Method for predicting toppling instability of layered rock mass underground engineering high side wall in excavation process

A technology of underground engineering and prediction method, applied in the field of geotechnical engineering, can solve the problems such as the influence effect is not reflected, and the huge difference between the secondary stress field of the slope and the surrounding rock of the underground cavern is not considered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

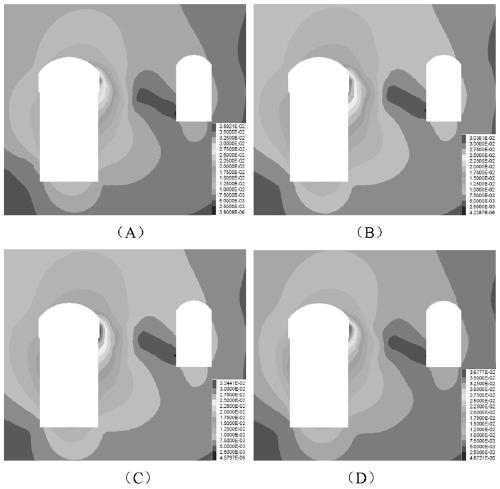

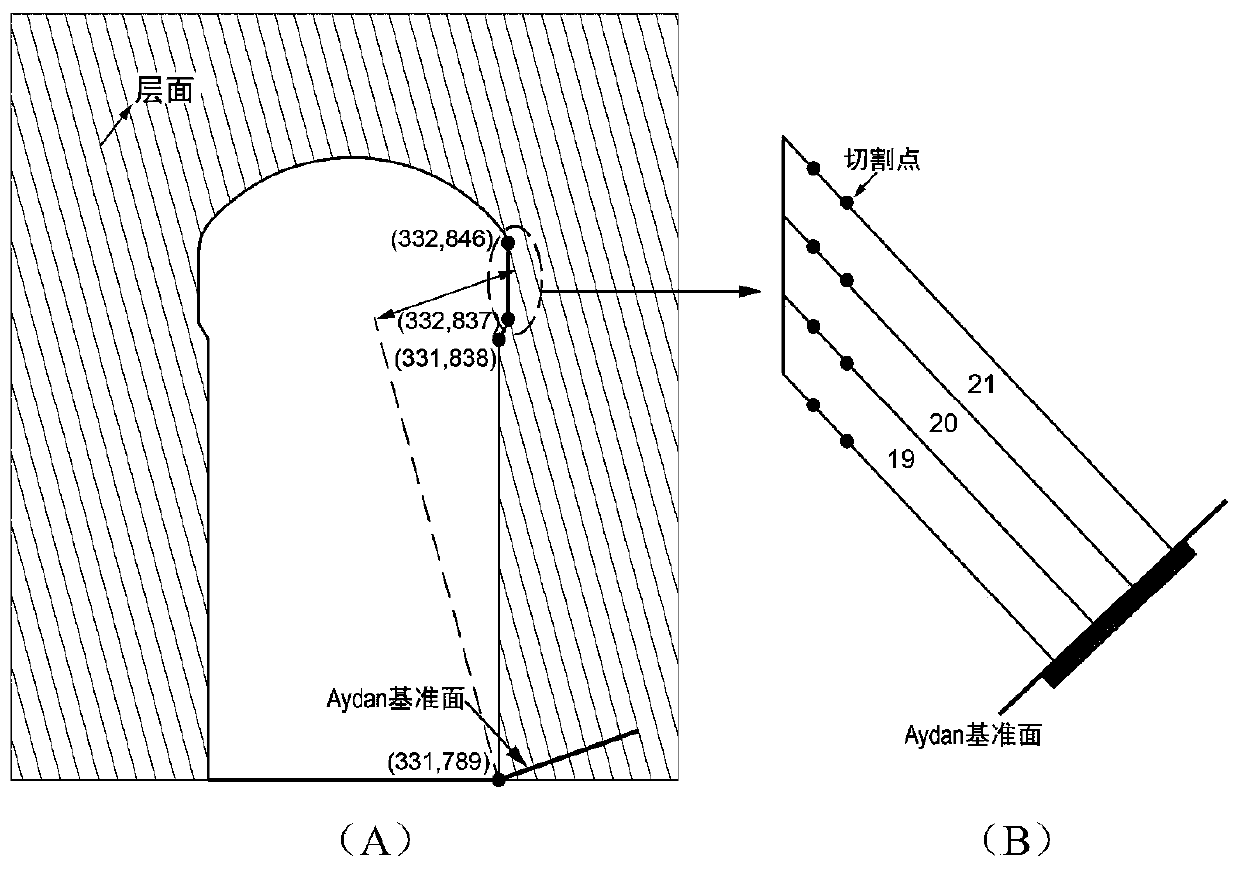

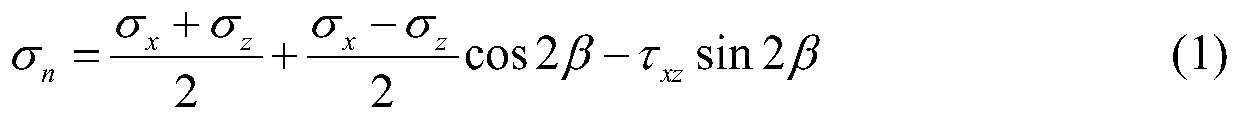

Image

Examples

Embodiment 1

[0050] In this embodiment, taking the underground powerhouse group of a large-scale hydroelectric power station excavated in the layered rock mass as an example, the method for predicting the toppling instability of the high side wall of the layered rock underground engineering during the excavation process provided by the present invention is described in detail. .

[0051] ①The rock stratum of the high side wall downstream of the main powerhouse of this large hydropower station has an anti-dipping layered structure, so the surrounding rock of the side wall downstream of the main powerhouse is delineated as the monitoring area, and the acceleration sensor equipped with the Canadian ESG microseismic monitoring system is installed downstream of the main powerhouse A total of 12 acceleration sensors are installed in areas such as the side rock anchor beam, the side wall and floor of the busway tunnel, and the top of the tailwater branch tunnel. It is connected with the data acqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com