Patents

Literature

68results about How to "Great market application potential" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

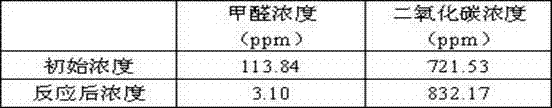

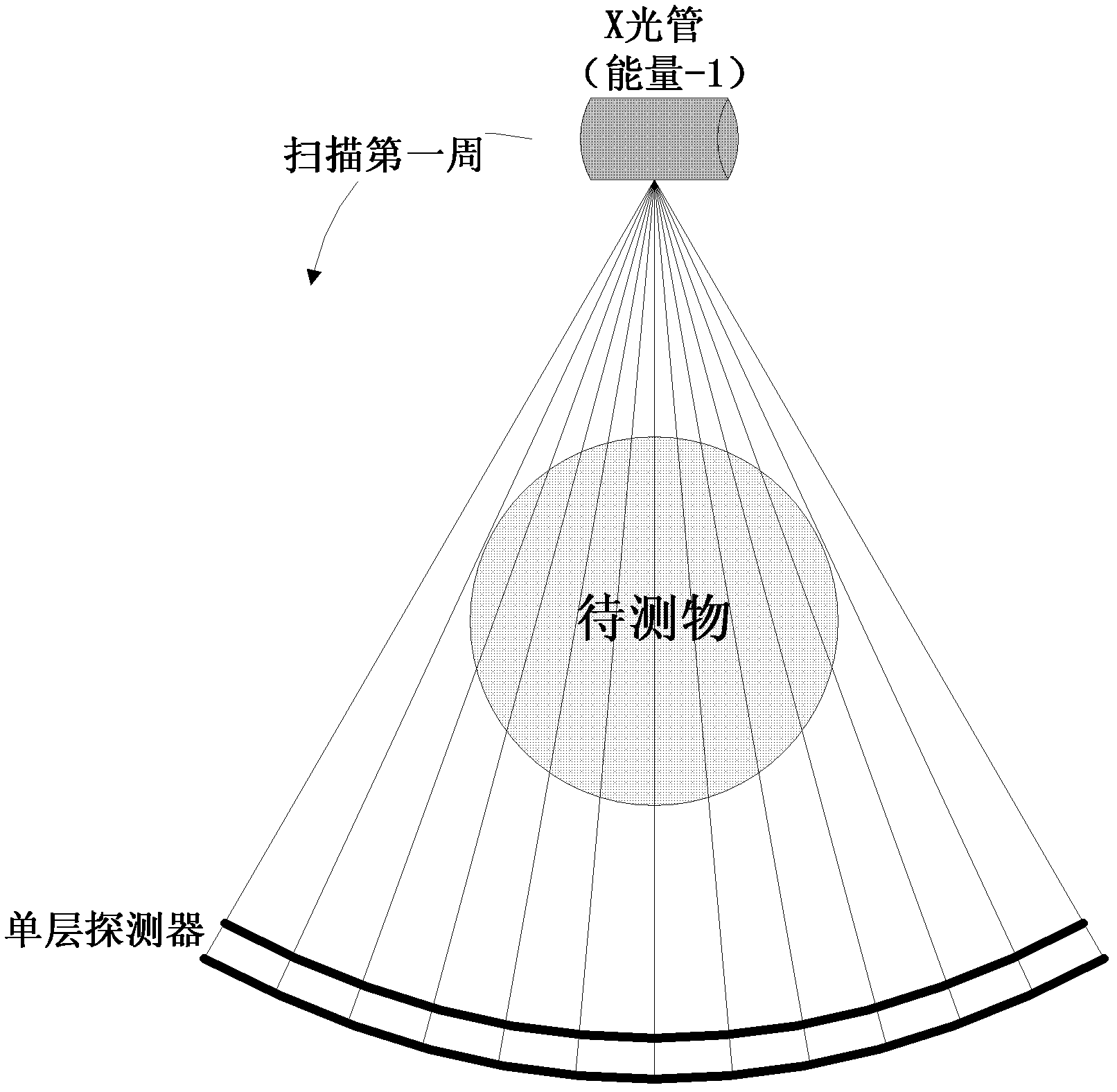

Metal alloy catalyst for formaldehyde purification and preparation method thereof

ActiveCN104646029AReduce dosageSpeed up decompositionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCatalytic oxidationBULK ACTIVE INGREDIENT

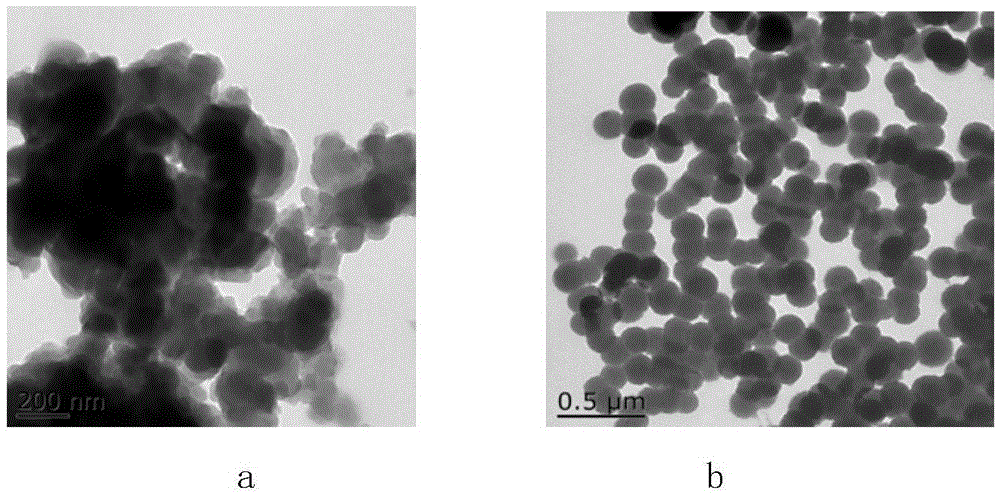

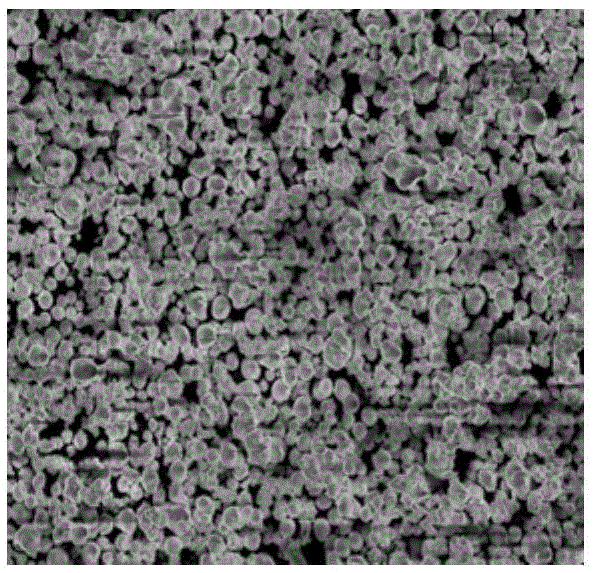

The invention discloses a metal alloy catalyst for formaldehyde purification and a preparation method thereof. The catalyst takes a metal alloy as an active center and takes a metal oxide as a carrier; the metal alloy is formed by compounding a precious metal A and a transition metal B; the precious metal A refers to any one of Pt, Ru, Rh, Pd and Ag; and the transition metal B refers to any one or a mixture of at least two out of Fe, Ni, Mn and Co. The preparation method comprises the following steps: synthesizing composite precious metal alloy nanoparticles by taking a precursor solution of the precious metal and the transition metal as a raw material under the CO atmosphere; loading the nanoparticles serving as active ingredients onto the carrier, reducing by virtue of hydrogen or a reducing solution to obtain the metal alloy catalyst. According to the catalyst disclosed by the invention, the indoor low-concentration harmful gas such as formaldehyde can be subjected to catalytic oxidation so as to prepare nontoxic and harmless CO2 and H2O under the room temperature conditions without light, electricity and other external auxiliary equipment, so that green purification of the formaldehyde is realized, and the catalyst has high stability.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

Room-temperature catalytic oxidizing agent of formaldehyde employing composite noble metal alloy, and preparation method thereof

ActiveCN103357409AFast decompositionReduce dosageDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementDecomposition

The invention discloses a room-temperature catalytic oxidizing agent of formaldehyde employing a composite noble metal alloy and a preparation method thereof. The catalyst is prepared by adopting a composite noble metal alloy as an active center, and compound crystalline nano-titanium dioxide as a carrier, wherein the composite noble metal alloy is an alloy active center which is compounded by noble metal and a rare earth element; the preparation method comprises the following steps of: selecting a salt solution containing the noble metal and a salt solution containing the rare earth element to dissolve into deionized water; slowly dropwise adding a KOH solution, carrying out high-speed agitation, rotary steam drying and baking; and roasting at the temperature of 400-600 DEG C and then leading in hydrogen to reduce, so as to obtain the room-temperature catalytic oxidizing agent of formaldehyde. By adopting the room-temperature catalytic oxidizing agent and the preparation method thereof, the catalytic activity is greatly improved; the formaldehyde is rapidly oxidized into carbon dioxide and water in a room-temperature condition namely when the temperature is 5-25 DEG C, so that the dosage of platinum metal is greatly reduced; and the room-temperature catalytic oxidizing agent has the advantages of simple process, low cost, good performance, fast decomposition velocity of formaldehyde and long service life, and can be widely applied to the equipment such as air conditioning equipment, a ventilating duct, a fresh air ventilator, an air purifier, an air humidifier and the like.

Owner:阜阳中科众汇净化材料有限公司

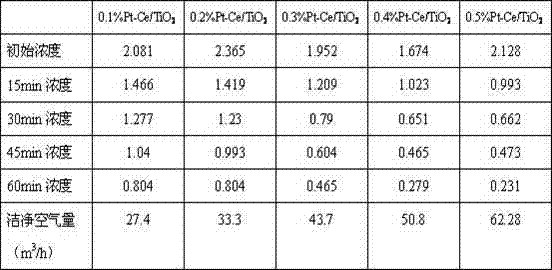

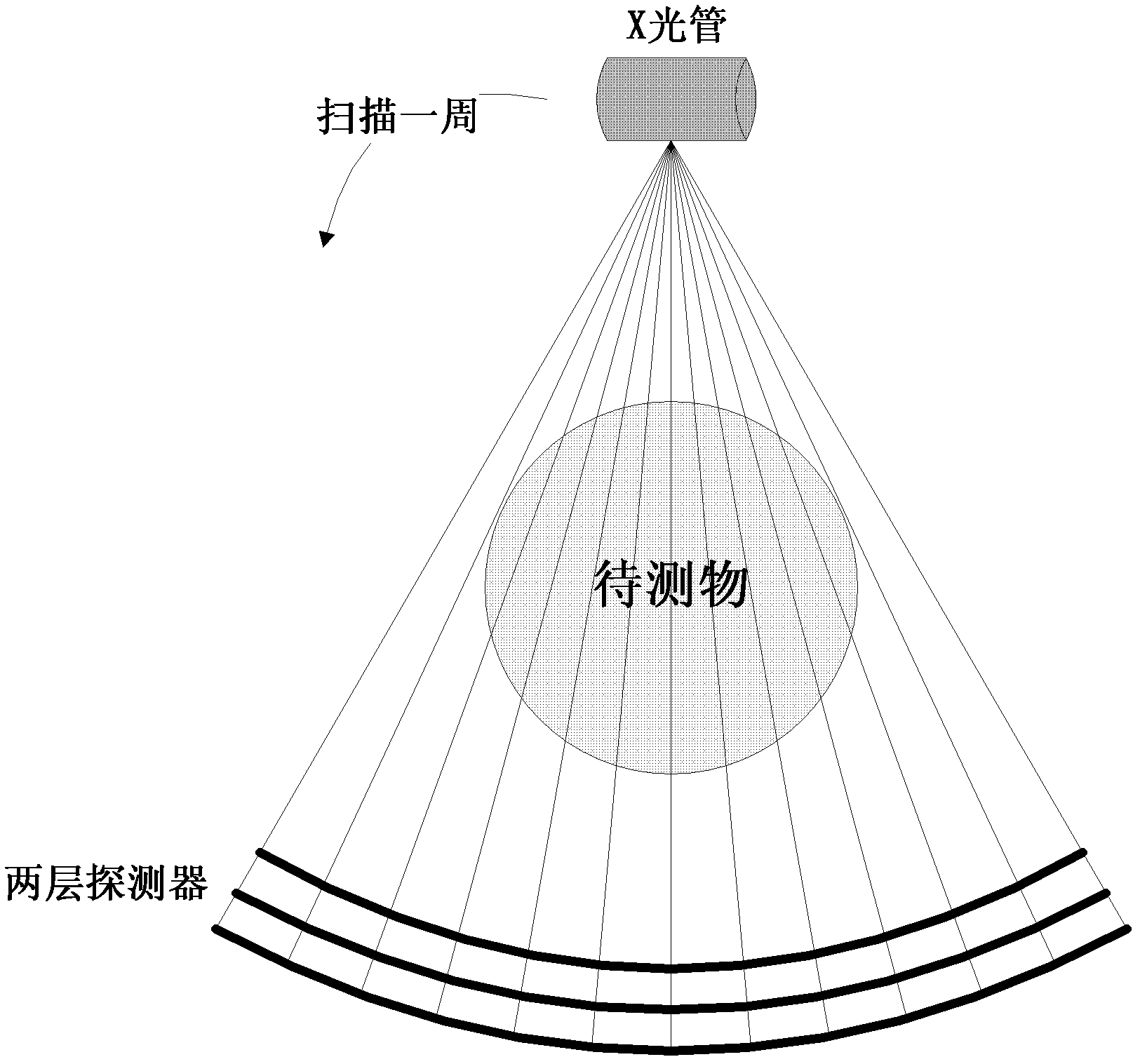

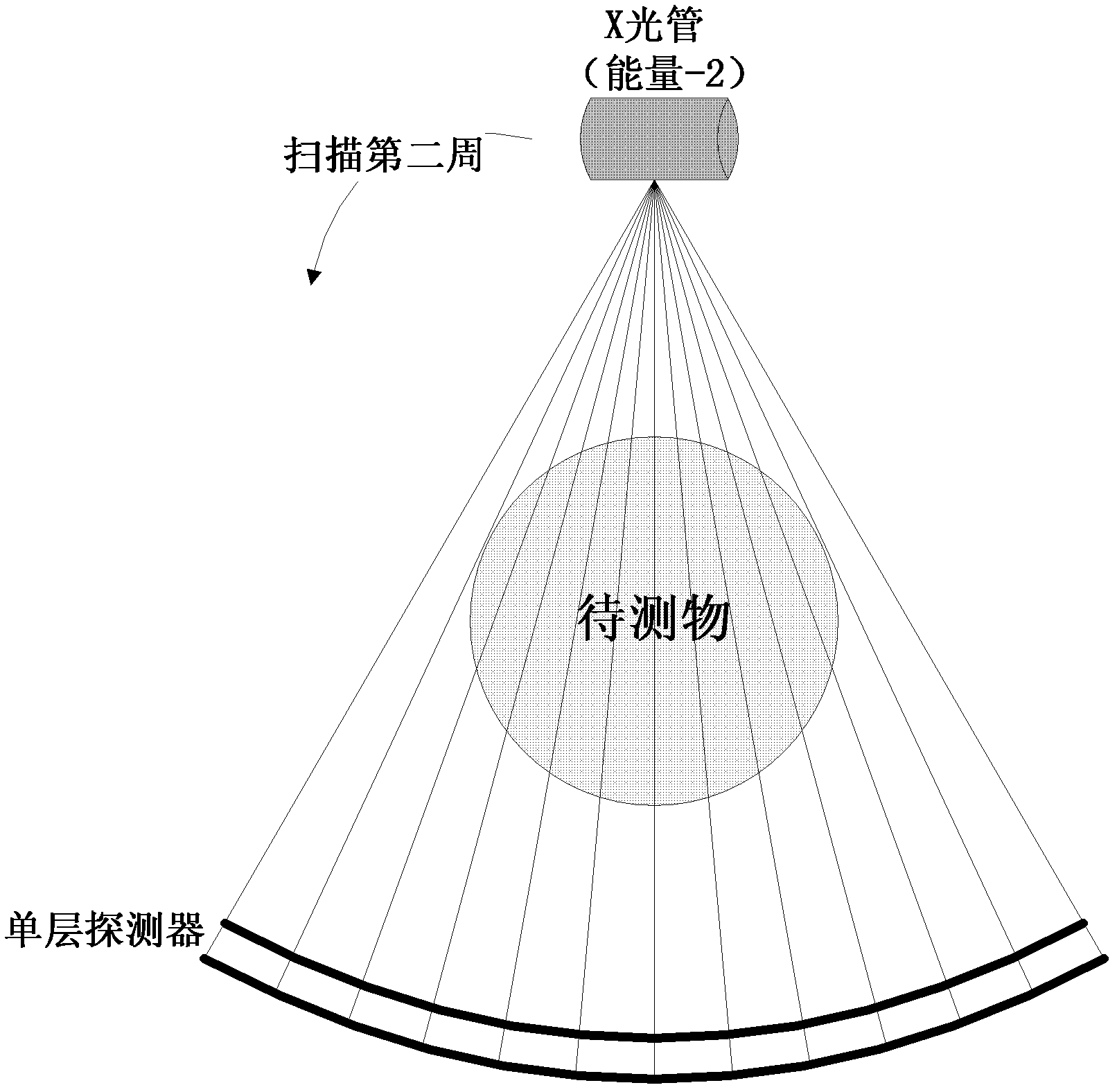

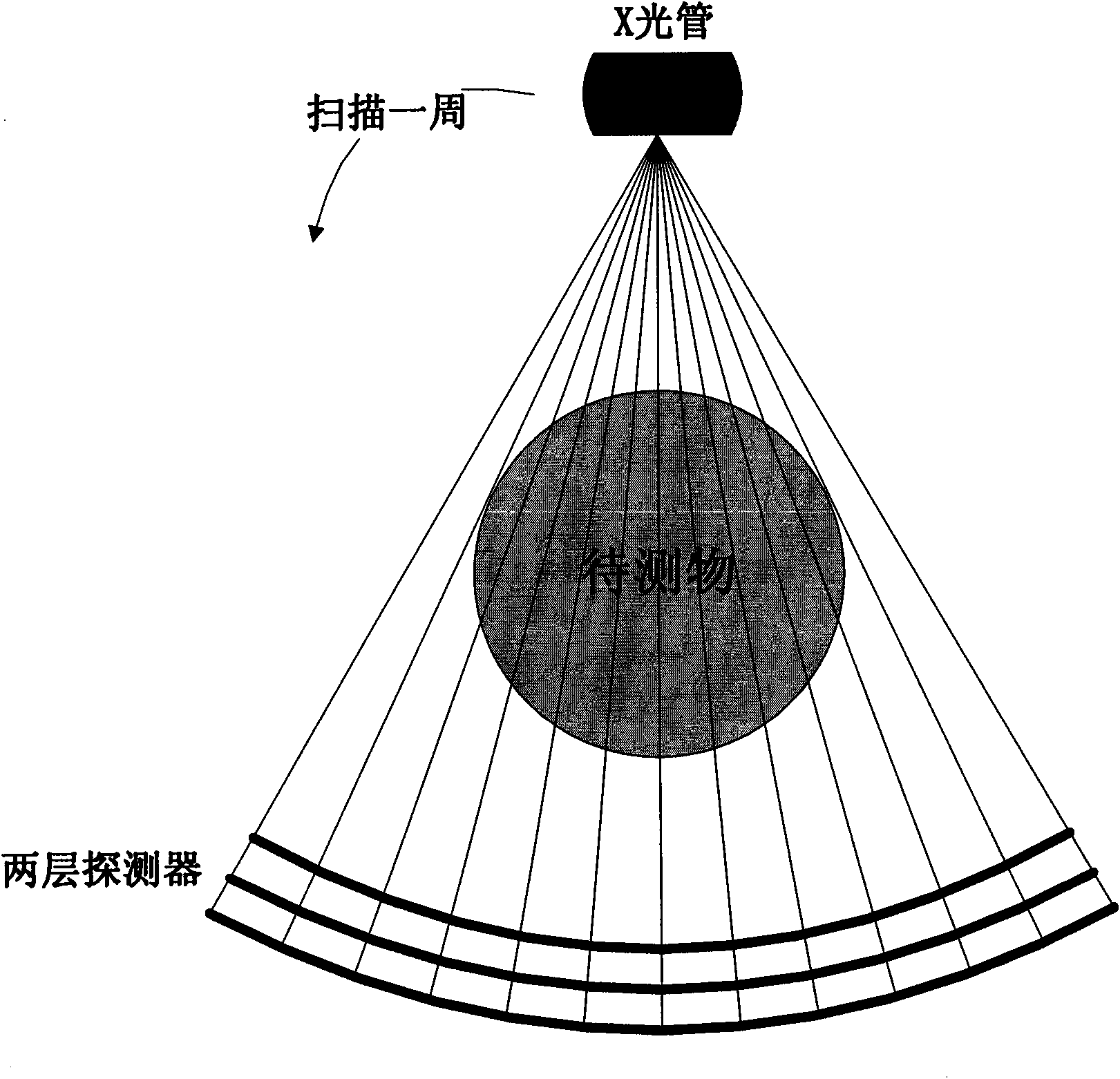

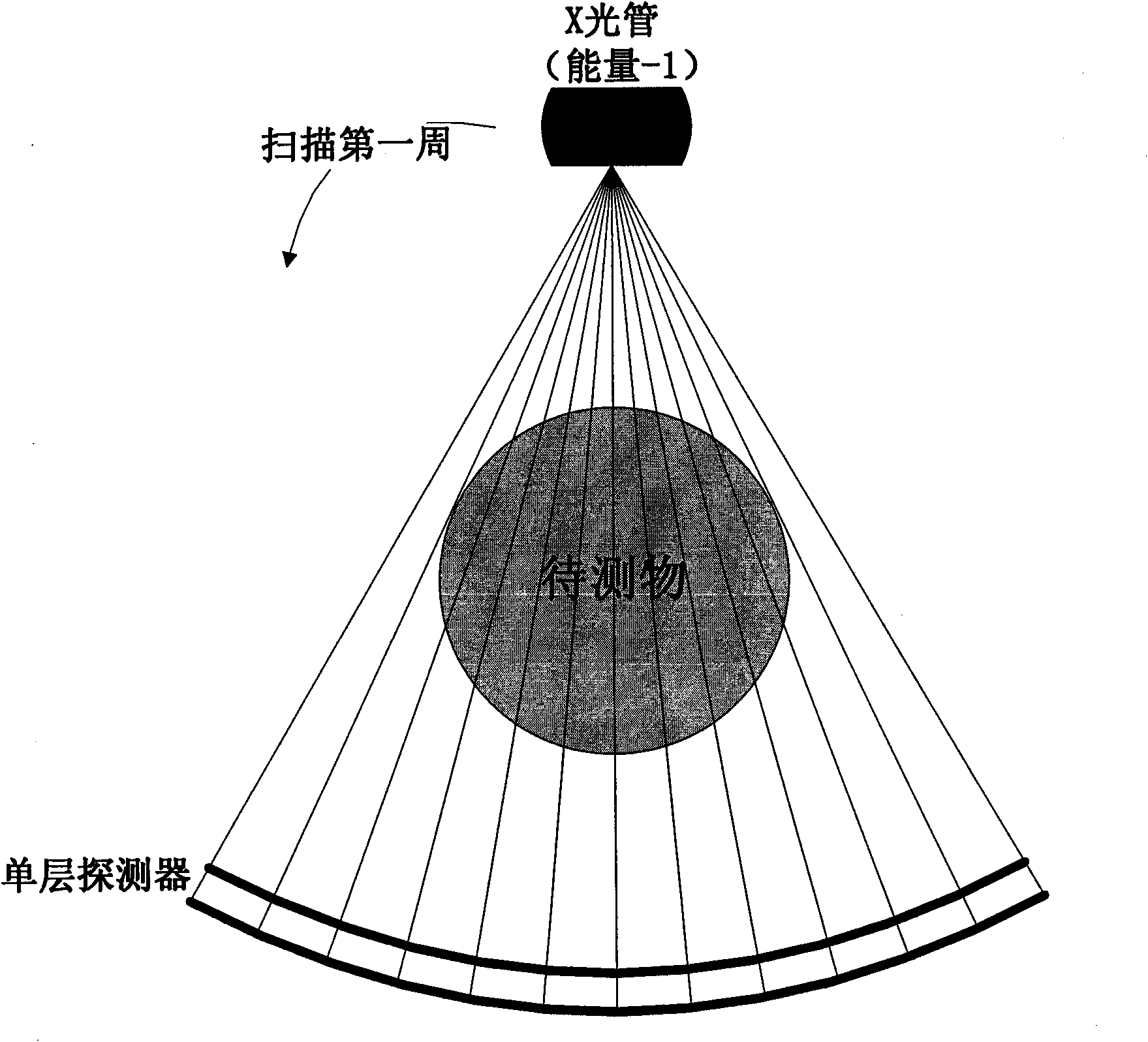

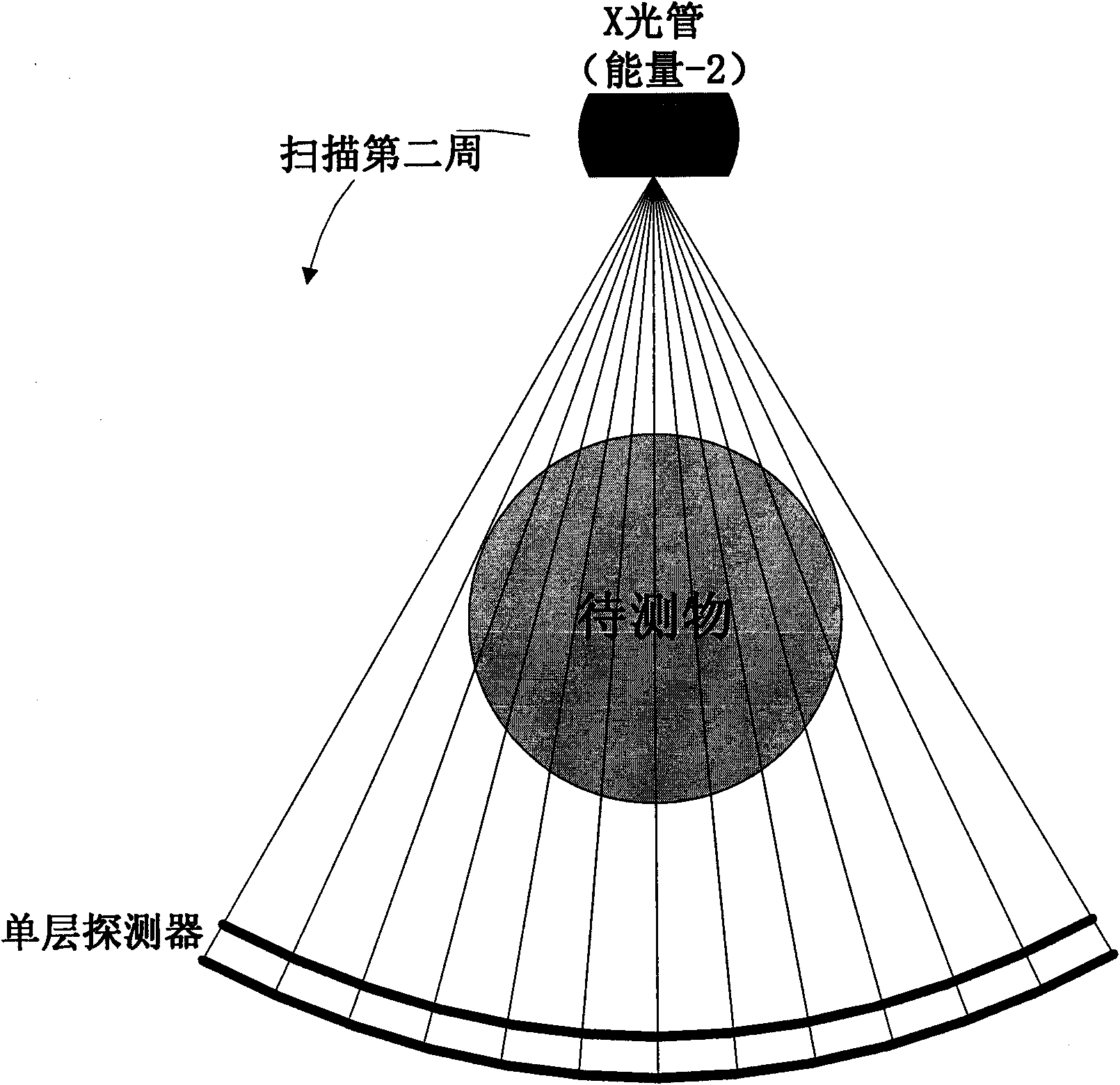

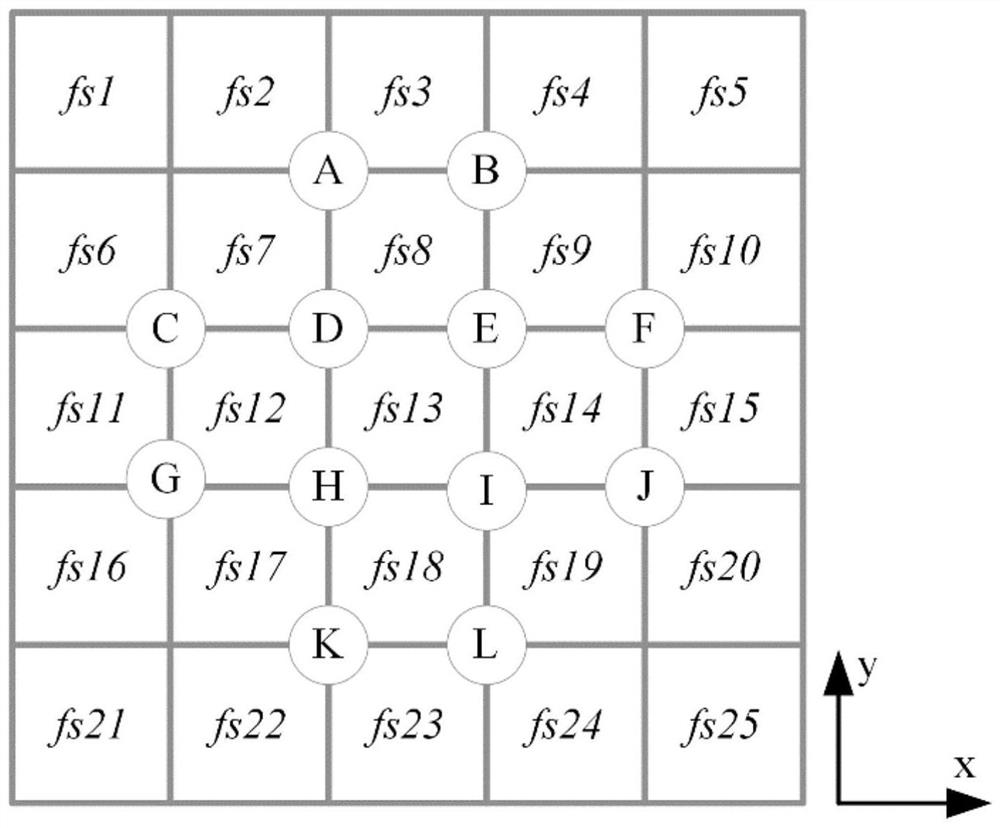

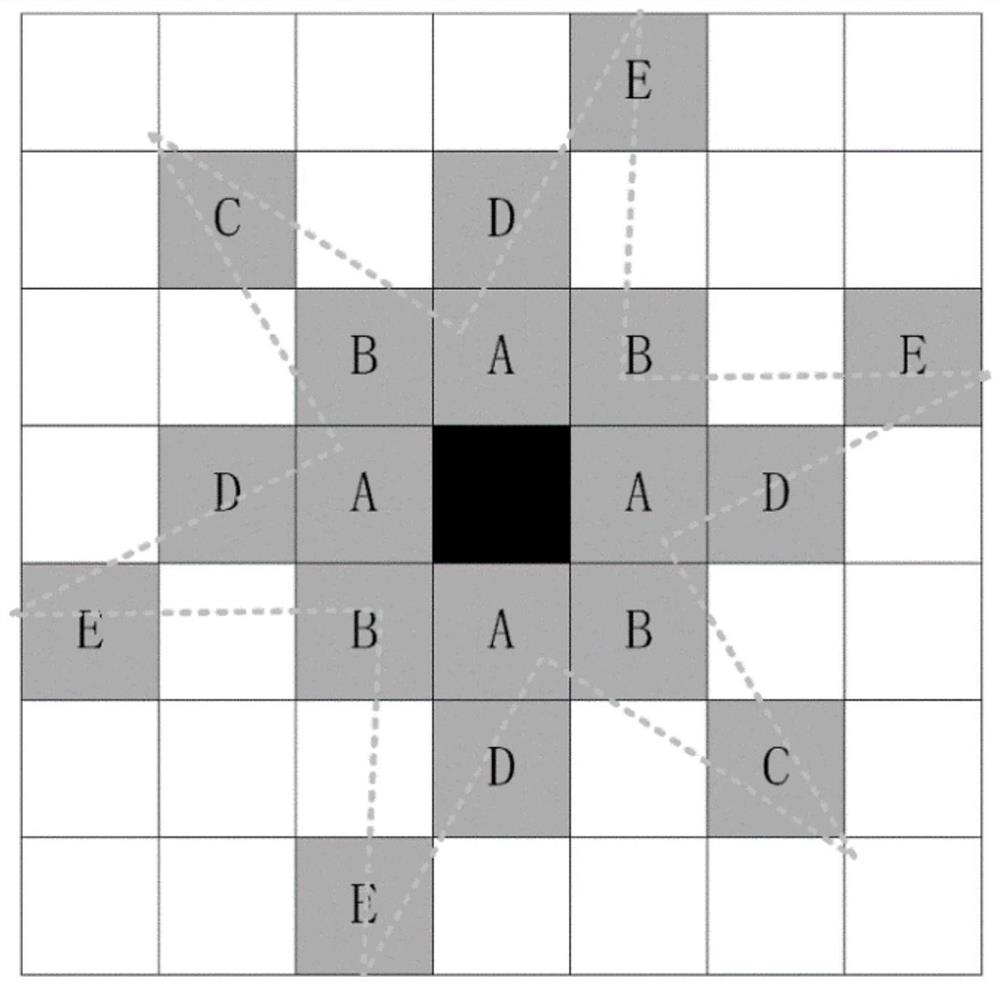

Dual-energy under-sampled matter identification method and system

ActiveCN102435621AReduce the numberLow costMaterial analysis by transmitting radiationDecompositionDual effect

The invention discloses a dual-energy under-sampled matter identification method and a dual-energy under-sampled matter identification system. The method comprises the following steps of: acquiring the computed tomography (CT) image of a detected matter by a CT image reconstruction method, acquiring a small quantity of dual-energy under-sampled projections, and solving photoelectric coefficient integration and Compton coefficient integration by looking up a table according to dual-energy projection data; performing region segmentation on the acquired CT image of the detected matter by an image processing technology, marking the segmented regions, and calculating the lengths of the small quantity of acquired dual-energy projection rays which pass through the marked regions; and establishing an equation system by a duel-energy preprocessing dual-effect decomposition and reconstruction method to calculate a Compton coefficient and a photoelectric coefficient, and further solving the atomic number and the electron density of a substance in each segmented region. The type of the substance in the detected matter can be identified by the atomic number of the substance.

Owner:TSINGHUA UNIV +1

Method for identifying material by means of dual-energy undersampling and system thereof

ActiveCN101900696AReduce the numberReduce radiation doseReconstruction from projectionTomographyImaging processingDual energy

The invention discloses a method for identifying a material by means of dual-energy undersampling and a system thereof. The method comprises the following steps of: obtaining the CT image of a material to be detected with a CT image rebuilding method; obtaining a small quantity of dual-energy undersampling projection; obtaining a photoelectric coefficient integral and a Compton coefficient integral according to the dual-energy projection data table lookup; performing region segmentation to the obtained CT image of the material to be detected with an image processing technology and marking the segmented regions; recomputing the length of the obtained small quantity of dual-energy undersampling projection ray which penetrates through each marked region; building an equations set with a dual-energy preprocessing double effect resolving and rebuilding method to be convenient for computing the Compton coefficient and the photoelectric coefficient so as to further obtain the material atomic number and the electron density in each segmented region; and identifying the type of the material to be detected with the material atomic number.

Owner:TSINGHUA UNIV +1

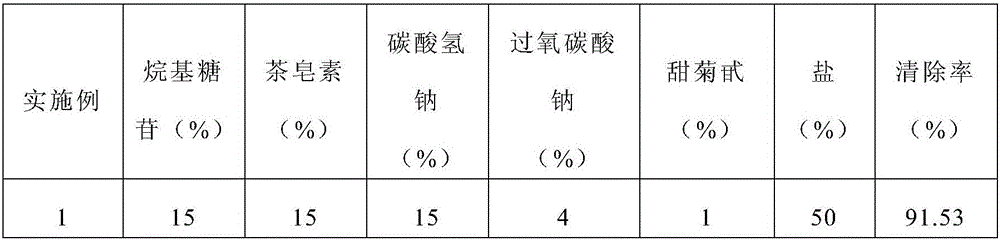

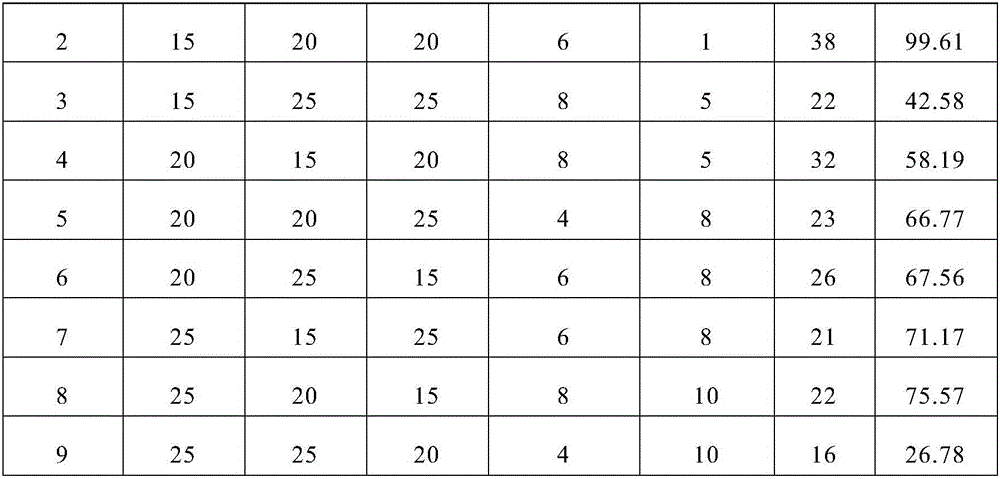

Fruit-vegetable washing salt powder and preparation and usage methods thereof

InactiveCN106833981AEasy to storeEasy to useInorganic/elemental detergent compounding agentsSurface-active non-soap compounds and soap mixture detergentsSodium bicarbonateGlycoside formation

The invention discloses fruit-vegetable washing salt powder and preparation and usage methods thereof, and belongs to the field of washing agents. The fruit-vegetable washing salt powder is prepared from the following components in percentage by mass: 15 to 25 percent of tea saponin, 4 to 8 percent of sodium peroxycarbonate, 15 to 25 percent of alkyl glycoside, 15 to 25 percent of sodium bicarbonate, 1 to 10 percent of stevioside and 15 to 50 percent of salt. The preparation method comprises the following steps: uniformly mixing the component according to a corresponding proportion; finishing packaging in a dry environment. The usage method comprises the following steps: dissolving the fruit-vegetable washing salt powder of a certain mass ratio in fresh water to form a solution; placing a fruit-vegetable sample soaked in a pesticide for 3 to 7 seconds in the solution for soaking for 1 to 5 minutes, and scrubbing; soaking in the fresh water for 30 to 90 seconds, and scrubbing; flushing with running water for 1 to 3 minutes. The fruit-vegetable washing salt powder has a remarkable effect of removing the residual pesticide, thereby preventing human body from being harmed by residues on the surfaces of fruits and vegetables; meanwhile, the fruit-vegetable washing salt powder has certain sterilizing and disinfecting effects; moreover, table salt is taken as a basic raw material, so that the fruit-vegetable washing salt powder has low production cost and a wide application prospect.

Owner:CHINASALT CHANGJIANG SALINIZATION

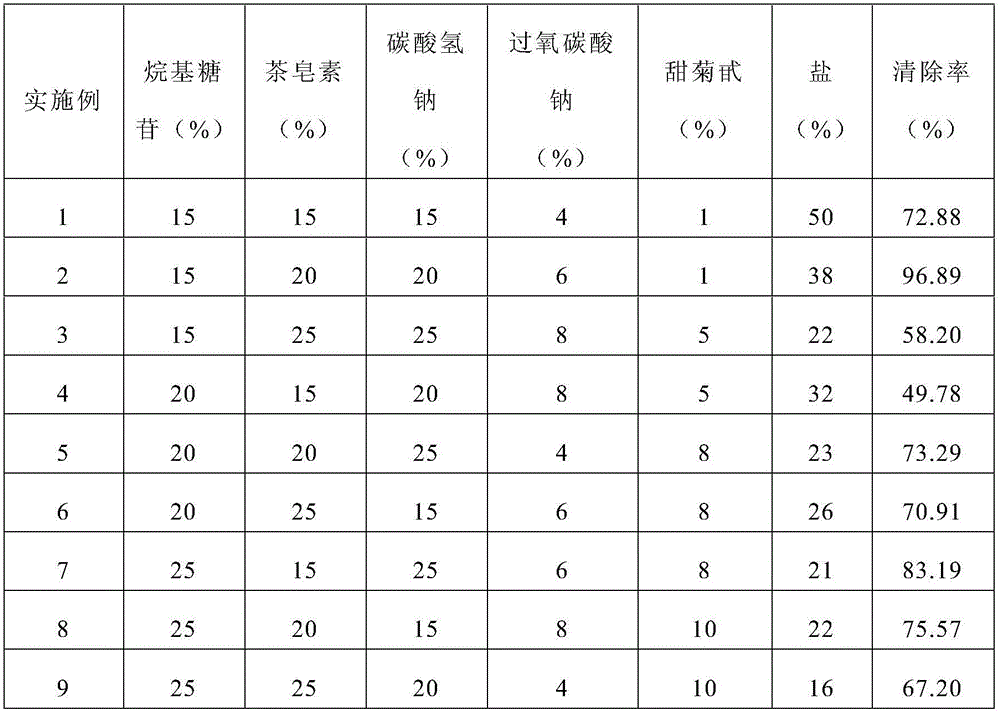

Selenium-enriched microbial fertilizer and preparation method thereof

InactiveCN109867569AImprove absorption efficiencyPromote absorptionClimate change adaptationAgriculture gas emission reductionMicrobial agentNutrients substances

The invention discloses a selenium-enriched microbial fertilizer and a preparation method thereof, and belongs to the technical field of fertilizers. The fertilizer is prepared from the following rawmaterials in parts by weight: 140-160 parts of a nitrogenous fertilizer, 40-60 parts of a phosphate fertilizer, 80-100 parts of a potash fertilizer, 20-30 parts of a medium-trace element chelating fertilizer, 5-10 parts of charcoal, 1-3 parts of polyaspartic acid, 1-3 parts of seaweed polysaccharide, 1-3 parts of a compound microbial agent, 0.5-1.5 parts of sodium selenite and 3-5 parts of iron nano-particles, wherein the composite microbial agent is prepared by mixing candida utilis, bacillus subtilis and bacillus natto according to a mass ratio of (1.5-2.5):1:(2.5-3.5). According to the invention, absorption efficiency of crops on the selenium is increased mainly by utilizing microbial activities, and meanwhile, nutrient elements such as N, P and K are scientifically proportioned, so that abundant basic nutrient substances are provided for the crops. The selenium-enriched microbial fertilizer disclosed by the invention is reasonable in formula, the preparation process is simple, fertilizer efficiency is remarkable, and safety and environment friendliness are achieved.

Owner:SHANDONG CREATE YIFENG FERTILIZER GRP CO LTD

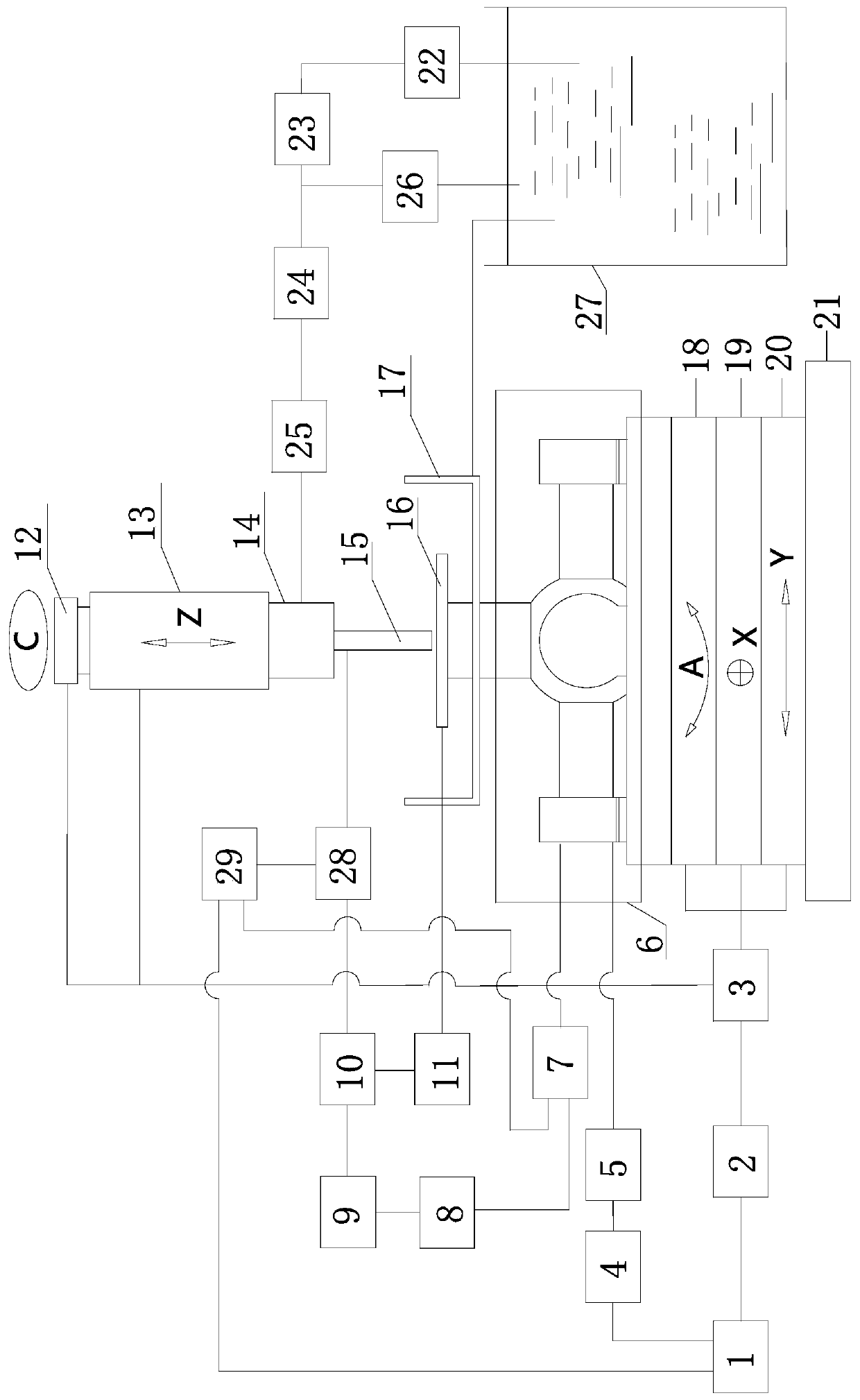

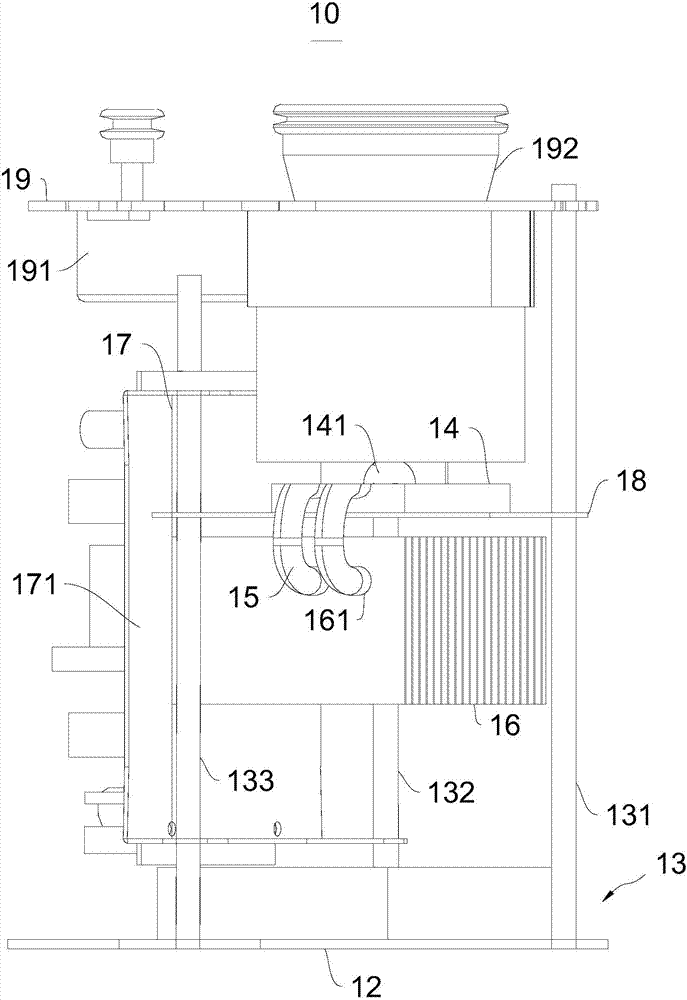

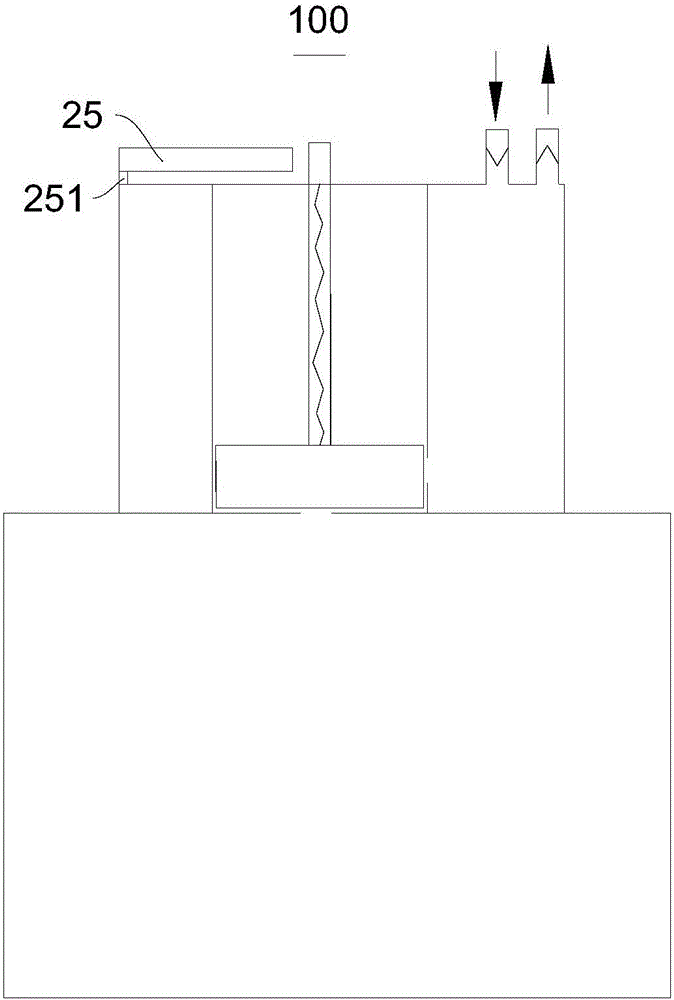

Ultrasonic modulation discharge-electrolysis high-efficiency milling system

The invention discloses an ultrasonic modulation discharge-electrolysis high-efficiency milling system, and belongs to the technical field of special machining. The ultrasonic modulation discharge-electrolysis high-efficiency milling system consists of an ultrasonic vibration control system, a multi-axis machine tool control system, a composite machining power supply control system and an electrolyte circulation system, wherein corresponding machining tracks are matched according to the profile characteristics of an anode workpiece; the machining tracks can be subjected to vector decomposition; the machining tracks are converted into control input quantity of the ultrasonic vibration control system and the multi-axis machine tool control system, the accurate synchronization of the millingprocess and the ultrasonic vibration is achieved; the ultrasonic vibration amplitude is detected in real time through a displacement sensor; the control input quantity serving as the composite machining power supply control system is processed through the programmable controller, the coupling effect of a variable voltage process and the ultrasonic vibration process is achieved, and the removal efficiency of the anode material and the stability of the machining process can be improved; and high-speed high-pressure electrolyte fluid provided by the electrolyte circulation system is directly conveyed into a machining gap through a rotary joint, so that the mass transfer efficiency of the fluid in the gap is enhanced, and the efficient composite machining with a smaller gap is achieved.

Owner:YANGZHOU UNIV

Exhaust device and engine

ActiveCN107676162APrevent inflowPrevent water ingressExhaust apparatusSilencing apparatusWater flowMain channel

The invention provides an exhaust device and an engine, and belongs to the technical field of engines. The exhaust device comprises an exhaust main pipe, a first exhaust pipe, an exhaust part and a floating block. The exhaust main pipe is provided with an exhaust main channel. One end of the exhaust main pipe is used for communicating with the exhaust end of an engine body. The first exhaust pipeis provided with a first exhaust channel. The exhaust part is provided with an exhaust chamber. One end of the exhaust part communicates with the first exhaust pipe. The other end of the exhaust partis provided with a first exhaust opening communicating with the exhaust chamber. The floating block is located in the exhaust chamber and comprises a sliding block and a closed block. The sliding block is connected to the exhaust part in a sliding manner and is provided with exhaust holes enabling the first exhaust channel to communicate with the first exhaust opening. According to the exhaust device, through the design of the floating block, after water flows into the exhaust device, the floating block moves upwards to achieve closing, water is prevented from entering the exhaust pipe, and therefore water is effectively prevented from flowing into the engine, and the service life of the engine is effectively prolonged. The engine comprises the exhaust device and has all the functions of the exhaust device.

Owner:SHAANXI JUZHEN POWER TECH CO LTD

Automatic cooling device and clothing

PendingCN107471779AReduce body temperatureFeel coolSynthetic resin layered productsRubber layered productsEngineeringRefrigeration

The invention provides an automatic cooling device and a clothing, and belongs to the field of living goods. The automatic cooling device comprises a radiation refrigeration layer, a transparent protection layer and a base layer fitting with a human body, the transparent protection layer is located at one side of the radiation refrigeration layer, the base layer is connected with the transparent protection layer, the base layer is located at one side, far from the transparent protection layer, of the radiation refrigeration layer, and the radiation refrigeration layer is located between the transparent protection layer and the base layer. The automatic cooling device can be attached to the human body through the base layer, and the radiation refrigeration layer is used to outwardly radiate the heat of the human body in an electromagnetic wave form in order to reduce the body surface temperature. When the external environment temperature is high, a user wears the clothing made through using the automatic cooling device and feels cool in order to avoid heatstroke, and the clothing has good integral use effect and high practicality. The clothing includes the automatic cooling device, and has all the functions of the automatic cooling device.

Owner:莫伟智

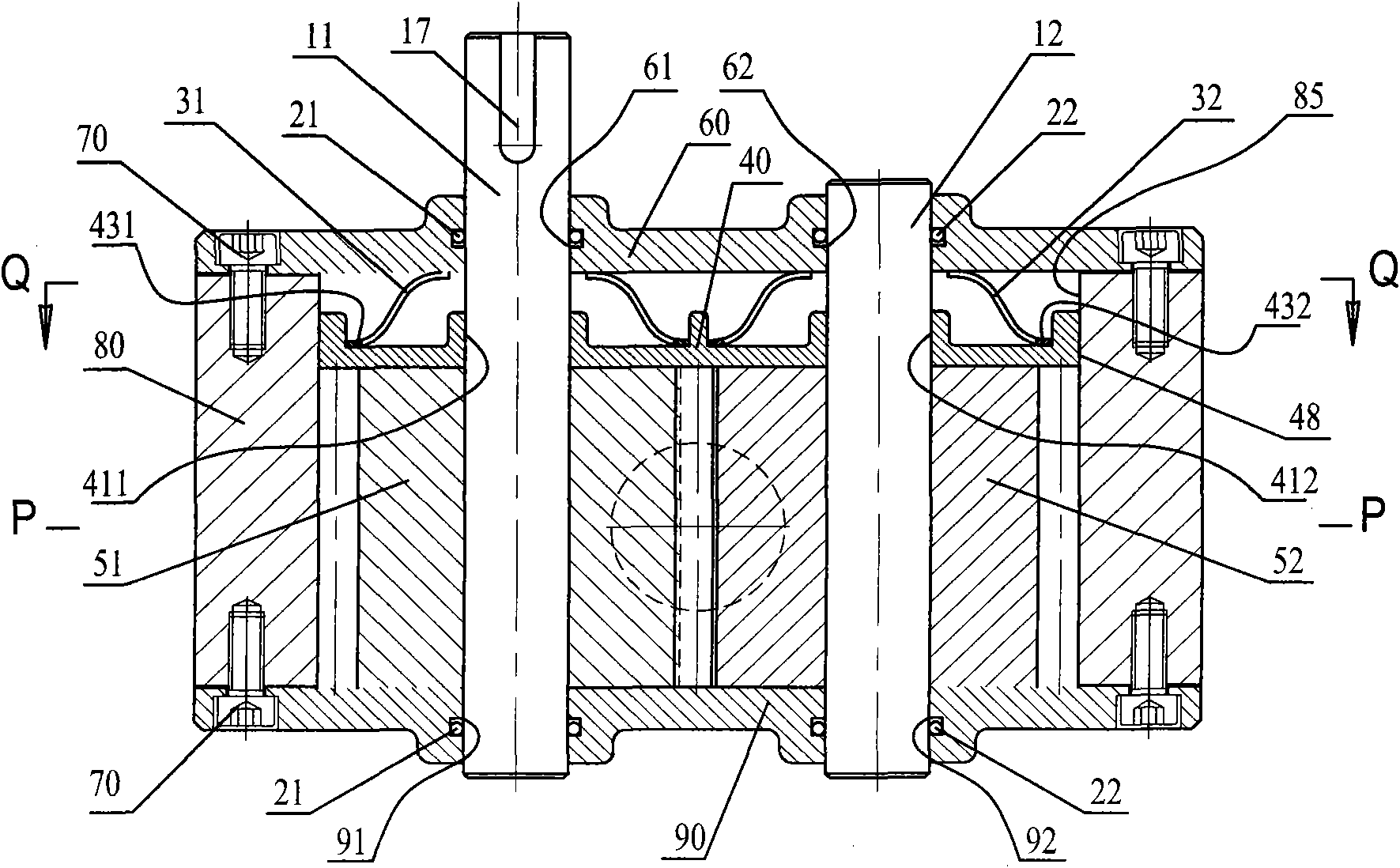

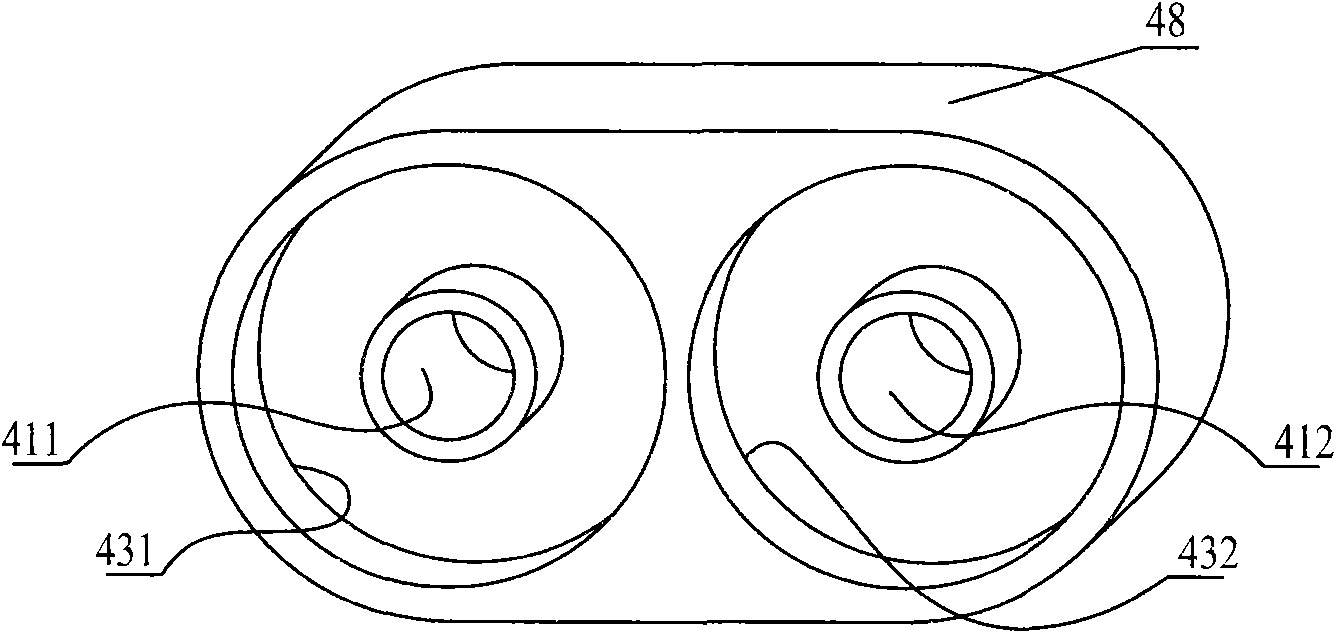

Compensation gear pump for annular spoke springs

InactiveCN102536796ANovel ideaSimple structureRotary piston pumpsRotary piston liquid enginesGear pumpDrive shaft

A compensation gear pump for annular spoke springs comprises a drive shaft, a driven shaft, a main gear, a slave gear, an annular spoke main spring, an annular spoke slave spring, an end surface compensation plate, a front outer end cover, an end cover bolt, a pump body and a rear outer end cover, wherein the end surface compensation plate is arranged between the main gear and the front outer end cover as well as between the slave gear and the front outer end cover; the circular ring of the annular spoke main spring is fixed at the concave main annular corner on the back of the compensation plate; the spoke of the annular spoke main spring is propped against the inner side surface of the front outer end cover; the circular ring of the annular spoke slave spring is fixed at the concave slave annular corner on the back of the compensation plate; and the spoke of the annular spoke slave spring is propped against the inner side surface of the front outer end cover. According to the axial rebounding force generated because the spokes of the annular spoke main spring and the annular spoke slave spring are respectively propped against the inner side surface of the front outer end cover, the front plane surface of the end surface compensation plate is clung to the end plane surfaces on one side of the main gear and one side of the slave gear, so that the end plane surfaces on the other sides of the main gear and the slave gear are clung to the inner plane surface of the rear outer end cover to ensure the efficient operation of the gear pump all the while.

Owner:HUNAN BALING FURNACE ENERGY CONSERVATION

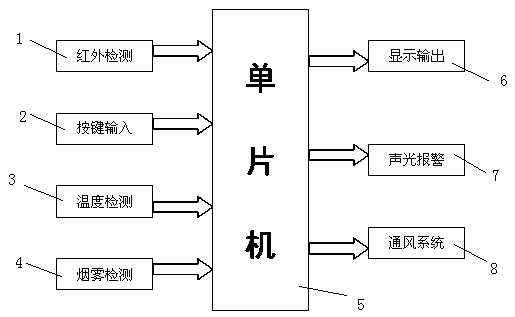

Household fire and theft prevention system

The invention discloses a household fire and theft prevention system. The system comprises an infrared detection circuit, a temperature detection circuit, a smoke detection circuit, a single-chip microcomputer, a keyboard input module, an alarm module and a ventilation device, wherein the infrared detection circuit is used for detecting infrared radiation of the human body and outputting corresponding data; the temperature detection circuit is used for detecting indoor temperature and outputting corresponding data; the smoke detection circuit is used for detecting indoor smoke and outputting corresponding data; the single-chip microcomputer is connected with the infrared detection circuit, the temperature detection circuit and the smoke detection circuit, receives the output data, compares the output data with preset thresholds, and outputs an alarm signal and a control signal when the output data exceed the preset thresholds; the keyboard input module is connected with the single-chip microcomputer and used for providing the thresholds; the alarm module is connected with the single-chip microcomputer, and used for receiving the alarm signal and giving an alarm; the ventilation device is connected with the single-chip microcomputer, and used for receiving the control signal and performing ventilation.

Owner:SUZHOU INST OF TRADE & COMMERCE

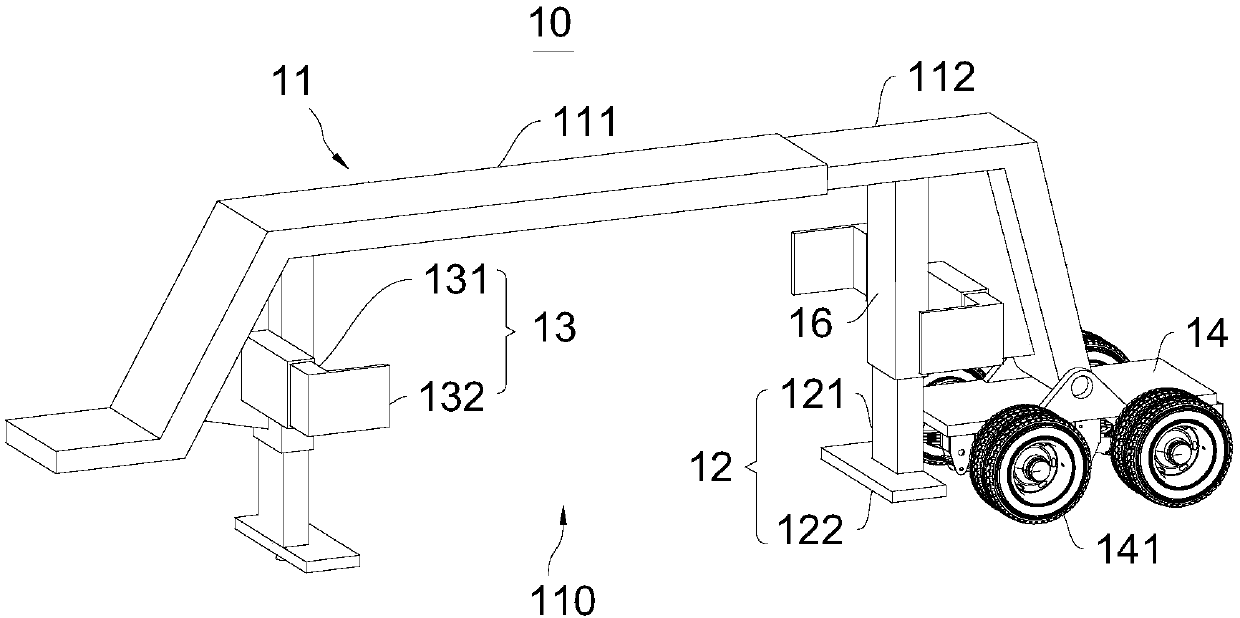

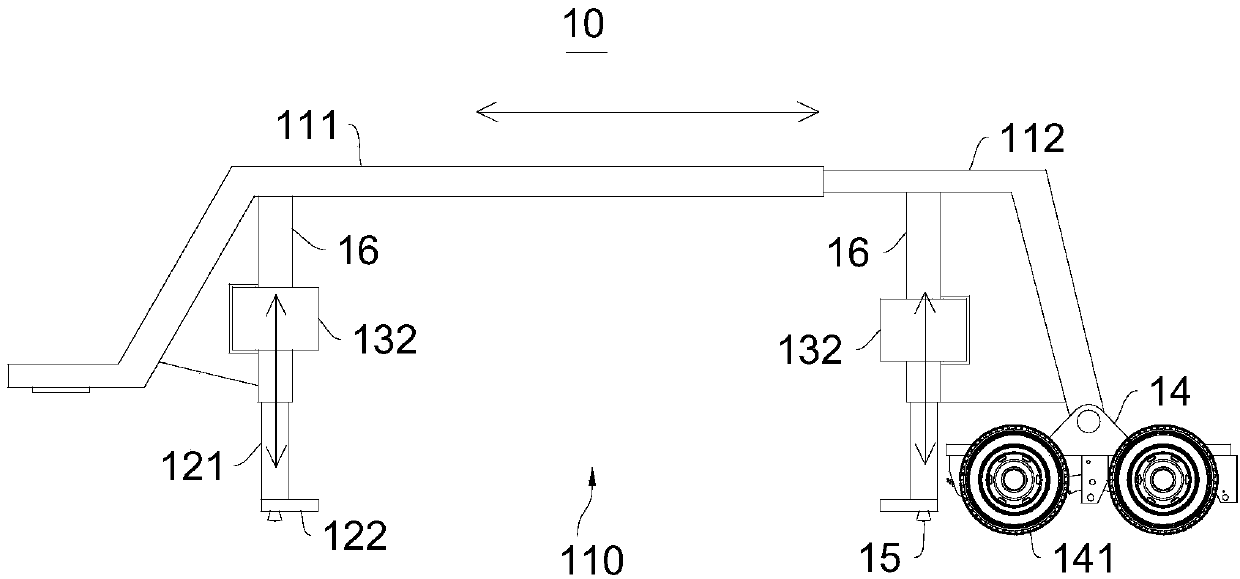

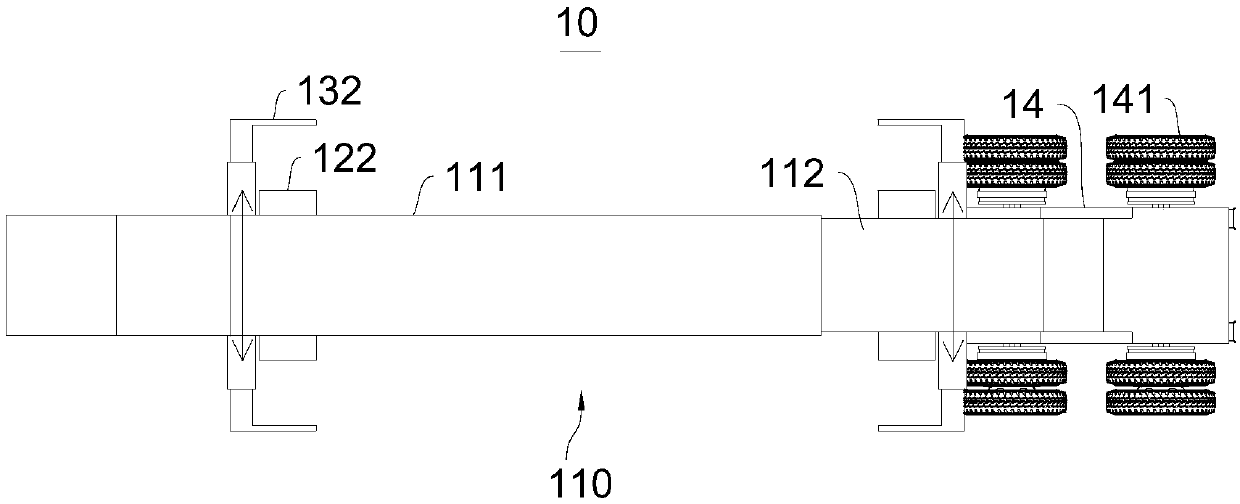

Transportation vehicle body and transportation vehicle

PendingCN107554389ALower center of gravityTransport stableVehicle to carry long loadsLoading-carrying vehicle superstructuresVehicle frameFixed frame

The invention provides a transportation vehicle body and a transportation vehicle and belongs to the technical field of transportation. The transportation vehicle body comprises a frame, fixing devices and a traveling device, wherein the middle portion of the frame is upwardly arched, a loading space for loading goods is formed below the arched middle portion, the fixing devices are connected withthe frame and used for fixing the goods located in the loading space, and the traveling device is connected with the frame. The transportation vehicle body has the advantages that the goods can be loaded below the frame, low overall gravity center and stable transportation are achieved, and the problems of height exceeding and width exceeding are avoided; due to the fact that the goods can be directly loaded and unloaded, hoisting equipment is not needed, and loading and unloading efficiency is increased evidently; the transportation vehicle body is reasonable in structural design and huge inmarket application potential. The transportation vehicle comprises the transportation vehicle body and has all the functions of the transportation vehicle body.

Owner:HUNAN SANY KUAIERJU RESIDENTIAL IND CO LTD

Method for synthesizing polypyrrole in oil solvent

The invention relates to a method for synthesizing polypyrrole in an oil solvent. The method comprises the following steps: sodium dodecyl sulfate, polyethylene glycol 6000, polyvinyl pyrrolidone, ethanol, butanol, peracetic acid, benzoyl peroxide, pyrrole monomer and the oil solvent are fully stirred under the condition of the room temperature or ice bath; the mixture is then subjected to ultrasonic, washing and drying, and a black polypyrrole product is obtained. According to the method, benzoyl peroxide is used as strong oxidant, and trichloromethane (isopropanol, cyclohexane, acetone, methylbenzene and the like) is used as the oil solvent. Therefore, polypyrrole polymers with the advantages of high purity, large yield, good stability, fast reaction, mild reaction conditions, high temperature resistance, good anti-pressure capacity, low cost input and the like can be prepared.

Owner:YANGZHOU UNIV

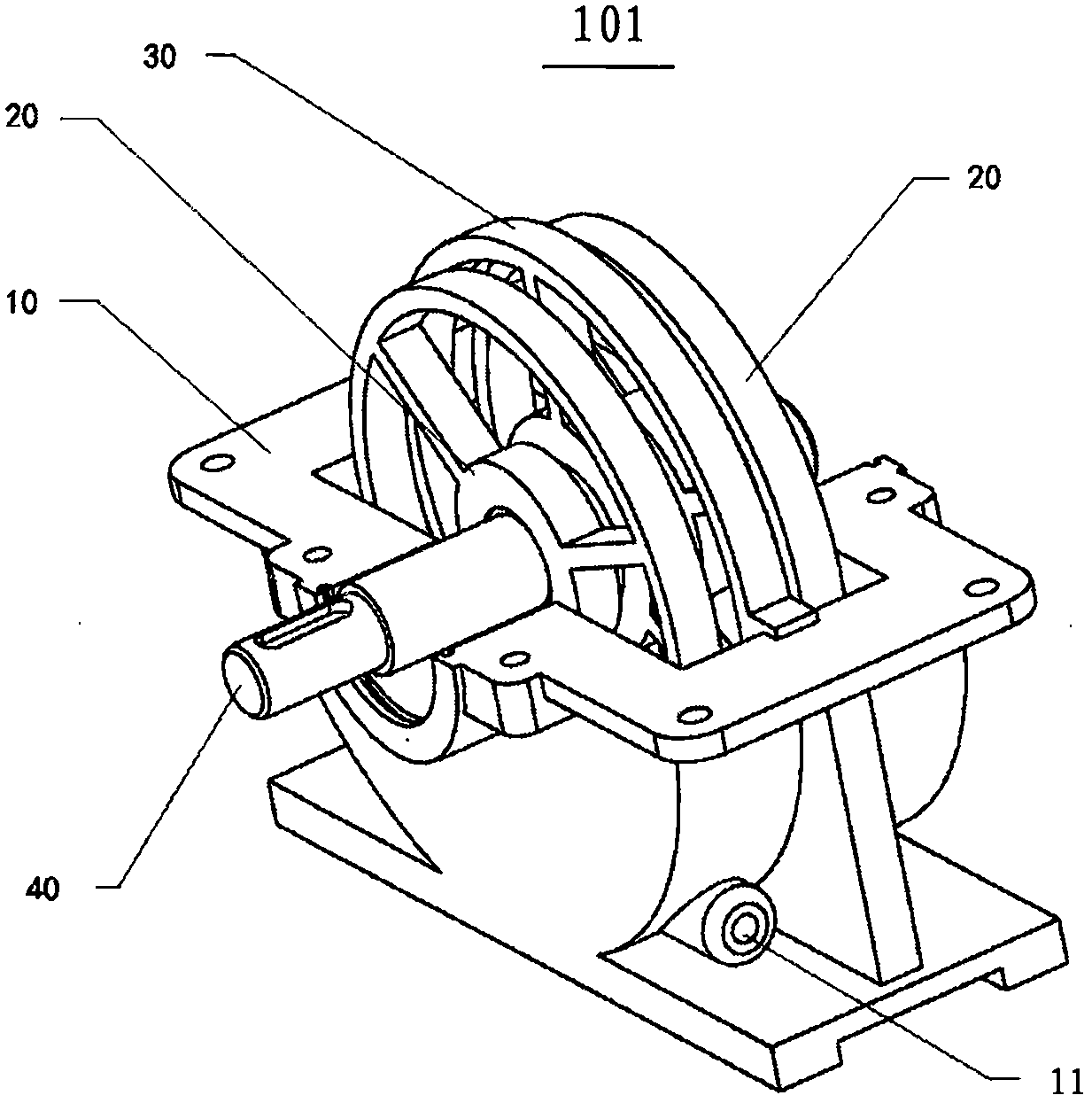

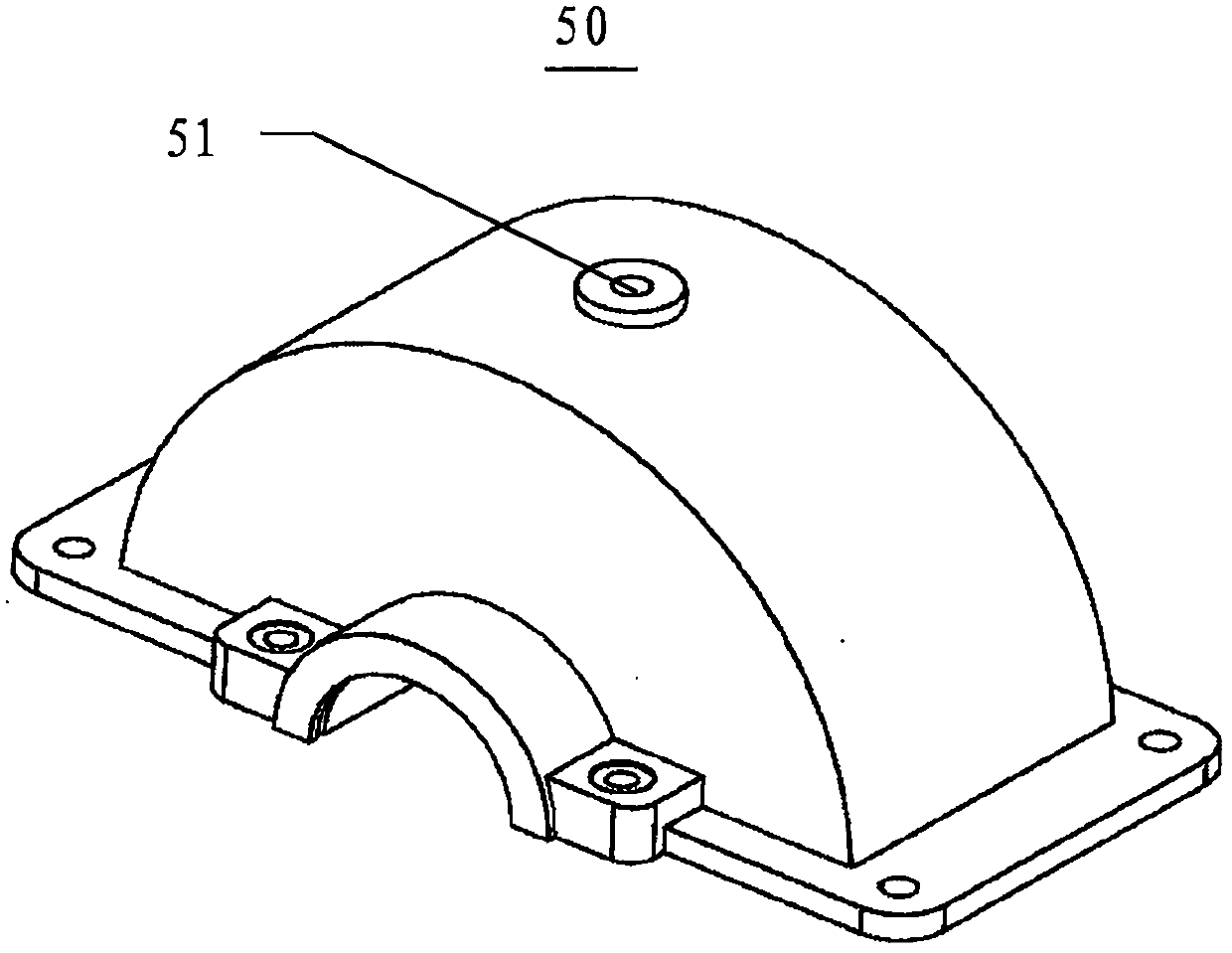

Braking device

PendingCN110725875ASpread evenlyLarge braking torqueLiquid resistance brakesLiquid viscosityEngineering

The embodiment of the invention provides a braking device, and belongs to the technical field of non-friction braking. The braking device includes a braking box body, a box cover, shear thickening liquid, two rotor shear rods, a stator shear rod, a shaft and a ventilation plug; a stator and rotors are placed inside the box body, the inside of the box body is filled with the shear thickening liquid, and the rotor shear rods and the stator shear rod are immersed in the shear thickening liquid. The rotor shear rods are fixed to the shaft in an assembled mode. The stator shear rod is placed at theposition, between the two rotor shear rods, inside the box body and is separated from the shaft. The physical characteristics of the shear thickening liquid (non-Newtonian fluid) are used, a reduction gearbox body is filled with shear thickening liquid, shearing is performed in the shear thickening liquid through the rotors, the viscosity of the liquid changes under impact, physical characterization changes from a liquid phase to a solid phase, at the moment, the rotation of the rotors is subjected to great resistance, and the resistance output is achieved through the shaft, the rods and other components connected to the rotors to achieve the purpose of braking. The solid-liquid phase transition of the shear thickening liquid is fast and reversible, so that the braking effect and the heatdissipation effect of the braking device are very good. The braking device has the characteristics such as large braking power, high heat dissipation efficiency and high reliability, and is widely used in high-speed and high-power vehicles and industrial fields.

Owner:张甫州

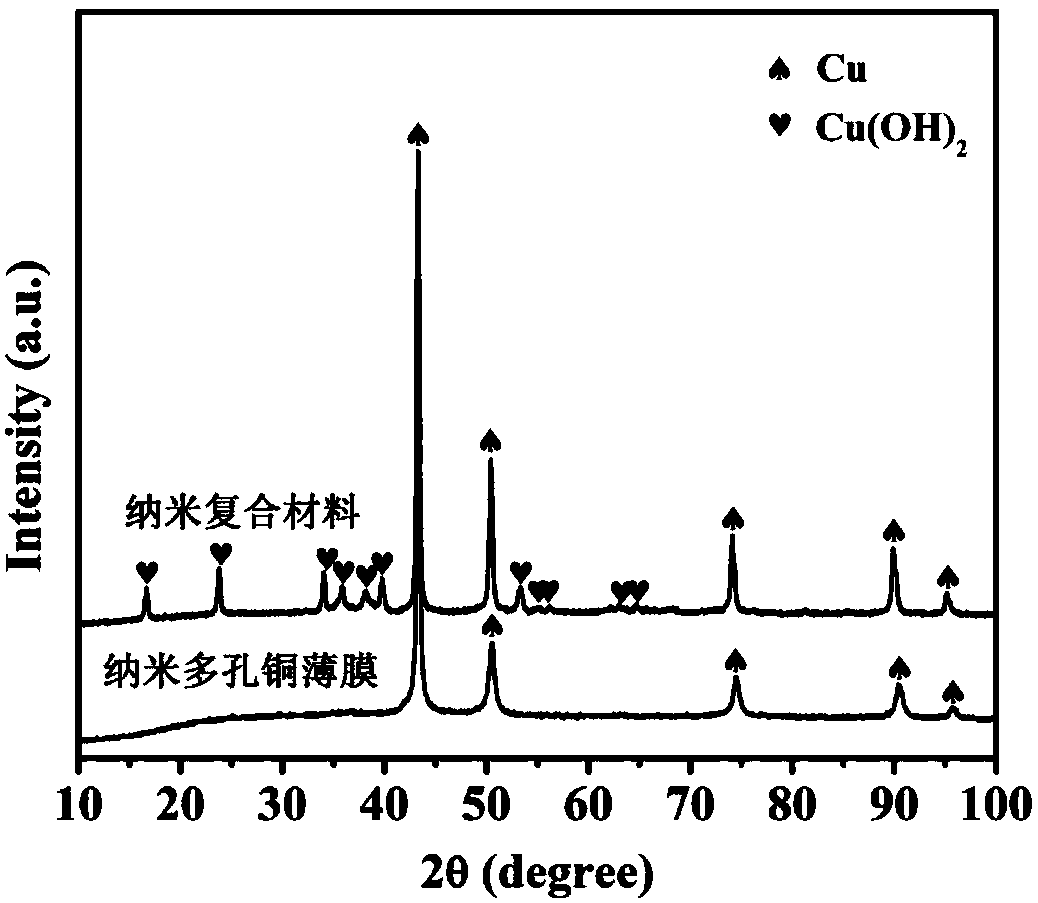

Nanoporous copper/cu(oh)2 nanowire array sensor electrode material and preparation method thereof

ActiveCN106226382BThickness is easy to controlEasy to prepareMaterial nanotechnologyMaterial electrochemical variablesGlucose sensorsComposite electrode

The invention discloses a nano porous copper / Cu(OH)2 nanowire array sensor electrode material and a preparation method thereof, and belongs to the technical field of micro-sensation. The preparation method of the nano porous copper / Cu(OH)2 nanowire array sensor electrode material mainly comprises the following two steps: by taking Cu-Zr-Al amorphous alloy as a precursor, preparing a flexible nano porous copper film of a double-continuous through hole structure by using a chemical alloy removing method; performing controllable growth on a Cu(OH)2 nanowire array on a nano porous copper film substrate by using an alkali oxidation method. The nano composite electrode material disclosed by the invention is of a structure similar to 'sandwich', Cu(OH)2 nanowires are uniformly and densely distributed on the nano porous copper substrate, have directivity and are uniform in morphology, large in internal specific surface area and very high in electric catalytic activity, the nano composite material can be directly used as an electrode material of a non-enzyme glucose sensor, the linear response range for glucose is 0.2-9 mM, the detection sensitivity is 2.09 mA / cm<2>.mM, the detection limit is 200 nM (S / N=-3.6), and the current response time is less than 1 second.

Owner:UNIV OF SCI & TECH BEIJING

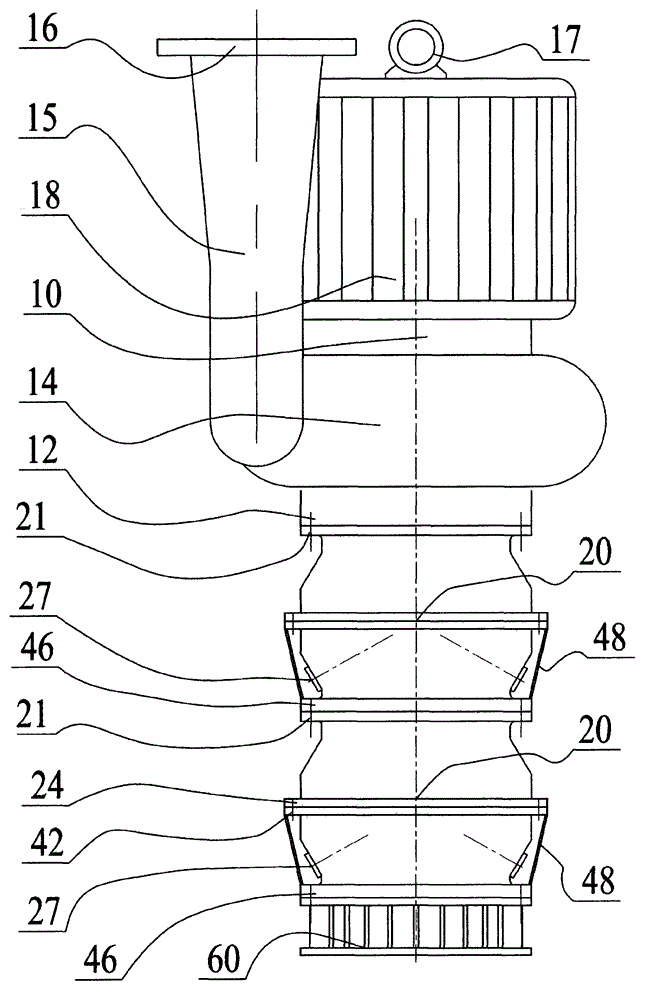

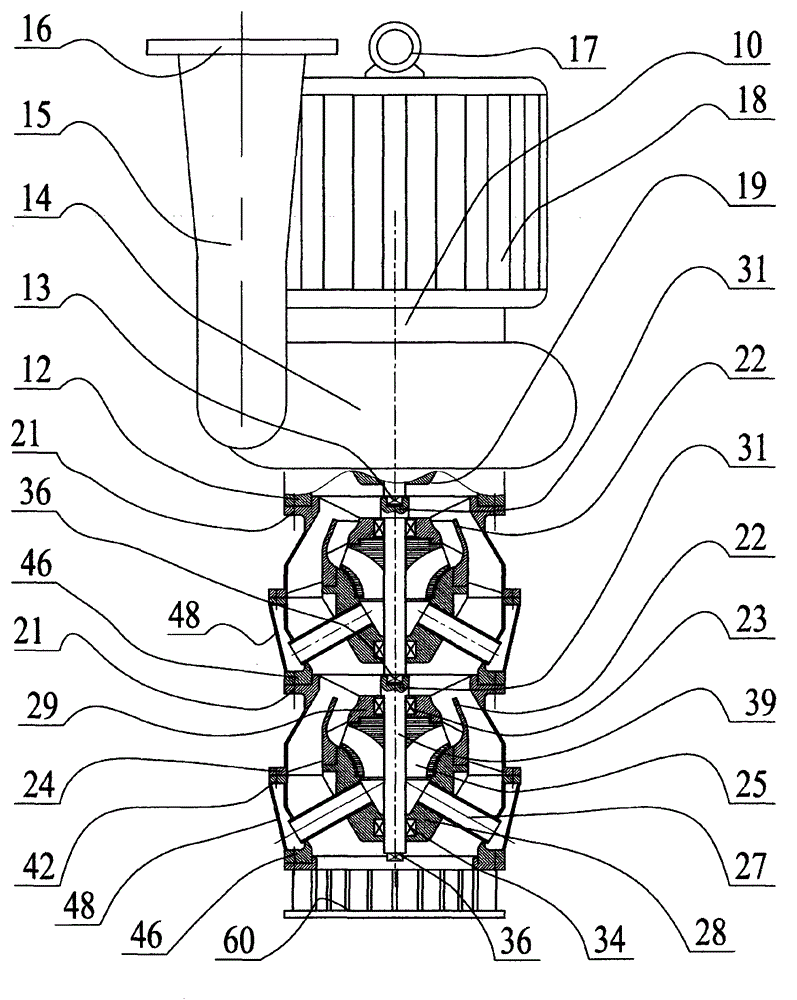

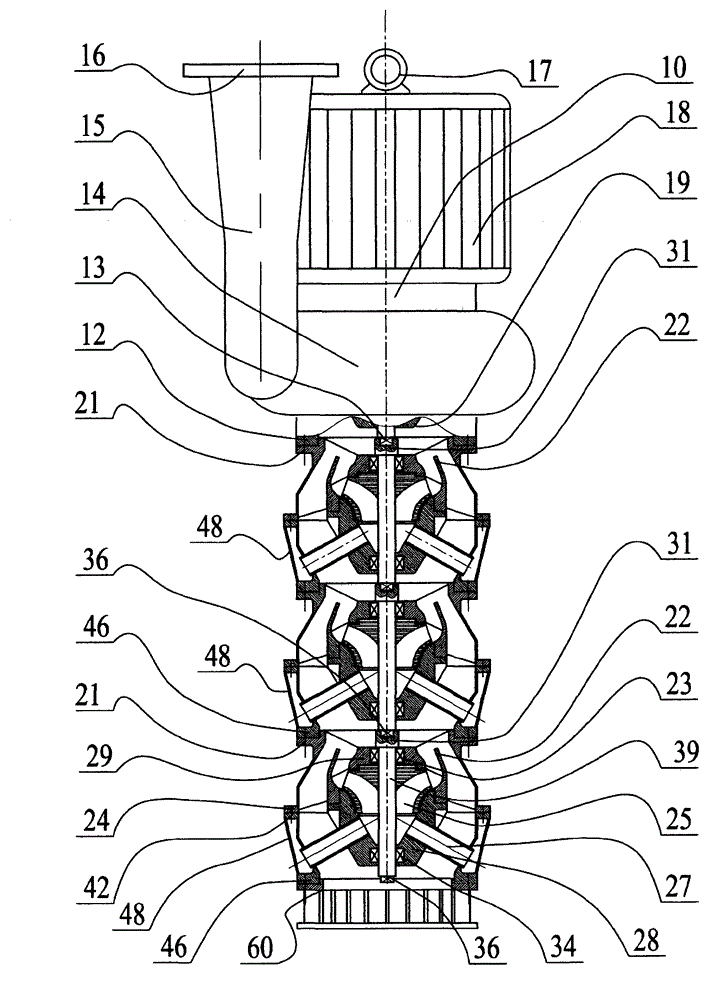

Novel centrifugal pump

InactiveCN102878090ANovel ideaSimple structurePump componentsPump installationsCentrifugal pumpFlange

The invention discloses a novel centrifugal pump. A waterproof variable-frequency motor is directly connected with a main pump, and one to three intermediate pumps are arranged between a main pump suction port and a fence filter. As an improvement, each intermediate pump is divided into an upper pump shell and a lower pump shell; each upper pump shell is connected with an upper pump inner bracket through three to six supporting rib plates; an annular isolation seat is crosswise connected with the supporting rib plates between the upper pump inner bracket and each upper pump shell; the outer circle of an upper bearing is also fixedly arranged in an inner hole of the upper pump inner bracket; each lower pump shell is connected with a lower pump inner bracket through three to six water suction pipes; the outer circle of a lower bearing is also fixedly arranged in an inner hole of the lower pump inner bracket; a peripheral filter screen covers outer ports of the water suction pipes between the outer edge of a lower shell intermediate flange of each lower pump shell and the outer edge of a lower shell outer flange; an upper shell intermediate flange of each upper pump shell is fixedly connected with the lower shell intermediate flange in a matching way; an inner hole of the upper bearing and an inner hole of the lower bearing are fixed with a coupling shaft together; a square groove is arranged at the upper end of the coupling shaft; a square boss is arranged at the lower end of the coupling shaft; and an impeller is positioned between the upper pump inner bracket and the lower pump inner bracket and is fixedly arranged on the coupling shaft.

Owner:NINGBO DAHONGYING UNIV

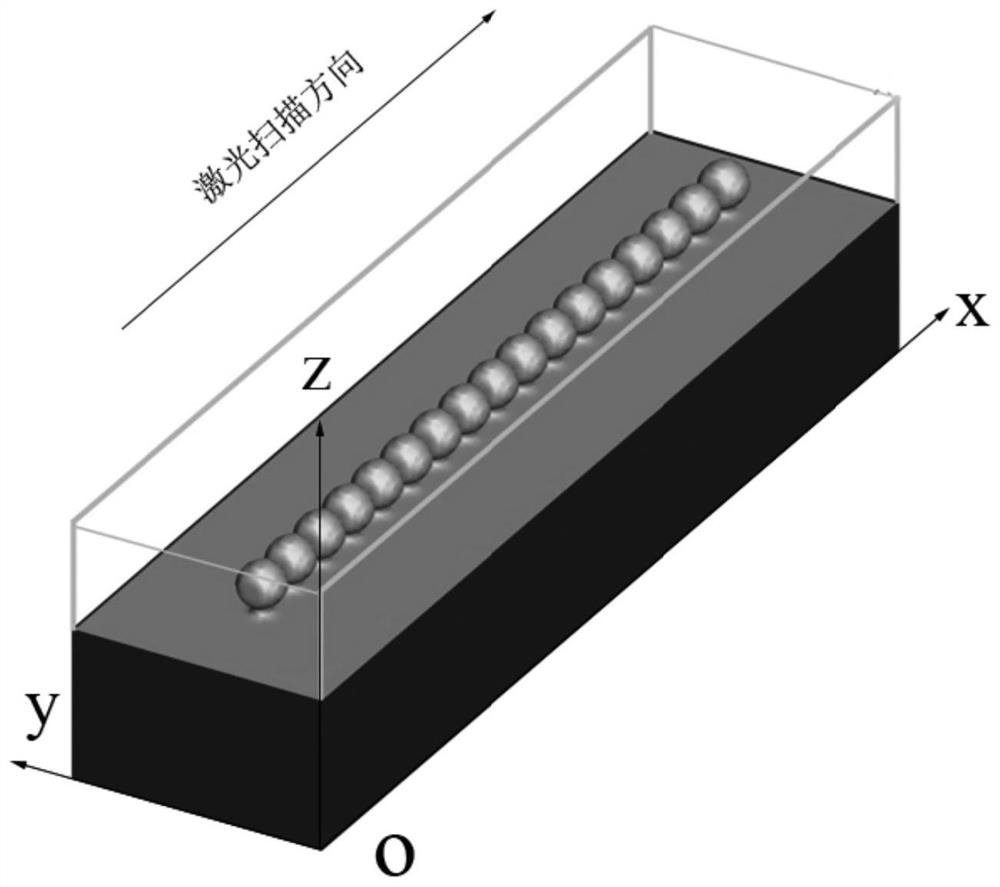

Numerical simulation method for microstructure evolution of magnesium alloy selective laser melting

InactiveCN113807033AAccurate Quantitative PredictionAccurate Quantification of Evolutionary ProcessesGeometric image transformationDesign optimisation/simulationSelective laser meltingMg alloys

The invention provides a numerical simulation method for microstructure evolution of magnesium alloy selective laser melting, which comprises the following steps of: simulating laser scanning by adopting a Gaussian surface heat source model; obtaining a flow field and a temperature field of a selective laser melting pool; applying a VOF method to track a free interface; selecting a specific two-dimensional section in a macroscopic geometric model to perform microstructure simulation calculation; respectively establishing an equiaxed crystal nucleation model in the molten powder and a nucleation model of columnar crystals epitaxially grown on the edge of the melting pool; respectively establishing a solid-phase solute diffusion model and a liquid-phase solute diffusion model; determining a growth kinetic model of dendritic crystals, and performing iterative calculation according to a cellular capture rule; and storing the data obtained by calculation, and carrying out visualization processing. The method can accurately and quantitatively predict the microstructure evolution process of the magnesium alloy in the selective laser melting process.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

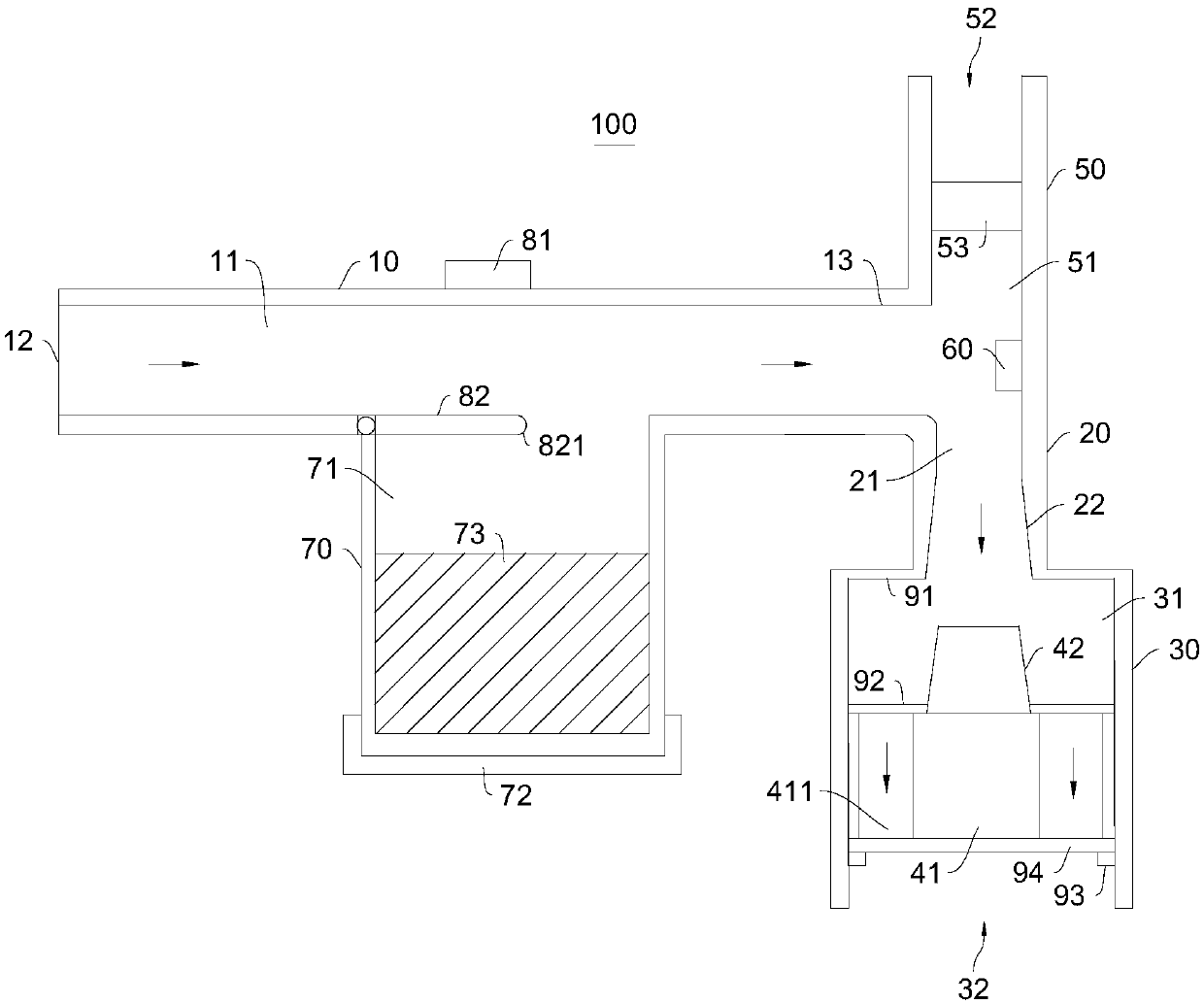

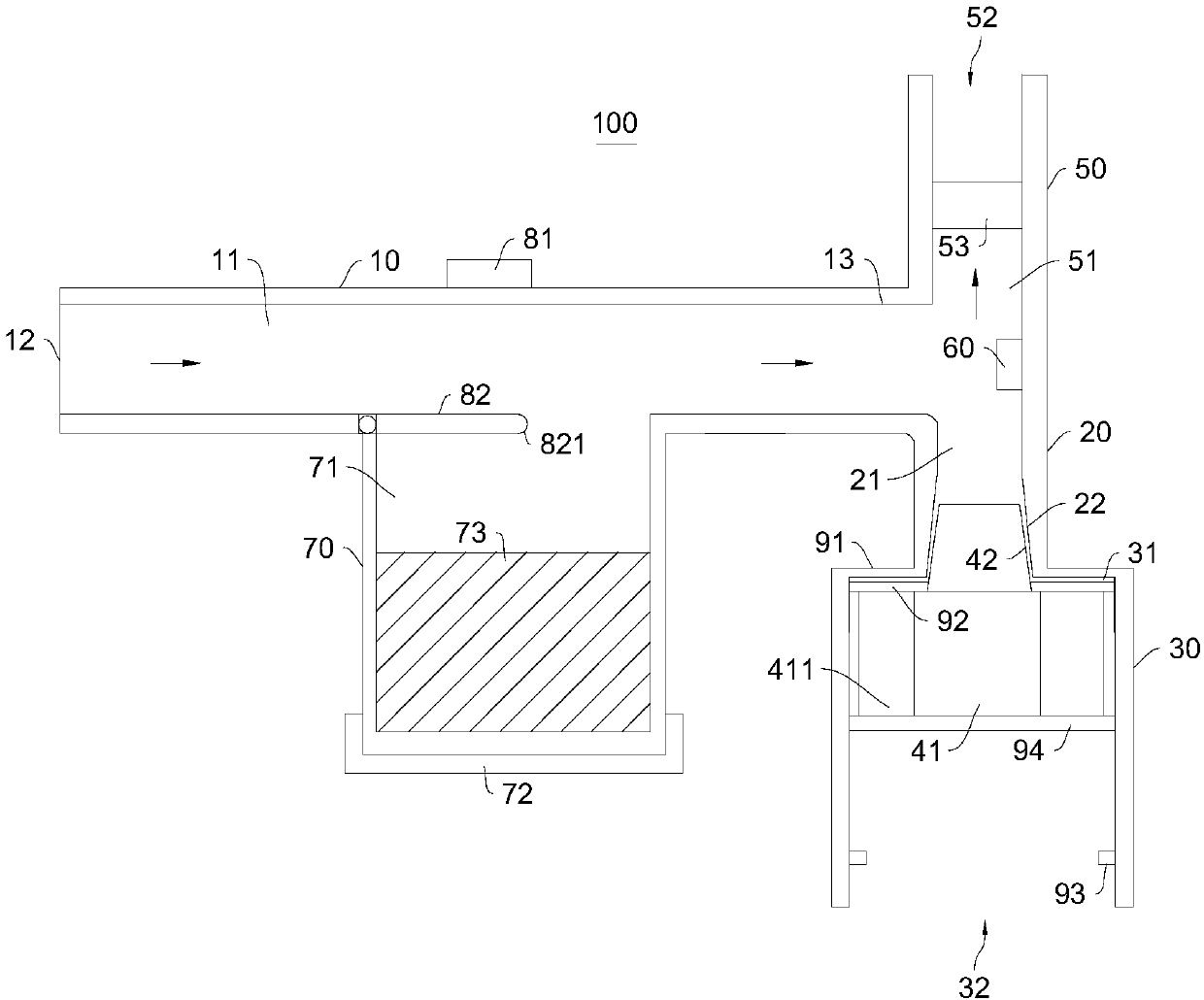

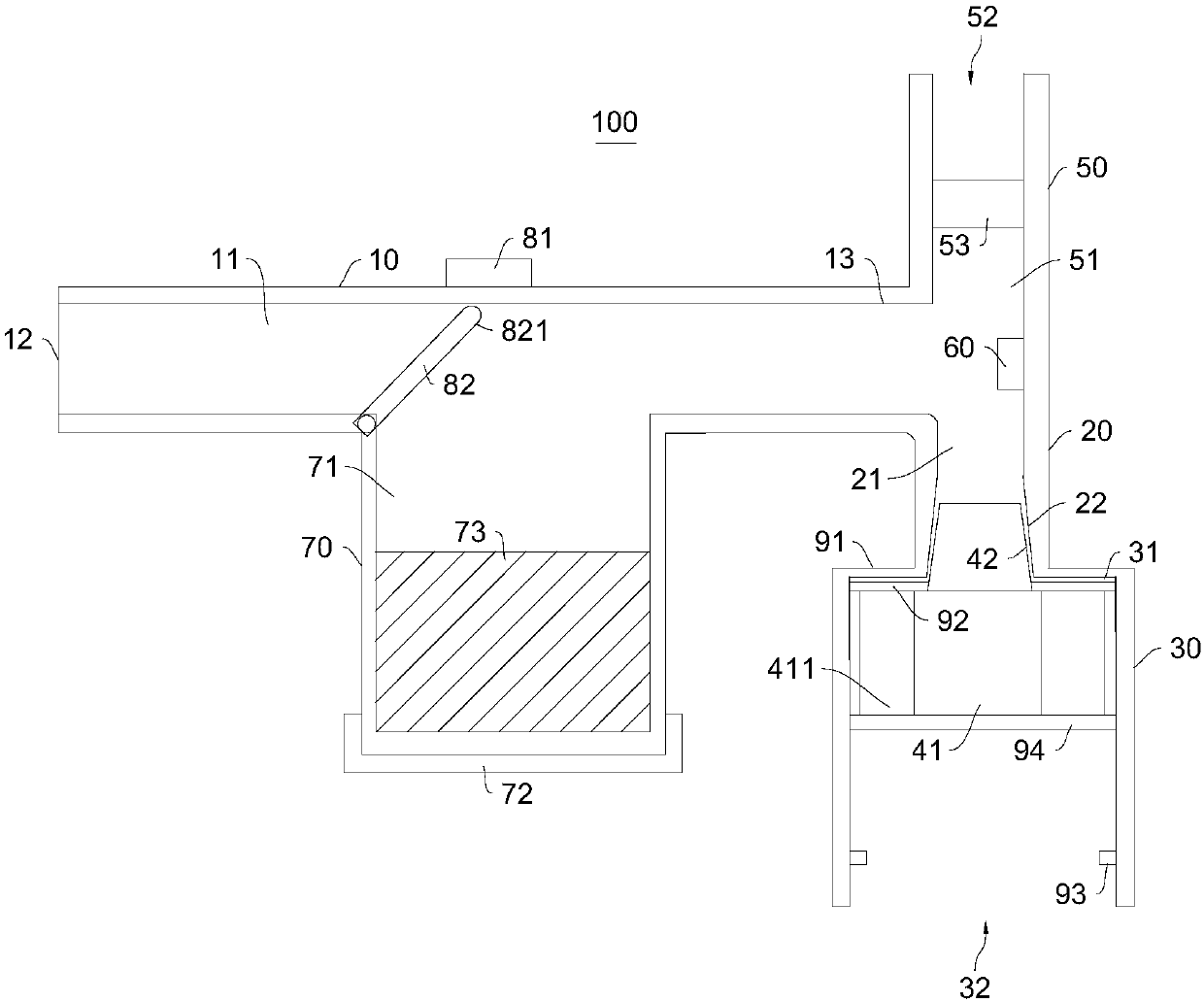

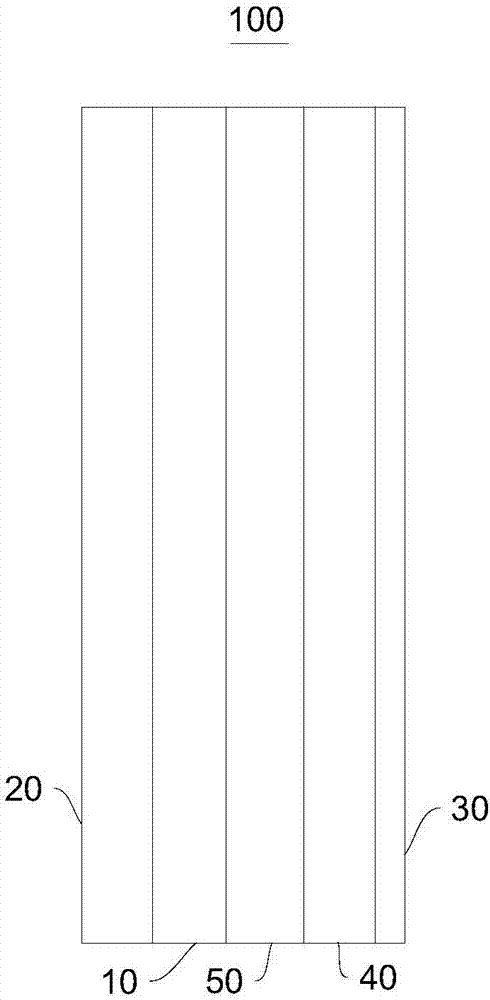

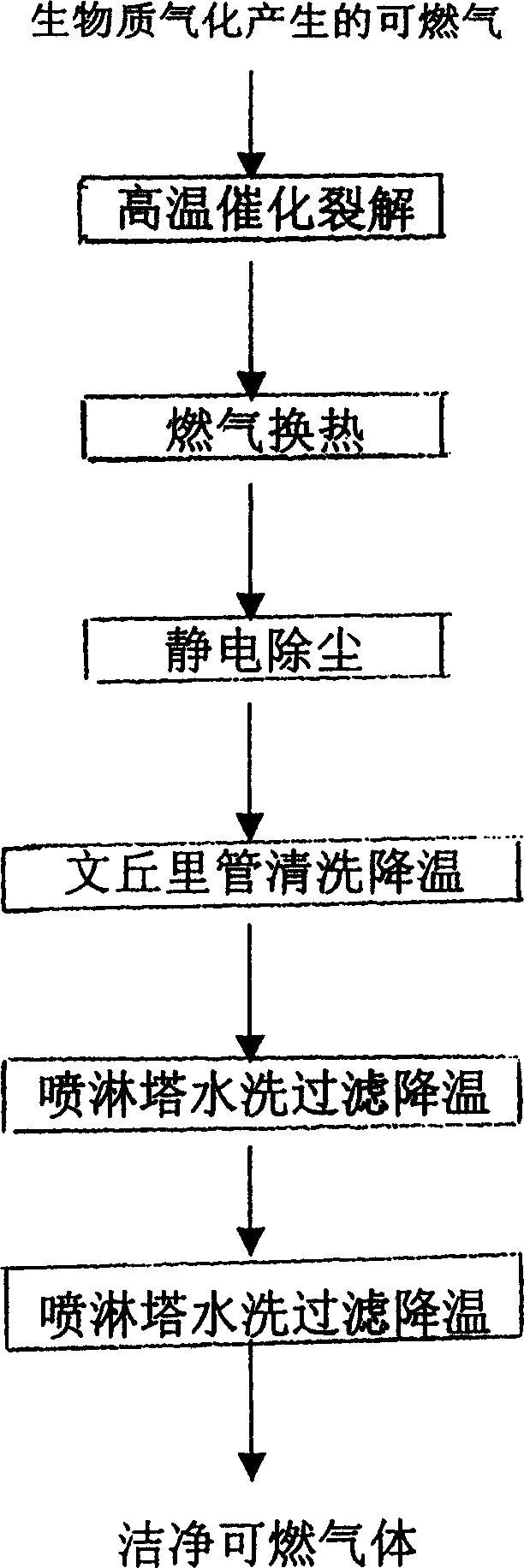

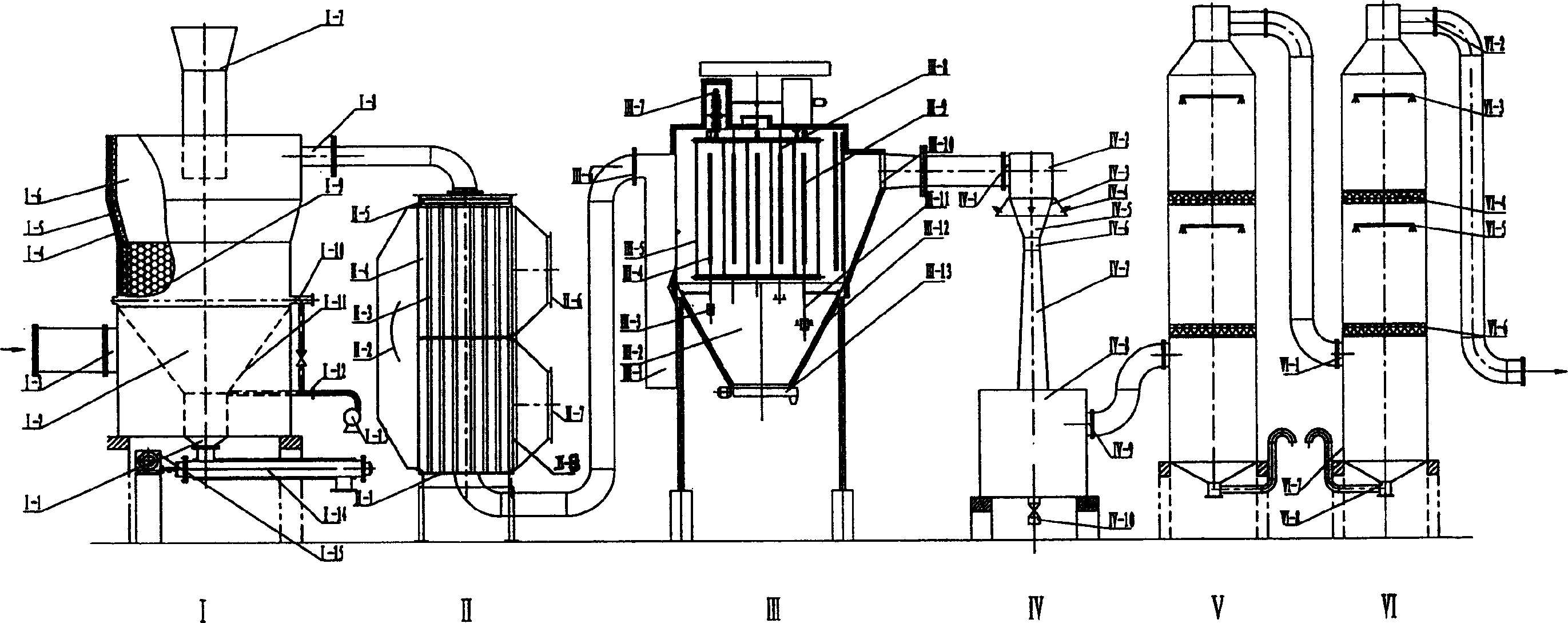

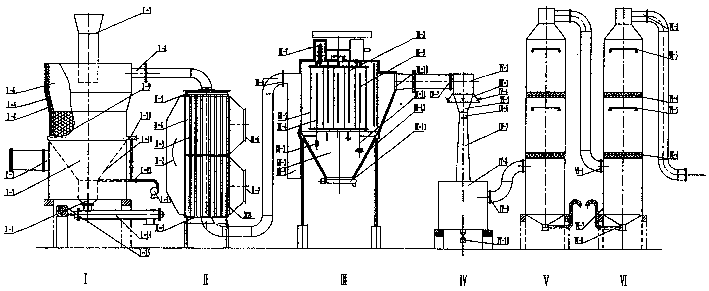

Cracking purification method for combustible gas by gasifying crude material

InactiveCN1190476CHigh temperature pyrolysisCalorific value stableCombustible gas catalytic treatmentPurification methodsDust control

A method of degrading and cleansing combustible gases produced during gasifying biological matters. It comprises) passing a cracking machine with a moving bed, the combustible gases will be cracked by high-temperature and catalysis in the charcoal bed at 800-1200degree C, most of tar is removed; b)reducing the temperature of combustible gases from 800degree C to 300-350degree C; c) dedusting by static electricity at a high-voltage electric field of 80000 volts, reducing the temperature to 250-300degree C; (d) washed by water, debusting and detarring, reducing the temperature to 60-80degree C; (E) washing, filtering and reducing the temperature to below 40degree C, the contents of tar and dust in the combustible gases will be reduced below 50mg / Nm3. The invention could remove completely dust and tar in combustible gases.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

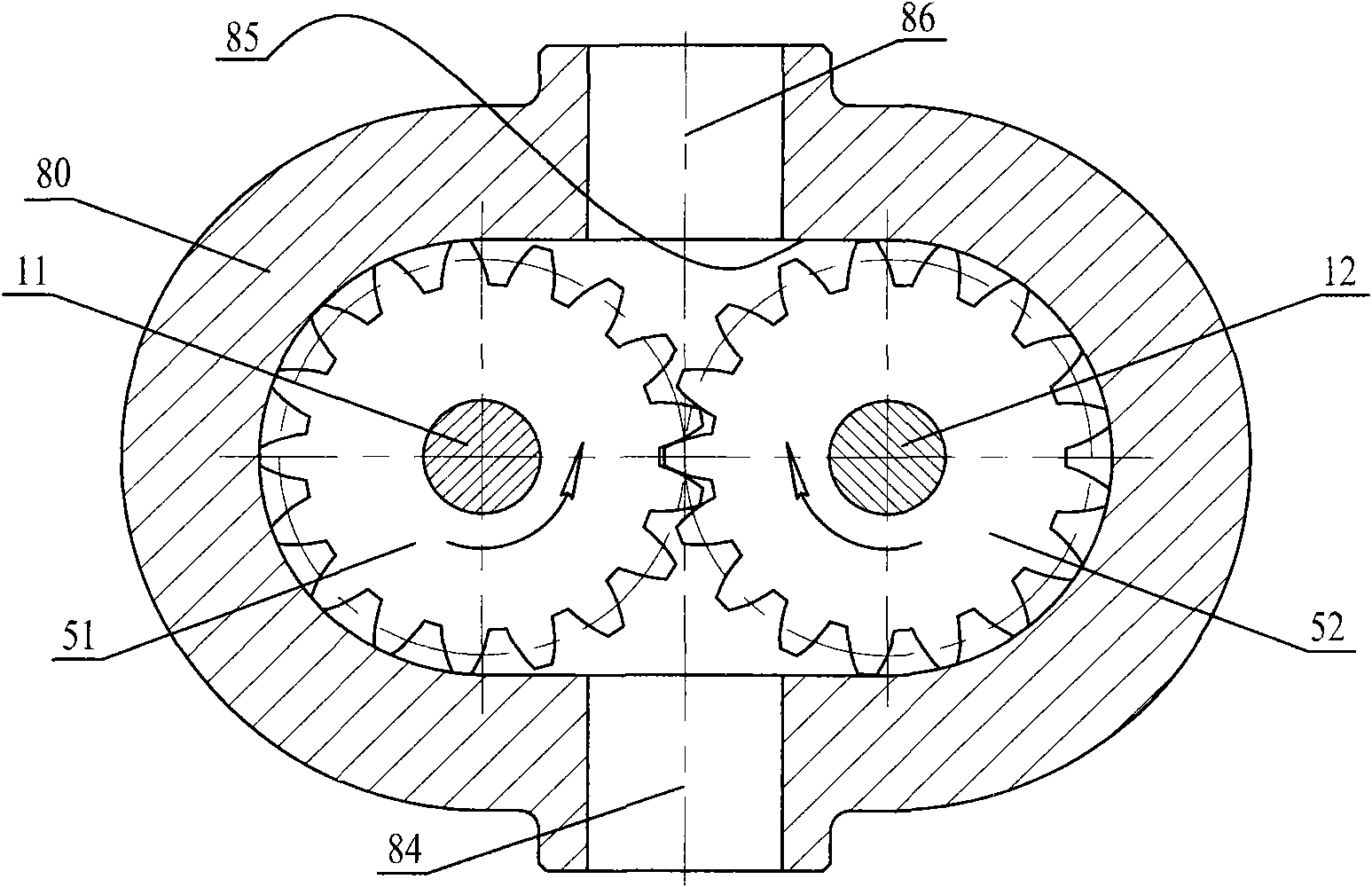

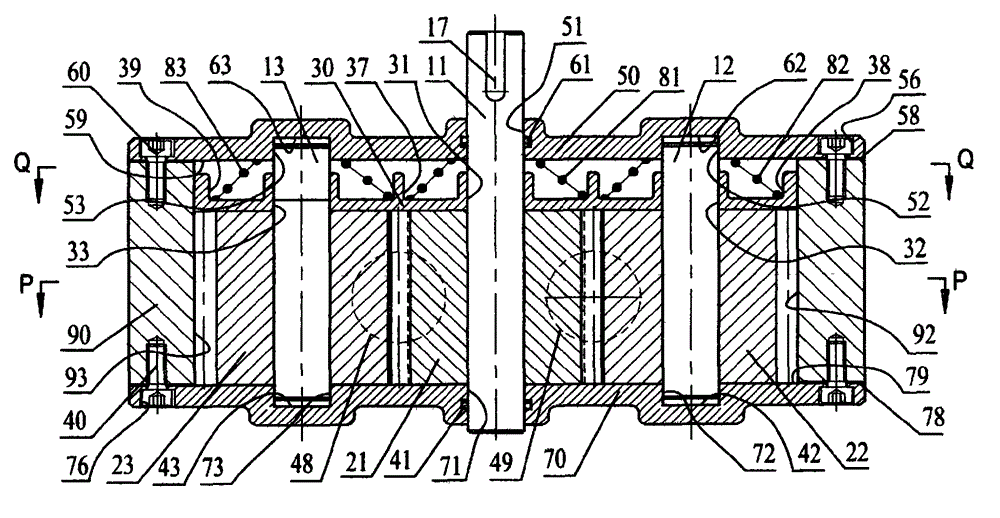

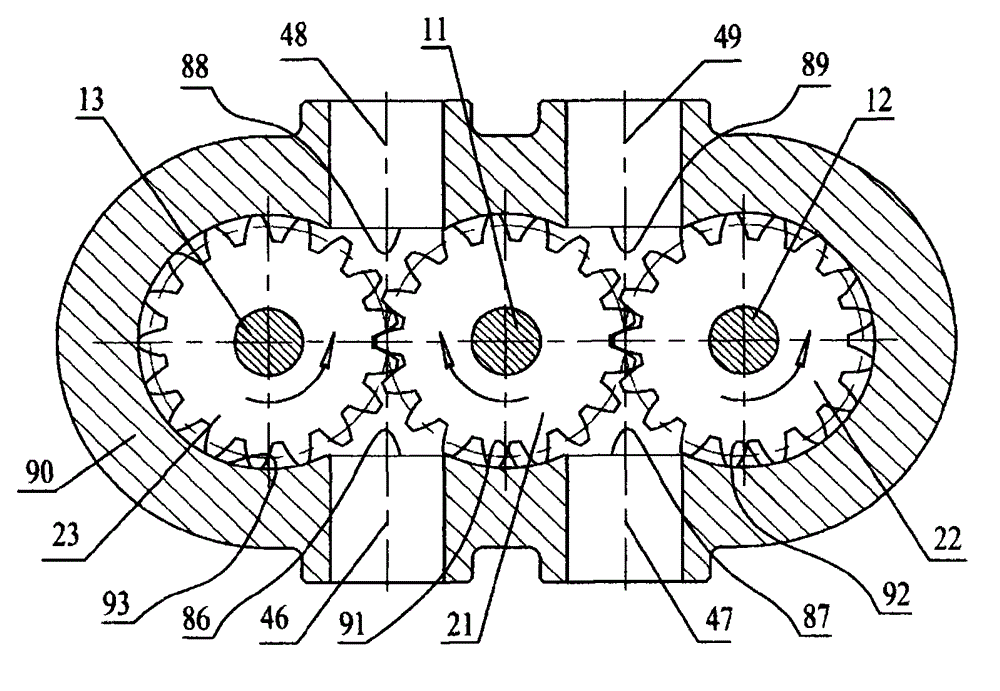

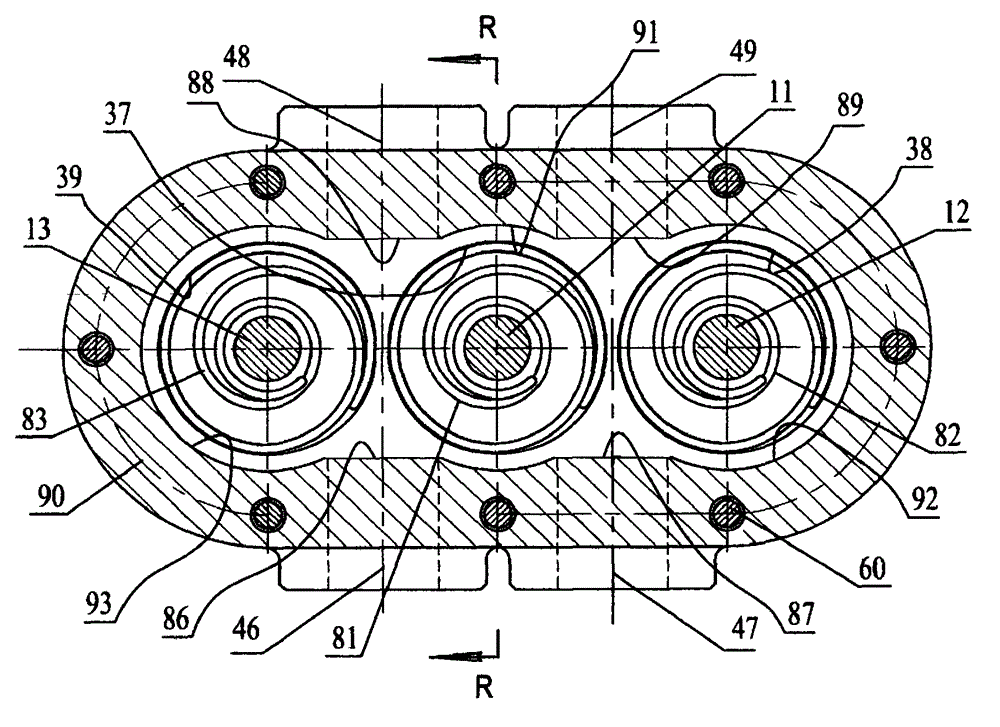

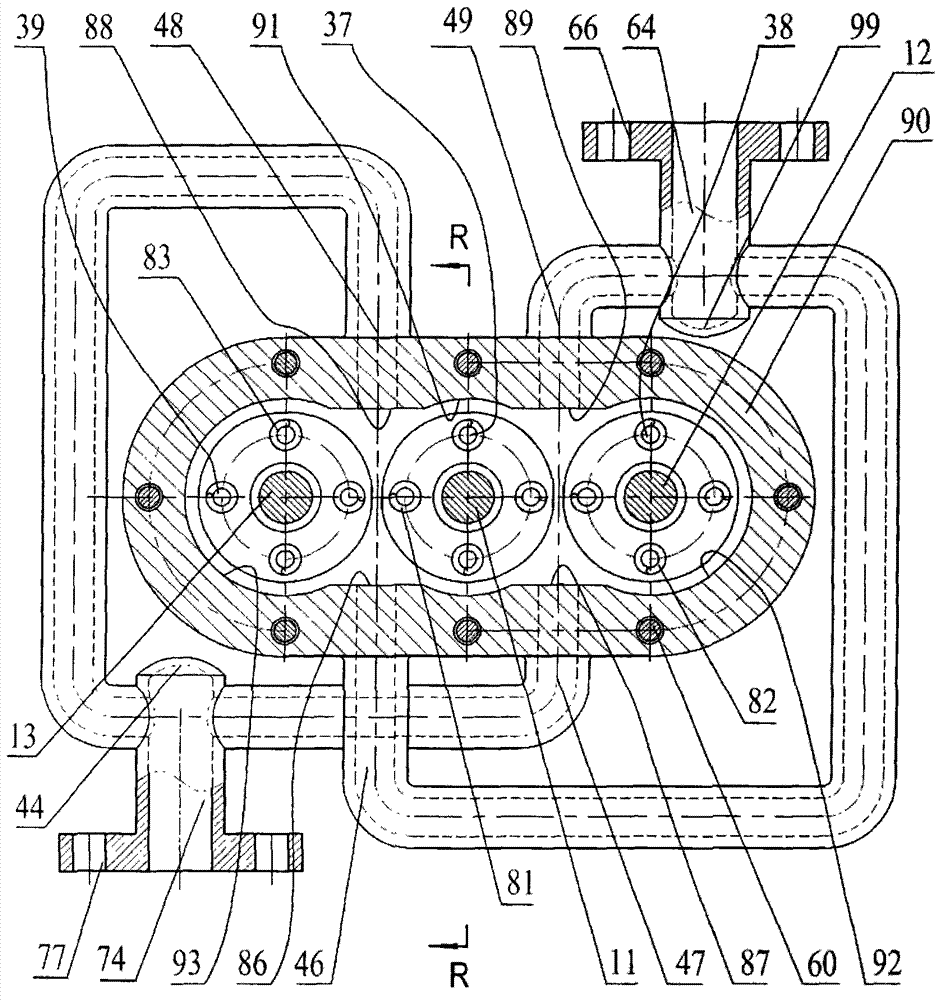

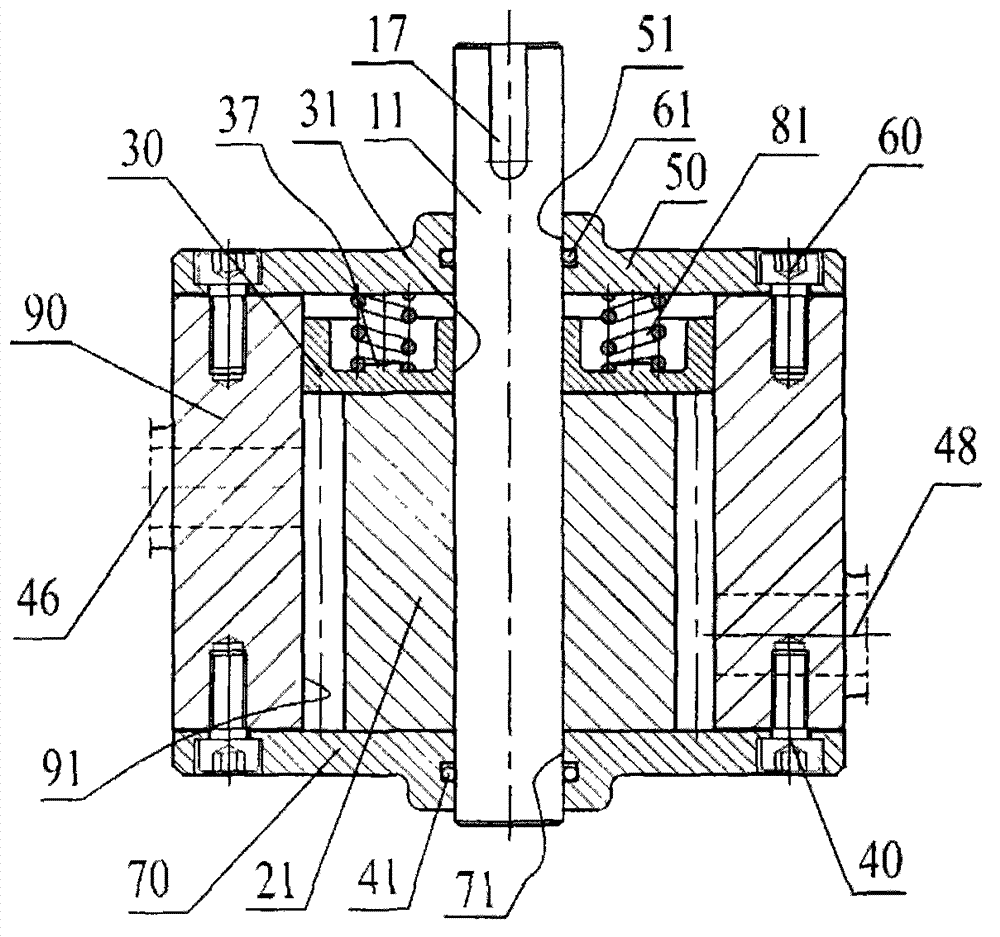

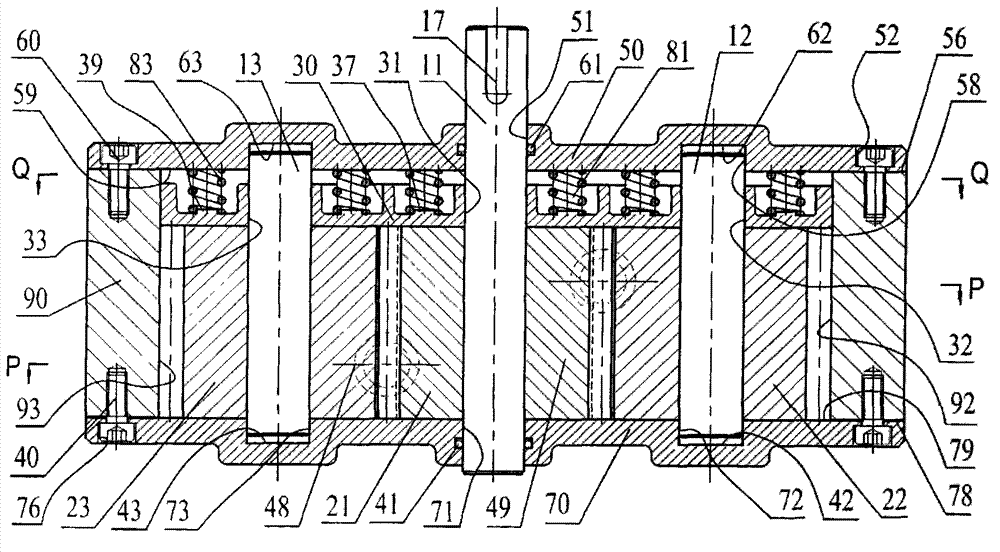

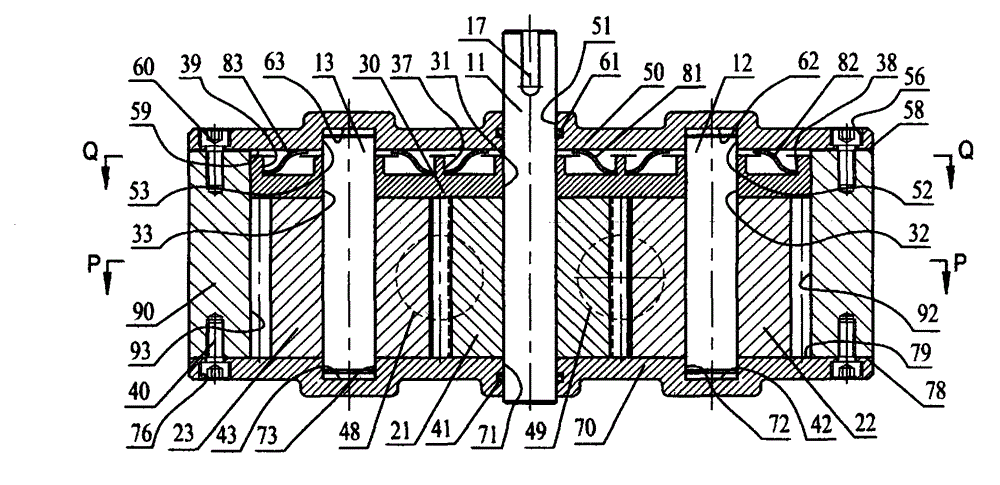

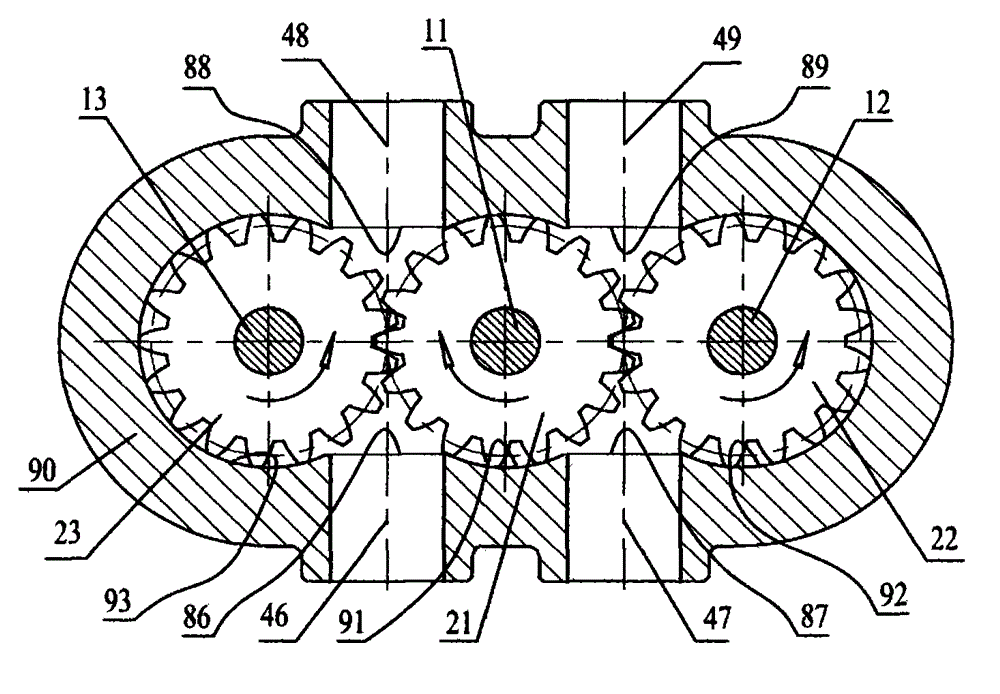

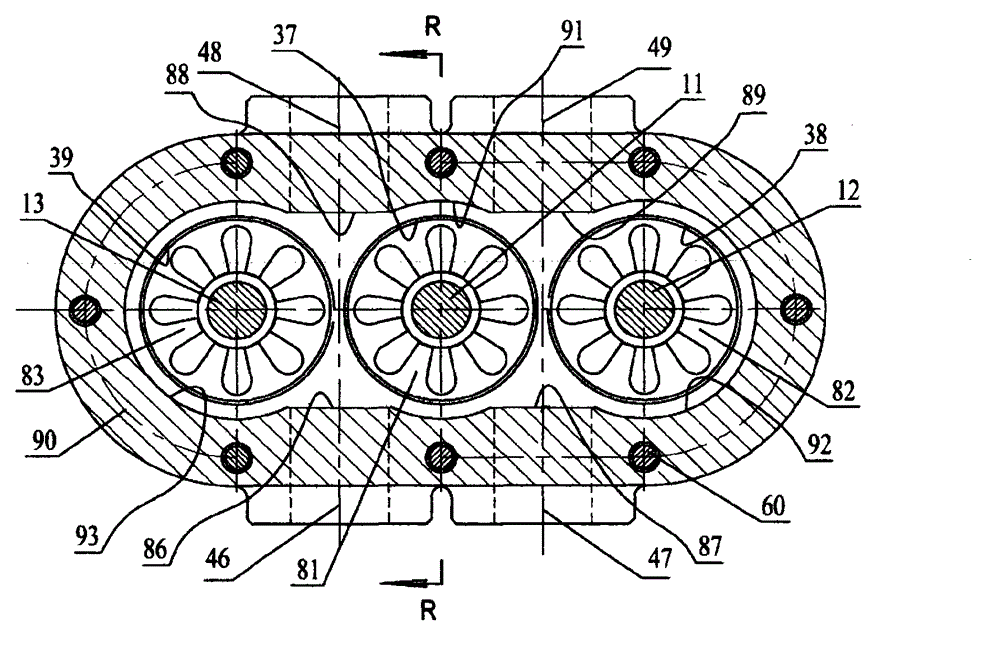

Special gear pump

InactiveCN102878071ASymmetrical force completely balancedFully balanced long runRotary piston pumpsRotary piston liquid enginesGear pumpDrive shaft

A special gear pump comprises a drive shaft, a right driven shaft, a left driven shaft, a main gear, a right driven gear, a left driven gear, a front outer end cover, a rear outer end cover, an intermediate conical spring, a right conical spring, a left conical spring and a pump body, wherein the improvement is that two central sections of arcs of an inner cavity of the pump body are in slide fit with an excircle of the main gear, a right large semi-arc of the inner cavity of the pump body is in slide fit with the excircle of the right driven gear, and a left large semi-arc of the inner cavity of the pump body is in slide fit with the excircle of the left driven gear; the drive shaft in the center of the main gear is parallel to the right driven shaft in the center of the right driven gear, and is also parallel to the left driven shaft in the center of the left driven gear; an inner plane of a rear cover of the rear outer end cover is closely fixed on the rear end face of the pump body; the inner plane of the front cover of the front outer end cover is closely fixed on the front end face of the pump body; and the right plane of a compensating disc on the end face is attached to the gear, the right driven gear and the left driven gear at the same time, and the intermediate conical spring, the right conical spring and the left conical spring are respectively arranged between the back side of the compensating disc on the end face and an inner plane of a front outer end.

Owner:张意立

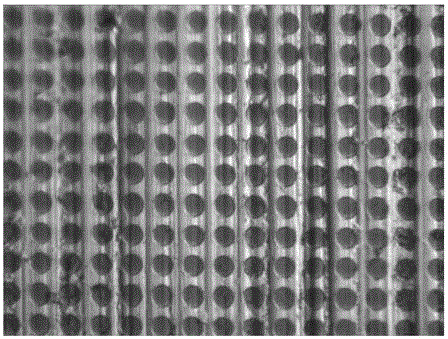

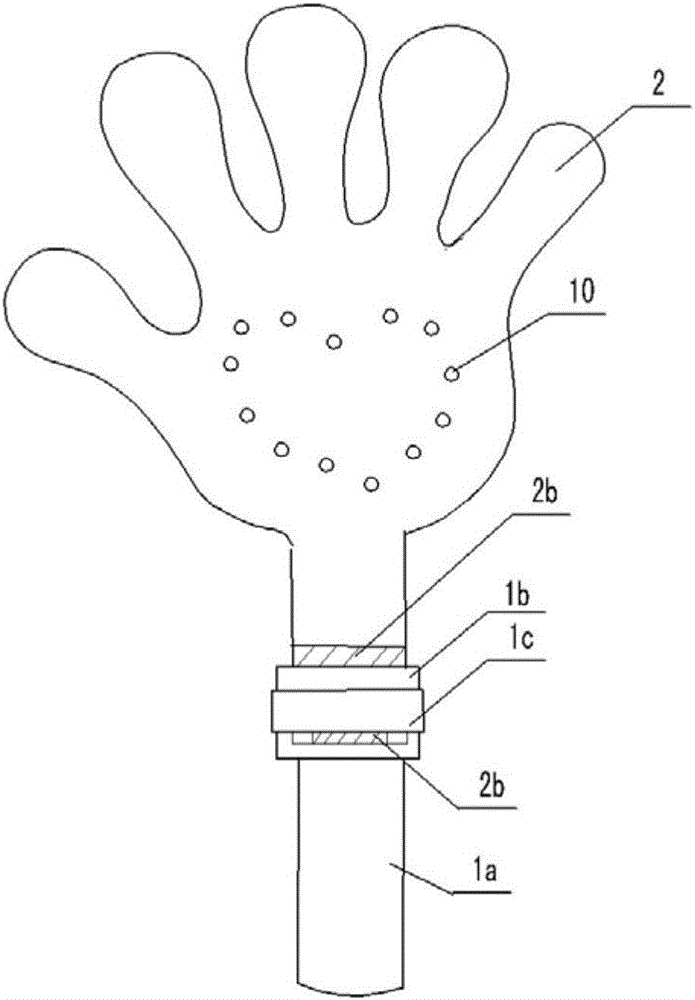

Self-driven luminescence applauding device based on friction nanometer motors and preparation method of applauding device

PendingCN106730882ARealize self-driven lighting effectReduce dependenceMusical toysFriction generatorsNanogeneratorMechanical energy

The invention discloses a self-driven luminescence applauding device based on friction nanometer motors and a preparation method of the applauding device. The applauding device comprises two palms and at least one friction nanometer motor, and each friction nanometer motor is formed by two friction parts which are fixed on the beating surfaces of the palms respectively; the first friction part is a flexible substrate where a metal aluminum sheet and a PDMS film are fixed sequentially, and array type PDMS bulges are integrally formed on the surface of the PDMS film; the second friction part is a flexible substrate where a metal aluminum sheet is fixed, and array type aluminum bulges are arranged on the metal aluminum sheet; electrodes are led out from the metal aluminum sheets of the two friction parts and connected with the pins of light emitting diodes respectively; mechanical energy is formed when the two palms are clapped, and the friction nanometer motors convert the mechanical energy into electric energy so that the light emitting diodes can illuminate. The self-driven luminescence applauding device is simple in structure and stable in performance and has a wide application prospect.

Owner:HEFEI UNIV OF TECH

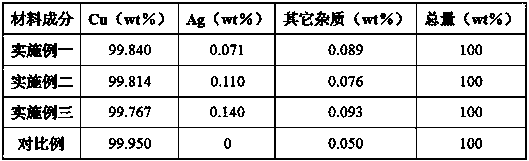

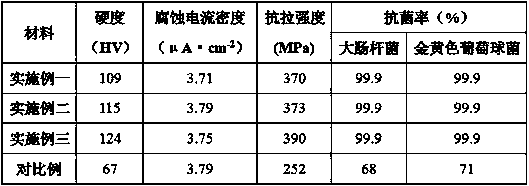

Silver-containing anti-bacteria copper alloy and preparation method thereof

InactiveCN108842092AImprove antibacterial propertiesNo pollution in the processEscherichia coliStaphylococcus aureus

The invention discloses silver-containing anti-bacteria copper alloy and a preparation method thereof and belongs to the technical field of metal materials. Based on the fact that the sum of the weight percentages is 100%, the silver-containing anti-bacteria copper alloy comprises, by weight percentage, 0.07%-0.15% of silver, 99.75%-99.92% of copper and 0.01%-0.1% of other impurities; and the silver-containing anti-bacteria copper alloy is prepared through a vacuum induction smelting method. The preparation technology of the silver-containing anti-bacteria copper alloy is simple and easy to implement; the mechanical performance and corrosion resistance are excellent; the obvious anti-bacteria performance advantage is achieved compared with oxygen-free copper; the anti-bacteria effect is greater than 99.9% for escherichia coli and staphylococcus aureus; the effect is remarkable; and the remarkable economic and social benefits are achieved.

Owner:FUZHOU UNIV

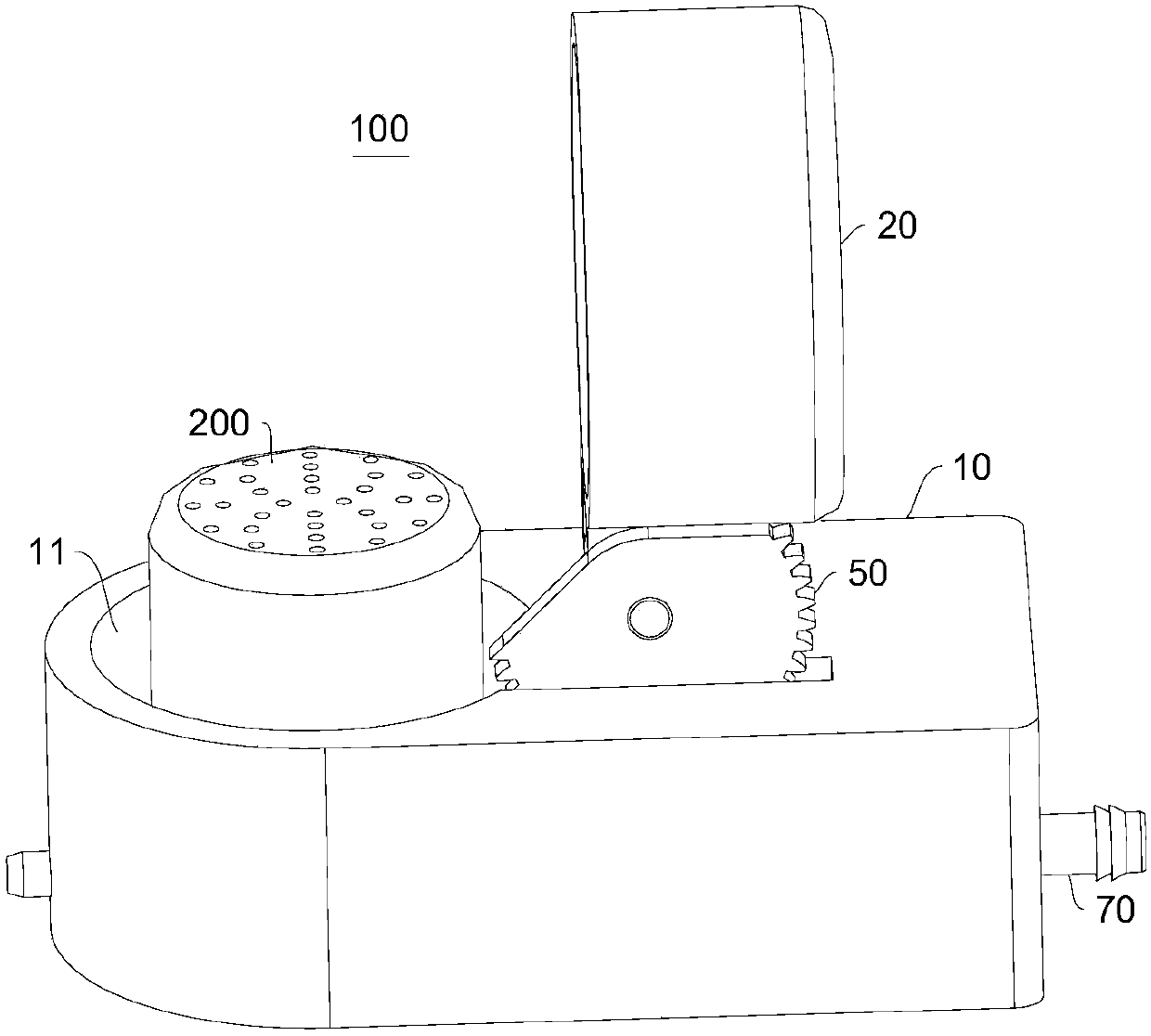

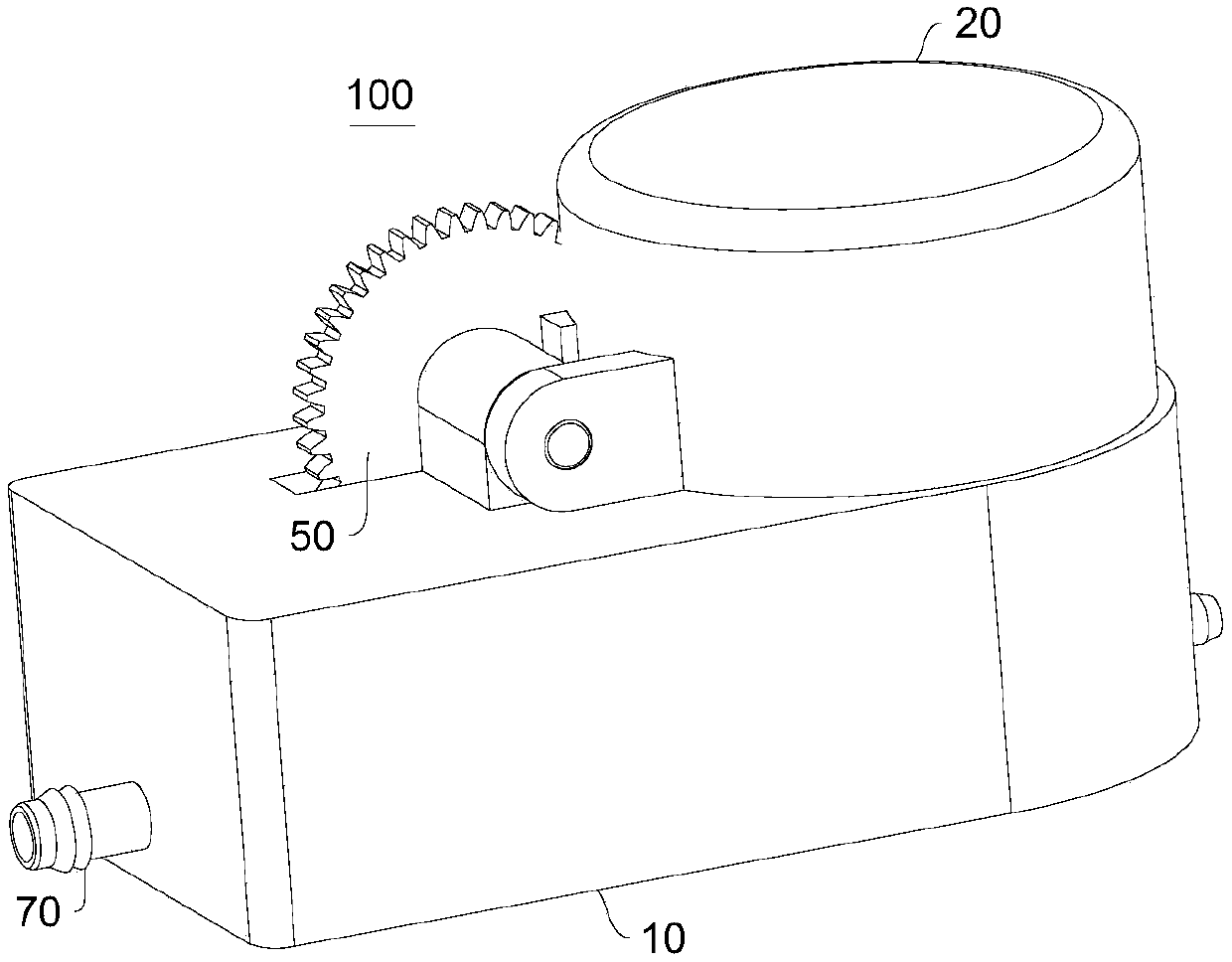

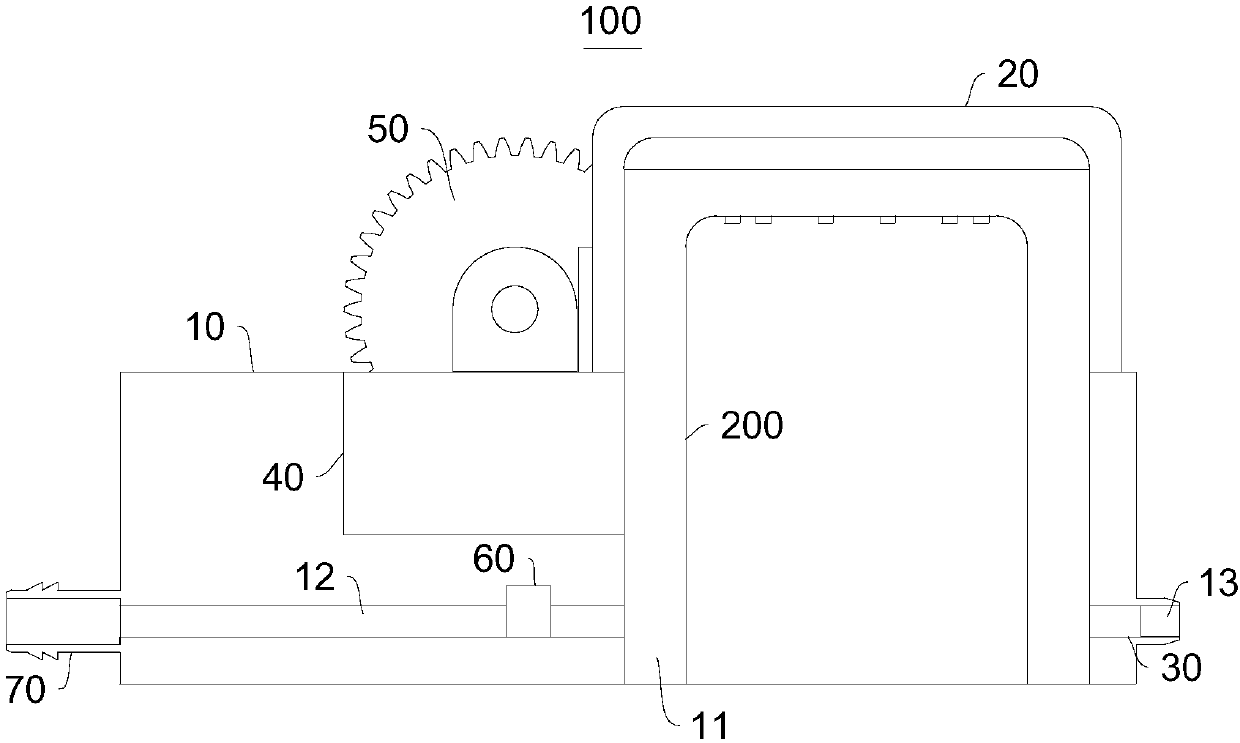

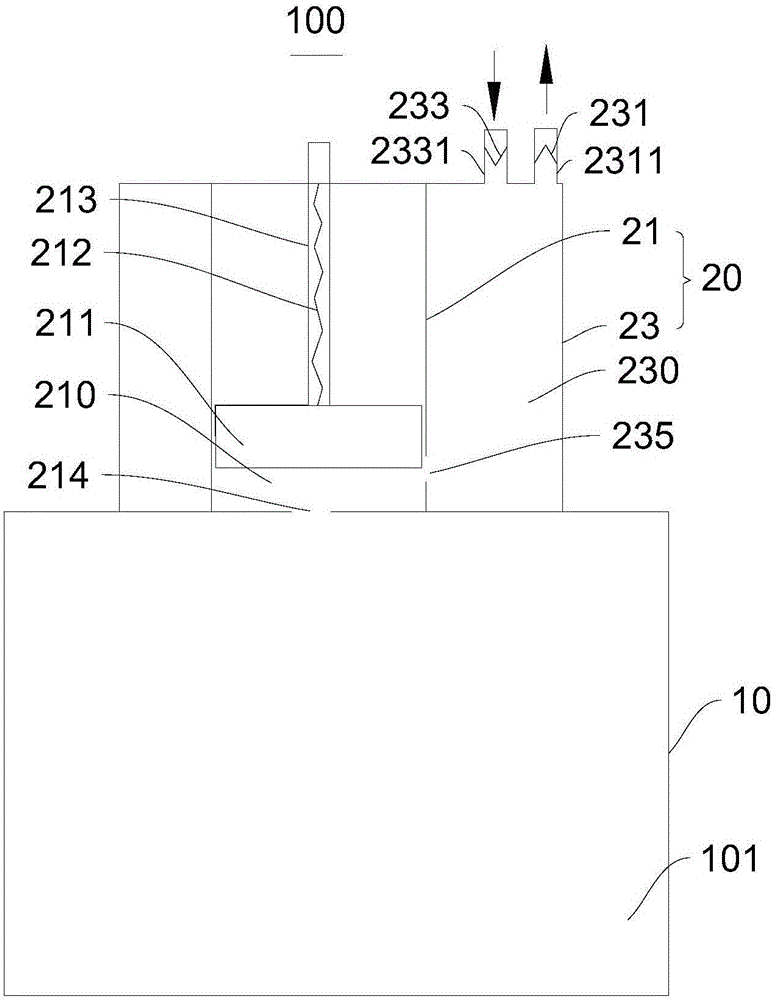

Protection device and sensor structure

PendingCN108037164AExtended service lifeReasonable structural designMaterial electrochemical variablesEngineeringTotal function

The invention provides a protection device and a sensor structure and belongs to the technical field of electrochemical sensors. The protection device comprises a fixed seat and a movable top cover, wherein the fixed seat is provided with an accommodating groove used for accommodating an electrochemical sensor; the movable top cover is rotationally connected with the fixed seat, the fixed seat isprovided with an air inlet channel and an air exhaust channel both communicated with the accommodating groove, and the air inlet channel is used for inputting protective gas and allowing gas in the accommodating groove to be discharged from the air exhaust channel. The protection device can open the accommodating groove when needed, so that the electrochemical sensor is exposed in an external space for normal work; when not needed, the electrochemical sensor is protected, so that the service life of the electrochemical sensor is favorably improved. The sensor structure comprises the protectiondevice and has all functions of the protection device.

Owner:广州承葛生物科技有限公司 +1

Double-flange cylinder spring gear pump

ActiveCN102900667AFirmly connectedSymmetrical force completely balancedRotary piston pumpsRotary piston liquid enginesGear pumpDrive shaft

The invention relates to a double-flange cylinder spring gear pump. A left inlet pipeline and a right inlet pipeline are converged into an oil inlet header pipe provided with an inlet pipe flange; a left outlet pipeline and a right outlet pipeline are converged into an oil outlet header pipe provided with an outlet pipe flange; two arcs at the center of the inner cavity of a pump body and the excircle of a driving gear are in sliding fit, and the right large semicircle of the inner cavity of the pump body and the excircle of a right driven gear are in sliding fit; a driving shaft at the center of a driving gear and a right driven shaft at the center of the right driven gear are parallel to each other, the driving shaft at the center of the driving gear and a left driven shaft at the center of the left driven gear are parallel to each other; the inner plane of the rear cover of a rear outer end cap is tightly fixed on the rear end face of the pump body; the inner plane of the front cover of a front outer end cover is tightly fixed on the front end face of the pump body; and the frontal plane of an end face compensating disc is attached to the driving gear, the right driven gear and the left driven gear, and a middle cylinder spring, a right cylinder spring and a left cylinder spring are respectively arranged between the back of the end face compensating disc and the inner plane of the front outer end face.

Owner:苏州盛泽科技创业园发展有限公司

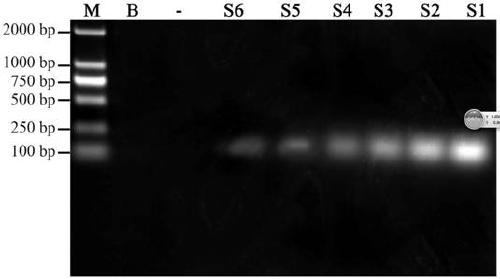

Kit for detecting HSV-2 nucleic acid

InactiveCN109609699AHigh specificityGood repeatabilityMicrobiological testing/measurementMicroorganism based processesImage resolutionHerpes simplex disease

The invention discloses a kit for detecting HSV-2 nucleic acid, comprising a specific primer pair HSV2-F and HSV2-R for detecting herpes simplex virus type 2, a fluorescent probe HSV2-P and a positivequality control substance. Both ends of the probe are modified separately, the 5' end is labeled with report fluorescein or fluorescent dye, and the 3' end is labeled with any minor groove binder without a fluorescent background. The positive quality control substance is a solution of a recombinant PUC57 plasmid containing a herpes simplex virus type 2 HSV-2 target gene gG sequence. The kit of the invention has the characteristics of fast and accurate detection, high resolution, high specificity, high efficiency and low cost, can realize qualitative detection of herpes simplex virus type 2 HSV-2, and has wide clinical application values.

Owner:ZHEJIANG PROVINCIAL PEOPLES HOSPITAL

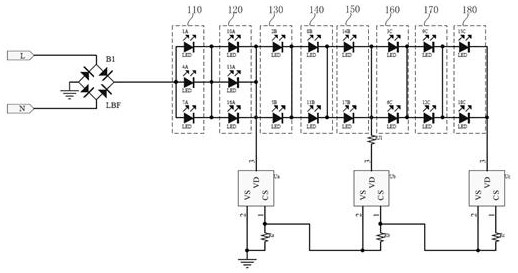

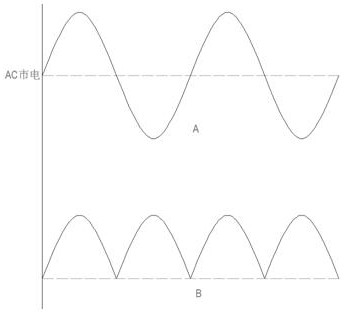

Silicon controlled rectifier adjusting circuit of high-voltage lamp strip

InactiveCN111615235AReduce installation difficultyIncrease brightnessElectrical apparatusSilicon-controlled rectifierFull bridge

The invention discloses a silicon controlled rectifier adjusting circuit of a high-voltage lamp strip. The silicon controlled rectifier adjusting circuit comprises a live wire input end, a zero line input end, a full-bridge rectification module, a first group of LED circuit modules, a second group of LED circuit modules, a third group of LED circuit modules, a first silicon controlled rectifier chip, a second silicon controlled rectifier chip and a third silicon controlled rectifier chip. The lamp strip comprises a plurality of minimum lamp strip units, the minimum lamp strip units are arranged in parallel, and each minimum lamp strip unit comprises the silicon controlled rectifier adjusting circuit of the high-voltage lamp strip in any embodiment. According to the silicon controlled rectifier adjusting circuit of the high-voltage lamp strip, the defects of the application of an existing LED lamp strip are overcome, an external large-size power supply is removed, and the LED lamp stripis directly connected to the mains supply for use, so that the LED lamp strip is free of driving, the installation difficulty is reduced, and the silicon controlled rectifier adjusting circuit of thehigh-voltage lamp strip can be well applied to a narrow space and is not limited by the size and power adaptation of the power supply. The silicon controlled rectifier adjusting circuit of the high-voltage lamp strip is compatible with the existing silicon controlled rectifier dimming circuits, and saves the application cost.

Owner:GUANGDONG MICROVIEW TECH CO LTD

Pressure holding gear pump

InactiveCN102878072ASymmetrical force completely balancedSymmetrical force completely symmetrical and evenRotary piston pumpsRotary piston liquid enginesGear pumpDrive shaft

The invention relates to a pressure holding gear pump. The pressure holding gear pump comprises a driving shaft, a right driven shaft, a left driven shaft, a driving gear, a right driven gear, a left driven gear, a front outer end cover, a back outer end cover, a middle ring bar spring, a right ring bar spring, a left ring bar spring and a pump body. The pressure holding gear pump has the following improvements that two sections of arcs in the center of an inner cavity of the pump body are in sliding fit with the excircle of the driving gear; the right majority circular arc in the inner cavity of the pump body is in sliding fit with the excircle of the right driven gear; the left majority circular arc in the inner cavity of the pump body is in sliding fit with the excircle of the left driven gear; the driving shaft in the center of the driving gear is parallel to the right driven shaft in the center of the right driven gear, and the driving shaft in the center of the driving gear is parallel to the left driven shaft in the center of the left driven gear; an inner plane of a back cover of the back outer end cover is hermetically fixed on the back end face of the pump body; an inner plane of a front cover of the front outer end cover is hermetically fixed on the front end face of the pump body; and a horizontal frontal plane of an end face compensation disk keeps close to the driving gear, the right driven gear and the left driven gear at the same time, and the middle ring bar spring, the right ring bar spring and the left ring bar spring are respectively arranged between the back surface of the end face compensation disk and the inner side plane of the front outer end cover.

Owner:张意立

Extraction process of cordyceps polysaccharide

The invention provides an extraction process of cordyceps polysaccharide, comprising extraction of the polysaccharide and purification of the polysaccharide. The extraction process herein enables cordyceps polysaccharide to be effectively extracted; the cost is lowered; the extraction process has important economic valve and great market application potential and is suitable for industrial production.

Owner:FOSHAN UNIVERSITY

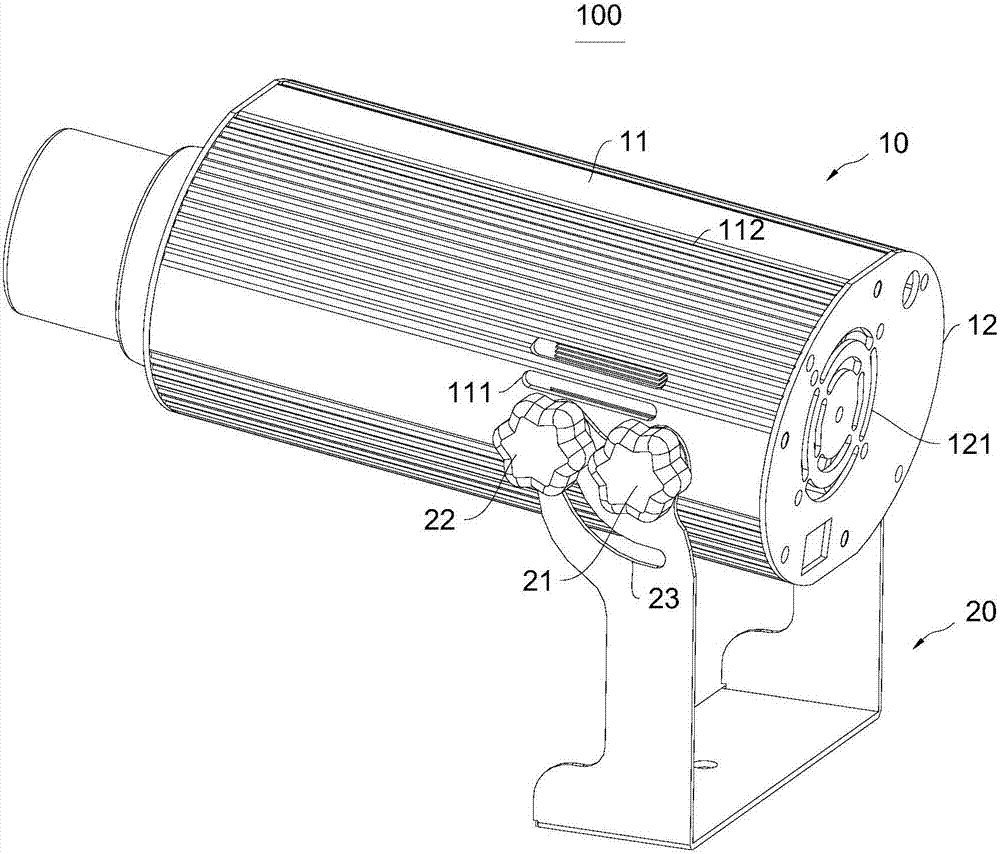

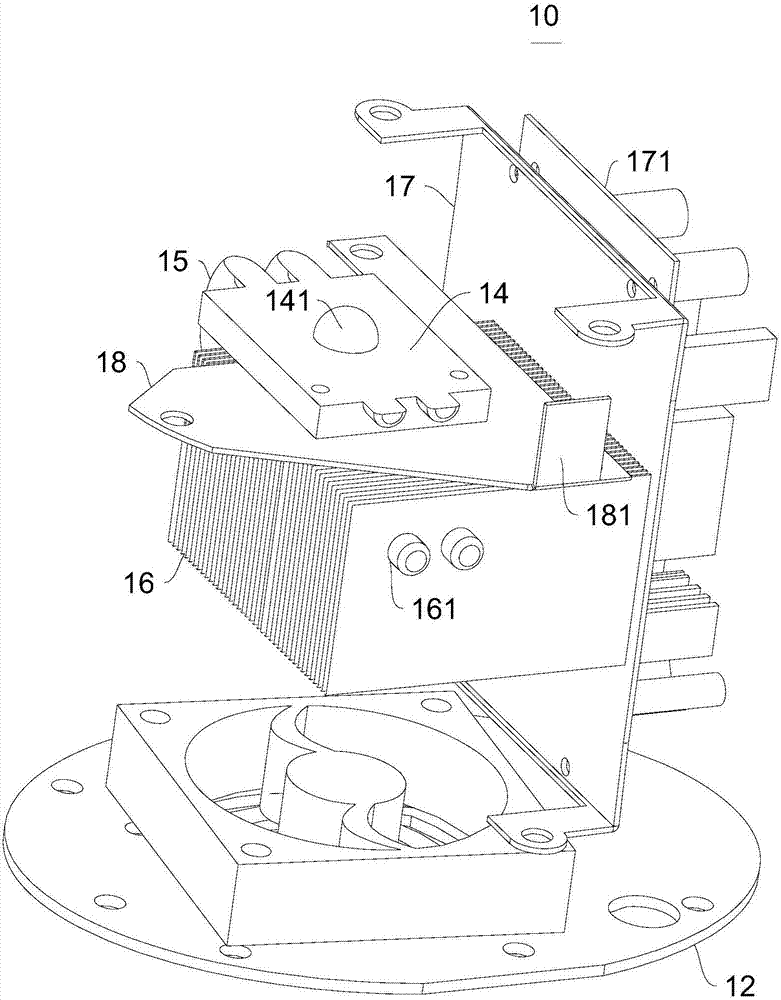

Projection lamp and projection device

InactiveCN107289377ASuitable temperatureExtended service lifeElectric circuit arrangementsLighting heating/cooling arrangementsCooling effectEngineering

The invention provides a projection lamp and projection equipment, belonging to the technical field of lamps. The projection lamp includes a supporting frame, a lamp frame, a heat conducting member and a cooling block. The cooling block includes a plurality of stacked and spaced cooling fins. The lamp frame is connected to the supporting frame. The cooling block is provided with fixing holes along the stacking direction of the cooling fins. Through the heat dissipation block, one end of the heat conduction element is connected to the lamp holder, and the other end of the heat conduction element extends into the fixing hole so that the heat conduction element and the heat dissipation block are relatively fixed. The projection lamp can guide the heat generated by the LED lamp on the lamp stand to the heat sink through the heat conducting part, and use the heat sink to achieve the effect of heat dissipation. Always maintain a suitable temperature, which can effectively prolong the service life of the LED lamp, the overall use effect is better, and the use cost is greatly reduced. The structure design is reasonable, and its market application potential is huge. The projection device includes a projection lamp, which has all the functions of the projection lamp.

Owner:曾民霖

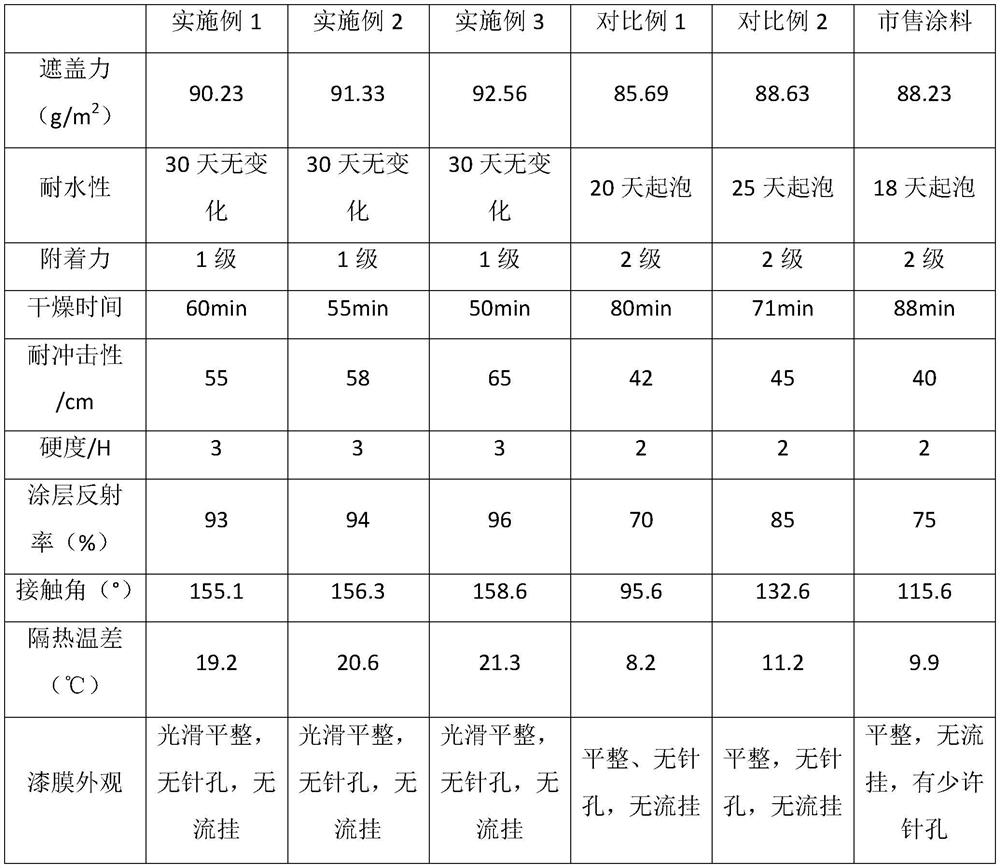

Composite nano waterproof heat-insulating coating for buildings and preparation method thereof

ActiveCN112552760AGood heat insulation and waterproof effectImprove waterproof performanceChemical industryPolyurea/polyurethane coatingsAcid etchingDefoaming Agents

The invention discloses a composite nano waterproof heat-insulating coating for buildings and a preparation method thereof, and belongs to the technical field of coatings. The coating is prepared fromthe following raw materials in parts by weight: 150-200 parts of emulsion, 60-80 parts of waterborne polyurethane, 60-80 parts of filler, 60-80 parts of a heat insulation composite nano material, 30-50 parts of an organic silicon hydrophobic agent, 5-10 parts of a coalescing agent, 3-6 parts of a defoaming agent and 3-6 parts of a synergist. According to the invention, a large amount of heat-insulating composite nano-materials are added, the hydrophobic and heat-insulating properties of the material are greatly improved through two-step modification of acid etching and hydrophobicity, and meanwhile, the added synergist has very strong adhesion ability, can be firmly adsorbed on the surfaces of the nano-materials and filler particles, and is stably dispersed in the coating, and the peelingand cracking phenomena of the subsequent coating are greatly reduced and the service life of the coating is prolonged. The coating has the advantages of good heat-insulating effect, good water resistance and long service life, and has wide market application potential.

Owner:艾斯贝科环保科技(北京)有限公司

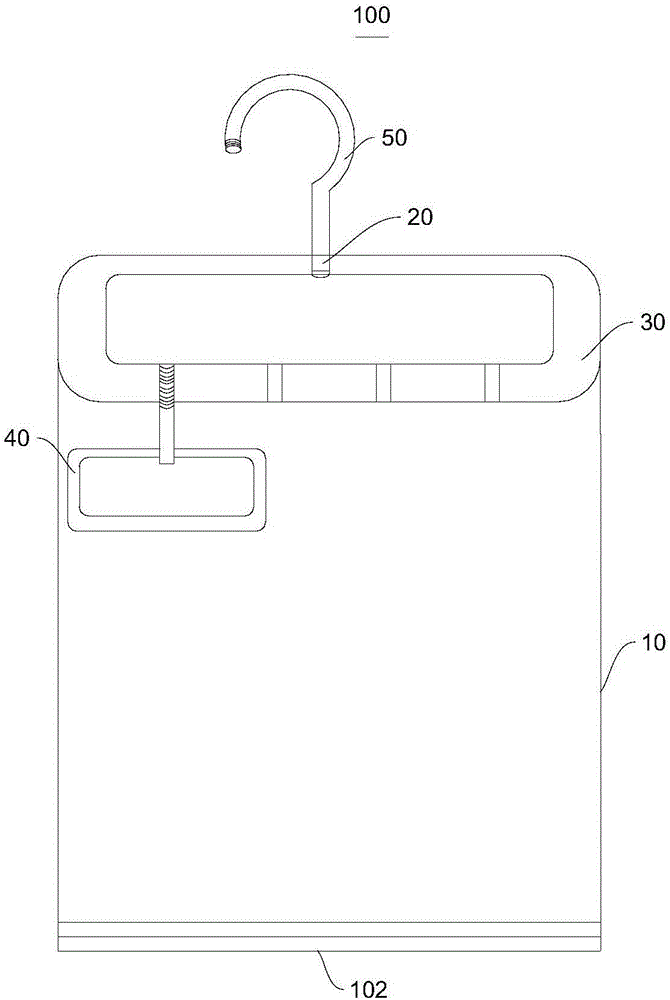

Vacuum bag and application method thereof

ActiveCN106820890AEasy to operateIngenious and reasonable designApparel holdersEngineeringControl unit

The invention provides a vacuum bag and an application method thereof and belongs to the technical field of vacuum storage. The vacuum bag comprises a bag body and a detecting member, wherein the bag body is provided with an accommodating cavity; the detecting member is connected with the bag body and composed of a control unit and a suction and inflation unit; the suction and inflation unit is provided with a first chamber, the control unit is provided with a second chamber, the first chamber and the second chamber are communicated through a first through hole, and the second chamber and the accommodating cavity are communicated through a second through hole. According to the vacuum bag, a user can directly observe whether the bag body is leaked through the detecting member. Meanwhile, the vacuum bag is simple in operation, skillful and reasonable in design, good in use effects, compact in structure and enormous in market application potential. The application method of the vacuum bag can rapidly achieve a detecting function and obtain good integral application effects.

Owner:YANCHENG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com