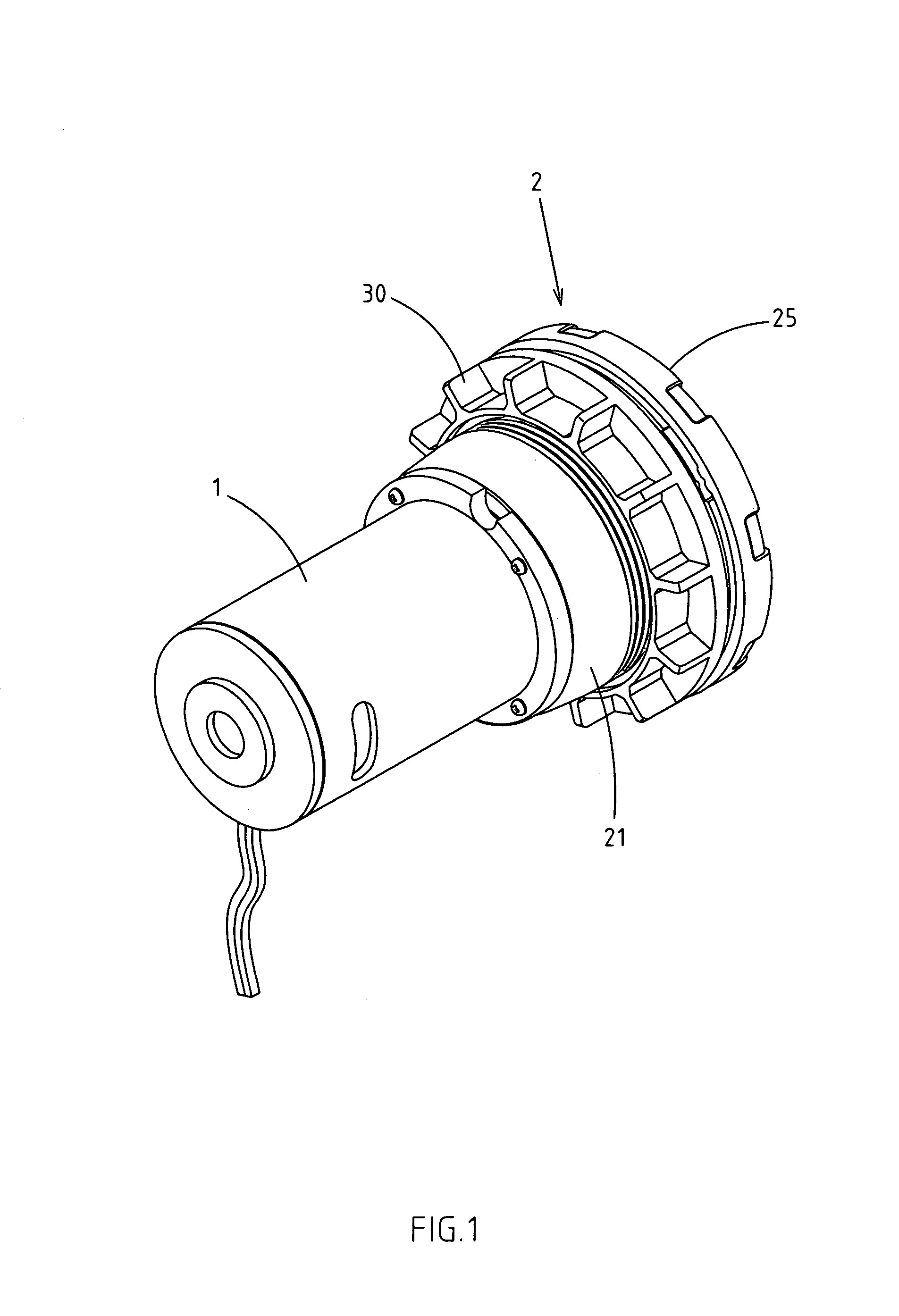

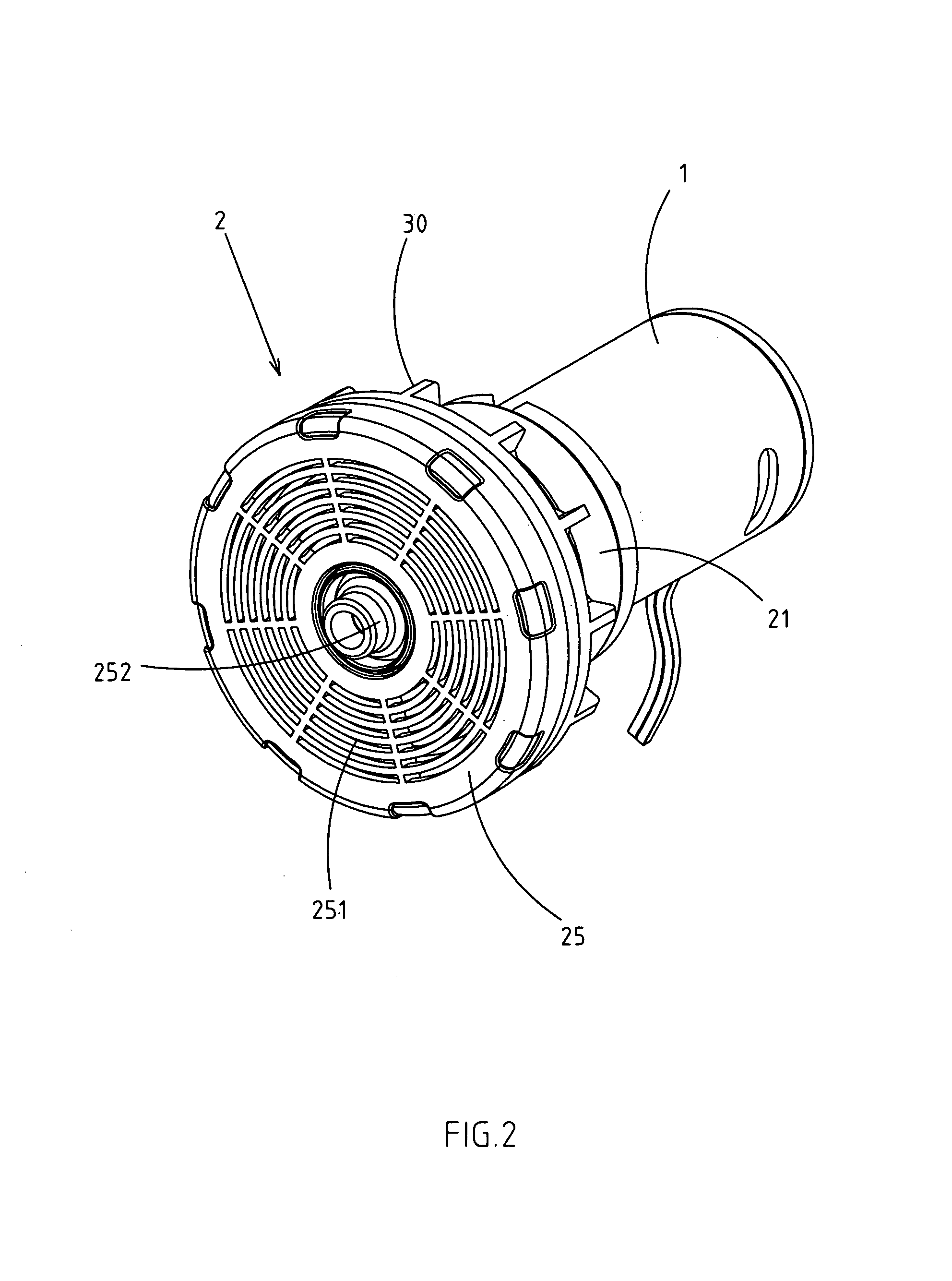

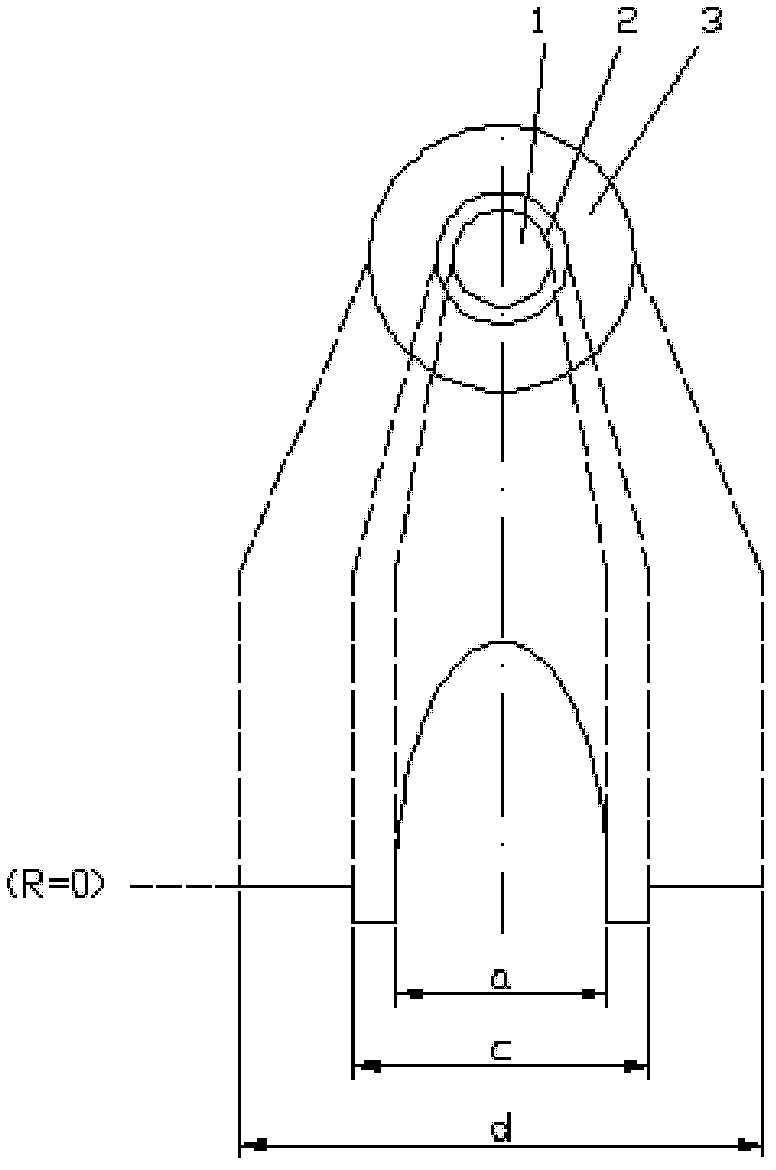

Structure of a swirl generator for liquid

The structure of swirl generator for liquid includes a motor with a head affixed to a swirl generator. The bearing seat of the swirl generator forms a fixation section, allowing the swirl extension to be affixed to the inside of the bearing seat easier and quicker, and installing the water guide cover at the opening of the bearing seat. Therefore, the swirl generator structure has advantages of easy assembly and decomposition for repair.

Owner:CHANG HONG JUN

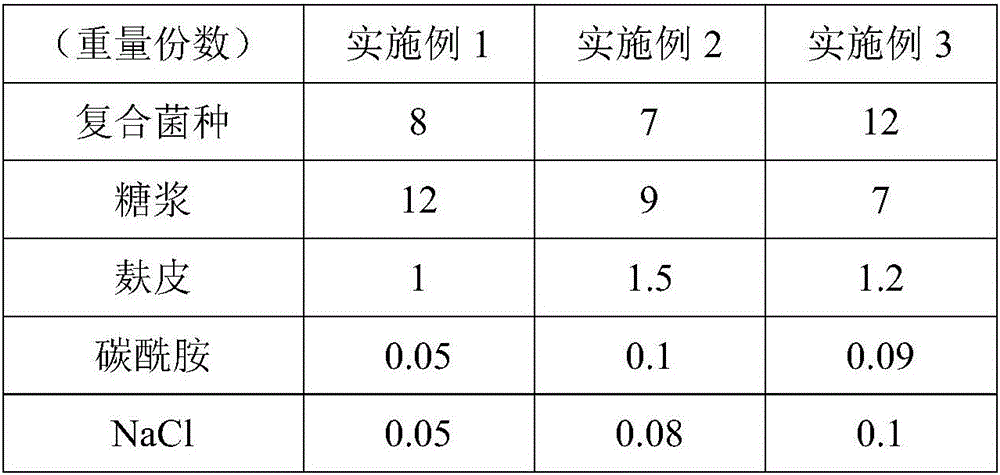

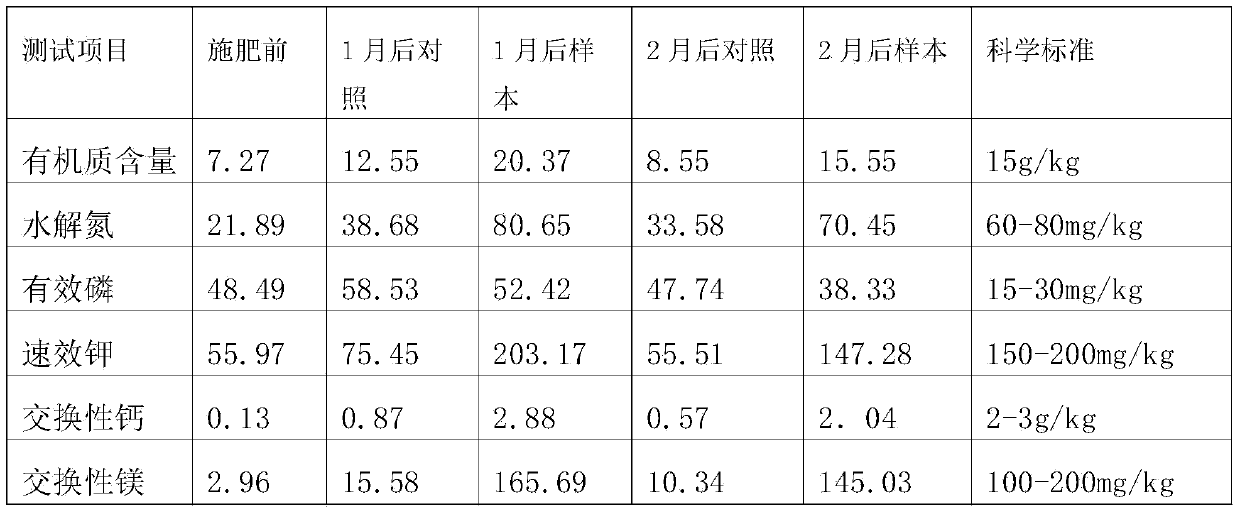

Orchard grass intercropping method

InactiveCN105993478AReduce disease incidenceImprove fertilityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersDiseaseTree trunk

The invention relates to the technical field of agriculture, and provides an orchard grass intercropping method. The method comprises the following steps: zones are divided, wherein grass is planted between orchard lines, and straws are laid within a range of 0.5m from tree trunks; plowing is carried out, wherein an EM inoculant is spread to grass planting zone soil, and plowing is carried out after 20-30 days; seed soaking is carried out, wherein grass seeds are soaked with the EM inoculant for 4-12h, and are air-dried at a shaded and ventilated place; sowing is carried out, wherein a sprinkler irrigation treatment is carried out with a diluted composite bacterial fertilizer, and uniform sowing is carried out with a sowing amount of 12-15kg / Mu when the soil is moist; management is carried out, wherein watering is carried out after sowing, and sprinkler irrigation is carried out with a diluted EM inoculant when seedlings uniformly shoot; and maintenance is carried out, wherein a grass height is maintained at 10-20cm, and a mixture of trimmed-off grass and straws is laid within a range of a tree base. The method has water-retaining, fertilizer-retaining and drought-resisting functions. With the method, farm chemical is not applied, and the effect of green manure is good. Chemical fertilizer is saved, and disease degree can be reduced from the source. Soil salinization can be effectively ameliorated, and fruits can be green and organic.

Owner:北京百丰生物科技集团有限公司

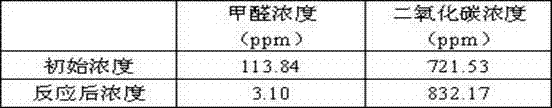

Room-temperature catalytic oxidizing agent of formaldehyde employing composite noble metal alloy, and preparation method thereof

ActiveCN103357409AFast decompositionReduce dosageDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementDecomposition

The invention discloses a room-temperature catalytic oxidizing agent of formaldehyde employing a composite noble metal alloy and a preparation method thereof. The catalyst is prepared by adopting a composite noble metal alloy as an active center, and compound crystalline nano-titanium dioxide as a carrier, wherein the composite noble metal alloy is an alloy active center which is compounded by noble metal and a rare earth element; the preparation method comprises the following steps of: selecting a salt solution containing the noble metal and a salt solution containing the rare earth element to dissolve into deionized water; slowly dropwise adding a KOH solution, carrying out high-speed agitation, rotary steam drying and baking; and roasting at the temperature of 400-600 DEG C and then leading in hydrogen to reduce, so as to obtain the room-temperature catalytic oxidizing agent of formaldehyde. By adopting the room-temperature catalytic oxidizing agent and the preparation method thereof, the catalytic activity is greatly improved; the formaldehyde is rapidly oxidized into carbon dioxide and water in a room-temperature condition namely when the temperature is 5-25 DEG C, so that the dosage of platinum metal is greatly reduced; and the room-temperature catalytic oxidizing agent has the advantages of simple process, low cost, good performance, fast decomposition velocity of formaldehyde and long service life, and can be widely applied to the equipment such as air conditioning equipment, a ventilating duct, a fresh air ventilator, an air purifier, an air humidifier and the like.

Owner:阜阳中科众汇净化材料有限公司

Method for preparing high-cerium nano-stage rare earth polishing powder from rare earth ore concentrate

InactiveCN101215446AReduce manufacturing costFast decompositionPolishing compositions with abrasivesMolten stateHigh energy

A method for preparing rare-earth polish powder in high cerium nanometer magnitude from rare earth ore concentrate, which is characterized in that the producing steps comprise directly preparing mixed carbonic acid rare-earth from rare earth ore concentrate dense sulphating roasting and infusion with a method of precipitating ammonium acid carbonate, mixing the mixed carbonic acid rare-earth and alkali 0.5-2 parts, heating to 600-800 DEG C to melt the compound, keeping the temperature for 1-4 hours in the molten state, cooling, grinding, then, adding industrial hydrofluoric acid HF>=45% whose adding amount is 10%-20% of the weight of rare-earth concentrate powder, and obtaining oxyfluoride rare earth enriched products, the oxyfluoride rare earth enriched products are grinded, watered, water filtered, mixed in a mixer, then packed into a high-energy ball mill with sieve, and filled with nitrogen, wet powder is ball-abraded with high energy, a high pressure current rotary passage is arranged on the lower portion of a rear sieve of a high-energy ball mill room, the water of sieved powder is dried under the impetus of high speed currents and then baked, and finished polish powder whose powder particle size is <=500nm is obtained.

Owner:浩华科技实业有限公司

Method for preparing optical fiber preform rod

InactiveCN102320732AHigh silicon contentEasy to purifyGlass deposition burnersGlass fibre productsSilanesUltimate tensile strength

The invention relates to a method for preparing optical fiber preform rod, which comprises the following steps: directly coating a uniform quartz loose body on an external surface of a core rod by using silane or siloxane as a raw material through an external vapor deposition method so as to form a loose-body preform rod, slowing heating the loose-body preform rod at a high temperature for dehydration, and sintering the loose-body preform rod to obtain a transparent optical fiber preform rod. The invention adopts clean silane or siloxane as a raw material for forming the quartz coating, does not generate a lot of harmful hydrogen chloride, overcomes the disadvantage that chlorine-containing raw material introduces single bonds which can block atomic bonds into the coating, increases the purity and strength of the preform rod material, and improves the mechanical strength of optical fibers.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

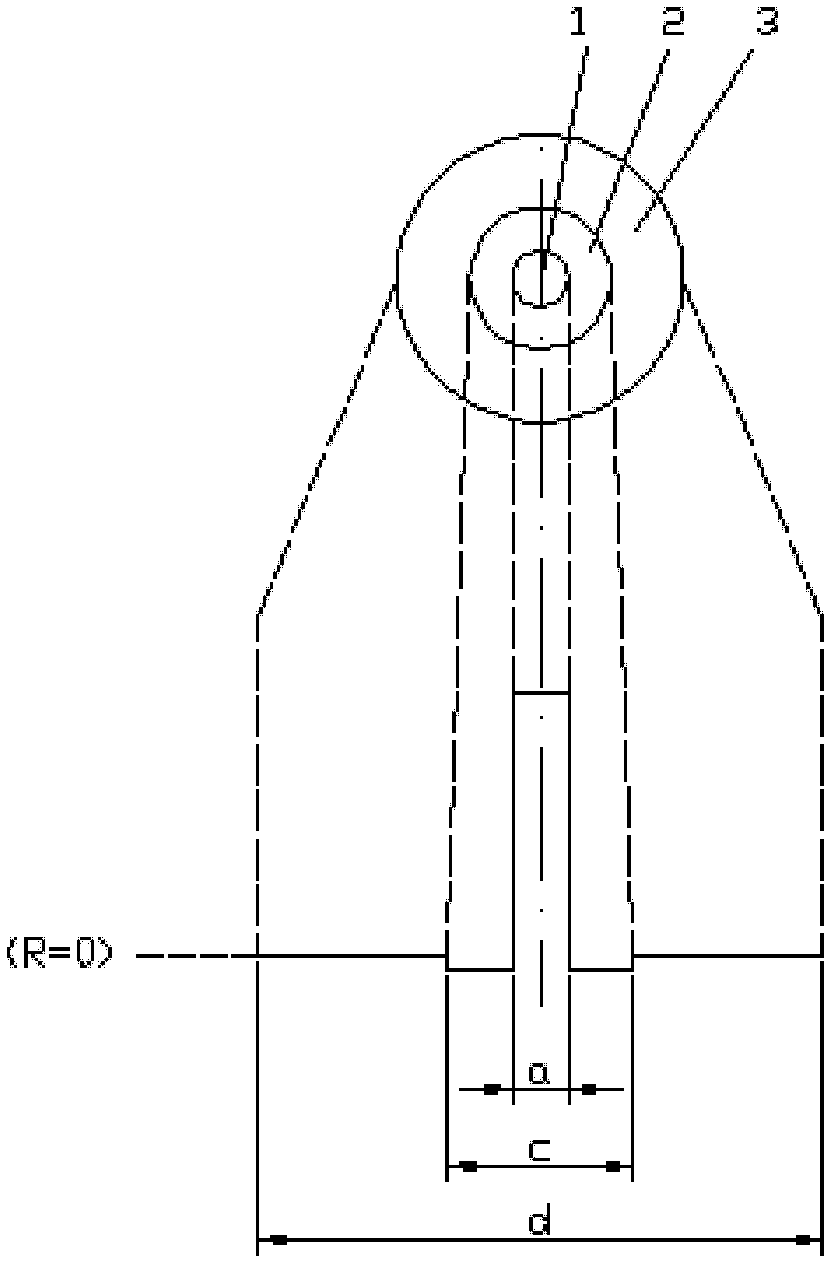

Method for preparing rare earth chloride from mixed rare earth concentrate or monazite concentrate

InactiveCN105543510AShort processAlkali decomposition temperature range is lowProcess efficiency improvementRare earthMonazite

The invention relates to a method for preparing rare earth chloride from mixed rare earth concentrate or monazite concentrate and belongs to the field of hydrometallurgy. According to the method, the rare earth chloride with the rare earth leaching rate reaching 94.87-99.26% is prepared by controlling the alkali decomposing temperature, the reaction time and the reaction pressure of the mixed rare earth concentrate or the monazite concentrate in the high-pressure alkali decomposing process. The method has the beneficial effects that the mineral decomposing rate is high under the high-pressure condition, the decomposing temperature is reduced, the reaction time is shortened, and energy conservation and environment friendliness are achieved; caustic soda can be recycled, so that cost is reduced; no three-waste pollution is generated, and various valuable elements are comprehensively recycled; and the technological process is short, and the method is suitable for industrial production.

Owner:李梅

Method for producing alumina with aluminum-containing metallurgical material

InactiveCN101863500AImprove product qualityStrong process adaptabilityAluminium oxides/hydroxidesSodium bicarbonateAluminium sulfate

The invention relates to a method for producing alumina with aluminum-containing metallurgical material; the process comprises sulfuric acid decomposition of aluminum-containing metallurgical material, aluminium sulfate solution purification, aluminum precipitation of sodium carbonate salt, aluminum hydroxide calcination, sodium carbonate salt regeneration, sulphuric acid regeneration and other main procedures; the sulphuric acid, sodium bicarbonate and other chemical raw materials used in an alumina production process can be regenerated and recycled; and the method has the advantages of good alumina product quality, low production cost, environmental-friendliness and the like.

Owner:CENT SOUTH UNIV

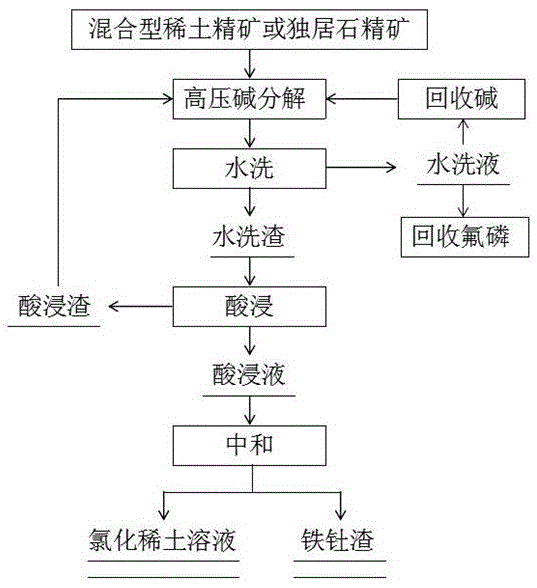

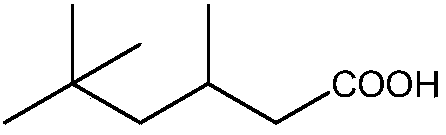

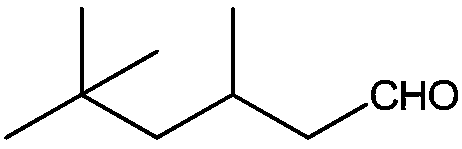

System and method for preparing isononanoic acid and method for preparing metal organic skeletal catalyst

ActiveCN108047027AHigh selectivityPromote decompositionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDecompositionMetal-organic framework

The invention provides a system and method for preparing isononanoic acid and a method for preparing a metal organic skeletal catalyst. The system includes an oxidation reactor used for oxidizing isononylaldehyde to isononanoic acid; a cooler used for cooling a part of material flow that flows out of the oxidation reactor; a metal ion separator used for separating excessive metal ions from the material flow that flows out of the cooler; a peroxide decomposition reactor used for decomposing a peroxide in the other part of the material flow that flows out of the oxidation reactor; and a rectification apparatus used for separating the material flow that flows out of the peroxide decomposition reactor to obtain the isononanoic acid product, wherein the material outlet of the metal ion separator is connected to the material inlet of the oxidation reactor. The invention further provides an isononanoic acid preparation method that is good in selectivity and safety and high in yield.

Owner:WANHUA CHEM GRP CO LTD

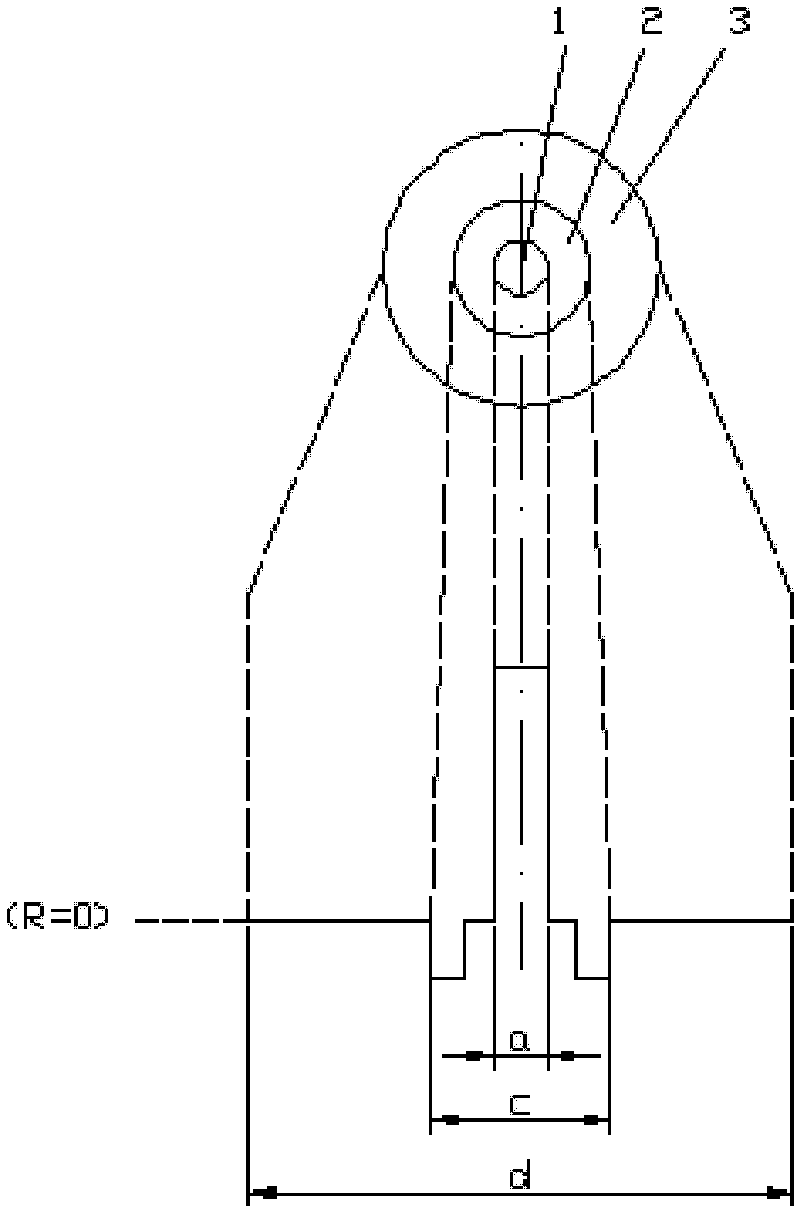

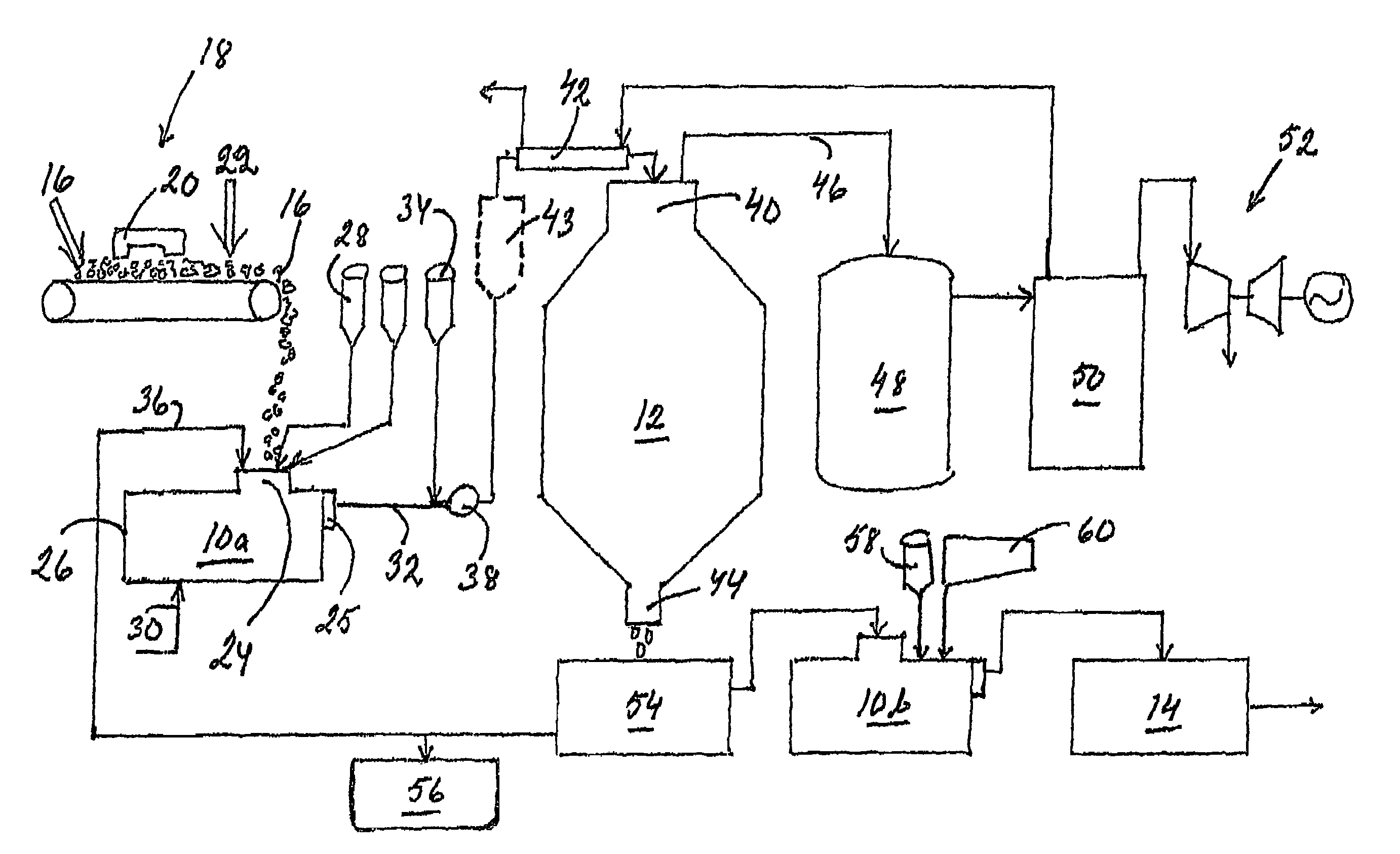

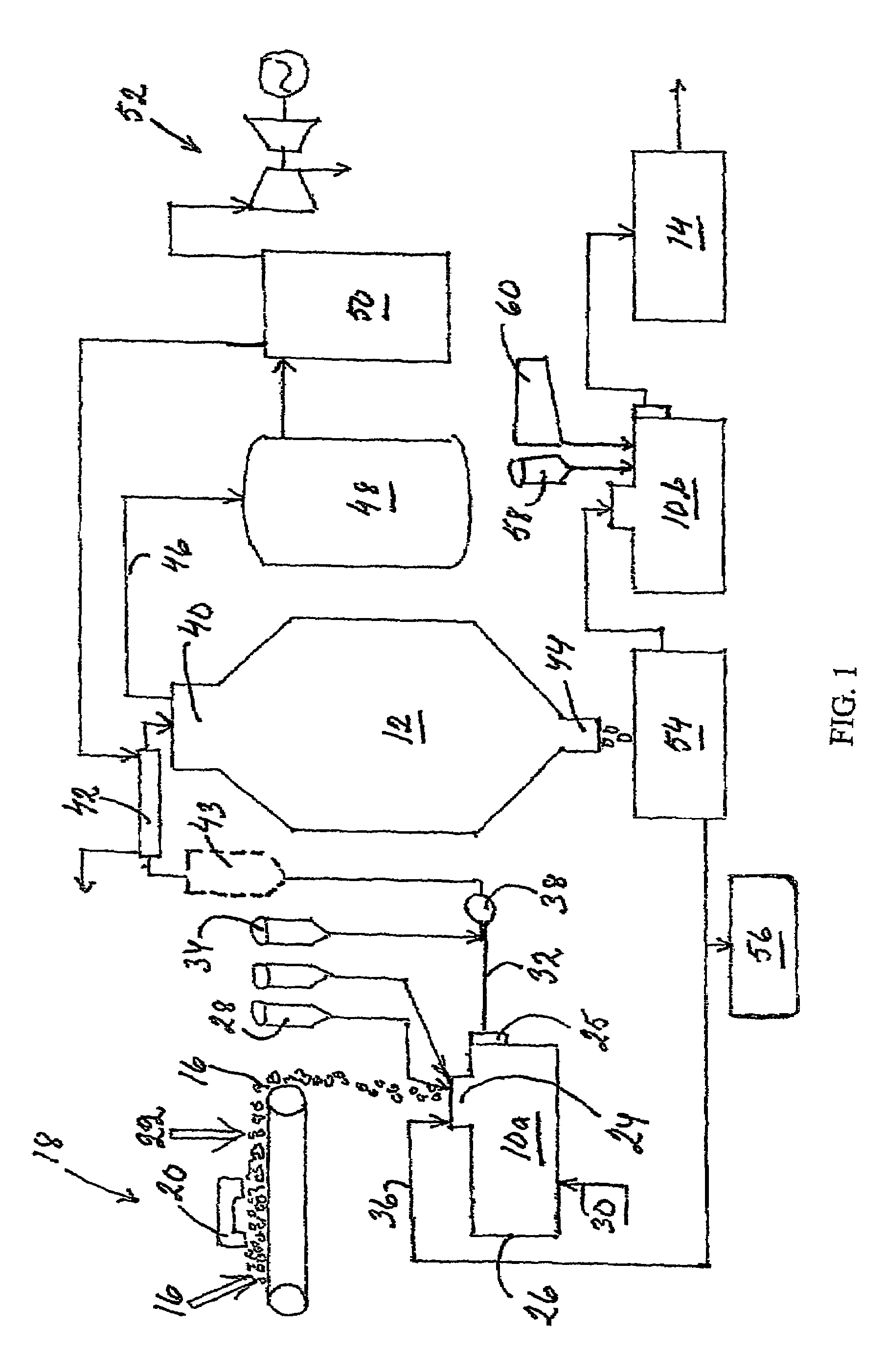

Method and device for disintegration of organic material and use of the device

InactiveUS7314190B2Improve efficiencyFast decompositionWaste water treatment from animal husbandryWaste water treatment from animal processingOrganic matterPre treatment

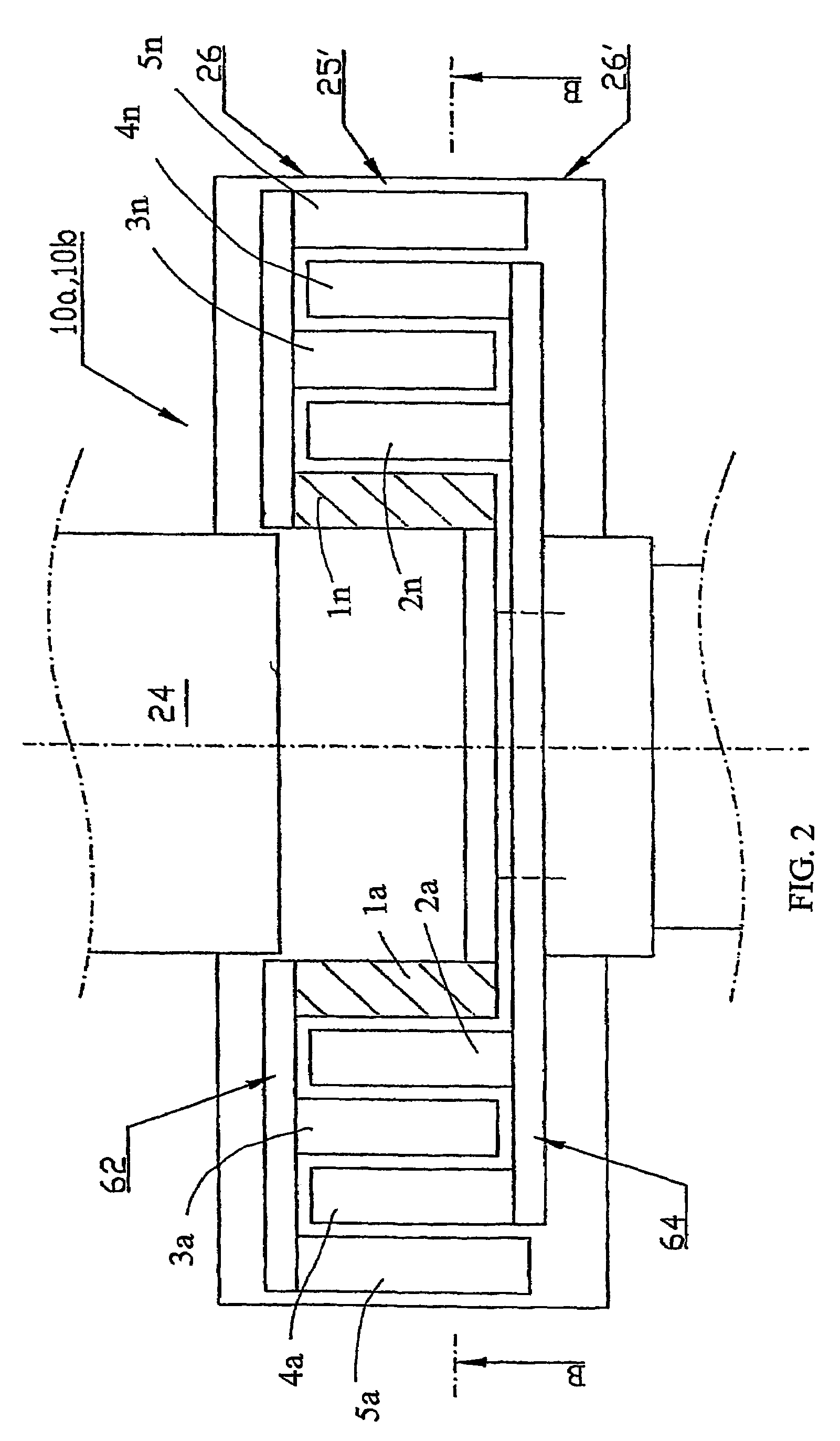

A method and apparatus for biological and / or chemical decomposition of waste containing organic matter. The method includes waste pretreatment in which waste is fragmented and homogenised in a pretreatment apparatus (10a, 10b) operating on the principle of a multi-ring double action impact mill. The apparatus has either two rotors (62, 64) or a rotor and stator disposed inside a housing (26), which rotors and / or stator are equipped with blades having impact surfaces, and which form one or more rings (1,2,3, . . . ) coaxial with the rotor. The waste is fed into the housing through the hub of rings formed by the blades, and travels by the effect of a rotor or rotors, to the outer ring of the ring (7) formed by the outermost blades, and further to the discharge opening (25, 27′) at the outer ring.

Owner:FRACTIVATOR OY

Method for electrolyzing vanadium slurry and extracting vanadium pentexide using film

InactiveCN101008047ASpeed up the extraction processHigh recovery ratePhotography auxillary processesProcess efficiency improvementElectrolysisAmmonium metavanadate

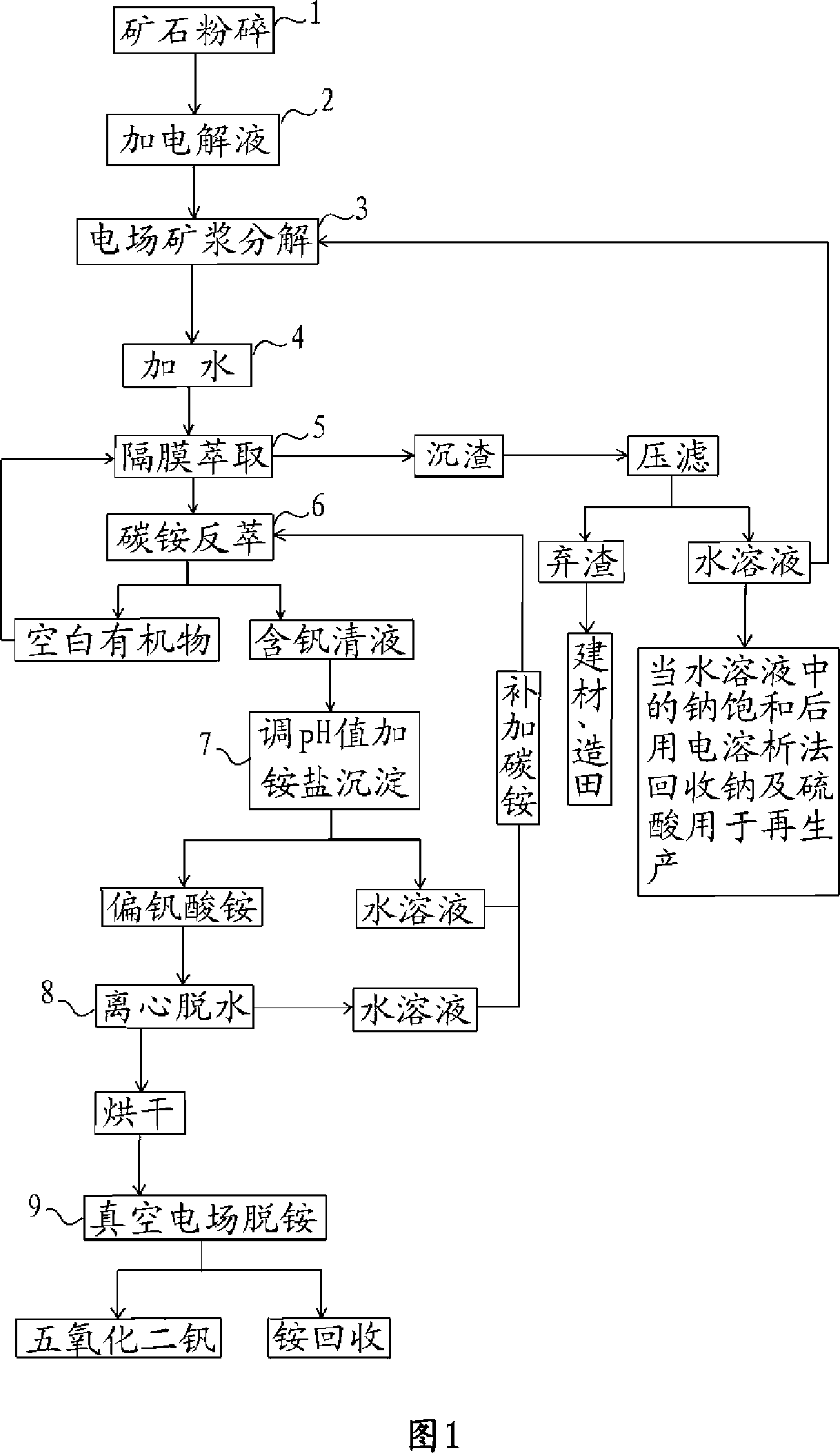

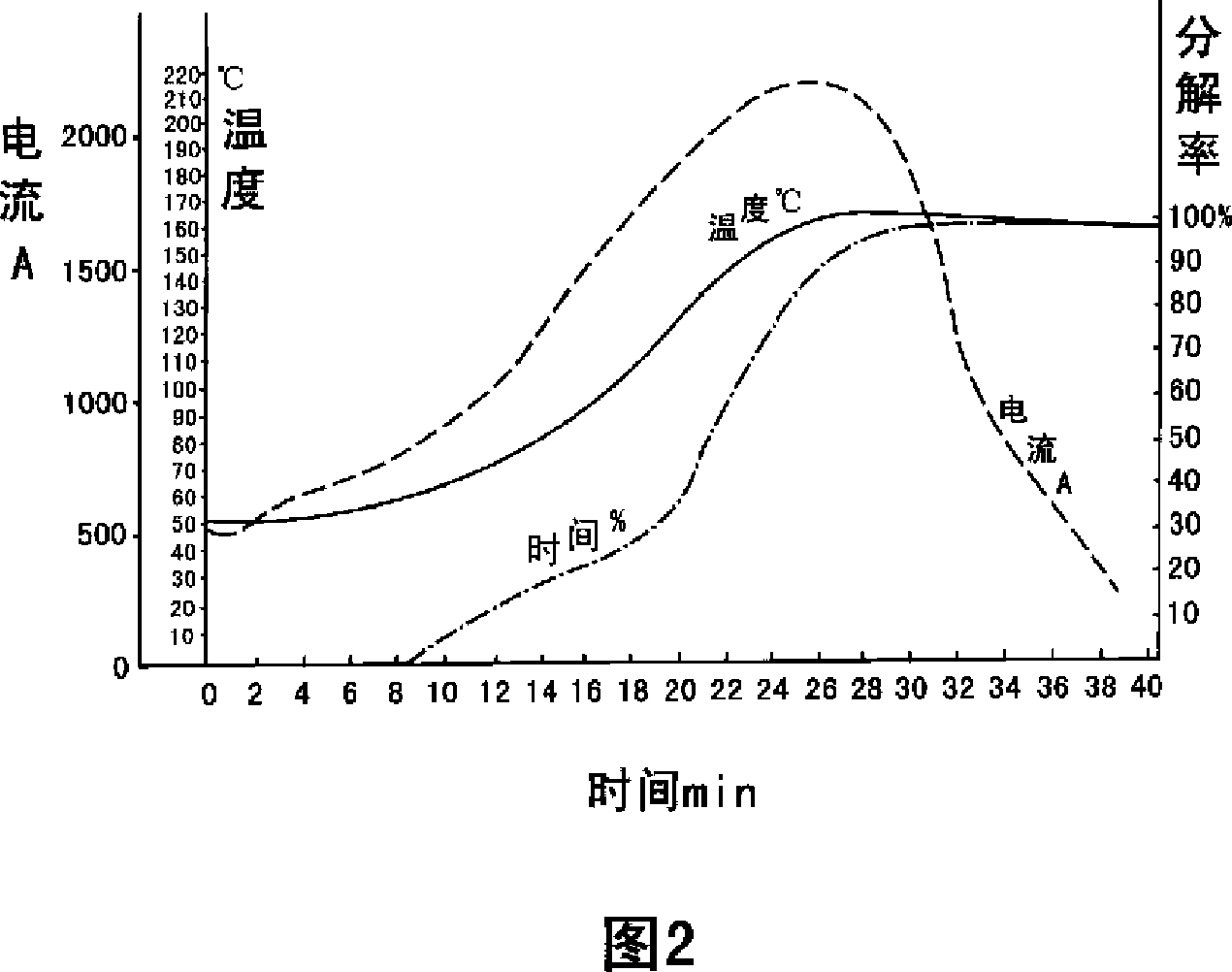

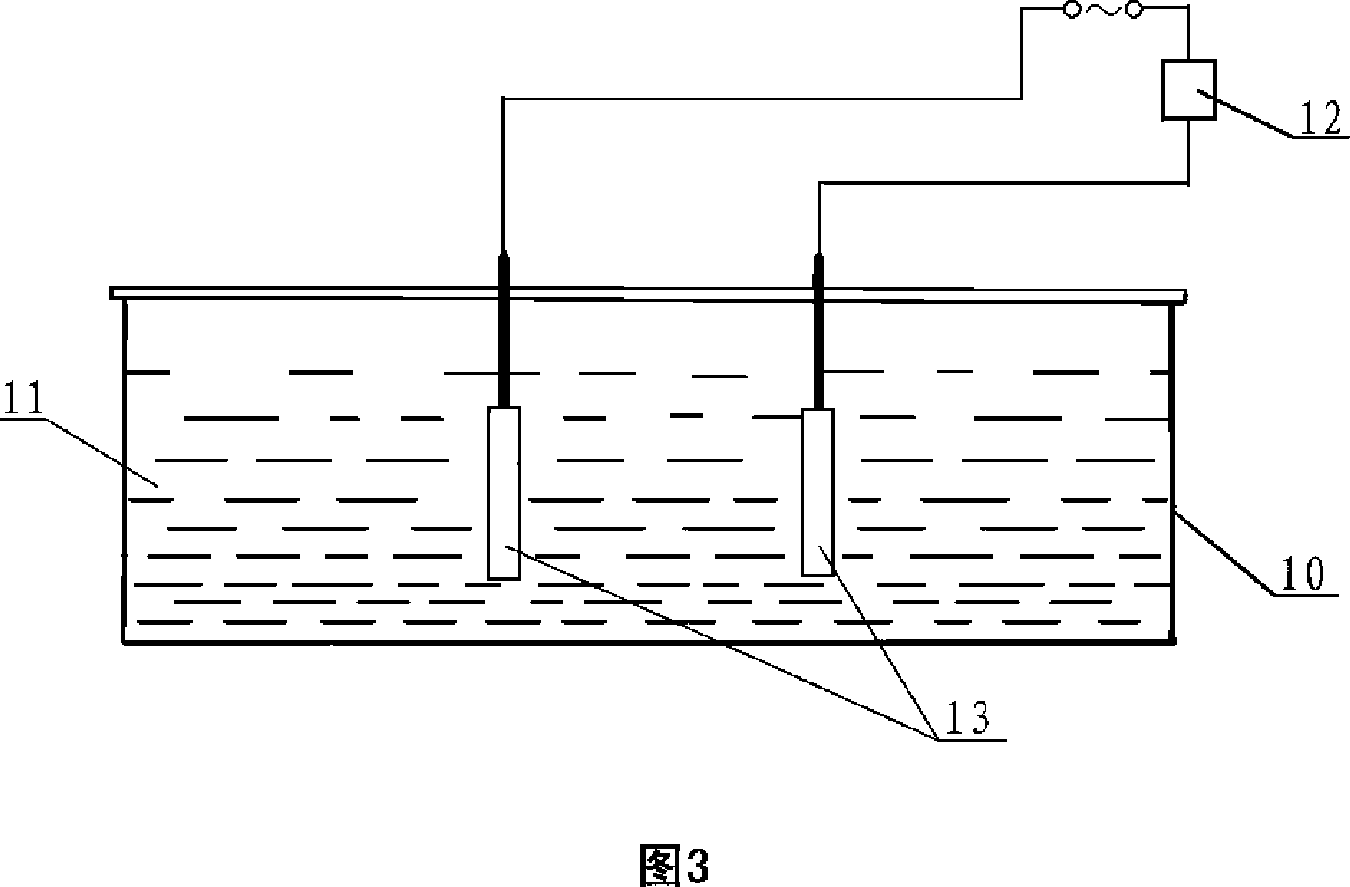

The invention relates to a method for preparing vanadic anhydride through electric field disintegrating vanadium ore diaphragm extraction, comprising following steps: disintegrating vanadium ore, grinding into vanadium- containing powdered ore of 100- 250 order; mixing vanadium- containing slurry with liquid and solid ratio being 1: 1.5 - 2 with vanadium- containing powdered ore and electrolytic solution; putting vanadium- containing slurry into alternating current field decomposer for electrolysis, the voltage of electric field is 0 -110 voltage, current is 0- 3000 A, the discharging disintegrating time is 30- 90 minutes, and stopping when vanadium- containing slurry becomes into solid; adding water for diluting and extracting vanadium with diaphragm; feeding got organic phase for teschemacherite back extraction, adding ammonium salt into vanadium- containing liquid, heating and stirring, cooling and aging, getting ammonium vanadate and water solution. The invention is characterized by short production cycle, no pollution, low energy consumption, small investment for production device, small occupying area and high vanadium recovering rate.

Owner:襄阳中经九丰矿业科技有限公司

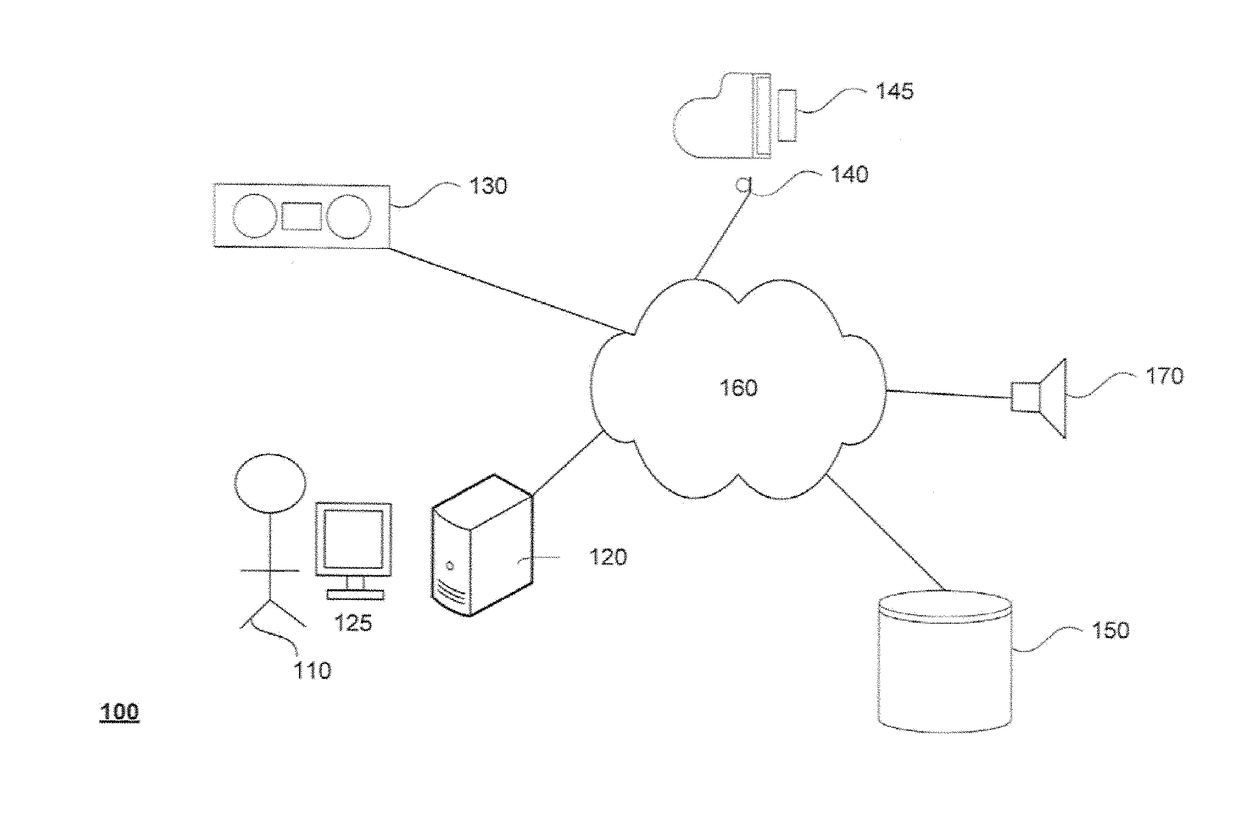

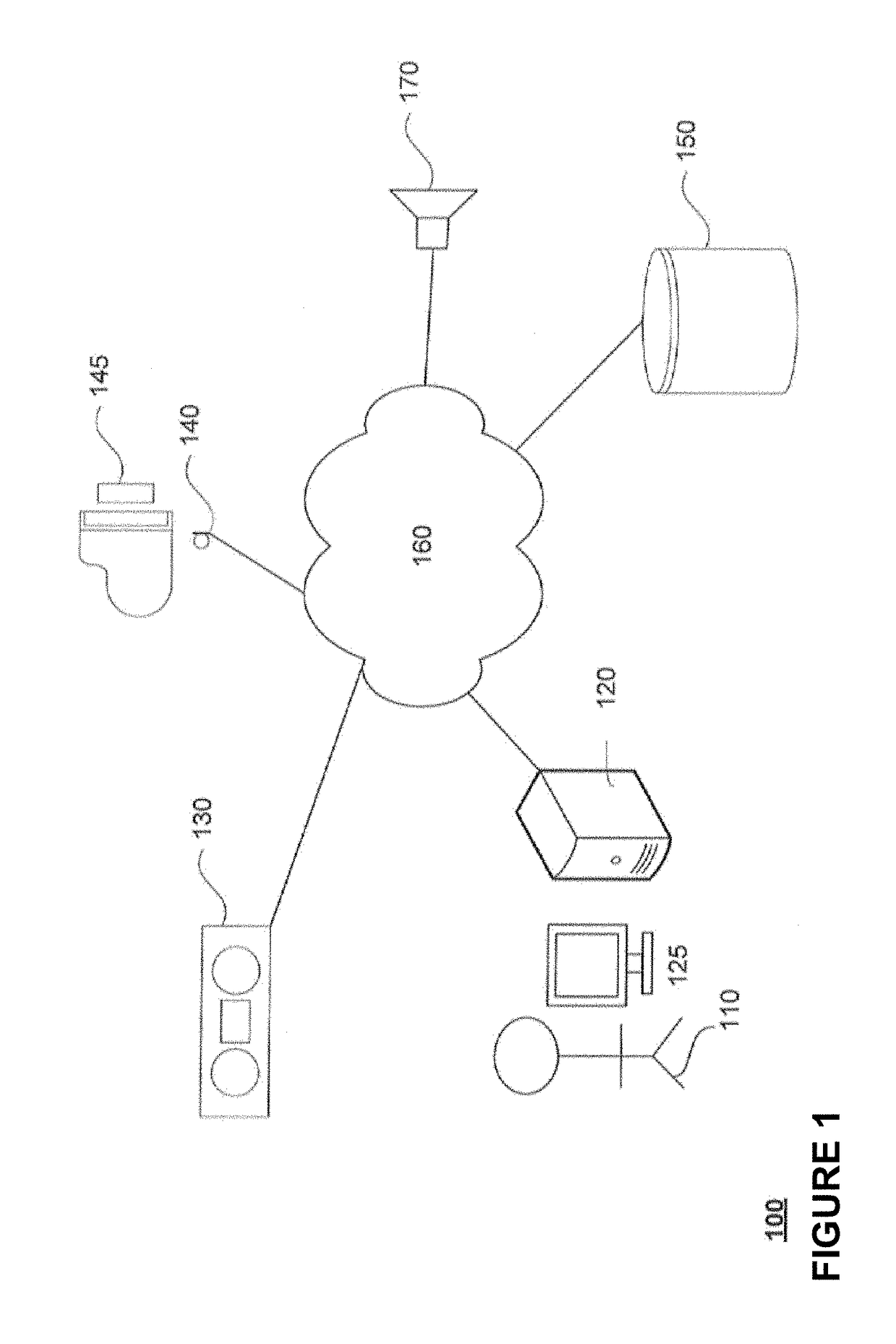

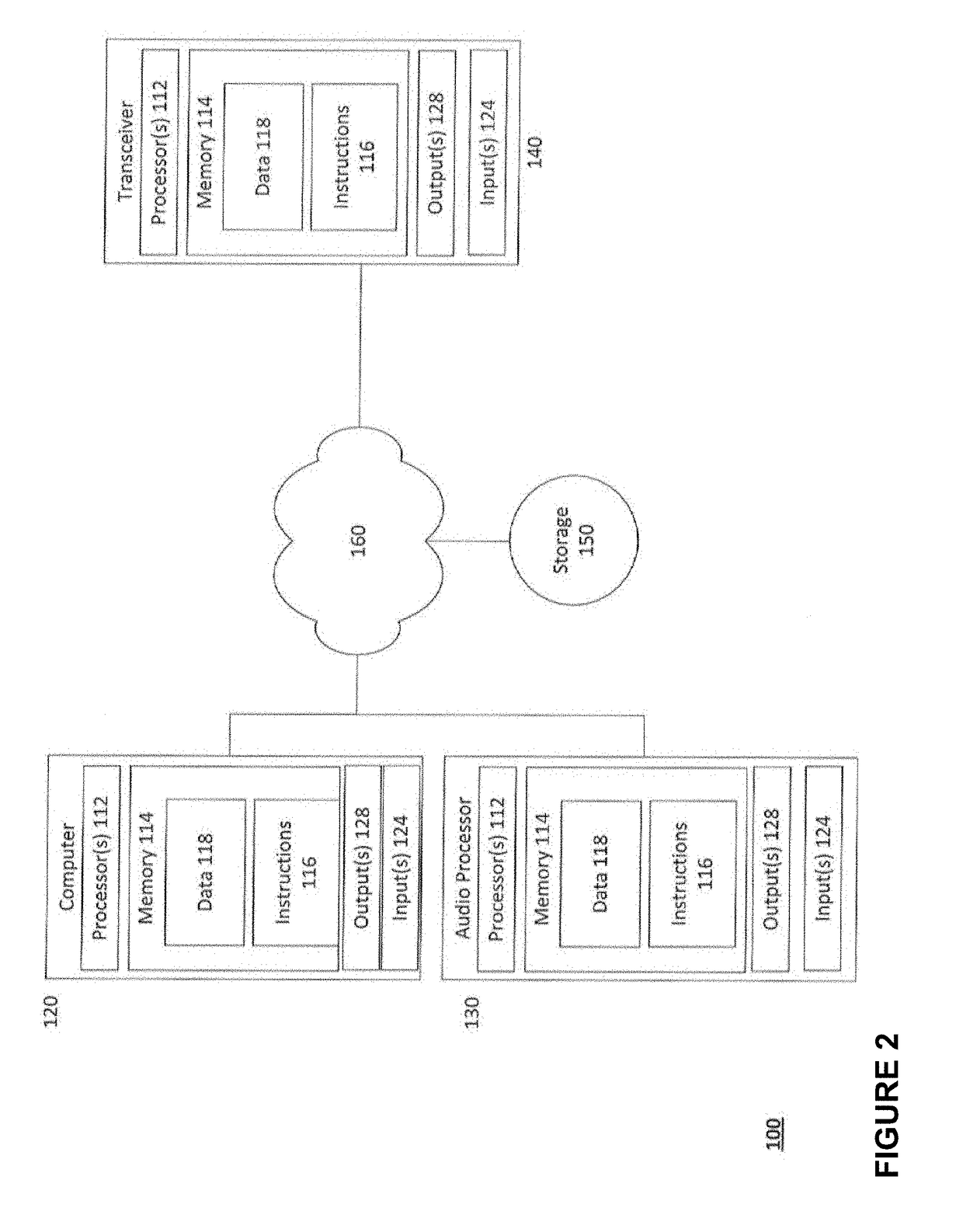

Tonal/transient structural separation for audio effects

ActiveUS20180088899A1Fast decompositionSpeech analysisMicrophones signal combinationVIT signalsSpeech recognition

The technology relates to processing one or more audio streams. The processing may include segmenting the one or more audio streams into structural components comprising a tonal stream and a transient stream. The tonal stream and the transient stream may be processed and combined to provide an output sound signal. The one or more audio streams may include a first audio stream from a first sound source and a second audio stream from a second sound source. The tonal stream may comprise sound from the first audio stream and the transient stream may comprise sound from the second audio stream. One or more sound effects may be added to the tonal stream or transient stream prior to combining.

Owner:EVENTIDE INC

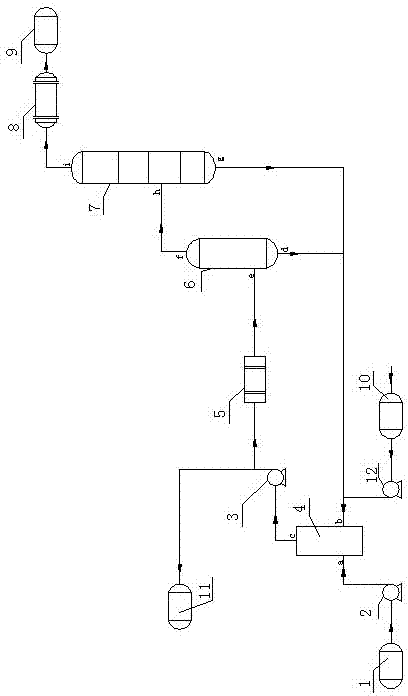

Method and system for removing vanadium impurities in titanium tetrachloride

ActiveCN103613126AFast decompositionHigh activityTitanium halidesTitanium tetrachlorideTitanium chloride

The invention discloses a method and a system for removing vanadium impurities in titanium tetrachloride. The system is composed of a crude titanium tetrachloride feeding tank, a feeding pump I, a forced circulating pump, a forced circulating pump groove, a heating heat exchanger, a flask tank, a purifying tower, a condensation heat exchanger, a titanium tetrachloride storage tank, a fatty acid feeding tank, a slurry tank and a feeding pump II. The method comprises the steps: adding crude titanium tetrachloride and fatty acid into the forced circulating pump groove; then, adding the crude titanium tetrachloride and the fatty acid into the heating heat exchanger to carry out reduction reaction to obtain titanium tetrachloride slurry, wherein the titanium tetrachloride slurry contains suspended dichlorooxovanadium solids; enabling the titanium tetrachloride slurry to enter the flask tank, and carrying out flask separation; discharging dichlorooxovanadium solid contained slurry into the forced circulating pump groove, and enabling gaseous titanium tetrachloride to enter the purifying tower; and discharging the dichlorooxovanadium solid contained slurry in the purifying tower into the forced circulating pump groove, and enabling the gaseous titanium tetrachloride to enter the condensation heat exchanger to obtain the vanadium removed titanium tetrachloride. The method and system disclosed by the invention have the advantages that the equipment scaling and pipeline blocking phenomena are reduced, the productivity is improved, the energy consumption is reduced, the vanadium removal efficiency is high, and the quality of a product is stable.

Owner:中信钛业股份有限公司

Fertilizer for rapidly improving sandy soil and preparation method thereof

A disclosed fertilizer for rapidly improving sandy soil comprises 2-4 parts of a rapid-release organic fertilizer(chicken manure, duck manure, pig manure, bean cakes and the like), 2-4 parts of a sustained-release organic fertilizer(crop straws, cow dung and the like), and 3-5 parts of a water-retaining fertilizer (turf or coconut shell powder). The fertilizer is capable of rapidly improving the fertilizer-retaining water-retaining capability of sandy soil and improving crop yield. A preparation method of the fertilizer comprises: airing 2-4 parts of the rapid-release organic fertilizer to a half-dry state, crushing 2-4 parts of the sustained-release organic fertilizer, mixing the rapid-release organic fertilizer with the sustained-release organic fertilizer, adding water to have the humidity of 60-70%, adding an EM microbial bacterial fertilizer according to a standard of 0.5-1 Kg of the microbial bacterial fertilizer for 1 cubic meter of the mixture, piling up fermentation piles and fermenting for 10-50 days, adding water into the water-retaining fertilizer to have the humidity of 80-90%, and uniformly mixing with the fermented fertilizer, so as to obtained the final fertilizer.

Owner:徐州绿维现代农业科技有限公司

Production process of draft rice wine

InactiveCN101307278AFast decompositionLow viscosityAlcoholic beverage preparationProteolytic enzymesYeast

The present invention relates to an alcohols manufacture process, in particular to a process for manufacturing unpasteurized rice wine, comprising the steps that: rice is made into a finished product by tocrushing, boiling, cooling, liquefying, acid adjusting, saccharifying, heat-retaining fermentation, squeezing, filtration and aseptic bottling, wherein proteolytic enzyme is added in the saccharifying process, and active dry yeast is added in the heat-retaining fermentation process. The alcohol brewed by the process has the characteristics of low sugar degree, low alcohol content, few precipitates, and light, clean wine color with glycol.

Owner:周卫芳

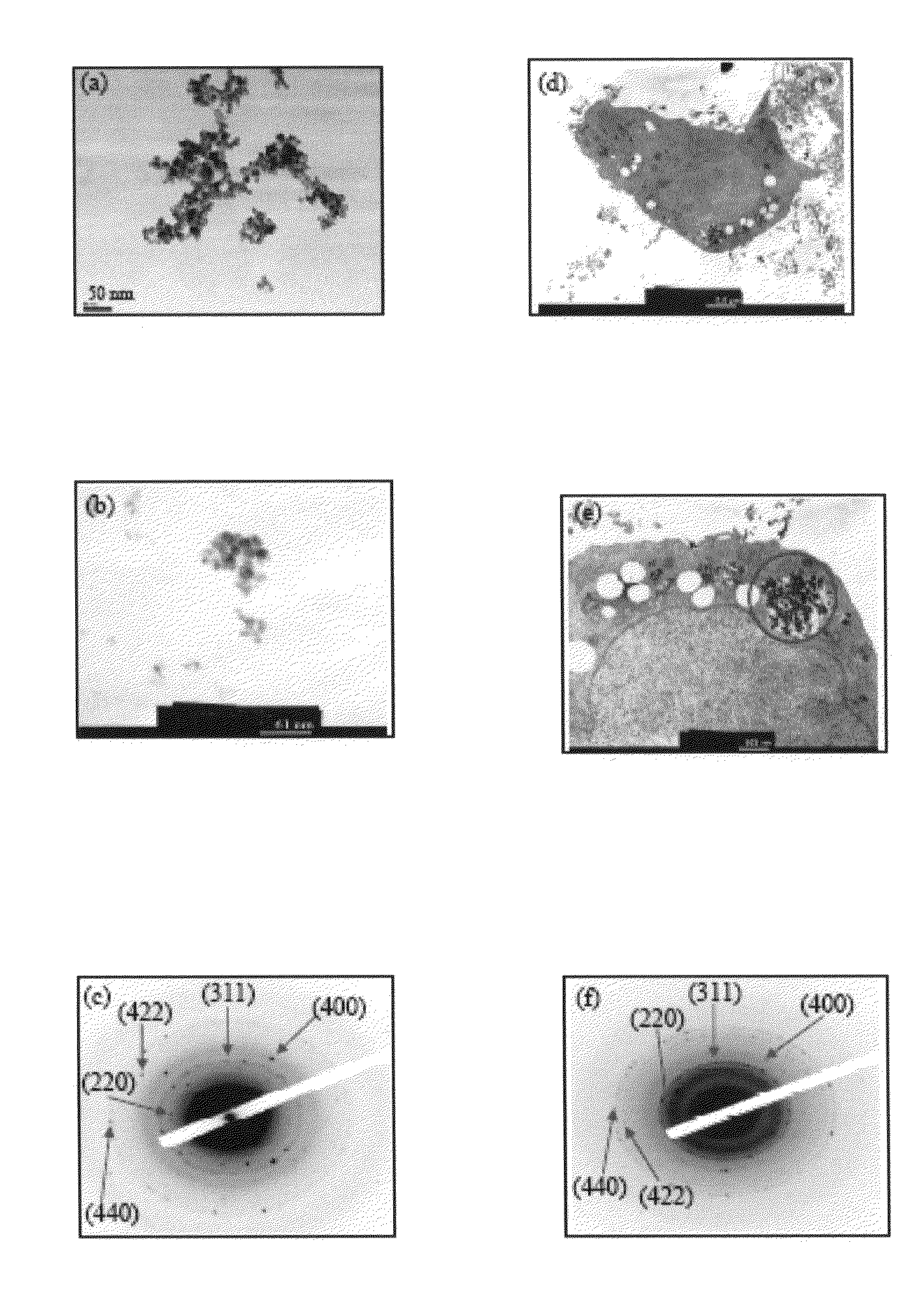

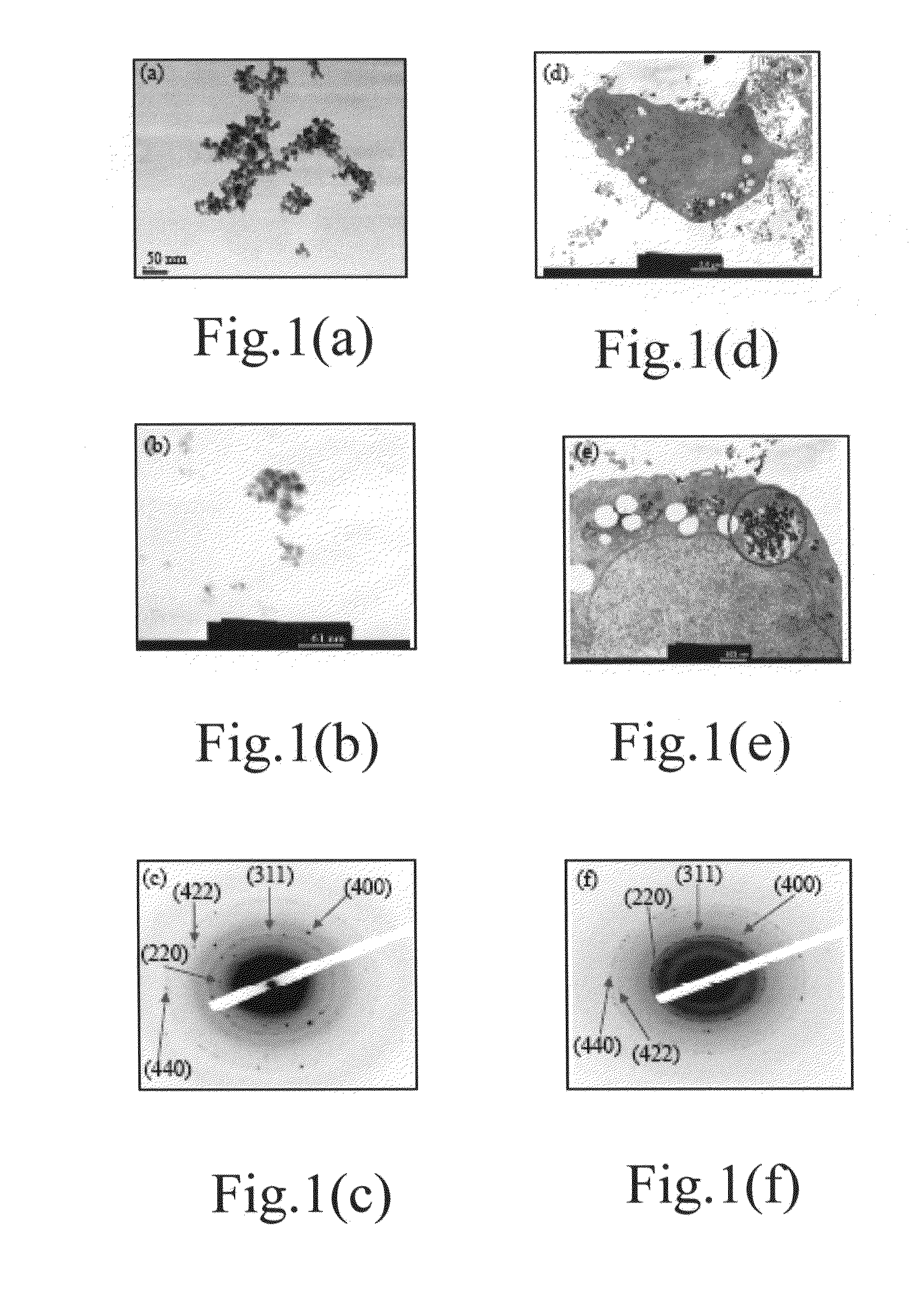

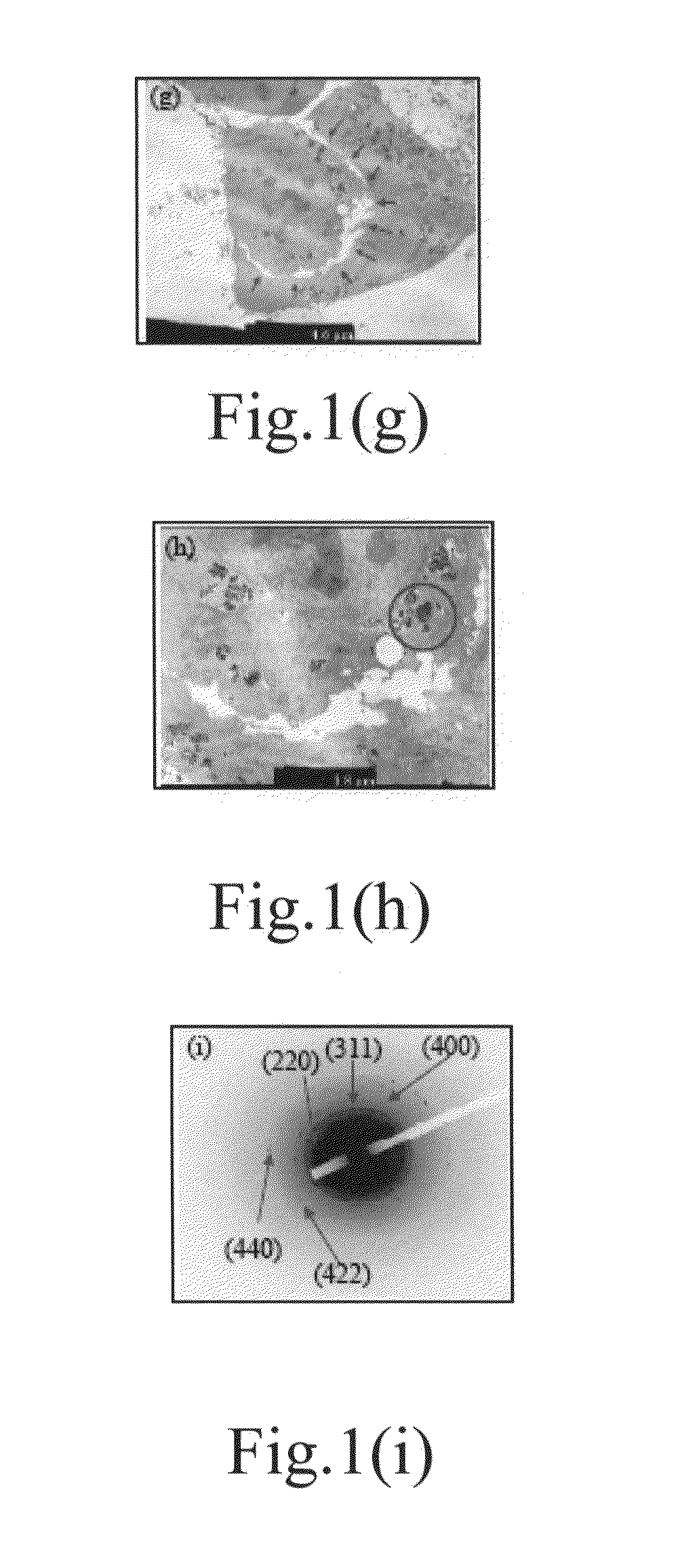

Magnetic nanocomposite for inhibiting/treating cancer and method for fabricating the same

ActiveUS20110104294A1Fast decompositionFacilitate gradual releaseBiocidePowder deliveryWater insolubleHalf-life

The present invention discloses a magnetic nanocomposite for inhibiting / treating cancer and a method for fabricating the same. The magnetic nanocomposite comprises a core formed of a plurality of magnetic nanoparticles made of ferric ferrous oxide (Fe3O4); a shell made of a carboxy-functionalized polyaniline; and an anti-tumor medicine bound to the external surface of the shell. The method of the present invention fast fabricates the magnetic nanocomposite in a simple way. The medicine of the present invention has a longer half life and a better thermal stability. The present invention disperses the water-insoluble medicine in water uniformly to decrease the biological rejection. Moreover, the magnetic nanocomposite of the present invention is guided to the nidus by an external magnetic field to increase the local concentration of the medicine and provide an effective chemotherapy. Therefore, the present invention has competitive advantage over the conventional BCNU.

Owner:CHANG GUNG UNIVERSITY

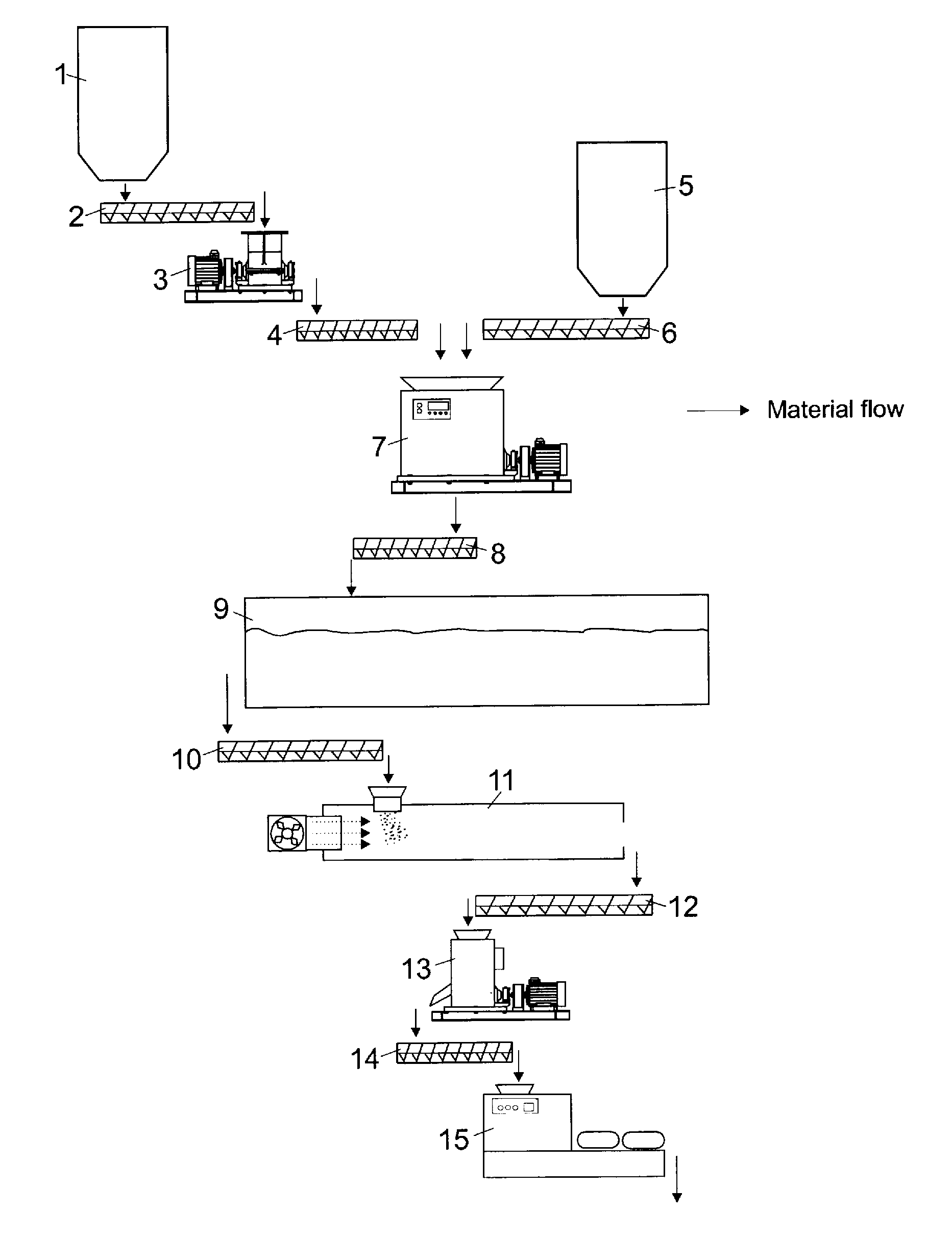

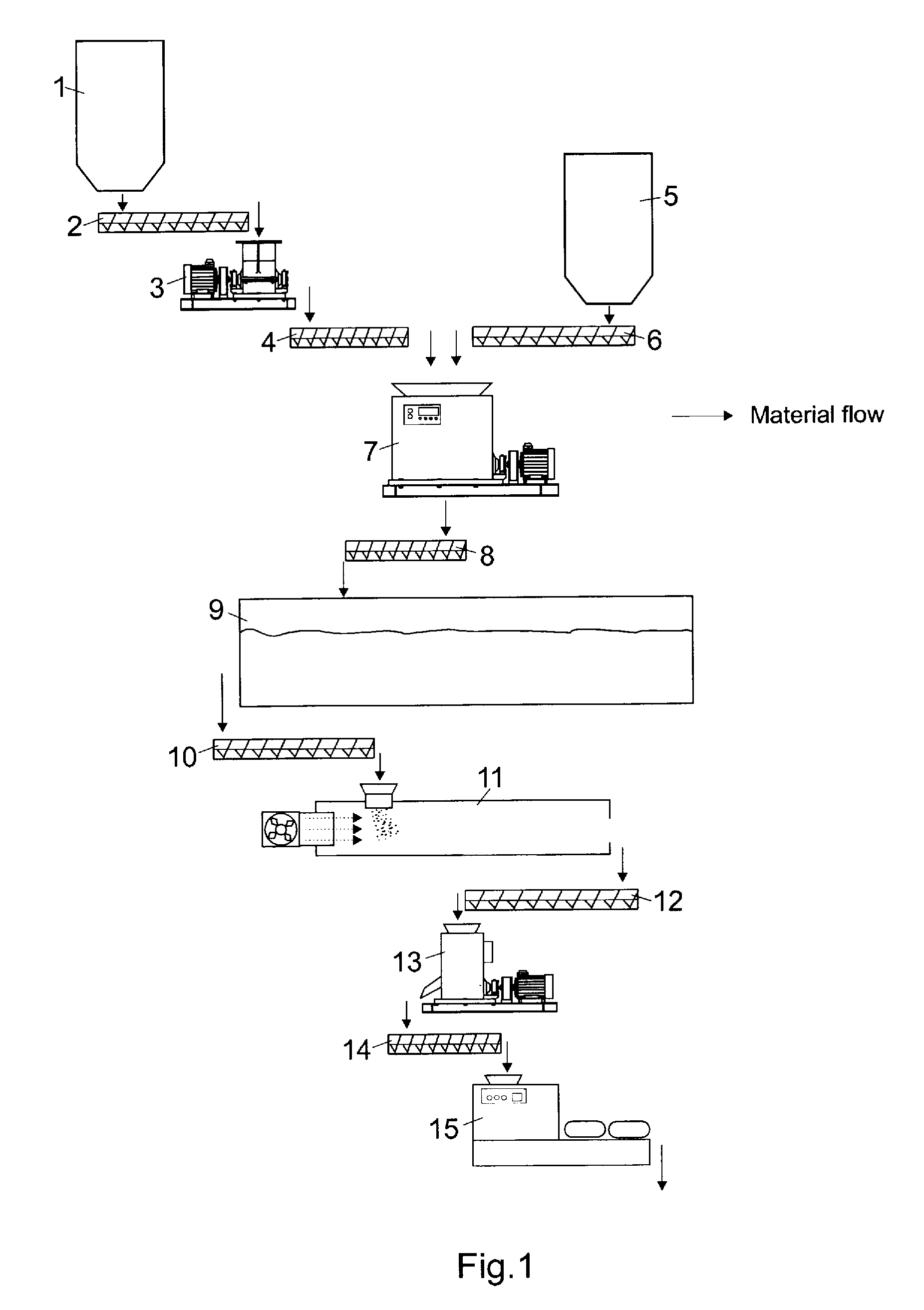

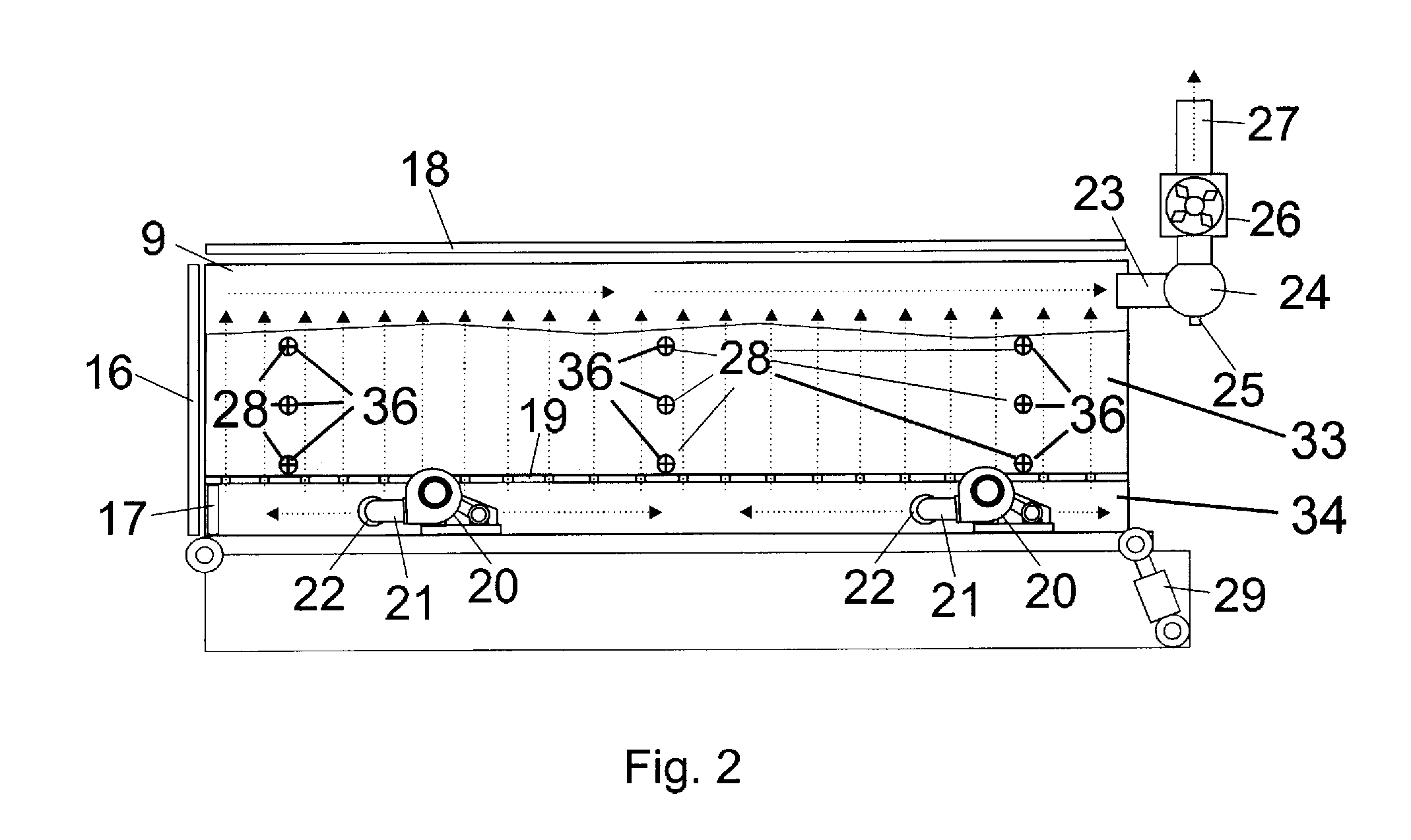

Method of Aerobic Treatment of Poultry Manure and Apparatus for Producing Organic Fertilizer

ActiveUS20140196512A1High activityFast decompositionBioreactor/fermenter combinationsBio-organic fraction processingFecesEngineering

A bio-chamber and a method of making organic fertilizer from poultry manure. The bio-chamber has a chamber body that defines a receiving chamber and an aeration chamber. The aeration chamber underlies the receiving chamber and is divided therefrom by a partition. The partition has a plurality of holes formed therein. An oxygen probe and a temperature probe are positioned inside the receiving chamber. An air blower is connected to the aeration chamber and is operable to blow air therein. The method comprises: mixing the poultry manure with a carbon carrier; loading the mixture into the receiving chamber; monitoring the temperature and the oxygen concentration of the mixture; aerating the mixture; and regulating the temperature and the oxygen concentration by adjusting the operation of the air blower. The temperature and oxygen concentration are regulated to provide conditions that permit aerobic bacteria to propagate and biodegrade the mixture.

Owner:1867239 ONTARIO

Preparation method of monolithic catalyst for formaldehyde purification

InactiveCN106955681AAvoid uneven distributionImprove utilization efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsDecompositionCatalytic oxidation

The invention discloses a preparation method of a monolithic catalyst for formaldehyde purification. The preparation method comprises the following steps: (1) preparing a monolithic honeycomb substrate having an adsorption and immobilization activity coating; (2) keeping the monolithic honeycomb substrate having the adsorption and immobilization activity coating in contact with a solution containing a noble metal salt and a transition metal salt, so that active components in the solution are adsorbed to the surface of the honeycomb composite material; and (3) reducing with a reducer to obtain the monolithic catalyst for formaldehyde purification. Monolithic honeycomb ceramic / honeycomb stainless steel is used as the substrate, and the active components are loaded by an adsorption method, so that the active components are distributed uniformly, the utilization rate of the noble metal is high, and the preparation process is simple, easy to operate and good in repeatability. Formaldehyde can be completely catalytically oxidized into innocuous and nonpoisonous carbon dioxide and water at room temperature under the condition of low loading quantity of the noble metal, the decomposition speed is high and the service life is long.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

Manufacture method of disinfection cupboard with function of rapidly sterilizing ozone

The invention relates to a manufacture method of a disinfection cupboard with the function of rapidly sterilizing ozone, belonging to the research field of applying a catalytic decomposition technology principle to environmental protection and pollution prevention. The disinfection cupboard with the function of rapidly sterilizing ozone comprises a disinfection cupboard main body and components mounted in the cupboard, i.e. a delay timer, a miniature fan, an ozone catalytic decomposer, an ozone-decomposing accelerator, and the like, wherein the delay timer confirms that an ozone disinfection generator immediately starts a blower after disinfecting every time; the ozone catalytic decomposer and the ozone-decomposing accelerator work in set time to eliminate residual ozone in the cupboard and then stop working; the miniature fan drives an airflow in the disinfection cupboard to circularly flow by the ozone catalytic decomposer to be processed; the ozone catalytic decomposer can adopt an operculum-shaped or honeycomb-shaped structure which is formed by metallic multi-layered corrugated boards and has greater known specific surface area and smaller air resistance; a catalyst is coated on the surface of the ozone catalytic decomposer; and the decomposing accelerator is formed by a heater.

Owner:BEIJING YUJIAMING TRI STATE ION RES INST

Method for treating tailing slurries with Caro's acid

InactiveUS6090297AMinimize decomposition and hydrolysisEfficient dilutionPeroxyhydrates/peroxyacidsSulfur compoundsCyanideSlurry

A process for treating precious metal tailing slurries with Caro's acid, in which the Caro's acid is accompanied by reduced amounts of Caro's acid mist, is disclosed. The hot Caro's acid-containing mixture, formed by reaction of concentrated sulfuric acid and hydrogen peroxide, is quenched with water to reduce or eliminate the Caro's acid mist. The resulting cooled and diluted mixture is introduced into a precious metal tailings slurry to reduce the amount of cyanide values in the slurry.

Owner:FMC CORP

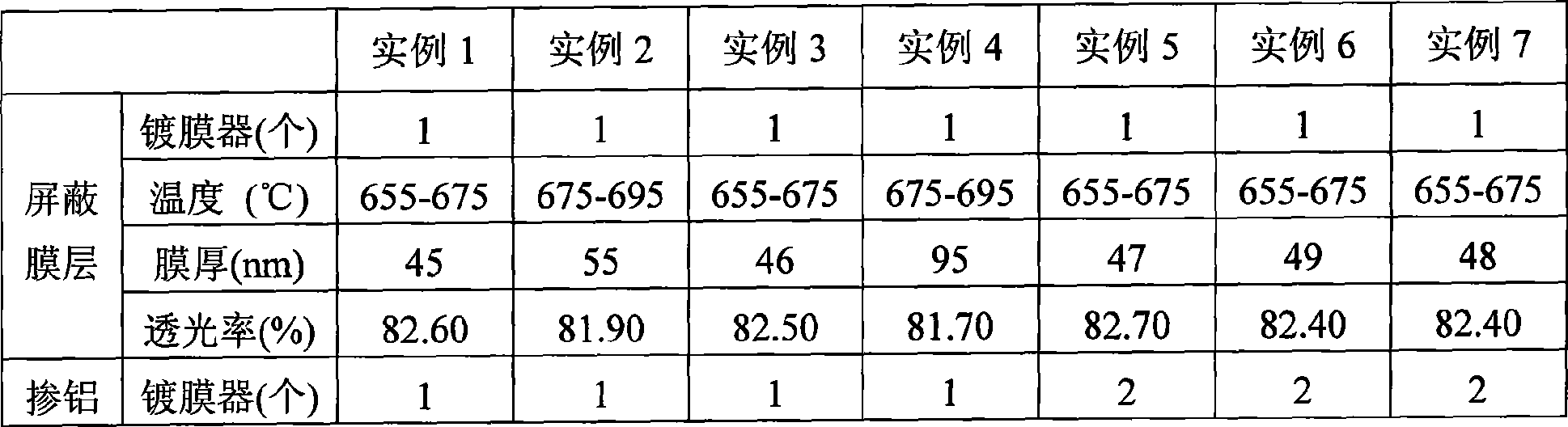

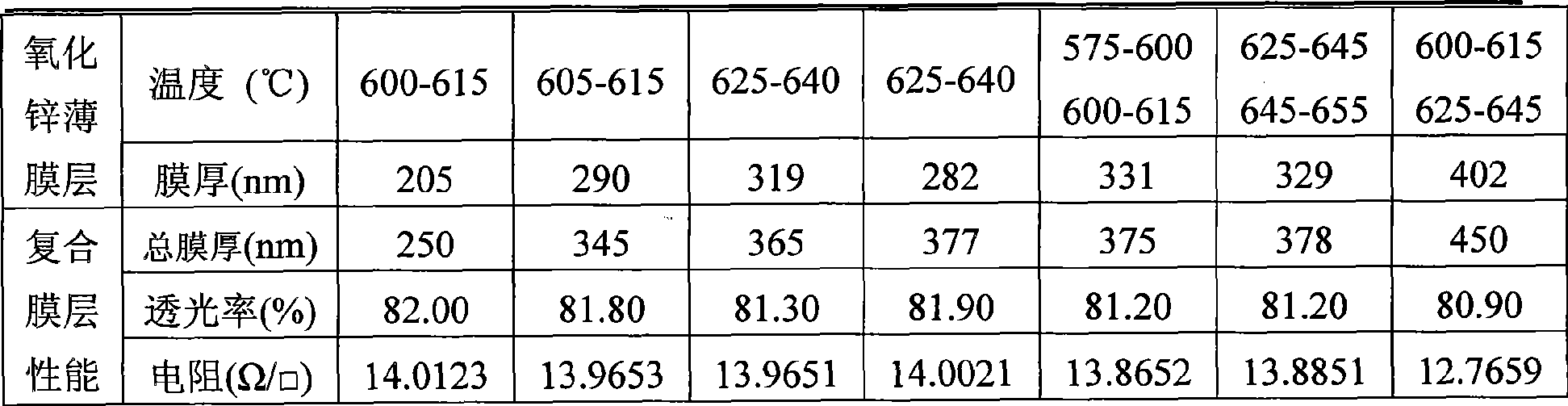

Method for online production of TCO film glass by float process

The invention discloses a float online method for producing TCO film glass. The method comprises that: a chemical vapor deposition method is adopted in a tin groove of a float glass production line; a proplastid gas mixture containing silane, ethene, phosphine, an oxygenous source and a phosphorus source dopant uses inert gas as a carrier; a shielding film layer with thickness of between 45 and 95 nm and refractive index of between 1.65 and 1.85 is formed on the surface of a glass substrate at a temperature of between 635 and 695 DEG C; and within the temperature range of between 550 and 630 DEG C, the proplastid gas mixture containing a zinc source, an aluminum source, a stabilizing agent and a catalyst prefabricated to be gasified uses nitrogen gas or air as the carrier and is introduced to the movable glass surface deposited with the shielding film layer to form a TCO film with thickness of between 250 and 450 nm and low resistivity. The TCO glass has even film layer, high surface resistivity, high conductivity, good wearing resistance, strong alkali resistance and high conductivity and visible light transmittance.

Owner:WUJIANG CSG GLASS CO LTD

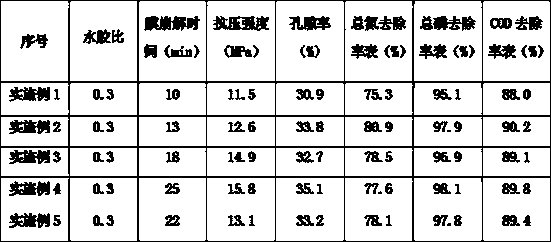

Ecological water purification concrete and preparation method thereof

The invention relates to the technical field of building materials, in particular to ecological water purification concrete and a preparation method thereof. The ecological water purification concretecomprises 15-25 parts of cement, 0.45-0.65 part of reinforcing material, 0-0.3 part of emulsion powder, 1-4 parts of water purifying material, 5-10 parts of water purifying particles, 65-75 parts ofaggregate and 0.05-0.15 part of water reducing agent, wherein the water purifying particles contain particles having a purifying function and a starch film located on the outer surface of the particles having the purifying function, the starch film is formed through drying after a starch film solution with the mass fraction of 5%-15% is sprayed on the outer surface of the particles having the purifying function, and the starch film solution is obtained by dissolving modified starch in a solvent. The prepared ecological water purification concrete can effectively solve the problem that the ecological water purification concrete in the prior art easily causes blockage and is short in service life, the porosity of the concrete is improved, and the concrete has long good water permeability.

Owner:JIAHUA SPECIAL CEMENT

Homo-polypropylene/carbon fiber/montmorillonite composite material and preparation method thereof

The invention relates to a homo-polypropylene / carbon fiber / montmorillonite composite material and a preparation method of the homo-polypropylene / carbon fiber / montmorillonite composite material. The homo-polypropylene / carbon fiber / montmorillonite composite material is prepared from the following raw materials in parts by weight: 85 to 95 parts of homo-polypropylene, 5 to 10 parts of carbon fibers, 2 to 3 parts of organic montmorillonite, and 3 to 5 parts of foaming masterbatches, the foaming masterbatches are prepared from the following raw materials in parts by weight: 60 to 70 parts of polyethylene, 20 to 30 parts of foaming agents, 1 to 3 parts of foam stabilizers, 3 to 5 parts of nucleating agents, 0.5 to 1.5 parts of zinc oxide, 0.5 to 1 part of a titanate coupling agent NDZ-201, 3 to 5 parts of PE wax and 0.5 to 1 part of zinc stearate. According to the homo-polypropylene / carbon fiber / montmorillonite composite material disclosed by the invention, the mechanical properties are excellent, the tensile strength reaches 36.9 MPa, the impact strength reaches 55.1 kJ / m<2>, and the flexural modulus reaches 1590 MPa. The foaming material has best foaming and biggest cell density, the cell density reaches 2.3*10<7> / cm3, and the porosity of the foaming material is 17.7%.

Owner:GUANGZHOU JUZHU GENERAL TECH INST CO LTD

Air sand and preparation method thereof

InactiveCN103011895AStable structureAchieve the desired purposeCeramicwarePolyvinyl alcoholPolyethylene glycol

The invention provides air sand and a preparation method thereof. Air clay is prepared from the components of: silicon dioxide, calcined shell powder, polyethylene glycol, polyvinyl alcohol, foam powder k12, glycerol and propylene glycol. The preparation method comprises the following steps of: (1) adding the silicon dioxide which is used as a main body, the calcined shell powder which is used as a molecular structure connecting carrier, and the polyethylene glycol, the polyvinyl alcohol and the foam powder k12 which are used as reaction elements into a heatable reaction kettle; (2) stirring when the reaction kettle rotates at a constant speed of 25rpm; (3) raising the temperature to ensure that the reaction elements fully react with the silicon dioxide and the calcined shell powder to achieve an effect of shaping micro-particles; (4) after the temperature is up to 120 DEG C, stopping heating and continuously mixing; (5) adding a propylene glycol solution with the concentration being about 70 percent, stirring, mixing, and adjusting the rotating speed of the reaction kettle to be 20 rpm; (6) lowering the temperature, adding the glycerol, and adjusting the rotating speed of the reaction kettle to be 40rpm; (7) rotating for 10 minutes to obtain the air sand. The method has the characteristics of reasonable technological process and high product yield.

Owner:LISHUI ZHUOYUE STATIONERY MFR

Process for producing D-serine

InactiveUS7186532B2Increase productionIncrease productivitySugar derivativesBacteriaEscherichia coliMicroorganism

The present invention relates to: a process for producing D-serine wherein a microbial cell which is modified to have a higher L-serine deaminase activity than Escherichia coli DH5α strain, a culture of said cell, or a processed product thereof is brought into contact with DL-serine in a DL-serine-containing medium to decompose L-serine, and the remaining D-serine is recovered from the medium; and a microorganism used for this production process. D-serine is a useful compound as a synthetic intermediate for useful medicaments such as D-cycloserine.

Owner:KYOWA HAKKO BIO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com