Ecological water purification concrete and preparation method thereof

An ecological concrete and water purification technology, applied in the field of building materials, can solve problems such as easy clogging and short service life, and achieve the effects of increasing porosity, increasing water permeability, and good water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

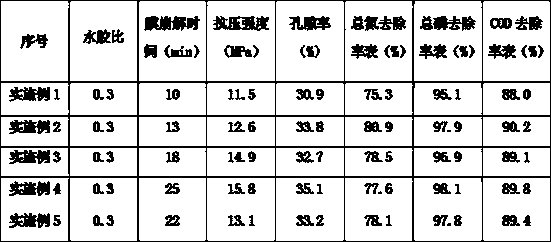

Examples

Embodiment 1

[0039] As a preferred embodiment of the present invention, the present invention includes a water purification granule for concrete, comprising granules with purification function and a starch film on the outer surface of the granule with purification function, and the starch film has a mass fraction of 5 % starch film solution is sprayed on the outer surface of the granule with purification function and then dried, and the starch film solution is obtained by dissolving modified starch in a solvent.

[0040] Among them, the particles with purification function are preferably molecular sieves. The modified starch is obtained through esterification and modification of corn starch, and the solvent is 1,4-dioxane.

[0041] The preparation method of the water purification particles is as follows:

[0042] a. Clean the molecular sieve and dry it at 105°C, then cool it to room temperature;

[0043] b. Dissolving the modified starch in 1,4-dioxane to obtain a starch film solution wi...

Embodiment 2

[0054] As another preferred embodiment of the present invention, the present invention includes a water purification granule for concrete, comprising particles with purification function and a starch film on the outer surface of the particle with purification function, and the starch film has a mass fraction of A 10% starch film solution is sprayed on the outer surface of the granule with purification function and then dried, and the starch film solution is obtained by dissolving modified starch in a solvent.

[0055] Among them, the particles with purification function are preferably fruit shell activated carbon. The modified starch is obtained through esterification and modification of potato starch, and the solvent is dichloromethane.

[0056] The preparation method of the water purification particles is as follows:

[0057] a. Clean the shell activated carbon and dry it at 105°C, then cool it to room temperature;

[0058] b. Dissolving modified starch in methylene chlori...

Embodiment 3

[0069] As another preferred embodiment of the present invention, the present invention includes a water purification granule for concrete, comprising granules with purification function and a starch film on the outer surface of the granule with purification function, and the starch film has a mass fraction of A 15% starch film solution is sprayed on the outer surface of the granule with purification function and then dried, and the starch film solution is obtained by dissolving modified starch in a solvent.

[0070] Among them, the particles with purification function are preferably walnut shells. The modified starch is obtained through esterification and modification of tapioca starch, and the solvent is chloroform.

[0071] The preparation method of the water purification particles is as follows:

[0072] a. Clean the walnut shells and dry them at 105°C, then cool to room temperature;

[0073] b. Dissolving modified starch in chloroform to obtain a starch film solution wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com