Room-temperature catalytic oxidizing agent of formaldehyde employing composite noble metal alloy, and preparation method thereof

A precious metal and oxidant technology, used in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of slow decomposition of formaldehyde, limited market application, and high consumption of precious metals , to achieve the effect of fast decomposition of formaldehyde, great market application potential and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] Example 1: Content 0.1%Pt-Ce / TiO 2 preparation.

[0030] Dissolve dinitrosodiamine platinum and cerium nitrate in deionized water at the same time, stir at 60°C for 2 hours at high speed, slowly add nano-titanium dioxide slurry, stir at high speed for 1 hour, slowly add KOH solution dropwise, stir at high speed for 1 hour, and dry by rotary evaporation , dried at 120°C, baked at 400-600°C for 2 hours, passed through H 2 After 2 hours of reduction, the composite precious metal alloy formaldehyde catalytic oxidizer is obtained.

[0031] Similar methods can be used to prepare 0.2%Pt-Ce / TiO 2 , 0.3%Pt-Ce / TiO 2 , 0.4%Pt-Ce / TiO 2 , 0.5%Pt-Ce / TiO 2 catalyst.

example 2

[0032] Example 2: Preparation of content 0.5%Pd-Zr / TiO2.

[0033] Select palladium tetrachloride and zirconium nitrate to be dissolved in deionized water at the same time, stir at 60°C for 2 hours at high speed, slowly add nano-titanium dioxide slurry, stir at high speed for 1 hour, slowly add KOH solution dropwise, stir at high speed for 1 hour, spin dry, 120 Dry at ℃, bake at 400-600℃ for 2 hours, pass H 2 After 2 hours of reduction, the composite precious metal alloy formaldehyde catalytic oxidizer is obtained.

example 3

[0034] Example 3, content 1% AU-La / TiO 2 preparation of

[0035] Dissolve gold tetrachloride and lanthanum nitrate into deionized water at the same time, stir at 60°C for 2 hours at high speed, slowly add nano-titanium dioxide slurry, stir at high speed for 1 hour, slowly add KOH solution dropwise, stir at high speed for 1 hour, spin dry, 120 Dry at ℃, bake at 400-600℃ for 2 hours, pass H 2 After 2 hours of reduction, the composite precious metal alloy formaldehyde catalytic oxidizer is obtained.

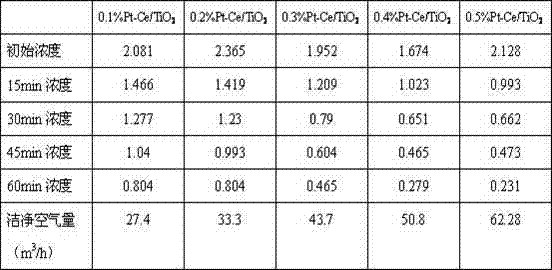

[0036] In the test experiment of the present invention, adopt a rated wind volume 150m 3 / h purification device, the size of the formaldehyde catalytic oxidation module assembly is 300×300×10mm, and a total of 60g of catalyst powder is coated.

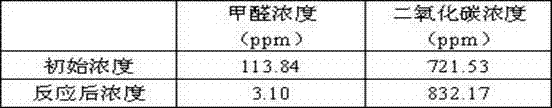

[0037] PTR-MS proton transfer mass spectrometer and INNOVA1312 gas multi-point sampling detector were used to test the product. At 15°C, the data are shown in Table 1, showing that formaldehyde is converted into carbon dioxide and water, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com