Method for synthesizing polypyrrole in oil solvent

A technology of oily solvent and polypyrrole, which is applied in the field of preparing polypyrrole by chemical oxidation method, can solve the problems of long time consumption and low yield of polypyrrole, and achieve the effect of convenient preparation process, high yield and high reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

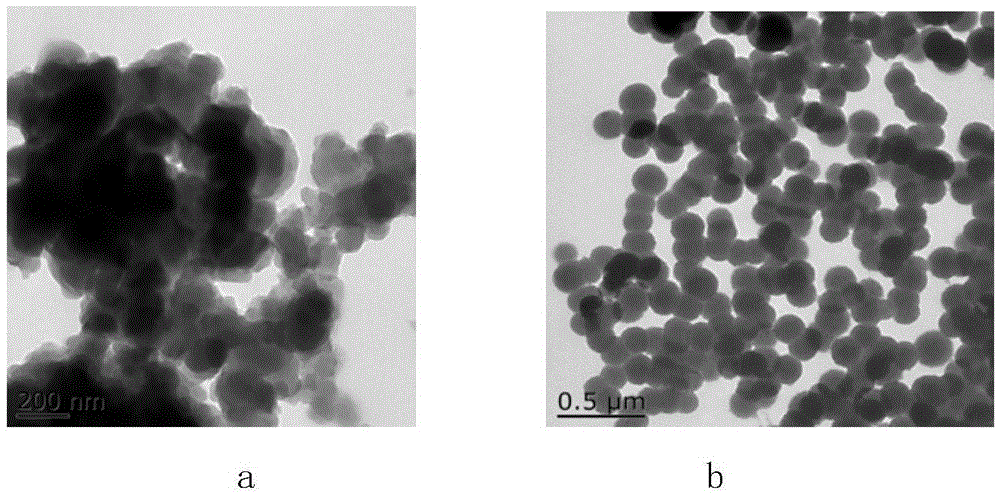

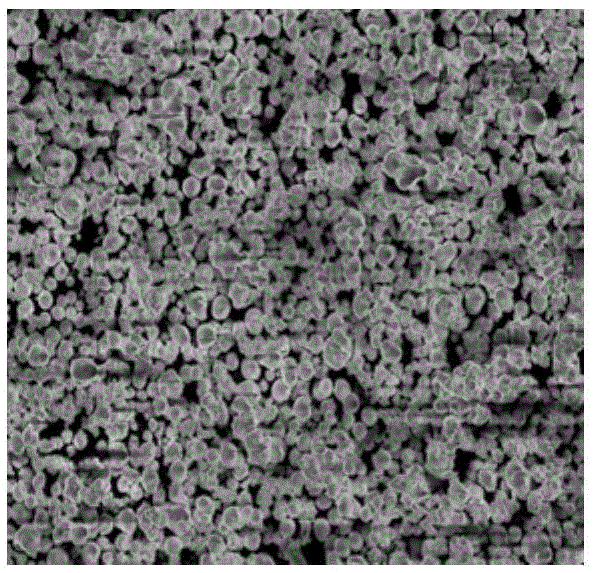

Image

Examples

preparation example Construction

[0029] Preparation of reaction solution; sodium lauryl sulfate, polyethylene glycol 6000, polyvinylpyrrolidone, ethanol, a small amount of butanol, peracetic acid, benzoyl peroxide, pyrrole monomer, and chloroform (isopropanol , cyclohexane, acetone, toluene, etc.).

[0030] Treatment of reactive monomers: avoid light, store at low temperature (3°C), and keep away from strong acids, strong alkalis, and strong oxidants.

[0031] Preparation of peracetic acid; the content of peracetic acid was prepared at 40%.

[0032] In the present invention, the optimum formula is obtained by changing and dropping different amounts of additives, keeping the reaction conditions constant, and conducting a comparative test.

[0033] 1. Weigh each raw material according to the following schemes;

Embodiment 1

[0034]Embodiment 1: 0.20% sodium lauryl sulfate, 0.35% polyethylene glycol 6000, 0.10% polyvinylpyrrolidone, 0.15% ethanol, 0.07% butanol, the amount of peracetic acid added to make the pH 2-3, 5.0 % benzoyl peroxide, 2.5% pyrrole monomer, and the rest are chloroform (isopropanol, cyclohexane, acetone, toluene, etc.), totaling 100%.

Embodiment 2

[0035] Embodiment 2: 0.25% sodium lauryl sulfate, 0.30% polyethylene glycol 2000, 0.14% polyvinylpyrrolidone, 0.13% ethanol, 0.05% butanol, the amount of peracetic acid added to make the pH be 2-3, 5.5 % benzoyl peroxide, 3% pyrrole monomer, and the rest are chloroform (isopropanol, cyclohexane, acetone, toluene, etc.), totaling 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com