Road safety maintenance construction equipment

A construction equipment and safety technology, applied in the field of road safety maintenance construction equipment, can solve the problems of inconvenient use, increase the cost of road maintenance and use, and achieve the effects of avoiding chapping, facilitating maintenance and improving comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

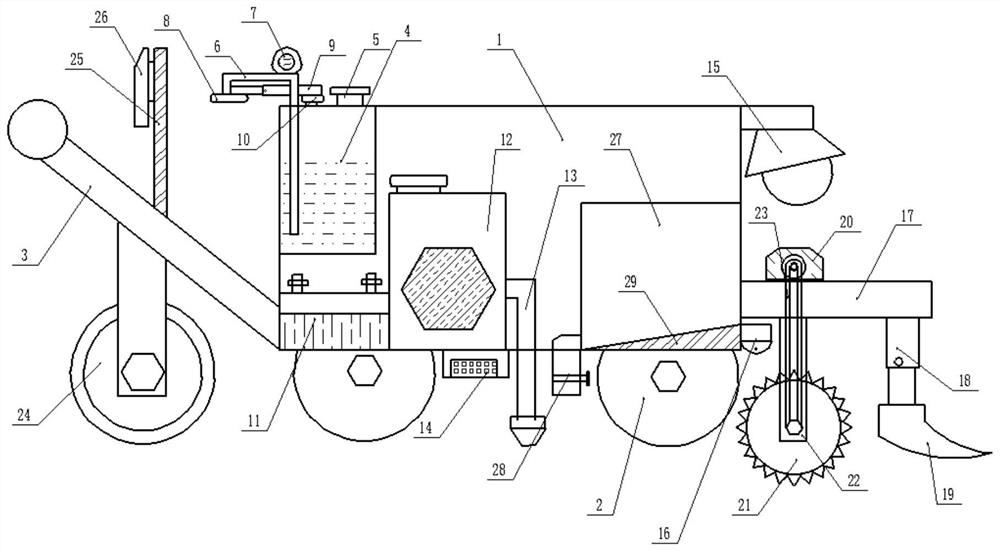

[0021] Example 1: Please refer to Figure 1-3 , a road safety maintenance construction equipment, including a mobile vehicle 1, the mobile vehicle 1 is provided with a guide wheel 2, the guide wheel 2 is convenient for the device to move, the side wall of the mobile vehicle 1 is provided with a push handle 3, and the push handle 3 is convenient for the control device. One end of the road is beneficial to the maintenance of the road, and it is convenient for the device to maintain each position of the road, which is convenient to use.

[0022] The mobile vehicle 1 is provided with a water tank 4, and the water tank 4 is provided with a water inlet pipe 5, and the water inlet pipe 5 is convenient for replenishing the water in the water tank 4 in time for its subsequent use.

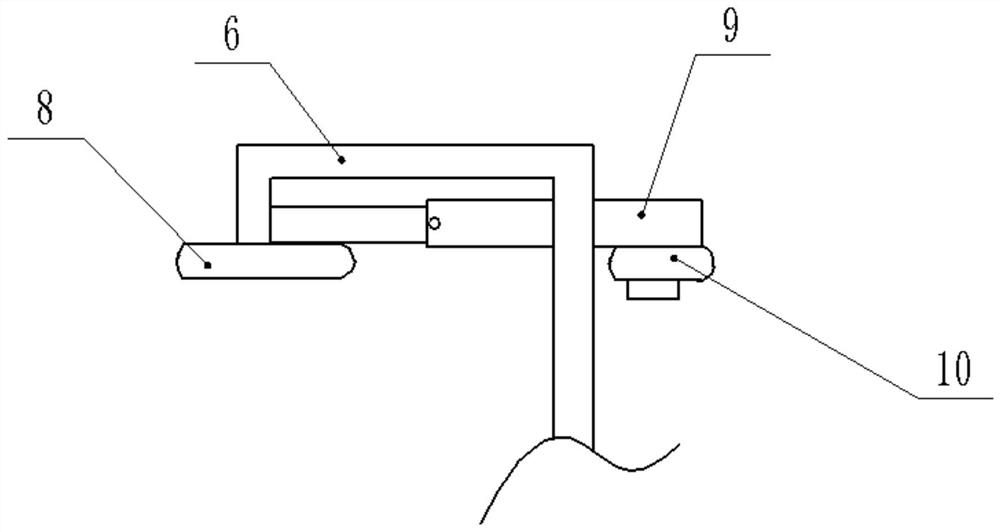

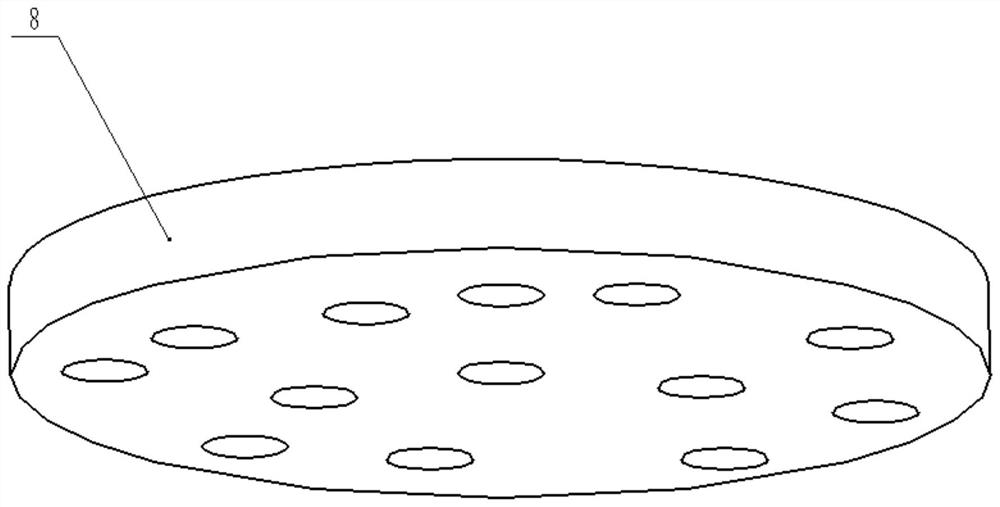

[0023] The water tank 4 is provided with a water spray pipe 6, and the outlet end of the water spray pipe 6 is provided with a spray plate 8, and a water pump 7 is installed on the water spray pipe 6. One ...

Embodiment 2

[0029] Embodiment 2: On the basis of Embodiment 1, a storage battery 11 is installed on the mobile vehicle 1, and the storage battery 11 supplies power for each electronic component to ensure the normal operation of each component and is convenient to use.

[0030] Mobile car 1 is provided with illuminating lamp 15, and illuminating lamp 15 provides illumination when light is dark, and the normal work of convenience device is convenient to use.

[0031] Push handle 3 is provided with protective plate 25, and protective plate 25 avoids getting wet to the staff when spraying water, guarantees the safety when spraying water, convenient to use.

[0032] Mobile vehicle 1 is provided with camera 16, and display 26 is installed on protective plate 25, and camera 16 is electrically connected with display 26 by wire, and the situation of looking at the road clearly by camera 16 is convenient to feed back in display 26 in time, and is beneficial to its in time. The maintenance of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com