Numerical simulation method for microstructure evolution of magnesium alloy selective laser melting

A technology of laser selective melting and microstructure, which is applied in the field of additive manufacturing, can solve problems such as the inability to dynamically describe the microstructure evolution process, and achieve the effects of shortening the research and development cycle, improving quality, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

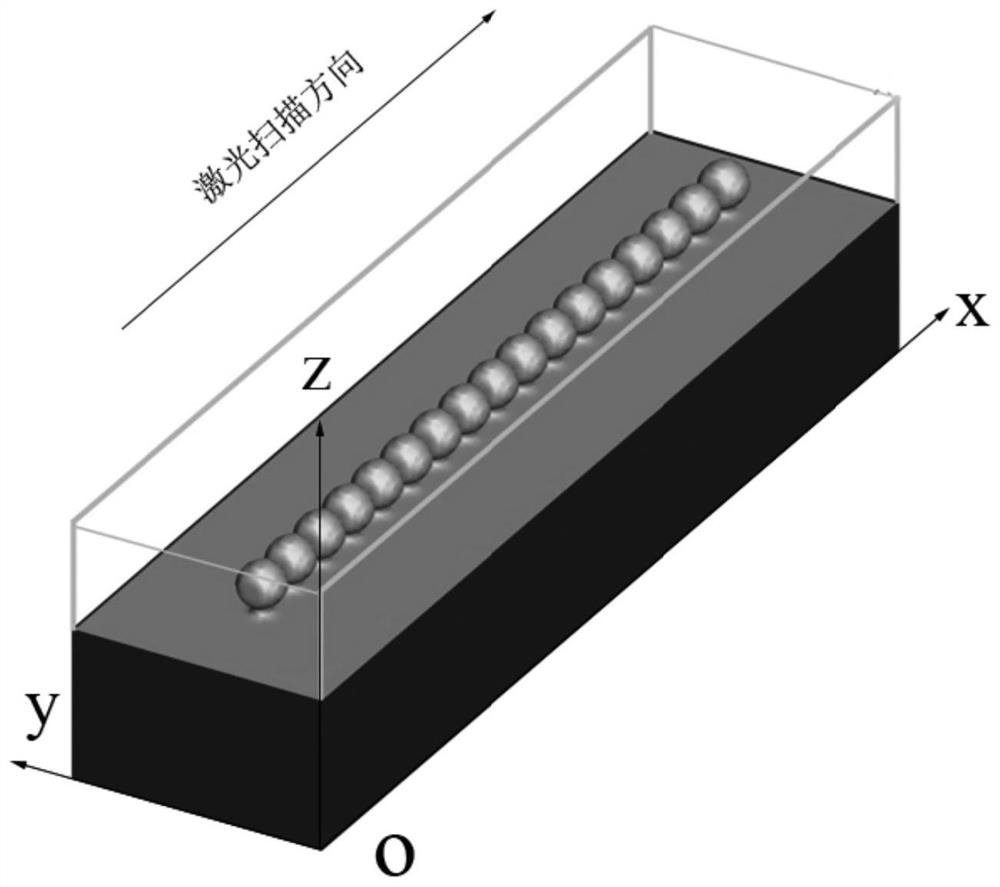

[0056] This embodiment provides a numerical simulation method for microstructure evolution of magnesium alloy laser selective melting, specifically, this embodiment is an equiaxed crystal growth simulation under the SLM process.

[0057] Such as Figure 9 As shown, the method specifically includes the following steps:

[0058] Step 1, establish a macroscopic geometric model in the modeling software, divide the unit grid, set the boundary conditions, and determine the physical parameters of the material;

[0059] Step 1 is specifically implemented in the following steps:

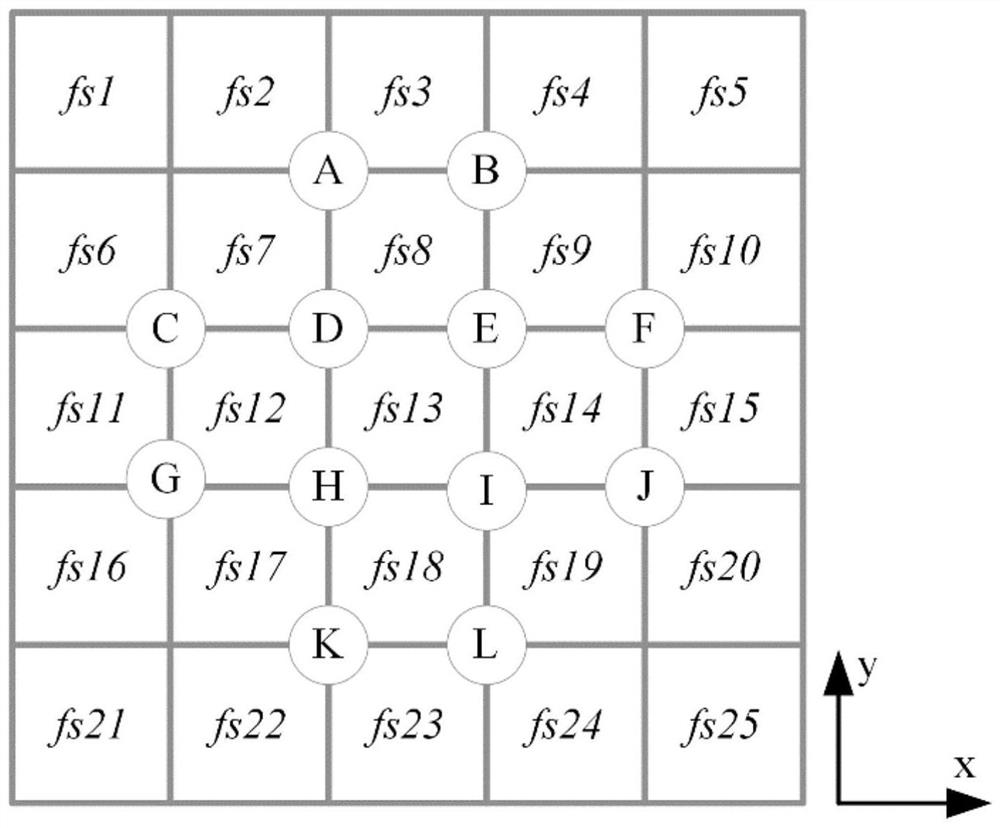

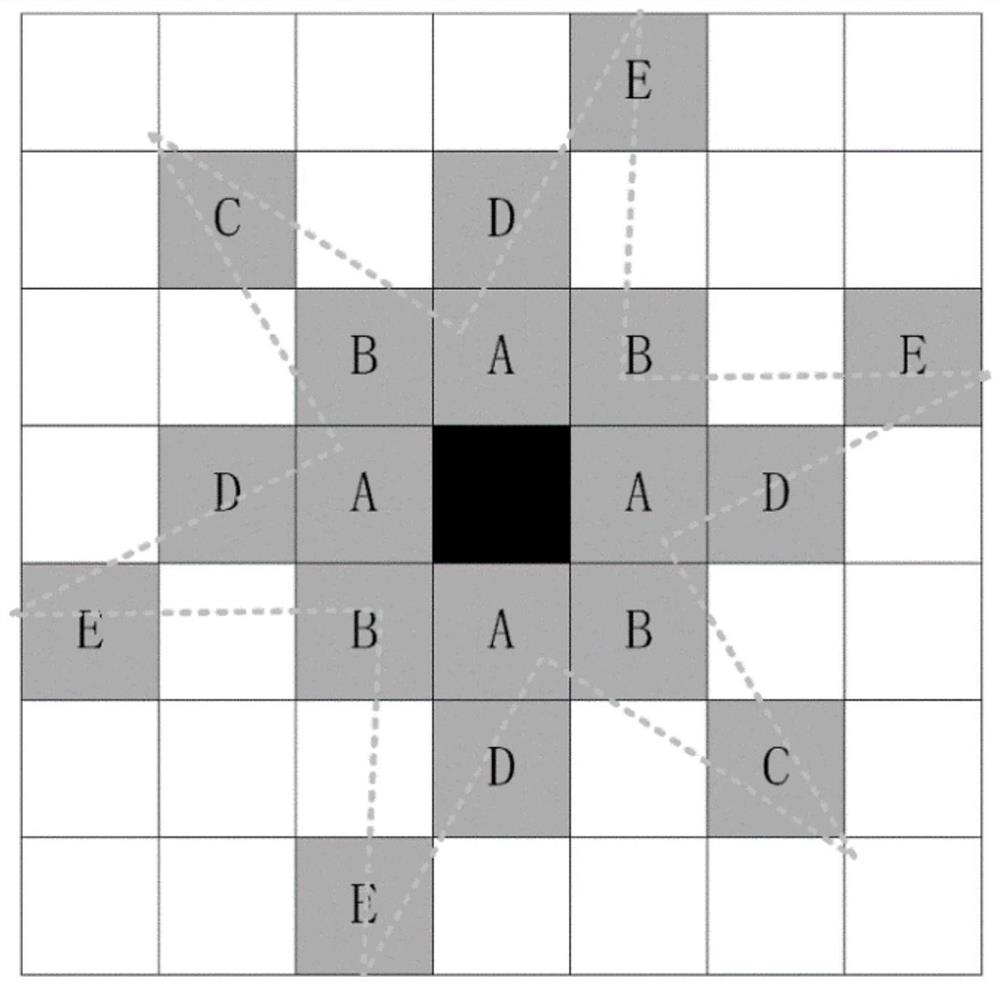

[0060] Firstly, a three-dimensional model is established with a geometric size of 800 μm × 200 μm × 200 μm. The model is a regular cuboid, and the model grid is divided into structural quadrilateral grids with a grid size of 4 μm. Under this condition, after dividing the grid The number of meshes in the model is 500,000, and the number of nodes is 914,751; the initialization of the phase interface is realiz...

Embodiment 2

[0202] This embodiment provides a numerical simulation method for the microstructure evolution of magnesium alloy laser selective melting. Specifically, this embodiment is a simulation of the growth from planar to cellular and then to columnar crystals under the SLM process.

[0203] The method specifically includes the following steps:

[0204] Steps 1 to 4 and steps 6 to 8 in this embodiment are correspondingly the same as steps 1 to 4 and steps 6 to 8 in Embodiment 1, and the only difference is that step 5 is different.

[0205] In the present embodiment, step 5 is implemented according to the following steps:

[0206] In step 5.2, the establishment process of the nucleation model of columnar crystals grown epitaxially at the edge of the molten pool is as follows: for the nucleation of columnar crystals grown epitaxially on the base material grains, the nucleation model of columnar crystals grown epitaxially at the edge of the molten pool is as follows:

[0207]When the su...

Embodiment 3

[0211] This example provides a numerical simulation method for the microstructure evolution of magnesium alloy laser selective melting. Specifically, this example is a dendrite growth simulation of the transition from columnar crystals to equiaxed crystals under the SLM process.

[0212] The method specifically includes the following steps:

[0213] Steps 1 to 4 and steps 6 to 8 in this embodiment are correspondingly the same as steps 1 to 4 and steps 6 to 8 in Embodiment 1, and the only difference is that step 5 is different.

[0214] In step 5, the area corresponding to the microscopically calculated temperature field obtained in step 4 is the microscopically calculated area. For the microscopically calculated area, the equiaxed crystal nucleation model in the molten powder and the columnar crystal grown epitaxially at the edge of the molten pool are respectively established. nucleation model;

[0215] Specifically, step 5 is implemented in the following steps:

[0216] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com