Soil-based crack-proof water-retaining composite material and preparing method thereof

A composite material and soil-based technology, applied in the direction of organic fertilizers, fertilizer mixtures, applications, etc., can solve the problems of difficult laying and preservation of plastic film, non-degradable plastic film, and deterioration of sandy land environment, so as to achieve abundant reserves, reduce water loss, increase The effect of soil infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

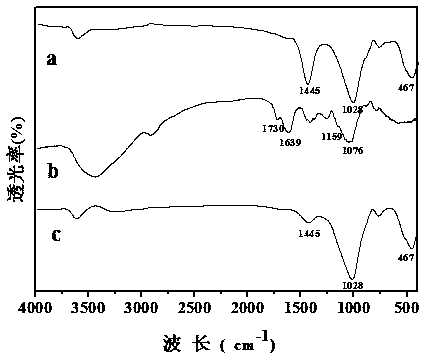

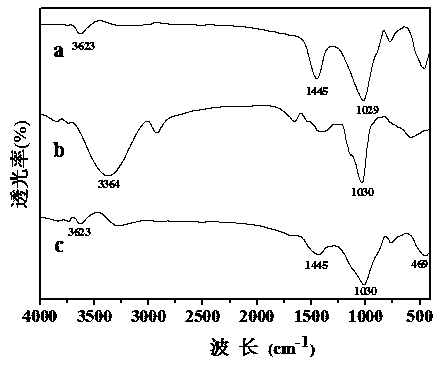

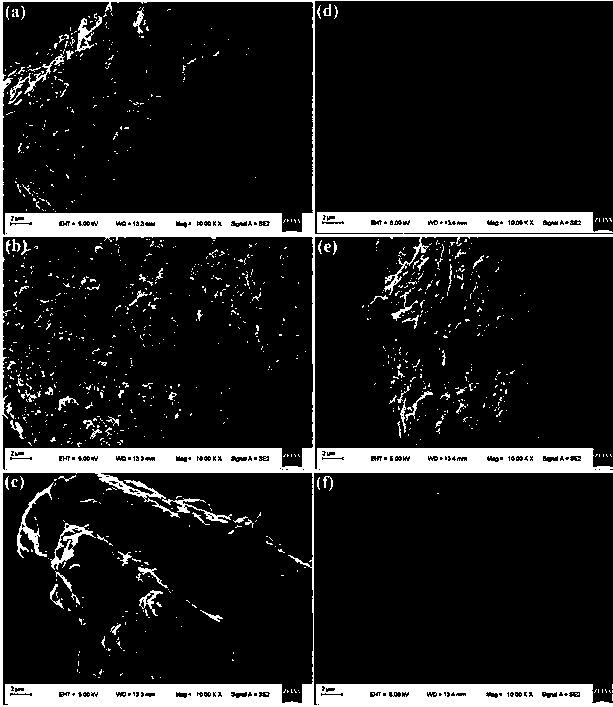

Image

Examples

Embodiment 2

[0043] Take a certain amount of loess, add 3.0%~7.0% of the mass of biomass straw powder, 4.0%~8.0% of biological glue (xanthan gum, guar gum, konjac gum, Arabic gum), mix well and add Tap water with 60%~80% red clay quality, stirred for 30~60min at a stirring speed of 300~600r / min. Granulate and dry to obtain the loess-based anti-cracking and water-retaining material.

Embodiment 3

[0045] Take a certain amount of laterite, add 3.0%~7.0% of the mass of biomass straw powder, 12%~15% of starch (soluble starch, oxidized starch), mix well and add tap water with 60%~80% of the mass of laterite, Stir for 30~60min at a stirring speed of 300~600r / min. After granulating and drying, the clay-based anti-cracking and water-retaining material can be obtained.

Embodiment 4

[0047] Take a certain amount of loess, add 3.0%~7.0% of the mass of biomass straw powder, 12%~15% of starch (soluble starch, oxidized starch), mix well and add tap water with 60%~80% of the mass of laterite, Stir for 30~60min at a stirring speed of 300~600r / min. After granulating and drying, the loess-based anti-cracking and water-retaining material can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com